Transphorm TDINV1000P100 User manual

August 3, 2017 © 2017 Transphorm Inc. Subject to change without notice.

evk006.2

1

User Guide

TDINV1000P100: 1kW Inverter Evaluation Board

Introduction

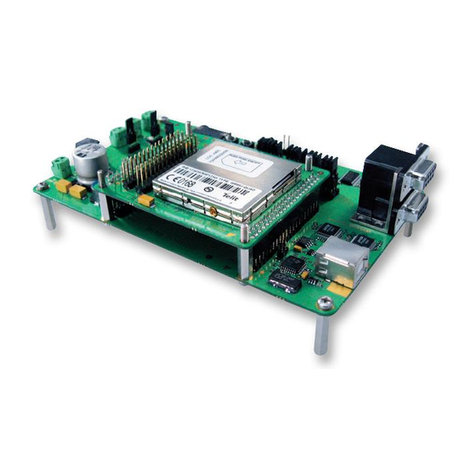

The TDINV1000P100 1kW inverter kit from Transphorm provides an easy way to evaluate the performance advantages of GaN

power transistors in various inverter applications, such as solar and UPS. The kit provides the main features of a single-phase

inverter in a proven, functional configuration, operating at or above 100kHz. At the core of the inverter are four 150mΩGaN

FETs configured as a full bridge. These are tightly coupled to gate-drive circuits on a board which also includes flexible

microcontroller options and convenient communication connection to a PC. The switch-mode power signals are filtered to

provide a pure sinusoidal output.

The TDINV1000P100-KIT is for evaluation purposes only.

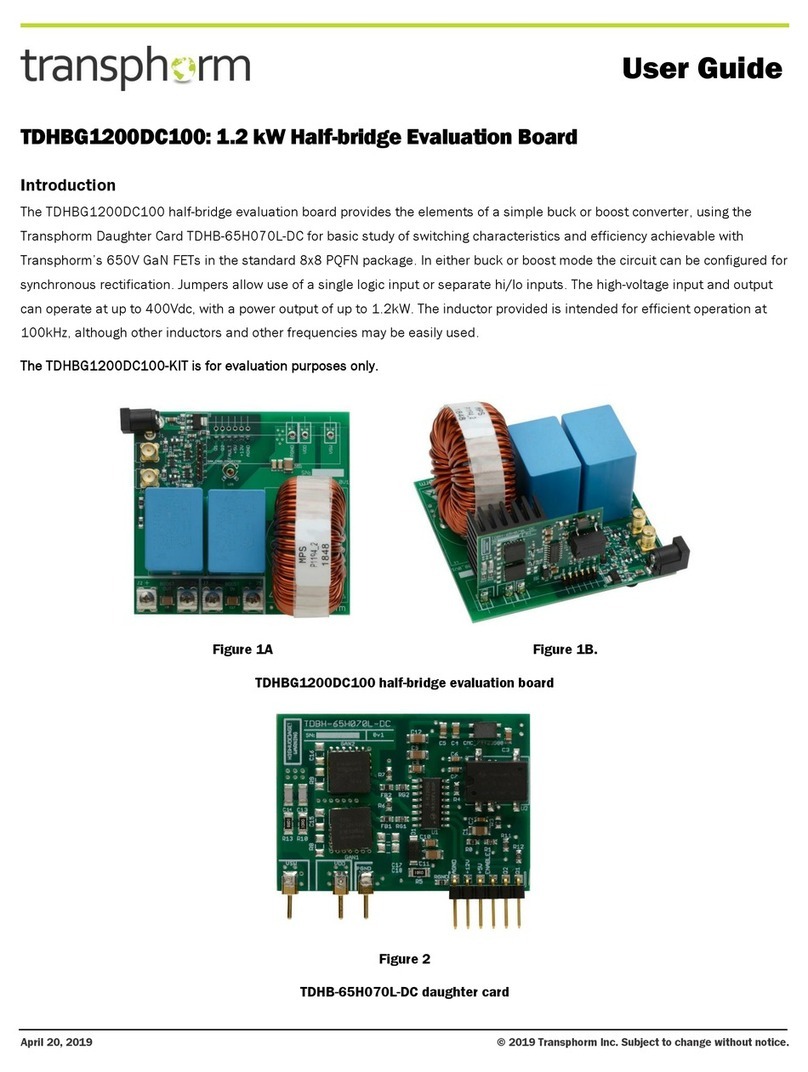

Figure 1. TDINV1000P100 inverter evaluation board

The control portion of the circuit is designed around the popular C2000™ family of microcontrollers from Texas Instruments (TI).

The source code is available along with related support information directly from TI. In addition to this general resource,

Transphorm provides original firmware which comes loaded in flash on the microcontroller. The source code, configured as a

complete project, is also available at transphormusa.com/pv1fw. This project is a convenient starting point for further

developments. The microcontroller itself resides on a small, removable control card, supplied by TI, so that different C2000

devices may be used if desired. The schematic for the TDINV1000P100 circuit board is provided at the end of this user guide

document, as well in thedesign files attransphormusa.com/pv1kit.

August 3, 2017 transphormusa.com

evk0006.2

2

TDINV1000P100 User Guide

The TDINV1000P100-KIT includes:

•TDINV1000P100 single phase inverter assembly

•Texas Instrument F28035 control card

•9V power supply

TDINV1000P100 input/output specifications

High-voltage input: 400VDC max

Auxiliary supply (J1): 9VCC

Input: 0VDC - 400VDC

Output: VDC / √2VRMS at 50/60Hz 1, up to1000VA

PWM frequency: 100kHz - 300kHz 2

1The$output$frequency$may$be$changed$in$the$software;$as$delivered$it$is$60Hz

2The$switching$frequency$may$be$changed$in$the$software;$as$delivered$it$is$100kHz

Power dissipation in the GaN FET is limited by the maximum junction temperature. Refer to the TPH3206PSB datasheet.

Circuit description

Refer to Figure 2 for ablock diagram of the inverter circuit. Adetailed schematic is also available in the design files at

transphormusa.com/pv1kit.

The TDINV1000P100 inverter is a simple full-bridge inverter. Two GaN half-bridges are driven with pulse-width modulated

(PWM) command signals to create the sinusoidally varying output. The output filter largely removes the switching frequency,

leaving the 50/60Hz fundamental sinusoid. The high-frequency (100kHz+) PWM signals are generated by the TI microcontroller

and connected directly to high speed, high voltage gate drivers. Aconnection for external communication to the microcontroller

is provided byanisolated USB interface. Except for thehigh-voltage supply for the power stage, all required voltages for the

control circuitry are derived from one 9V input.

August 3, 2017 transphormusa.com

evk0006.2

3

TDINV1000P100 User Guide

Figure 2. Circuit block diagram

The inverter takes advantage of diode-free operation, in which the freewheeling current is carried by the GaN FETs themselves,

without the need of additional freewheeling diodes.For minimum conduction loss, the gates of the transistors are enhanced

while they carry the freewheeling current. The high and low-side VGS waveforms are therefore pairs of non-overlapping pulses, as

illustrated in Figure 3 below.

Figure 3. Non-overlapping gate-drive pulse; A is a deadtime set in the firmware

Gate drivers

High-voltage integrated drivers supply the gate-drive signals for the high and low-side power transistors. These are 2500V

isolation drivers (Silicon Labs Si827x family), specifically chosen for high-speed operation without automatic deadtime insertion.

The deadtime between turn-off of one transistor in a half bridge and turn-on of its mate is set in the firmware.

Hi/Lo

Gate

Driver

V

P

V

N

Hi/Lo

Gate

Driver

V

P

V

N

Hall Sensor

Current

Voltage

Feedback

GaN

Half-bridge Filter

AC

Output

TMS320F28069

Microcontroller

Power Stage

controlCARD

V

SENSE

(HV

DC

)

Feedback4

5

2

Isolated USB

Interface

JTAG

UART

V

P

V

N

High Voltage

DC Input

+V

GG

+5V +3.3V

V

N

Low Voltage Supply

9V

CC

-15V

CO

Input

August 3, 2017 transphormusa.com

evk0006.2

4

TDINV1000P100 User Guide

Output filter

A simple LCL filter on the output (L3, L4, C37 and C54 - C57) attenuates the switching frequency, producing a clean sinusoidal

waveform for output connections in terminals J4 and J5. The filter inductors and capacitors used on the demo board were

chosen to provide the optional combination of benefits: low loss, good attenuation of the switching frequency, and small size.

Consult the schematic and/or bill of materials to verify values; but in general, the cutoff frequency will be around 5 - 10kHz to

accommodate 100kHz switching. The inductors have powder cores with relatively low permeability (60-90) and soft saturation

characteristics. The inductors and/or capacitors can be changed to evaluate different filter designs.

Current sensing

Hall sensors U8 and U10 provide linear current feedback to the microcontroller. These signals could be used to control output

power flow, and/or to protect against short circuits. The firmware provided with the kit, however, does not actually make use of

this feedback. Note that these are placed at an intermediate point of the output filter. Refer to the bill of materials to confirm

the sensor part numbers, but typical would be the Allegro ACS712-20A sensor, which has a ±20A range (100mV/A). These parts

are pin compatible with a ±5A and ±30A versions of ACS712, should higher or lower ranges be desired. Note also that resistor

dividers scale the 5V outputs for the 3V range of the A/D.

Communication

Communication between the microcontroller and a computer is accomplished with a standard USB cable. The isolated USB

interface enables simultaneous operation of two physical ports to the microcontroller: a JTAG port for debug and loading of

firmware, and a UART for communication with a host application.

Control card

The microcontroller resides on a removable card, which inserts in a DIM100 socket on the inverter PCB. The socket can accept

many of the C2000 series control cards from Texas Instruments. The TMDSCNCD28035 Piccolo control card supplied with the

kit provides capability to experiment with a wide variety of modulation and control algorithms. It comes loaded with firmware to

allow immediate, out-of-the-box, operation. Should the user wish to use an alternative microcontroller family, an appropriate

control card can be designed to insert into the DIM100 socket.

Heat sink

The two TO-220 GaN transistors on each half-bridge are mounted on a common heat sink. The heatsink is adequate for 1000W

operation WITHOUT forced air flow. Even higher efficiency at high power may be achieved by minimizing the temperature rise.

This may be accomplished with forced airflow. Alternately the heatsinks could be replaced with larger and more effective ones.

Connections

Power for the AC output is derived from the high voltage DC input. This will typically be a DC power supply with output voltage up

to 400VDC. A 22µF, low ESR, film capacitor is provided as a bypass capacitor for the high voltage supply, along with several

smaller value ceramic capacitors in parallel. This is not intended to provide significant energy storage, but to provide high

frequency bypassing. It is assumed that the power supply or preceding DC-DC stage contains adequate output capacitance.

The control, communication, and gate-drive circuits are all powered from a single 9V input (VGG). A wall-plug adaptor is provided.

August 3, 2017 transphormusa.com

evk0006.2

5

TDINV1000P100 User Guide

Note that only the USB port is isolated; all other signals on the board are referenced to the negative terminals of the high and

low voltage supplies, which are tied together on the PCB. The heatsinks are also connected to the negative terminals of the

supplies.

Connection sequence

Refer to Figure 4. Insert the microcontroller card to the DIM100 socket before applying any power to the board. To use the

preloaded firmware, verify that jumper JP1 is removed. This releases the JTAG port and allows the microcontroller to boot from

flash. For communication with a host over the JTAG port, JP1 should be installed.

With the supply turned off, connect the high-voltage power supply to the +/- inputs (J2 and J3).

DO NOT apply too much force to

the J2 and J3 connectors, as excessive force may bend and/or crack the PCB.

If a load is to be used, connect the load to the output terminals (J4 and J5).

DO NOT apply too much force to the J4 and J5

connectors, as excessive force may bend and/or crack the PCB.

Insert the VGG (9V) plug to jack J1. LED1 should illuminate, indicating power is applied to the 5V and 3.3V regulators. Depending

on the specific control card used, one or more LEDs on the control card will also illuminate, indicating power is applied. A

flashing LED indicates the firmware is executing.

To use the pre-loaded firmware, no computer connection is required. If a computer connection is required for code modification,

connect the USB cable from the computer to the USB connector (CN3). LED2 should illuminate, indicating isolated +5V power is

applied over the USB cable.

Turn on the high voltage power. The high-voltage supply may be switched ON instantly or raised gradually.

Figure 4. Connections

August 3, 2017 transphormusa.com

evk0006.2

6

TDINV1000P100 User Guide

Test

Figure 5 shows typical waveforms. The negative terminal of the high-voltage supply is a convenient reference for the

oscilloscope measurements, provided there are not multiple connections to earth ground.

Typical efficiency results are shown in Figure 6. These data points correspond to efficiency measurements made in still air with

20 minutes’ dwell at each power level. Input power from the 350VDC source and output power to a resistive load were measured

with a Yokogawa WT1800 power analyzer.

Figure 5. Typical waveforms

Driver

Driver

Single-phase

240V

AC

Output

MCU

100kHz switching waveform Yellow: Load current using current probe

Green and Purple: Phase output voltages

with respect to higher voltage (-) input

August 3, 2017 transphormusa.com

evk0006.2

7

TDINV1000P100 User Guide

Figure 6. Typical efficiency: 350VDC input, 240VAC output

Design details

See Figure 7 for adetailed circuit schematic and Figure 8 for the PCB layers (also included in the design files). The parts list can

be found in Table 1.

Table 1. TDINV1000P100 evaluation board bill of materials (BOM)

Designator

Qty

Value

Description

Part Number

Manufacturer

X1

1

CSTCR

CSTCR6M00G53Z-R0

Murata

HS1, HS2

2

529802B02500G

529802B02500G

Murata

D1, D2

2

DO-214AC

ES1J

Aavid Thermalloy

FB1, FB2, FB3, FB4

4

120Ωferrite bead

603

MMZ1608Q121B

Fairchild

LED1, LED2

2

CHIP-LED0805

SML-211UTT86

TDK

C49, C53

2

0.1µF

C1812

C1812V104KDRACTU

ROHM

C1, C14, C16, C17,

C19, C20, C21, C22,

C23, C24, C25, C26,

C27, C28, C29, C30,

C31, C33, C34, C38,

C39, C40, C42, C43

24

0.1µF

C0603

06033C104JAT2A

Kemet

C5, C6, C7, C8, C9

5

0.1µF

C0805

08053C104KAT2A

AVX

C10, C54, C55, C56,

C57

5

0.1µF

C2225K

VJ2225Y104KXGAT

AVX

R21, R28

2

DNI

R0603

DNI

Vishay

R7

1

0Ω

R1206

ERJ-8GEY0R00V

Panasonic

R14

1

1MΩ

R0603

ERJ-3EKF1004V

Panasonic

R8, R15

2

1kΩ

R0603

CRCW06031K00FKEA

Vishay

R1

1

1kΩ

R0805

ERJ-6GEYJ102V

Panasonic

C36, C45

2

1nF

C0603

DNI

AVX

C12, C18

2

1µF

C0603

CC0603KRX5R6BB105

Yageo

C15

1

2.2µF

C0603

0603YD225MAT2A

AVX

R13, R17

2

2.2kΩ

R0603

ERJ-3GEYJ222V

Panasonic

C46, C47, C48, C50,

C51, C52

6

4.7nF

C1206

C1206C472KDRACTU

Kemet

R19, R26

2

5.23kΩ

R0603

ERJ-3EKF5231V

Panasonic

R6, R24, R31

3

9.09kΩ

R1206

ERJ-8ENF9091V

Panasonic

R18, R25

2

10Ω

R0805

ERJ-6GEYJ100V

Panasonic

August 3, 2017 transphormusa.com

evk0006.2

8

TDINV1000P100 User Guide

Designator

Qty

Value

Description

Part Number

Manufacturer

R22, R29

2

10.2kΩ

R0603

ERJ-3EKF1022V

Panasonic

R5

1

10MΩ

R1206

HVCB1206FKC10M0

Stackpole

R12, R16

2

10kΩ

R0603

ERJ-3GEYJ103V

Panasonic

C32, C35, C41, C44

4

10µF

C0805

C0805C106M4PACTU

Kemet

C4

1

10µF

C1206

CL31A106KAHNNNE

AVX

C2

1

22µF

C1206

CL31X226KAHN3NE

Samsung Electronics

L1, L2

2

22µH

805

LQM21FN220N00L

Murata

R10, R11

2

27Ω

R0603

CRCW060327R0FKEA

Vishay

U6

1

93LC46B

SOT23-6

93LC46BT-I/OT

Microchip

R2

1

348Ω

R0805

ERJ-6ENF3480V

Panasonic

R9

1

470Ω

R0603

ESR03EZPF4700

ROHM

R3, R4, R20, R23,

R27, R30

6

560kΩ

R1206

RC1206FR-07560KL

Yageo

U8, U10

2

ACS712

SO8

ACS712ELCTR-20A-T

Allegro Microsystems

DA1

1

BAW567

SOT363

BAW567DW-7-F

Diodes Inc

U5

1

FT2232D

LQFP48

FT2232D-REEL

FTDI

IC1

1

ISO7240

SO-16DW

ISO7240CDW

Texas Instruments

IC2

1

ISO7242

SO-16DW

ISO7242CDW

Texas Instruments

U4

1

LVC2G74

DCT

SN74LVC2G74DCTR

Texas Instruments

U7, U9

2

SI8273AB1

SOIC16N

SI8273AB1

Silicon Labs

U3

1

TPS73033

SOT23-5

TPS73033DBVR

Texas Instruments

U1

1

TPS79533

SOT223-6

TPS79533DCQR

Texas Instruments

J2, J3, J4, J5

4

KEYSTONE_7691

7691

Keystone

2

Q1, Q3 insulator

SP2000-0.015-00-54

Bergquist

2

Q2, Q4 insulator

53-77-9G

Aavid Thermalloy

C11

1

MKP1848622454P4

MKP1848622454P4

MKP1848622454P4

Vishay

U2

1

PTH08080WAH

PTH08080W_TH

PTH08080WAH

Texas Instruments

C13

1

100nF

C075-032X103

SA111E104MAR

AVX

C37

1

2µF/630V

EPCOS_B32674

B32674D6225K

Epcos

JP1

1

1X02

961102-6404-AR

3M

J1

1

PJ-002AH

PJ-002AH

CUI Inc

CN2

1

USBSHIELD

897-43-004-90-000000

Mill-Max

C3

1

100µF

PANASONICSMALCAP6X6

EEE-FPE101XAP

Panasonic

plastic shoulder

washers

4

plastic shoulder

washers

plastic shoulder washers

3049

Keystone

CONN SHUNT 2POS

.100

2

jumper

CONN SHUNT 2POS .100

65474-002LF

FCI

#4-40, 3/8" Phillips

pan head screw

2

#4-40, 3/8" Phillips

pan head screw

#4-40, 3/8" Phillips pan

head screw

9901

Keystone

#4-40 hex nut

1

#4-40 hex nut

#4-40 hex nut

4694

Keystone

standoffs 4-40 5/8"

4

standoffs 4-40 5/8"

standoffs 4-40 5/8"

1902F

Keystone

Q1, Q2, Q3, Q4

4

TPH3206PSB

TPH3206PSB

TPH3206PSB

Transphorm

1

Control card Piccolo

F28035

Control card Piccolo

F28035

TMDSCNCD28035

Texas Instruments

L3, L4

2

295µH inductor

295µH inductor

CWS-1SN-12471

CWS

CN1

Control card connector

control card connector

TMDSDIM100CON5PK

Texas Instruments

1

9V adaptor

Accessory

CUI

CUI

4

Nylon screw for

standoffs

nylon screw for standoffs

9330

Keystone

August 3, 2017 transphormusa.com

evk0006.2

9

TDINV1000P100 User Guide

August 3, 2017 transphormusa.com

evk0006.2

10

TDINV1000P100 User Guide

August 3, 2017 transphormusa.com

evk0006.2

11

TDINV1000P100 User Guide

Figure 7. Detailed circuit schematics

August 3, 2017 transphormusa.com

evk0006.2

12

TDINV1000P100 User Guide

(a) PCB top layer

(b) PCB bottom layer

August 3, 2017 transphormusa.com

evk0006.2

13

TDINV1000P100 User Guide

(c) PCB inner layer 2 (ground planes) and inner layer 3 (power plane)

Figure 8. PCB layers

Probing

There are no test points provided for probing the low-side gate or half-bridge switching node. To minimize inductance during

measurement, the tip and the ground of the probe should be directly attached to the sensing points to minimize the sensing

loop. For safe, reliable, and accurate measurement, a scope probe tip may be directly soldered to the low-side FET drain and a

short ground wire soldered to the low-side FET source. See Figure 9 for an alternative that does not require soldering the probe

tip.

Warnings

There is no specific protection against over-current or over-voltage on this board. The TDINV1000P100 board is for evaluation

purposes only.

August 3, 2017 transphormusa.com

evk0006.2

14

TDINV1000P100 User Guide

Figure 9. Low-inductance probing of fast, high-voltage signals

Table of contents

Other Transphorm Motherboard manuals