MEGA 120E PUMP OPERATION / MAINTENANCE MANUAL CONTENTS

CONTENTS

1INSTALLATION............................................................................................................3

1.1 UNPACKING ......................................................................................................3

1.2 TIE BOLT TORQUE ...........................................................................................3

1.3 UTILITIES / HOOK-UP .......................................................................................3

2OPTIONS ......................................................................................................................6

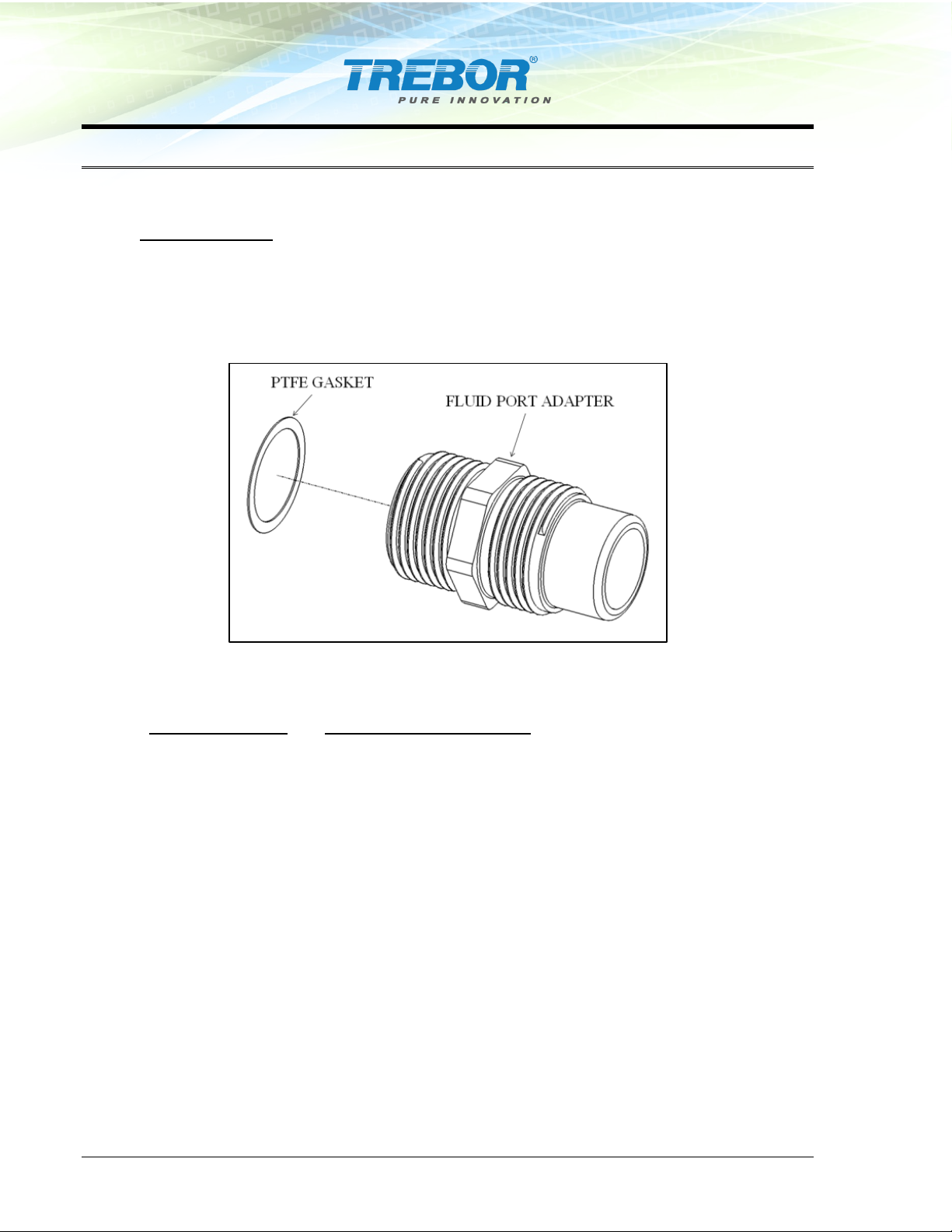

2.1 FLUID PORT CONNECTION OPTIONS............................................................6

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP ....................................6

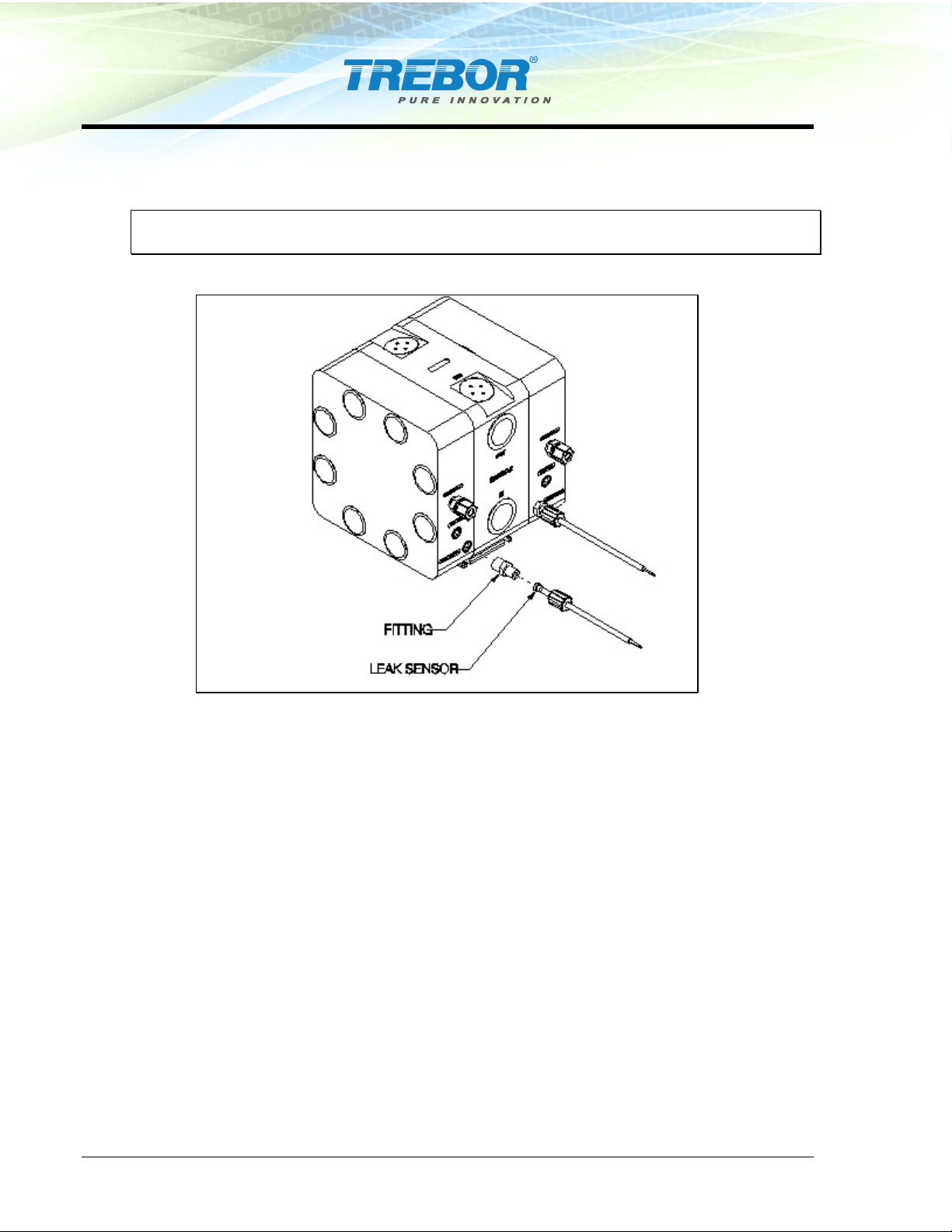

2.3 OPTIONAL LEAK SENSING ..............................................................................7

2.3.a Installation..............................................................................................7

2.3.b Removal.................................................................................................7

2.3.c Sensor Signal Specifications .................................................................8

3START-UP ....................................................................................................................9

3.1 HIGH TEMPERATURE OPERATION ................................................................9

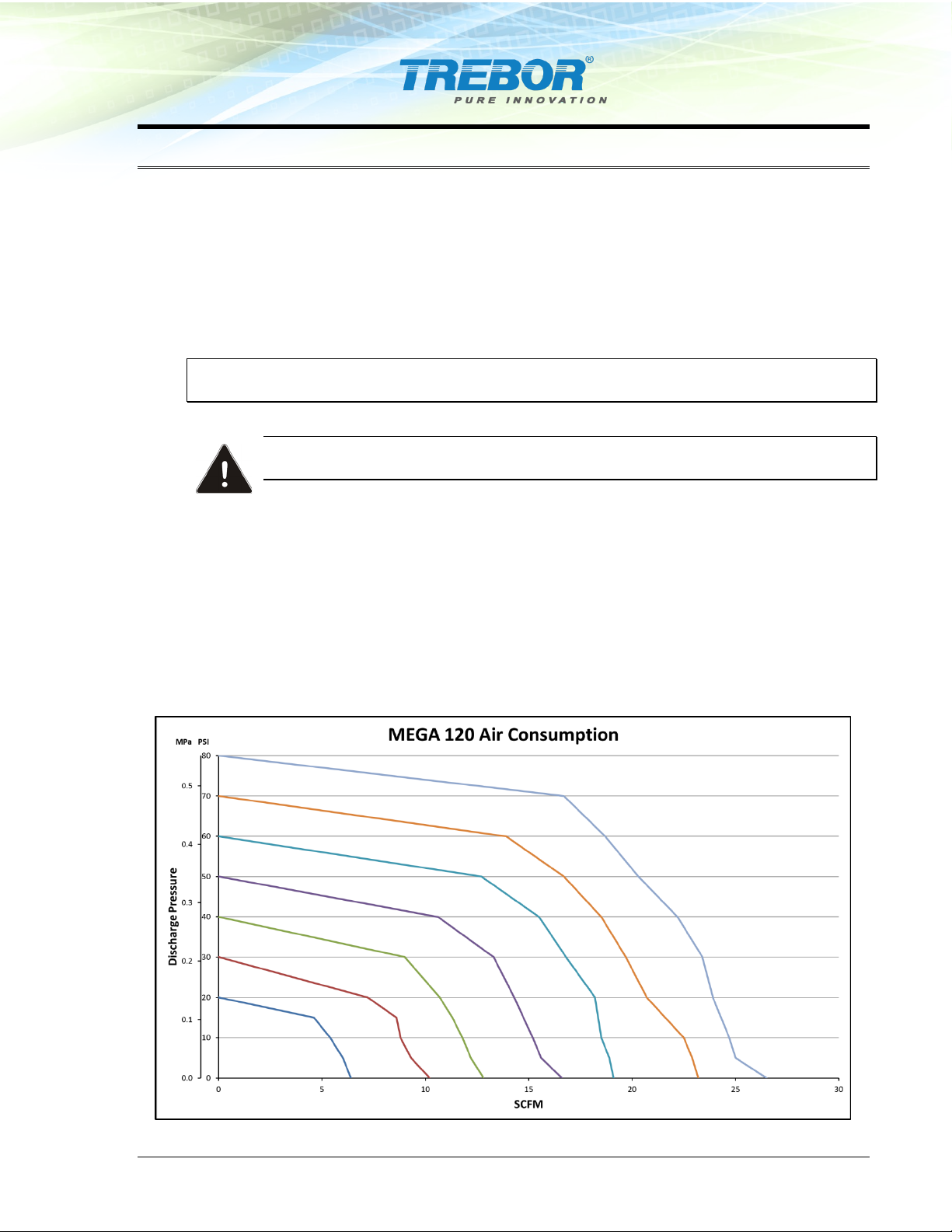

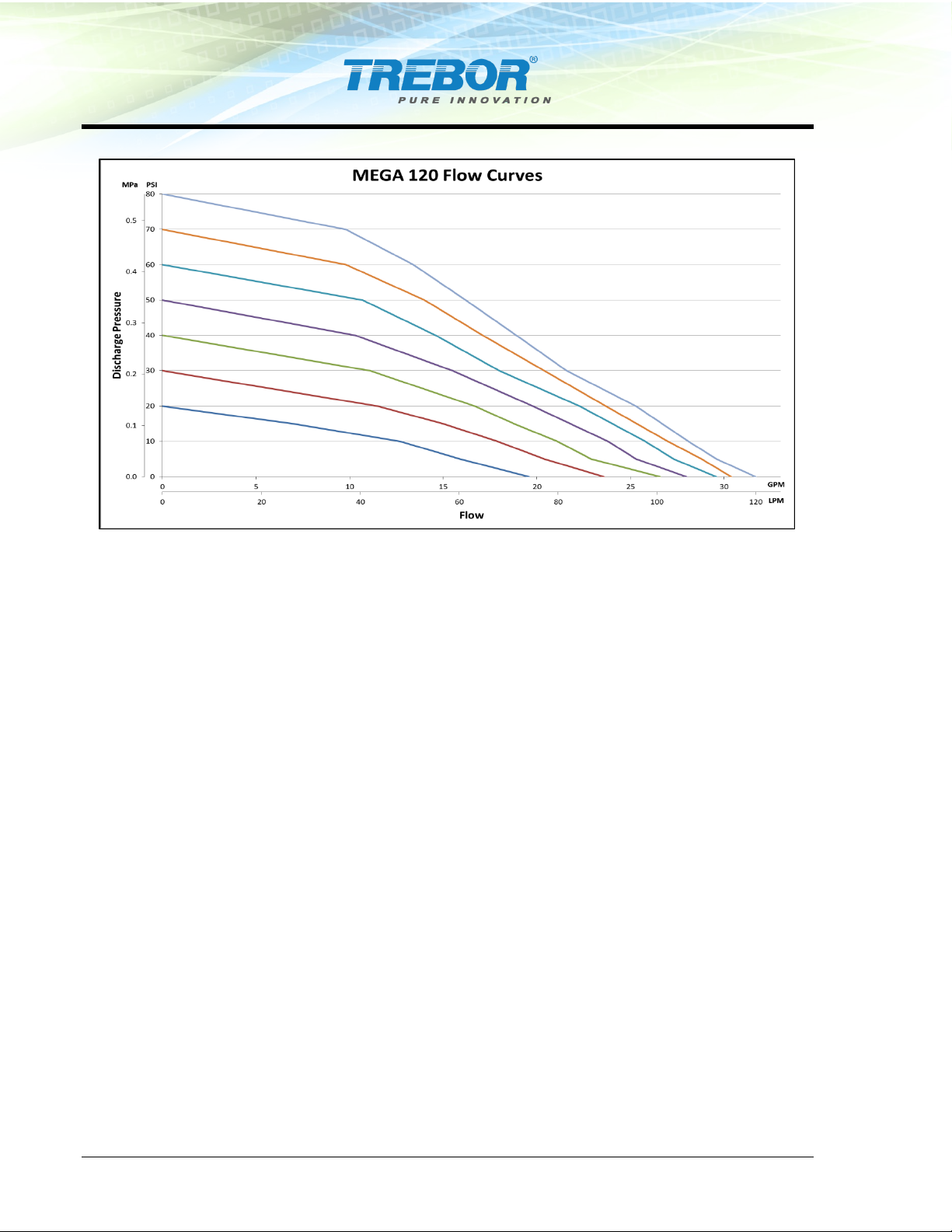

3.2 PERFORMANCE CHARTS ................................................................................9

4MAINTENANCE..........................................................................................................11

4.1 PREVENTIVE MAINTENANCE SCHEDULE...................................................11

4.1.a Preventive Maintenance Record .........................................................13

4.2 RECOMMENDED SPARE PARTS ..................................................................14

4.3 TOOLS..............................................................................................................14

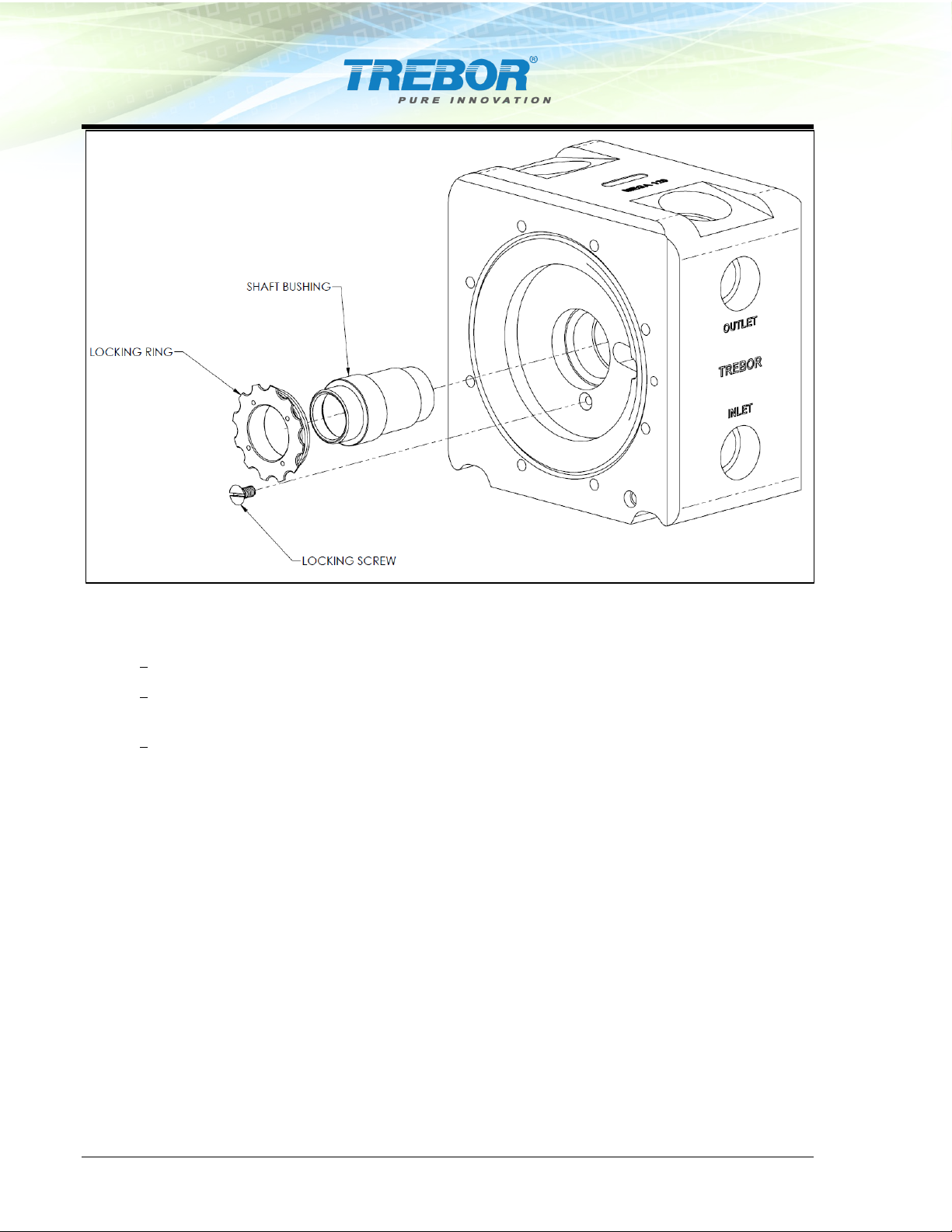

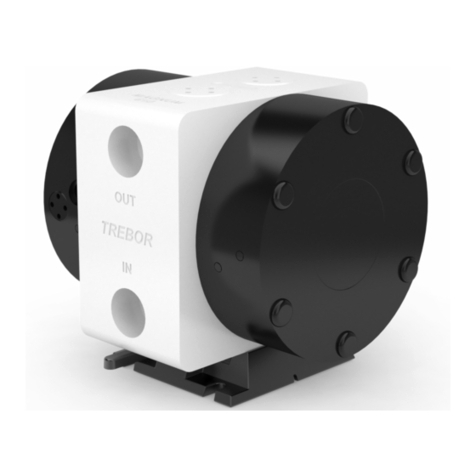

4.4 PARTS ILLUSTRATION...................................................................................15

4.5 PARTS LIST .....................................................................................................16

4.6 CLEAN-UP........................................................................................................16

4.7 DISASSEMBLY ................................................................................................16

4.7.a Quick Exhaust/Muffler Disassembly ....................................................17

4.7.b Body Disassembly ...............................................................................17

4.8 ASSEMBLY ......................................................................................................17

4.8.a Quick Exhaust (Both Heads) ...............................................................17

4.8.b Body Assembly ....................................................................................18

4.8.c Final Assembly ....................................................................................21

4.9 TESTING ..........................................................................................................22

4.9.a Performance Test ................................................................................22

4.9.b Dry Pump.............................................................................................22

4.9.c Dry Suction ..........................................................................................22

5TROUBLESHOOTING................................................................................................23

6WARRANTY AND EXCLUSIONS..............................................................................24

6.1TREBOR STANDARD LIMITED WARRANTY.................................................24

7CONTACT INFORMATION ........................................................................................25

7.1 GENERAL CONTACT INFORMATION ERROR! BOOKMARK NOT DEFINED.

7.2 TECHNICAL SUPPORT ....................... ERROR! BOOKMARK NOT DEFINED.

7.3 REGIONAL REPRESENTATIVES ....... ERROR! BOOKMARK NOT DEFINED.