Email fires@trendzoutdoors.co.nz Freephone 0508 252 784 Visit www.trendzoutdoors.co.nz

Page 3

Installation of the fire

. Prior to lifting the Trendz Outdoor Fire into position, ensure

the concrete footing has cured and been constructed to the

dimensions and strength rating recommended.

. Use a HIAB or mobile crane to lift the Trendz Fireplace into

position. Every fireplace has x . ton swift lift tabs in the top for

lifting. Most hiab trucks carry the swift lift clutches (except for the

Hudson which has x . ton swift lifts) to connect to the tabs.

. Use crane/HIAB to lift any other heavy components into position,

such as optional wood boxes, concrete chimney extension blocks.

. Complete A) or B) as suits your installation method

A) Site assembly of fire box: Fill the inside of the pre-cast

Trendz Fire with concrete up to the bottom level of the opening.

Ensure the concrete is filled level and flat by measuring and

marking correct height on back of fireplace prior to filling. Ensure

hearth (optional) is installed prior to pouring infill. When the

infill of concrete has cured (- days), assemble the steel fire box

inside the opening. This cannot be assembled then inserted (see

page for fire box assembly).

B) Pre-assembled fire box option: Remove the fire base plate (D)

and drill and fix the pre-fitted L brackets to your foundations with

the M x concrete screws supplied.

. Install concrete cap (Douglas) or steel flange (Burton/ Mini

Burton). Do not install stainless steel flue until all cladding/

painting is complete and (optional) steel wood boxes are installed.

. Pre-plastered and painted Burton and Mini Burton:

Place your fireplace on your prepared concrete pad. Remove

the base fire plate (D) and drill and fix the fitted L brackets to the

foundation with the M x concrete screws. Once complete,

reinstall fire plate. Fit concrete or steel wood boxes if ordered

and then the flue which will be couriered to you.

Packers may be needed to get the fireplace to sit level.

Assembly of the firebox

(Not needed if the fire box is pre-fitted)

The firebox must be assembled inside the cavity. Only finger tighten all

bolts, until the firebox is fully assembled

. Slide the back panel (B) into the fireplace cavity, lean against back

wall of fireplace.

. Slide the two sides (A) into the fireplace cavity ensuring the side

rails are facing inwards and bolt lugs are at rear.

. Bolt the back panel to the sides using the M bolts provided.

. Bolt top baffle (C) to the top of the side panels. To make the install

of this easier, insert a large Phillips head screwdriver through

rear bolt hole on one side of baffle, feed tip of screwdriver into

corresponding hole on side plate. Baffle can now hang on the

screwdriver while the first two bolts are inserted on the opposite

side. After the next two bolts are inserted tilt the front of the

baffle down to make sure the throat opening is -mm before

tightening the bolts.

. Slide the bottom steel fire plate (D) in to sit on the lower side rails

and bolt down. (Install optional hearth first).

. Insert the frame surround (E) and fix to concrete with the dyna

screws provided. x .mm holes will be pre-drilled in the side

walls of the firebox cavity.

TIP: Fix this in place after plastering and painting has been

finished. Use caution to ensure sharp corners of surround don’t

chip out plaster. Hand tighten dyna screws until sleeve isn’t loose

before inserting, this will prevent the screw spinning in the hole

when you tighten them. Ensure surround is centralised in firebox

opening and screws are inserted flush with surround before

tightening. You may need to tap them in with a hammer. Pull the

fire box forward so it meets the surround.

TIP: If the bottom plate or top baffle aren’t parallel to the

surround, remove bottom plate and place metal packers under

front/back of firebox side plates to level up the firebox. All bolts

must be hand tight only for this procedure.

Care of your fireplace

. Light a small fire - this should be for around - hours. This

process will help your cladding settle and set. Whether it’s plaster,

paint, stone, or any other material, it’s best to slowly introduce it

to the heat of the fireplace. We suggest repeating this process

times.

. Small cracks are normal - our fireplace shells are made from

concrete, therefore hairline cracks can appear due to extreme

temperature changes; these can be painted over without any

concerns. Over the years, we have worked on perfecting our

concrete mixture so you should not experience any structural

cracking. If you are concerned about the size of the cracks in your

fireplace, do not hesitate to contact us.

. Firebox maintenance - to help make sure that your firebox lasts

many long summers and colder winters, we recommend giving

the firebox a paint with Stove Bright®High-Temperature aerosol

paint in the colour satin black every - months. We also suggest

that you empty fire ashes with an ashpan shovel every - fires.

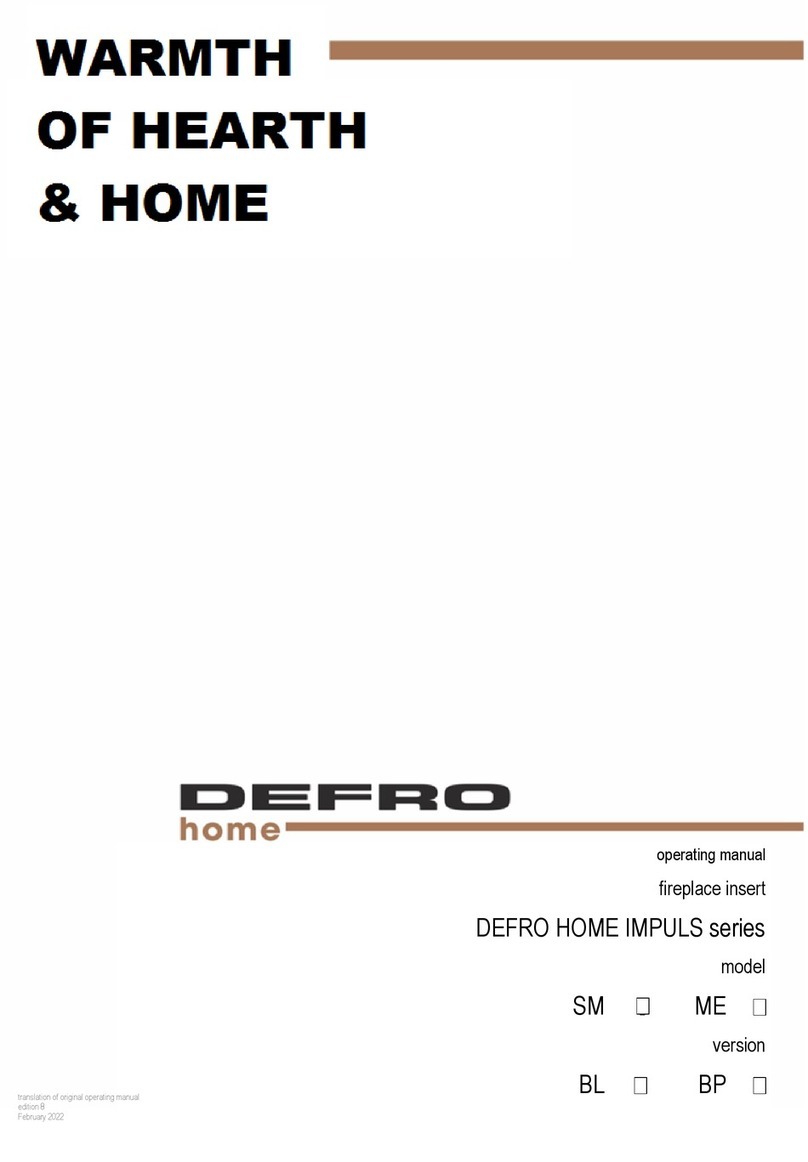

C

B

A

A

D

E