AP4119 Rail Tag Programmer User Guide

TransCore Proprietary

1–10

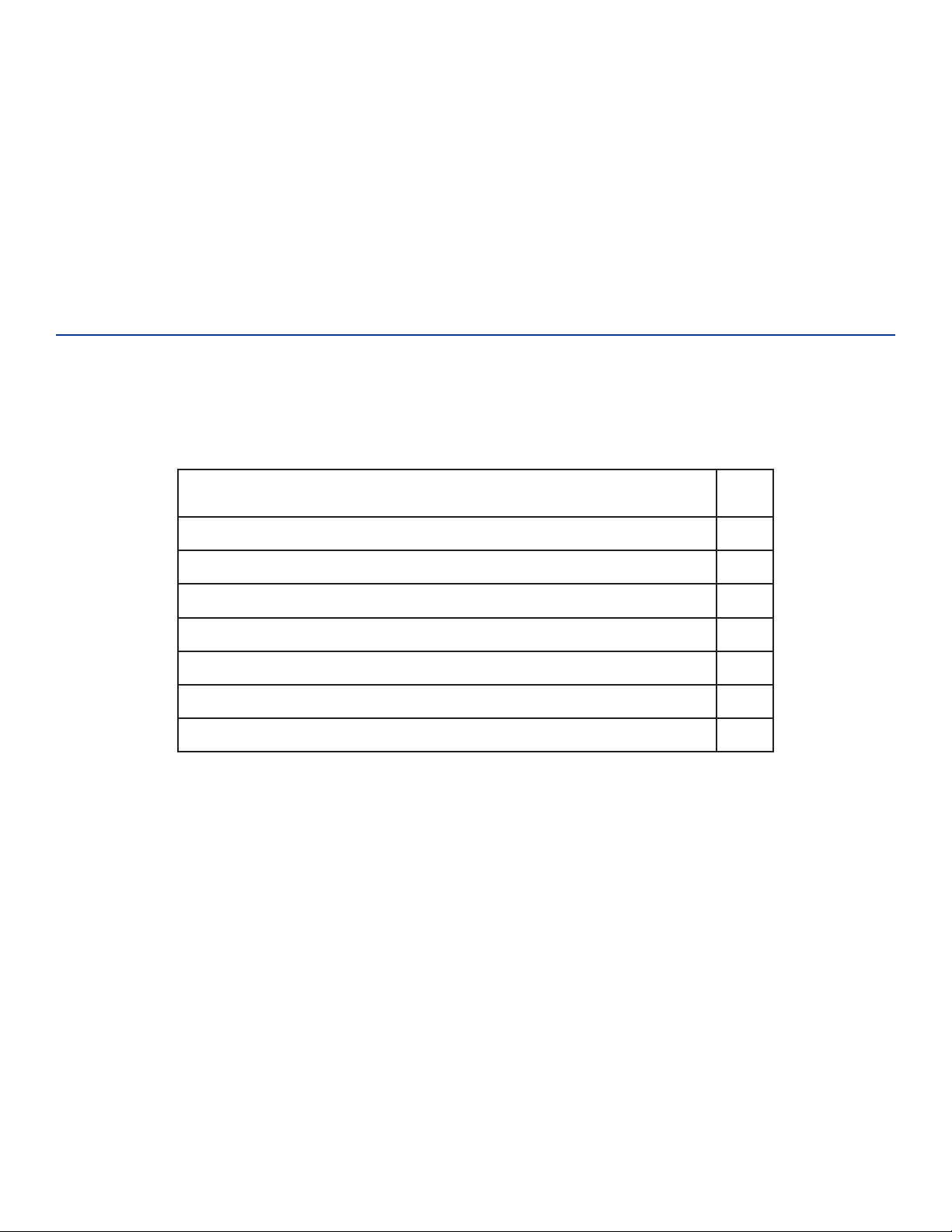

Table 2 PC Interface Protocol Settings

Protocol Setting

Data Rate 9600 bps

Data Bits 8

Parity None

Stop Bits 1

Software Flow Control None

Hardware Flow Control None

Download USB Drivers

Before using the AP4119 programmer with a USB connection, the proper drivers may need to be installed

on the host computer. The USB drivers can be installed during the AP4119 Host installation process (“Rail

Tag Programmer Host Software” on page 1–11). Alternatively, the FTDI USB drivers can be manually

installed by following the next steps:

1. Connect the USB cable from the USB port at the back of the AP4119 to one of the host computer’s USB

ports.

2. Allow the device driver to be detected and installed automatically. If the device driver fails to

automatically load, disconnect the AP4119 from the host computer.

3. Locate and download the device driver setup executable file for your operating system from https://

ftdichip.com/drivers/

Detailed installation guides can be found here: https://ftdichip.com/document/installation-guides/.

4. Launch the downloaded software and follow the steps to install the driver.

5. Reconnect the AP4119 and allow it to be detected by the operating system.

Note: While any hyperlinks included in this section were valid at the time of publication, TransCore

cannot guarantee their long term validity.

Connect the programmer to the host computer

1. Connect the RS–232 or USB cable from the unit to the host computer system.

2. Switch on power to the programmer. The POWER then READY LEDs should illuminate. When the

READY LED illuminates, begin using the tag programmer. The tag programmer has factory default

settings installed to allow tag reads only.

To configure the tag programmer for your tag requirements, use a PT5780 permissions tag or

License Certificate (requires AP4119 Host Software) to program specific operational and security

information into the programmer. “Chapter 2 Configuring the Programmer” on page 2–13 instructs

the user in configuring the tag programmer using the permissions tag.

If the READY LED does not illuminate or if the host system cannot communicate with the tag

programmer, refer to “Chapter 4 Troubleshooting” on page 4–31.