2

HT/STSpaceHumidityandTemperatureSensorInstallationInstructionsTG200921Issue1/B30/08/06 2 - 1

Installation Instructions - Sheet 2

HT/ST

Space Humidity and Temperature Sensor

Switch off supply

1

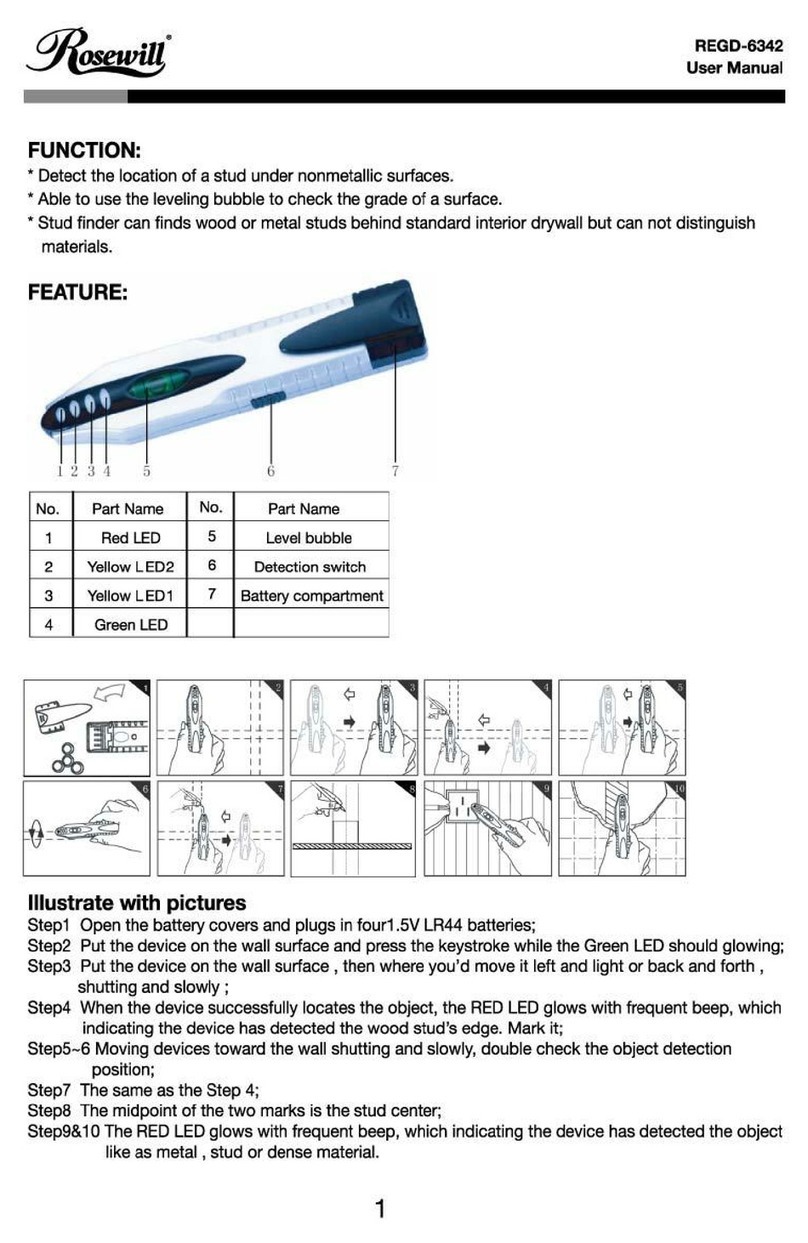

2.1 Maintenance

Over time, the sensing element may get covered in dust. The dust can be removed using compressed

air. Under no circumstances should water or cleansing agents be used on the sensing elements.

It is recommended that the accuracy of the sensor is verified every 12 months. If the sensor falls outside

the quoted accuracy, or the sensor tip is damaged, replace the tip as shown below.

Open housing

2

Unscrew board

3

Remove old sensor tip

4

ab

Caution: This unit contains static sensitive

devices. Suitable ant-static

precautions should be taken

throughout the operation to

prevent damage to the units.

BS EN100015/1 Basic Specifications:

protection of electrostatic sensitive devices.

J P R 4

L P 2 - P W R

T H

I 2 - N / T H

I 1 - N

I 1 - P

E A R T H

O

I

J P R 4

L P 2 - P W R

T H

I 2 - N / T H

I 1 - N

I 1 - P

E A R T H

hold sides of sensor tip near base of sintered filter

JPR4

LP2-PWR

TH

I2-N/TH

I1-N

I1-P

EARTH

discard old tip, see 2.2

HT/ST Installation Instructions - Sheet 2

HT/STSpaceHumidityandTemperatureSensorInstallationInstructionsTG200921Issue1/B30/08/06

2 - 4

ManufacturedforandonbehalfoftheEnvironmentalandCombustionControlsDivisionofHoneywellTechnologiesSàrl,Ecublens,Route

duBois37,SwitzerlandbyitsAuthorizedRepresentative,TrendControlSystemsLimited.

TrendControlSystemsLimitedreservestherighttorevisethispublicationfromtimetotimeandmakechangestothecontenthereof

withoutobligationtonotifyanypersonofsuchrevisionsorchanges.

Trend Control Systems Limited

P.O.Box34,Horsham,WestSussex,RH122YF,UK.Tel:+44(0)140321888Fax:+44(0)1403241608www.trend-controls.com

Trend Control Systems USA

6670185thAvenueNE, Redmond, Washington 98052, USA. Tel: (425)897-3900, Fax: (425)869-8445 www.trend-controls.com