Trebor Mega 120D Manual

7/23/20 –M120D-A

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

E-mail: treborservice@idexcorp.com

Mega 120D PUMP

Operation / Maintenance Manual

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL CONTENTS

CONTENTS

1INSTALLATION............................................................................................................3

1.1 UNPACKING ......................................................................................................3

1.2 TIE BOLT TORQUE ...........................................................................................3

1.3 UTILITIES / HOOK-UP.......................................................................................3

2OPTIONS......................................................................................................................5

2.1 FLUID PORT CONNECTION OPTIONS............................................................5

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP....................................5

2.3 OPTIONAL LEAK SENSING..............................................................................6

2.3.a Installation..............................................................................................6

3START-UP....................................................................................................................8

3.1 HIGH TEMPERATURE OPERATION................................................................8

3.2 PERFORMANCE CHARTS................................................................................8

4MAINTENANCE..........................................................................................................10

4.1 PREVENTIVE MAINTENANCE SCHEDULE...................................................10

4.1.a Preventive Maintenance Record .........................................................12

4.2 RECOMMENDED SPARE PARTS ..................................................................13

4.3 TOOLS..............................................................................................................13

4.4 PARTS ILLUSTRATION...................................................................................14

4.5 PARTS LIST.....................................................................................................15

4.6 CLEAN-UP........................................................................................................16

4.7 DISASSEMBLY ................................................................................................16

4.7.a Head Disassembly...............................................................................16

4.7.b Body Disassembly...............................................................................17

4.8 ASSEMBLY ......................................................................................................17

4.8.a Pilot Valve (Both Heads) .....................................................................17

4.8.b Shuttle Spool Assembly.......................................................................18

4.8.c Shuttle Assembly (Master Head).........................................................19

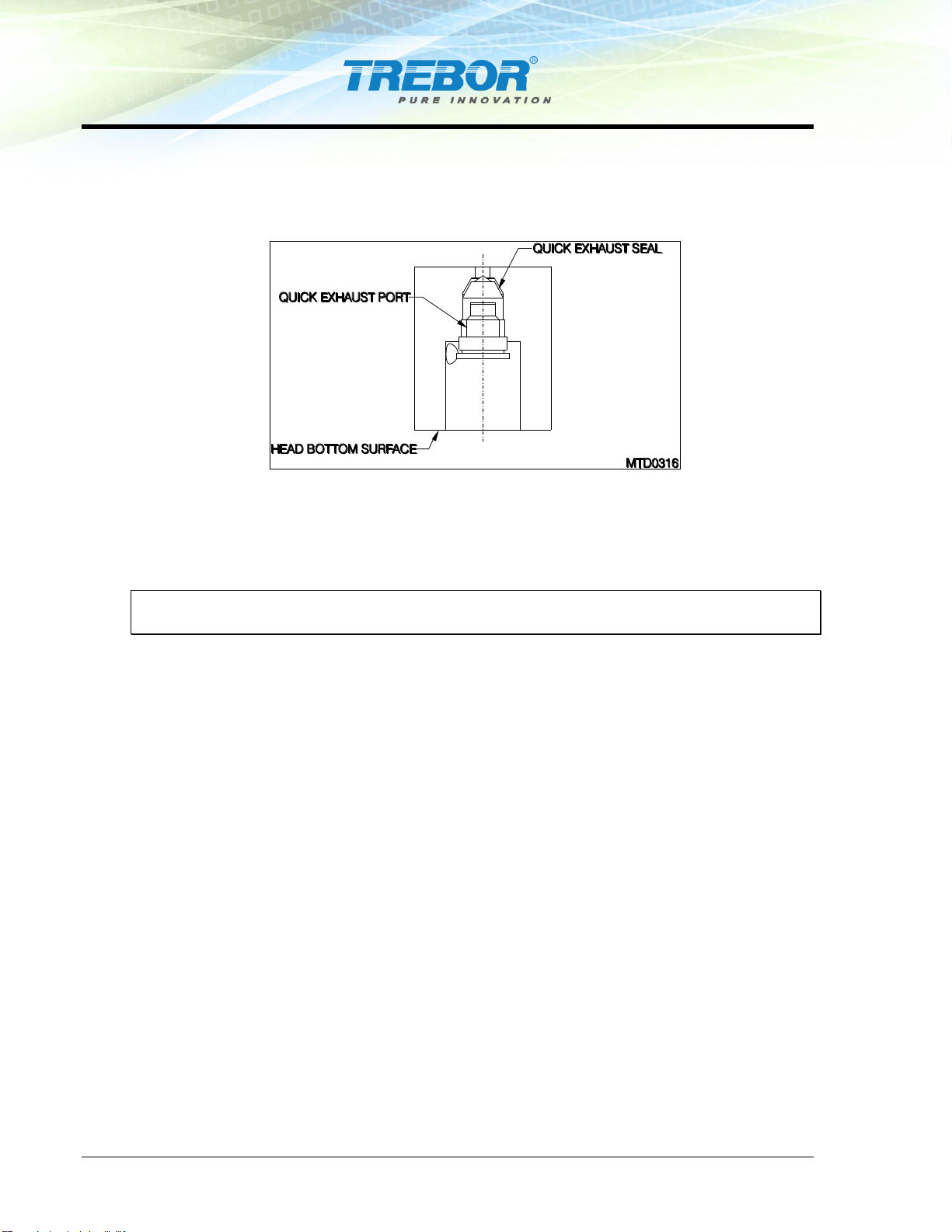

4.8.d Quick Exhaust (Both Heads)...............................................................20

4.8.e Body Assembly....................................................................................20

4.8.f Final Assembly ....................................................................................23

4.9 TESTING..........................................................................................................24

4.9.a Performance Test................................................................................24

4.9.b Dry Pump.............................................................................................24

4.9.c Dry Suction..........................................................................................24

5TROUBLESHOOTING................................................................................................25

6WARRANTY AND EXCLUSIONS..............................................................................27

7CONTACT INFORMATION........................................................................................28

7.1 GENERAL CONTACT INFORMATION............................................................28

7.2 TECHNICAL SUPPORT...................................................................................28

7.3 REGIONAL REPRESENTATIVES...................................................................28

8ADDENDA ..................................................................................................................29

8.1 DISCHARGE SLEEVE ADDENDUM ...............................................................29

8.2 MAGNETIC SHUTTLE ADDENDUM ...............................................................31

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 3

1 INSTALLATION

1.1 UNPACKING

After unpacking, the pump should be checked for any damage that may have occurred

during shipment. Damage should be reported to the carrier immediately.

The following items should be included within the shipping container:

Qty

Item

Description

1

120D

Mega 120D Pump

1

M120D

Operation/Maintenance Manual

1.2 TIE BOLT TORQUE

The tie bolts on the pump are tightened before leaving the factory. However, relaxation

may occur due to handling, material creep, or other unforeseen events. Trebor

recommends that all eight tie bolts be re-tightened upon pump install. The following

procedure should be used:

1. Remove black tie bolt caps (Item 17 in Figure 4-1) from both sides of all 8 tie

bolts

2. Apply 80 in-lbs. (9.0 N-m) of torque to each slave side bolt while holding the

master side bolt stationary. A star-pattern is advised.

a. The master side is the left side of the pump if you are looking at the fluid

ports.

3. Replace the tie bolt caps.

1.3 UTILITIES / HOOK-UP

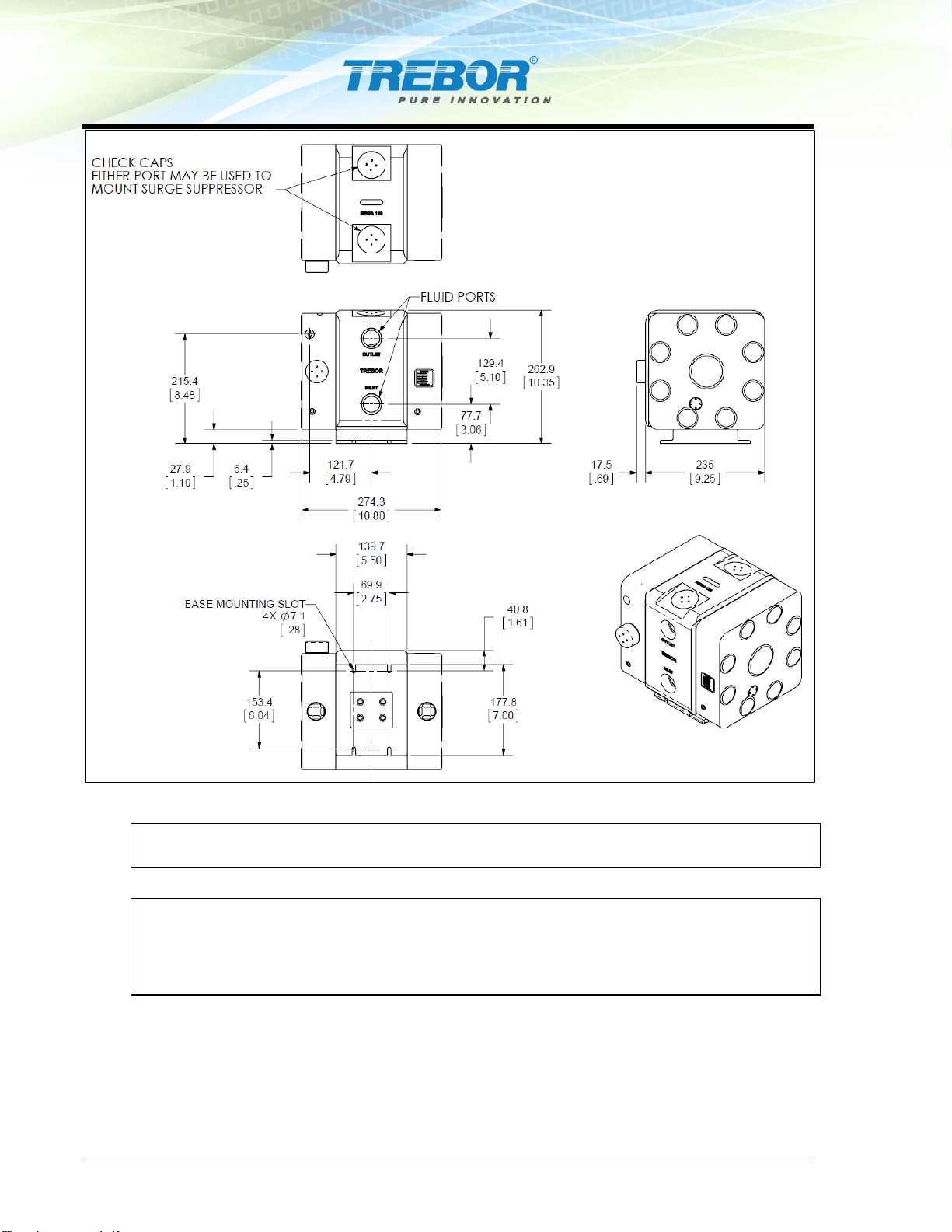

The pump is mounted using four 1/4” bolts. It is recommended that the pump be

mounted not more than 15from level to maintain self-priming ability and pumping

efficiency.

Air Inlet: 1/2” FNPT (3/8” Dia. [8mm] supply tube minimum).

Air Supply: 25-80 psig (0.17-0.55 MPa) clean dry air or nitrogen. (For Air

Consumption, See Section 3.1 Performance Charts)

Fluid Ports: Inlet/Outlet Fluid Fittings and Surge Suppressor require tightening to

specified torque values during pump installation. See Section 2 for

installation diagram and torque values.

Remote

Exhaust: 1/4” FNPT (3/8” Dia. minimum tube up to 6’ length, 1/2” Dia. Minimum

tube greater than 6’ length).

PAGE 4 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

Figure 1-1

ATTENTION: The pump should be operated with clean, dry air or nitrogen. Particulate,

water and oils in the air supply can damage the pump.

NOTE:

1. It is recommended that a filter be placed on the discharge side of the pump.

2. Although extensive efforts are made to deliver pumps to our customers completely

dry, new pumps may contain residual moisture from their final DI water test.

Recommended Maximum Operating Levels:

Maximum supply CDA/N2 pressure: 80 psig (0.55 MPa)

Maximum fluid temperature: 212°F (100°C)

MEASUREMENTS ARE IN mm

[in]

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 5

2 OPTIONS

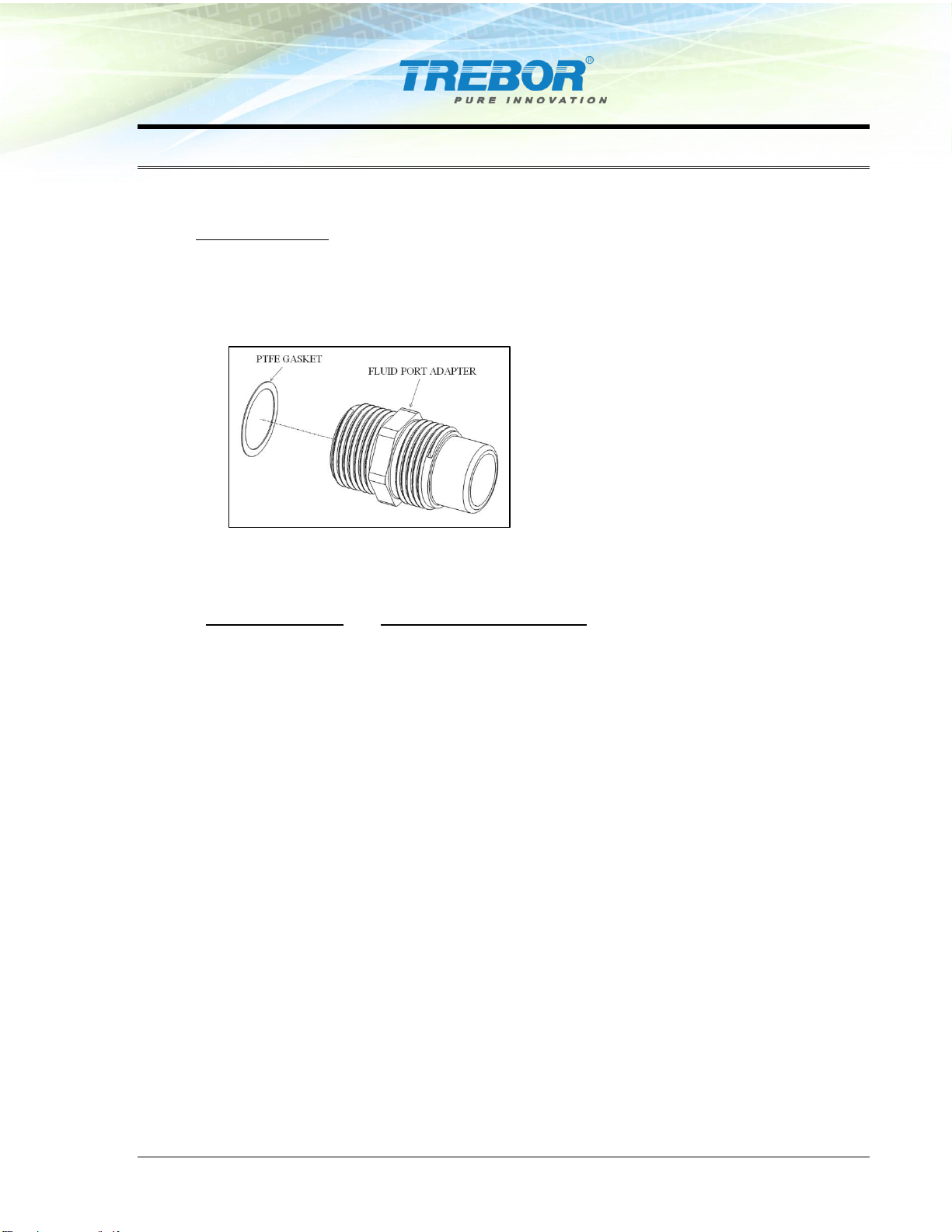

2.1 FLUID PORT CONNECTION OPTIONS

Available Options

A. Flare style tube adapter 1 1/4” tube fitting –made of high purity PFA

PVDF flare nuts (standard)

PFA flare nuts (optional)

B. Custom fittings Contact Trebor Representative

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP

Surge Suppressor

Assembled Height: mm (in)

SS85P5A0

434.9 (17.12)

SS95P5A0

382.5 (15.06)

Figure 2-1

PAGE 6 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

Figure 2-2

NOTE: See Surge Suppressor Operation Manual for detailed installation instructions.

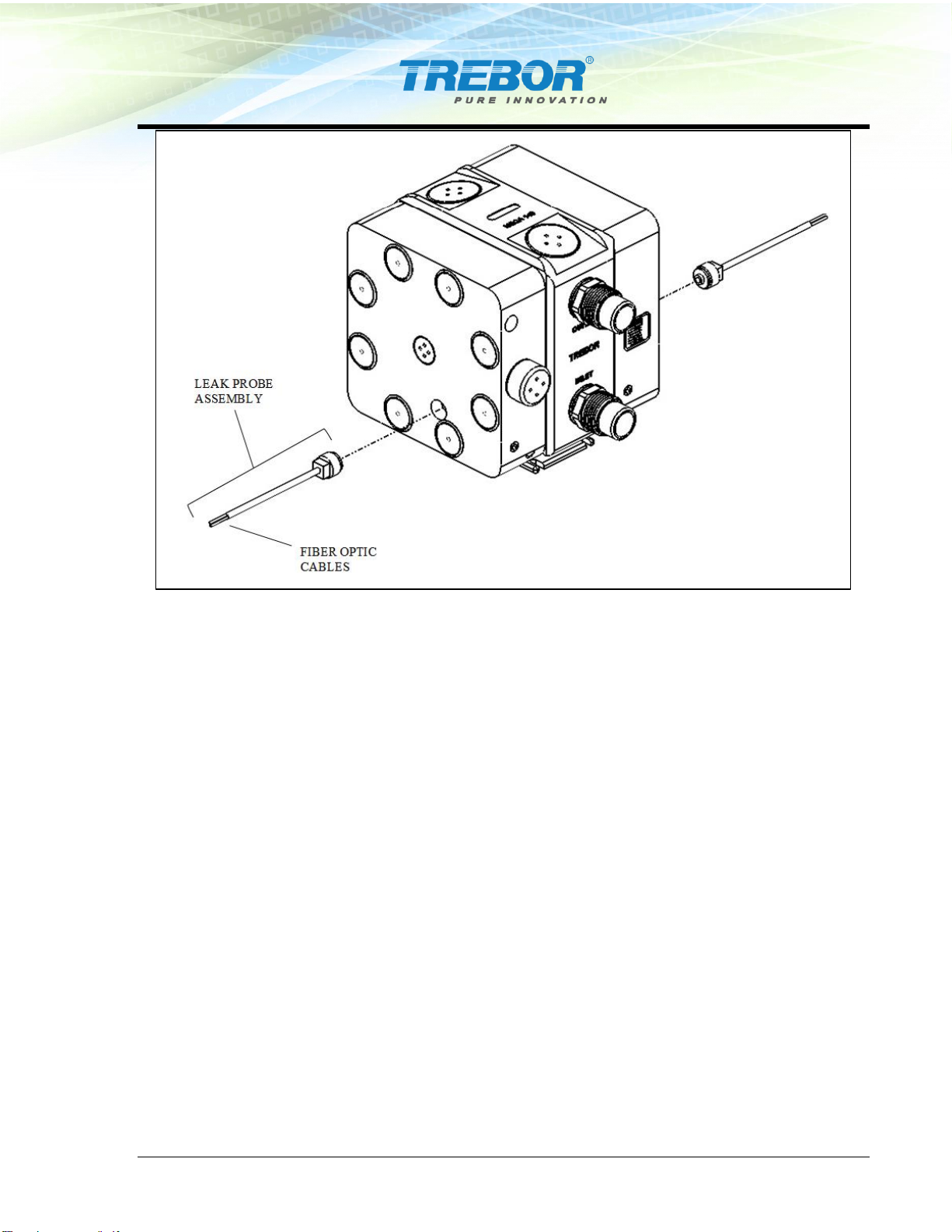

2.3 OPTIONAL LEAK SENSING

2.3.a Installation

•Remove plug and seal from port.

•Install probe assembly into leak sensor port. Probe is self-sealing and does not

require a seal.

•Thread probe cap into port. (NOTE: Do not over tighten; damage to threads will

occur.)

•Connect fiber optic cable to sensor (NOTE: Minimize bends in fiber optic cable to 2”

radius minimum to help ensure optimum signal strength.). Fiber optic cable can be

cut to desired length using the cable cutter provided.

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 7

Figure 2-3

PAGE 8 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

3 START-UP

•Pump air supply pressure should be regulated.

•Open the fluid suction (IN) line valve, if necessary.

•Open the fluid discharge (OUT) line valve, if necessary.

•Start with air regulator at low pressure setting (<15 psig). Increase or decrease

setting to attain desired flow, up to 80 psig (0.55 MPa).

•Refer to Troubleshooting, Section 5, if pump fails to start.

ATTENTION: Prolonged periods of dry running (> 5 minutes) will damage critical internal

pump parts.

CAUTION: When handling potentially dangerous fluids under pressure, the

pump and its fittings should be placed in an enclosure.

3.1 HIGH TEMPERATURE OPERATION

Pump operation at temperatures above 60°C requires periodic tightening of the tie bolt

nuts. The frequency of this procedure is best established by the user.

3.2 PERFORMANCE CHARTS

Pumping capacity is a function of air supply pressure and volume, suction head, suction

line restrictions, discharge head, discharge line restriction, and fluid properties. The

following data was taken using water at atmospheric temperature and pressure with

limited sample sizes. The data is intended to aid in system design and should be used

for general reference only.

Figure 3-1

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 9

Figure 3-2

PAGE 10 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

4 MAINTENANCE

Trebor pump maintenance can be divided into two categories: air system maintenance

and fluid system maintenance. The purpose of air system maintenance is to prevent air

system failures such as stalling or erratic cycling. The purpose of fluid system

maintenance is to maintain suction and lift capabilities.

Pump Rebuild Service

Trebor International provides a factory rebuild service for customers using Trebor

products. Trebor will rebuild any standard pump (exclusive of options). Please contact

Trebor International Sales Department for current pricing. The fixed rebuild price

includes a factory rebuild and parts equivalent to the standard rebuild kit. Each factory

rebuild comes with a new one-year warranty. Repairs requiring more extensive part

replacements will be quoted prior to proceeding with the pump rebuild. If the pump has

exceeded its useful life and cannot be rebuilt, the customer may elect to purchase a new

Trebor pump. If the customer chooses not to rebuild or replace the pump, a $150.00

evaluation charge will be required.

All returned pumps are to be shipped freight prepaid with a valid Purchase Order for the

cost of rebuild service. Please contact Trebor International prior to returning your pump

to obtain an RMA Number and Pump Return Data Sheet to ensure proper safety

precautions. Each pump will be evaluated and repaired within 5 working days of the

receipt of pump at Trebor facility.

4.1 PREVENTIVE MAINTENANCE SCHEDULE

The following maintenance schedule is recommended to optimize pump performance

and minimize failures. Tie bolt torque should be checked within 30 days of start-up and

at periodic intervals thereafter. If the pump is subjected to thermal cycle operation, the

tie bolt torque should be checked after the first 3 thermal cycles and periodically

thereafter. Certain operating conditions that require more frequent maintenance

intervals have been noted. In positive pressure inlet conditions where suction or lift is

not required, fluid system maintenance may be extended. However, tie bolt retorque is

still recommended.

Adhering to the recommended preventative maintenance schedule along with periodic

inspection of the pump will ensure continued efficient operation and overall reliable

pump performance.

It is recommended that the Preventive Maintenance Record (Section 4.1.a) be copied,

maintained, and kept with this unit for future reference.

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 11

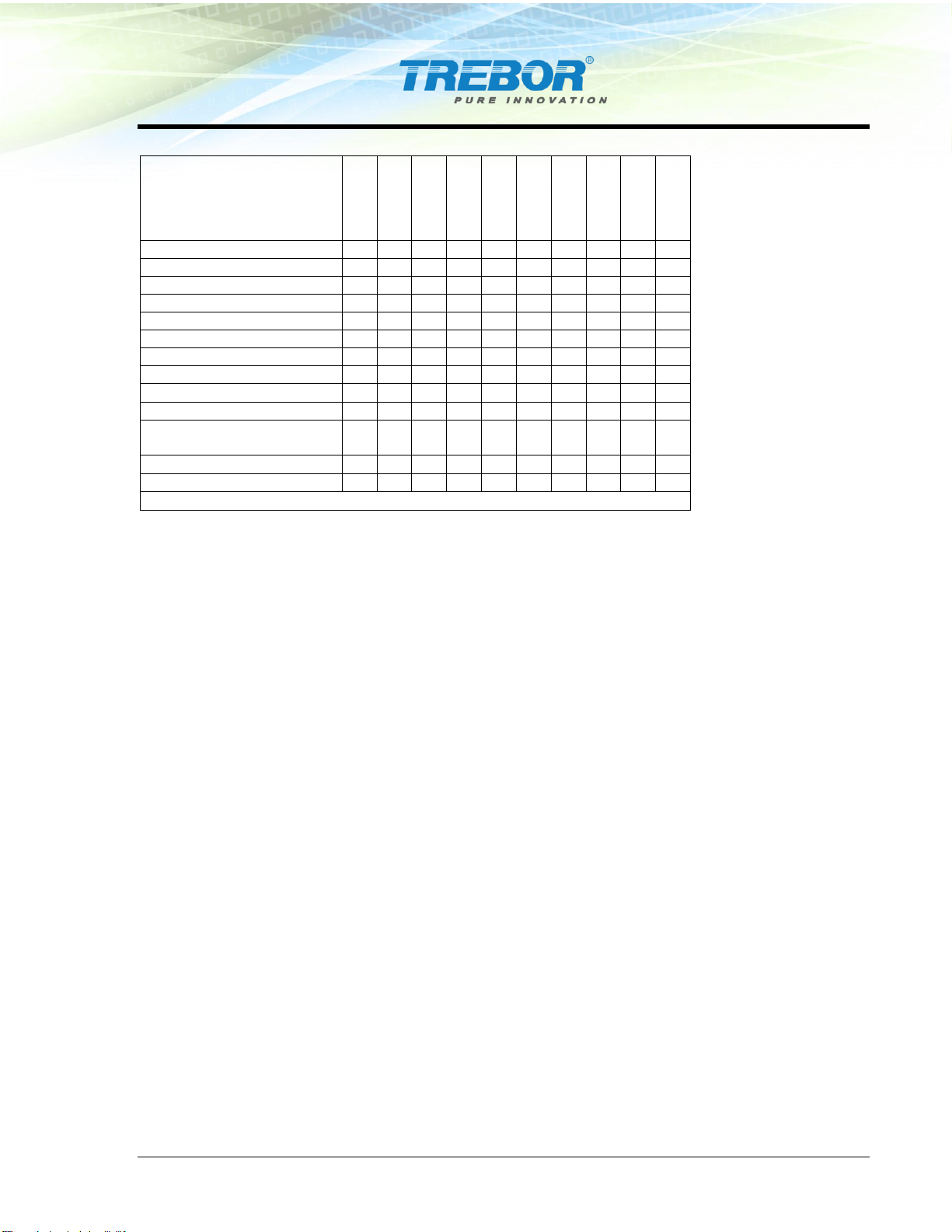

MEGA 120D Maintenance Schedule

Install

30 Days

3 Months

6 Months

9 Months

12 Months

15 Months

18 Months

21 Months

24 Months

Tie Bolt Torque (80 lb.-in)

I

I

I

I

I

C-Ring and Detent Legs

R

Pilot Button

R

Check Seat Wear Rings

R

Shaft Bushing

R

Shaft (High Suction Applications)

R

Shaft

R

Diaphragms and Main Seal

R

Quick Exhaust Seal

R

Check Balls and O-Rings

R

Check Balls and O-Rings

(High Suction Applications)

R

Exhaust Muffler Media

R

Distribution Pilots

R

I=Inspect, R=Replace

PAGE 12 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

4.1.a Preventive Maintenance Record

Company Name:

_____________________________________________________

Company Address:

_____________________________________________________

_____________________________________________________

Product:

_________________

Serial Number:

________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

Date:

________

Tech:

_____

Notes:

________________________________________

________________________________________

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 13

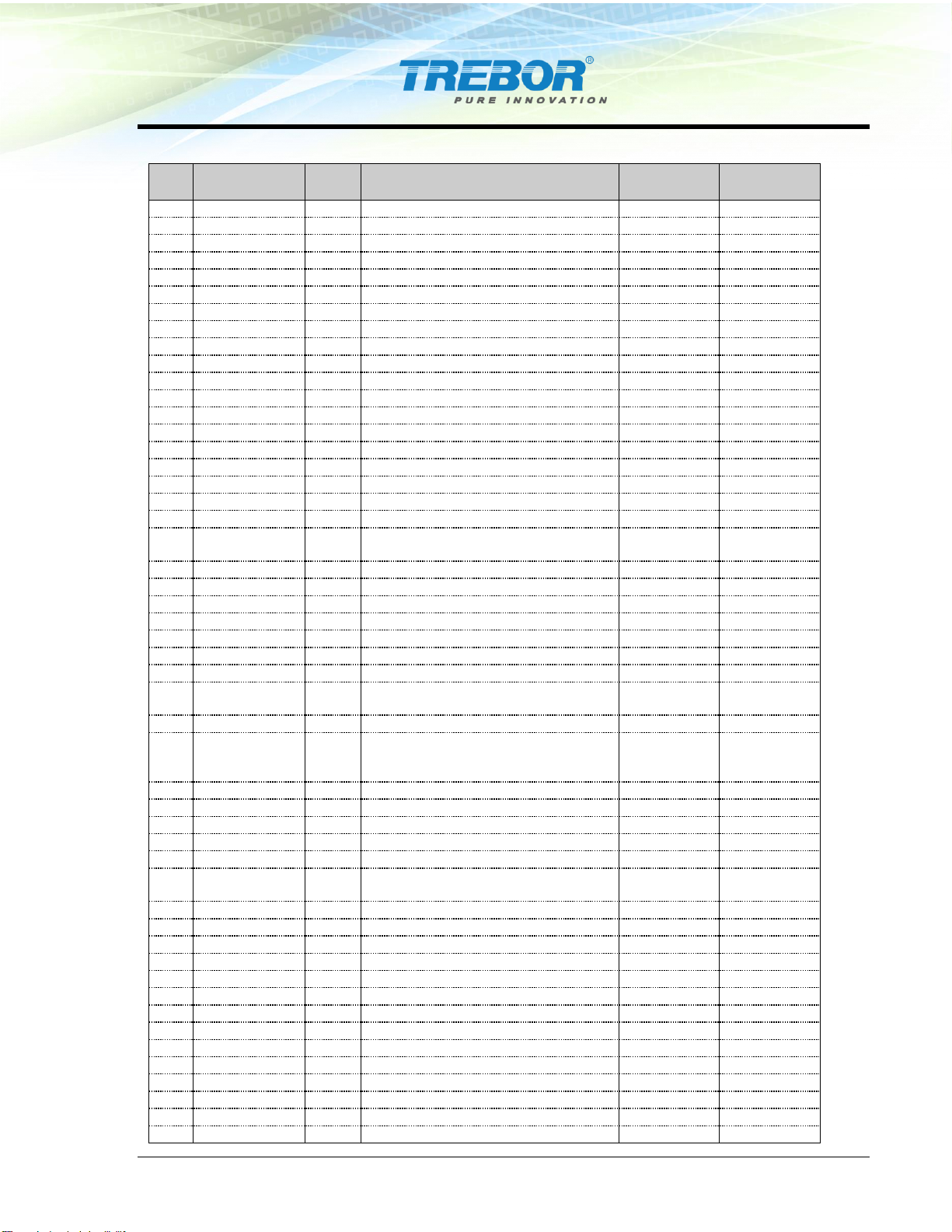

4.2 RECOMMENDED SPARE PARTS

KR120D-00-A Spares Rebuild Kit, which includes:

Part No

Qty

Description

KD120-00-A

1

Diaphragm Kit*

Includes:

(2)

(2)

1900B0023

98001585

Diaphragm Set

FKM O-Ring

KM120D-00-A

1

Maintenance Kit

Includes:

(2)

(2)

(2)

(2)

(2)

(1)

1900B0016

98002987

98003047

L0119

L0197

L0145

Quick Exhaust Port

Pilot Button

Quick Exhaust Seal

Muffler Assembly

Detent Leg

Detent Ring

98002240

2

FKM O-Ring

98004258

4

O-Ring, PTFE

98002303

4

FKM O-Ring

98004255

4

Check Ball

BL002

2

Suction Seat

BL007

2

Check Port Gasket

BL009

2

Fluid Port Gaskets

BL012

1

Shaft Bushing

L0100

16

Tie Bolt Cap

In critical applications, a spare pump is recommended to minimize potential down time.

4.3 TOOLS

The following tool kit is recommended as standard service equipment.

KT120-00-A Tool Kit, which includes:

Part No

Qty

Description

98001230

1

5/32” Allen Wrench

98002136

2

7/16” Nut Driver

98002859

1

7/16” Socket

98003150

1

Tool Case

98003305

1

Drive Handle

T0172

1

Check Sleeve Insertion Tool

T0173

1

Check Sleeve Removal Tool

T0146

1

¾” Pin Tool

T0147

1

1” Pin Tool

T0148

1

½” Pin Tool

T0159

1

2” Pin Tool

T0144

1

Cleaning Tool

T000A0021

1

Shaft Bullet

PAGE 14 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

4.4 PARTS ILLUSTRATION

Figure 4-1

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 15

4.5 PARTS LIST

ILL

NO

PART NO

QTY

DESCRIPTION

PM

YEAR #

MATERIAL

1

BL006

2

Check Bore Plug

PTFE

2

BL007

2

Gasket Seal, Check Port

1

PTFE

3

BL004

2

Discharge Sleeve

PTFE

4

98004255

4

Check Ball

1

PTFE

5

98004258

4

O-Ring

1

PTFE

6

BL003

2

Suction Sleeve

PTFE

7

BL002

2

Suction Seat

PTFE

8

BL001

1

Body

PTFE

9

BL012

1

Shaft Bushing

1

PTFE

10

L0195

1

Locking Ring

PTFE

11

BL011

1

Main Shaft

2

PFA

12

1900B0070

2

Push Plate

PTFE

13

1900B0023

2

Diaphragm Set

1

PFA

14

98001585

2

Main Seal

1

Viton

15

L0141-01

1

Master Head

PP

16

BL014

8

Tie Bolt Assembly

SS302, PFA

17

L0100

16

Tie Bolt Cap

1

LDPE

18

L0208

2

Cap, Pilot

PP

19

W0116

2

Seal, Pilot Cap

PTFE

20

W0123

2

Assembly, Pilot Valve, Wear Resistant

Peek, PTFE,

PPS, Viton

21

W0117

2

Seal, Pilot Sleeve

PTFE

22

AM040

2

Leak Port Cap

PP

23

L0167

2

Leak Port Seal

PTFE

24

98003047

2

Quick Exhaust Seal

1

Viton

25

1900B0016

2

Quick Exhaust Port

UHMW

26

L0119

2

Muffler Assembly

1

PP

27

98003080

2

Plug, Remote Exhaust

PE

28

AK058

1

NM Sleeve Assembly

Ceramic,

PTFE

29

L0105

1

Adapter, Detent

PP

30

L0131

1

Assembly, Spool External, High Load

Ceramic,

PEEK,

Torlon

30A

L0197

2

Leg, Detent

1

Torlon

30B

L0145

1

Ring, Detent, High Load

1

PEEK

31

L0113

1

Seal, Detent Cap

PTFE

32

L0104

1

Cap, Detent External

PP

33

L0139-01

1

Slave Head

PP

34

L0140

8

Bushing

NPRN,EPD

M

35

1900A0028-01

8

Tie Bolt Washer

SS316

36

98002341

8

Nut, Flange, SS, 1/4 - 20

SS18-8

37

98002620

1

Label Cap

LDPE

38

98001418

4

Insert

SS18-8

39

BL017

1

Pump Base

PP

40

98001093

4

Washer

SS18-8

41

98001375

4

Screw

SS18-8

42

98001108

4

Cap, Blue

LDPE

43

1900A0024

2

Main Transfer Tube

PFA

44

98002240

2

O-Ring

1

Viton

45

BL022

1

Shuttle Transfer Tube

PFA

46

98002303

4

O-Ring

1

Viton

47

98003755

1

Screw, Locking Ring

PTFE

48

98003769

2

Screw, Push Plate

PTFE

PAGE 16 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

4.6 CLEAN-UP

To help remove potentially dangerous chemicals, the pump can be flushed with DI water

or disassembled and thoroughly cleaned.

4.7 DISASSEMBLY

During the life of the pump it will be necessary to perform certain preventative

maintenance procedures to ensure its continued high performance. This section and the

next (4.8 Assembly) are provided for the user’s convenience in disassembly and re-

assembly in performing these procedures.

•Thoroughly clean/flush the pump using DI water (Refer to Section 4.6 Clean-Up).

•Remove tie bolt caps from the slave head.

•Remove nuts from the tie bolts (Slave Head side). Leave tie bolts in place.

•Lay the pump on its side with slave side up.

•Lift off the slave head.

•Remove the main seal and diaphragms.

•Remove the O-rings from the shuttle transfer tube.

•Remove the body assembly.

•Remove the second set of diaphragms and main seal.

•Remove the transfer tube and O-rings from the heads and body.

•Remove the remaining tie bolt caps and tie bolts.

NOTE: All polypropylene and fluoroplastic parts, when disassembled, should be

thoroughly washed and be free from chemical residue for handling purposes.

4.7.a Head Disassembly

•Remove label cap (Slave Head only).

•Remove smart pilot cap from master and slave heads.

•Remove pilot valve and seals from Master and Slave Heads.

•Remove the shuttle cap and seal from the Master Head.

•Remove the shuttle spool assembly from the adapter detent.

•Remove C-ring and detent legs from shuttle spool assembly.

•Remove Detent Adapter

•Do not remove the shuttle sleeve assembly from the shuttle bore.

•Remove the muffler spool and muffler pads from each head.

•Remove quick exhaust ports from heads.

•Remove quick exhaust seals.

•Remove remote exhaust plugs (if necessary).

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 17

4.7.b Body Disassembly

•Remove check bore plugs using 3/4” pin tool and remove seals.

•Remove sleeves, balls, o-rings and check seat. Do not use excessive force.

•Unthread push plate locking screw and push plate from the one side of the shaft.

•Remove remaining shaft and push plate from body.

•Unthread second locking screw and push plate from shaft.

•Unthread shaft bushing locking screw from body.

•Using 2” pin tool, insert pins in shaft bushing locking ring located in the master head

side of chamber and rotate CCW to remove bushing. Then push out bushing from

the slave head chamber side.

4.8 ASSEMBLY

Prior to beginning assembly, inspect all parts to ensure they are clean and dry. Wear

clean, protective gloves.

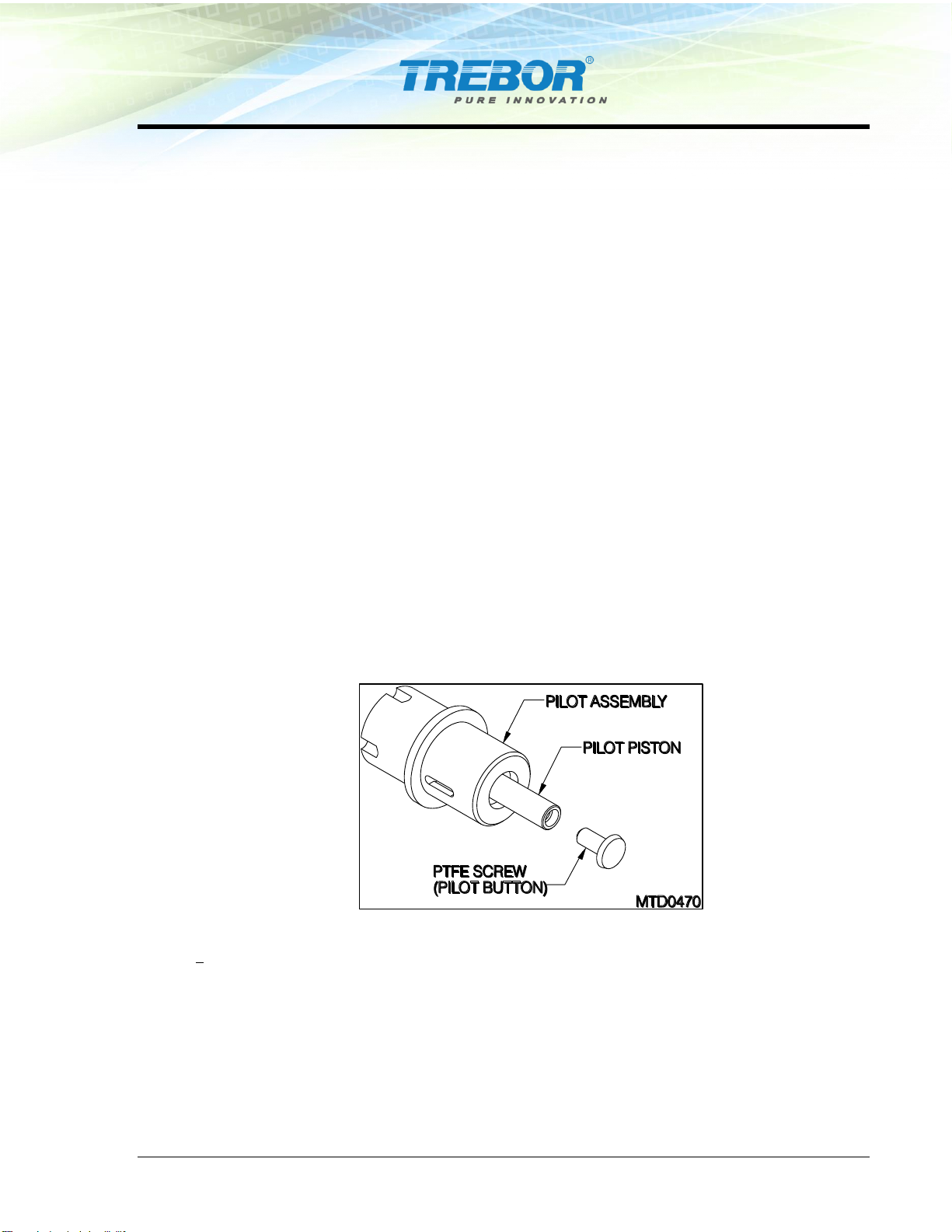

4.8.a Pilot Valve (Both Heads)

NOTE: Do not use any tools to install the pilot button. Use of tools may damage the

button.

•Remove existing pilot button and discard.

•Replacement pilot button should be tightened enough that the underside of the head

touches the pilot piston.

•No light should be visible between the bottom of the button head and the piston.

Figure 4-2

•Slide seal onto pilot valve body until even engagement with the shoulder is reached.

The shoulder is located in the center of the pilot valve body.

•Thread the pilot valve assembly into the pilot bore of the head as shown in Figure

4-3. Tighten to 25 in-lbs. Do not over tighten.

PAGE 18 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

Figure 4-3

•Install pilot cap seal.

•Thread pilot valve cap to engage seal. Tighten to 45 in-lbs.

•Repeat process for both heads

•Install label cap (Slave Head only).

4.8.b Shuttle Spool Assembly

•Hold shuttle spool (item 1) upright and align slot in detent legs (item 2) with notch on

shuttle spool, see Fig. 1.

•Apply pressure upward onto base of detent legs with thumb and index finger, as

shown in Fig. 2.

•Tilt the detent ring (item 3) over one of the legs, and align the groove on the inside of

the detent ring with the end of the detent leg. Tilt the other side of the ring down,

expanding it slightly, so that the other detent leg snaps into the detent ring groove.

See Fig. 3. The completed assembly should look like Fig. 4.

MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL PAGE 19

Figure 4-4

4.8.c Shuttle Assembly (Master Head)

NOTE: Ensure that the spool moves freely inside the sleeve prior to installation.

•Thread detent adapter into shuttle bore until flush against head. Tighten to 45 in-lbs.

•Insert shuttle spool assembly into adapter detent and Shuttle Sleeve. (Do not

lubricate.)

Figure 4-5

•Install the seal onto seal groove shoulder of the shuttle cap.

•Thread shuttle cap onto detent adapter. Tighten to 40 in-lbs.

ATTENTION: Threads should be snug. Do not over tighten.

PAGE 20 MEGA 120D PUMP OPERATION / MAINTENANCE MANUAL

4.8.d Quick Exhaust (Both Heads)

•Insert quick exhaust seal.

•Insert quick exhaust port in each head as shown. Tighten to 15 in-lbs. Do not over

tighten.

Figure 4-6

•Install 3 each muffler pads onto muffler spool and insert into exhaust port. Tighten to

40in-lbs.

4.8.e Body Assembly

NOTE: For easy installation, check sleeves that do not install easily (minimal effort) can

be placed in a freezer prior to assembly to assist insertion.

•Insert the suction seat. Press firmly using the check sleeve insertion tool until the

suction seat is at the bottom of the check bore.

•Install the o-ring. The o-ring should rest inside the cup shape in the seat.

•Install the check ball. Ensure the o-ring does not become dislodged.

•Insert the suction sleeve. Press firmly using the check sleeve insertion tool until the

suction sleeve meets the suction seat.

•Install the o-ring. The o-ring should rest inside the cup shape in the seat.

•Install the check ball. Ensure the o-ring does not become dislodged.

•Install the discharge sleeve. The edge of the non-threaded part of the check bore

should be approximately flush with the top of the discharge sleeve.

•See Figure 4-7 for the proper order of check assembly installation.

Table of contents

Other Trebor Water Pump manuals

Popular Water Pump manuals by other brands

Ingersoll-Rand

Ingersoll-Rand ARO AF0813S Series Operator's manual

Gardner Denver

Gardner Denver Welch 2580B-01 owner's manual

AutoAqua

AutoAqua Smart AWC Lite manual

Dolomite

Dolomite Mitos Programming instructions

INOXPA

INOXPA DIN-FOOD Installation, service and maintenance instructions

Zoeller

Zoeller 63 installation instructions

Wilo

Wilo TWU 3 Series Installation and operating instructions

Sandpiper

Sandpiper ST1 Service & operating manual

Cosmo

Cosmo Cosmo CPZ Installation and operating instructions

STRANGKO

STRANGKO 8560 930 user manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS EchoStorm VA2 Installation, operation and maintenance manual

Hayward

Hayward Super II SP3000 ECO Series owner's manual