Trianco S700 Manual

Air Source Heat Pump

S700, S1200

Installation and Service Manual

2

TABLE OF CONTENTS

Introduction…… …………………………………………………………………………………………………………………….

3

General information …………………………………………………………………………………………………………………………..3

Cycle diagram …….………….……………………….….………………………………………………………………………………………4

Safety precautions…….

…………………………………………………………………………………………….……………………..5

Warning ……………………………………………………………………………………………………………………………………………..5

Caution …………………………………………………………………………………………………………….………………………………6

Operating the unit…….

…………………………………………………………………………………………………………………….7

Features and function…………………………………………………………………………………………………………………………7

User interface ………….……………………………………………………….……………………………………………………………….7

Buttons…………………………………………………….…….………………….……………………………………….……………………..8

Controller operations…………………………………….…….………………….……………………………………….………………..8/9

Parameter checking and adjustment………….

……………………………………………………………………………….10

Unit status query table ……………………………………………………………………………………………………………………..10

Parameter list……………………………………………….…….………………….……………………………………….…………….....10

Error code table ……………………….…….………………….……………………………………….…………………………………...11

Wiring diagram

…………………………………………….…….………………….……………………………………….……………..12

Installation of the unit……….

……………………………………………………………………………………………………….…13

Installation guidelines ……………………………………………………………………………………………………………………….13

Precautions for selecting the location ……………………………………………………………………………………………….13

Selecting a location in cold climates ………………………………………………………………………………………………….13

Installation space ………………………………………………………………………………………………………………………………14

Mounting the unit ……………………………………………………………………………………………………………………………..14

Water pipe work ……………………………………………………………………………………………………………………………….15

Checking the water circuit …………………………………………………………………………………………………………………15

Connecting the water circuit ……………………………………………………………………………………………………………..15

Charging water ………………………………………………………………………………………………………………………………….16

Piping insulation ………………………………………………………………………………………………………………………………..16

Field wiring ………………………………………………………………………………………………………………………………………..16/17

Pre-operation Checks ………………………………………………………………………………………………………………………..17

Checks before initial start-up …………………………………………………………………………………………………………....17

Maintenance…..

………………………………………………………………………………………………………………….…………….17

Installation plan for complete system……………

………………………………………………….………….………………18

Trouble shooting………

………………………………………………………………………………………………………………………19

General guidelines ……………………………………………………………………………………………………………………………..19

Error codes and troubleshooting ………………………………………………………………………………………………………..20/21

After Sales service……………………………………………………………………………………………………………………………….22

Technical specification………………………………………………………………………………………………………………………..23

Heating Performance…………………………………………………………………………………………………………………………..23

3

INTRODUCTION

This manual includes the necessary information about the unit. Please read this manual carefully before you install,

operate, and maintain the unit.

By Fitting this Activair Air source Heat Pump, you agree:

The unit has been received in good condition.

You have carried out a heat loss calculation and are sure that this heat pump is suitable.

You have carried out a load and voltage test to determine the correct size of breaker to be used.

You meet the requirements of the appropriate Building Regulations

HEALTH AND SAFETY

INFORMATION FOR THE USER, INSTALLER AND SERVICE ENGINEER

Under the Consumer Protection Act 1987 and the Health and Safety at Work Act 1974, it is a requirement to provide

information on substances hazardous to health (COSHH Regulations 1998).

TR Engineering takes every reasonable care to ensure that its products are designed and constructed to meet these

safety requirements when the products are professionally installed and used. To fulfil the requirements, products

are comprehensively tested and examined before despatch.

When working on the appliance, it is the responsibility of the user or engineer to ensure that personal protective

clothing or equipment appropriate to parts that could be considered hazardous or harmful is worn.

This appliance may contain some of the items below:

Glass rope, mineral wool, insulation pads, ceramic fibre, and glass insulation.

When handling, avoid inhalation and contact with eyes. These may be harmful and cause irritation to the skin, eyes,

nose, or throat. Use disposable gloves, face masks and eye protection.

After handling, wash hands and other exposed areas. When disposing of materials, limit dust and the risk of

inhalation by using water spray. Ensure materials are securely wrapped.

Seek urgent medical attention if inhaled or ingested. Exposure to eyes and skin should be followed by immediate

cleansing of the affected areas and medical attention if necessary.

Glues, Sealants and Paints

The glues, sealants and paints used present no known hazards when the appliance is used in the manner for which it

is intended.

TEST SPECIFICATION

EN 14825:2018

EN 14511 – 4:2018 Clause 4

4

Cycle diagram

The whole cycle diagram is shown below.

5

SAFETY PRECAUTIONS

To prevent injury to the user, other people, or property damage, the following instructions must be followed.

Incorrect operation due to ignoring of instructions may cause harm or damage.

Install the unit only when it complies with local regulations, by-laws, and standards. Check the main voltage and

frequency. This unit is only suitable for earthed sockets.

The following safety precautions should always be considered:

- Be sure to read the following WARNING before installing the unit.

- Be sure to observe the cautions specified here as they include important items related to safety.

- After reading these instructions, be sure to keep it together with the manual in a handy place for future

reference.

Only to be installed by a professional person.

Incorrect installation could cause injury due to fire, electric shock, the unit falling or leakage of water. Consult the

dealer from whom you purchased the unit or a specialized installer.

Install the unit securely in a place.

When insufficiently installed, the unit could fall causing injury. When installing the unit in a small room, please take

measures (like sufficient ventilation) to prevent the asphyxia caused by the leakage of refrigerant.

Use the specified electrical wires and attach the wires firmly to the terminal board (connection in such a way that

the stress of the wires is not applied to the sections).

Incorrect connection and fixing could cause a fire.

Be sure to use the provided or specified parts for the installation work.

The use of defective parts could cause an injury due to fire, electric shocks, the unit falling etc.

Perform the installation securely and please refer to the installation instructions.

Incorrect installation could cause an injury due to fire, electric shocks, the unit falling, leakage of water etc.

Perform electrical work according to the installation manual and be sure to use a dedicated section.

If the capacity of the power circuit is insufficient or there is an incomplete electrical circuit, it could result in a fire or

an electric shock.

The unit must always have an earthed connection.

If the power supply is not earthed, you may not connect the unit.

Never use an extension cable to connect the unit to the electric power supply.

If there is no suitable, earthed wall socket available, have one installed by a recognized electrician.

Do not move/repair the unit yourself.

Improper movement or repair on the unit could lead to water leakage, electrical shock, injury, or fire. Have any

repairs and/or maintenance only carried out by a recognized service engineer.

Do not plug or unplug the power supply during operation

There is a risk of fire or an electric shock

Do not touch/operate the unit with wet hands

There is a risk of fire or an electric shock

6

Do not place a heater or other appliances near the power cable

There is a risk of fire or an electric shock

Be cautious that water could not be poured into the product directly, do not allow water to run into electric parts

There is a risk of fire or an electric shock

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly qualified

person to avoid a hazard.

This appliance has not been designed for use by persons (including children) with reduced physical, sensorial, or

mental faculties or by persons without any experience or knowledge of heating systems, unless they act under the

safety and supervision of a responsible person or have received prior training concerning the use of the appliance.

Children should be supervised to ensure that they do not play with the appliance

IF THE PRODUCT IS NOT TO BE USED FOR AN EXTENDED PERIOD OF TIME, WE STRONGLY RECOMMEND NOT

TO SWITCH ‘OFF’ THE POWER SUPPLY OF THE UNIT.

IF THE POWER IS NOT SUPPLIED, THE ANTI-FREEZE FUNCTION WILL NOT BE PERFORMED.

Do not install the unit in a place where there is a chance of flammable gas leaks.

If there is a gas leak and gas accumulates in the area surrounding the unit, it could cause an explosion.

Perform the drainage/piping work according to the installation instruction.

If there is a defect in the drainage/piping work, water could leak from the unit and household goods could get wet

and be damaged.

Do not clean the unit when the power is ‘on.’

Always shut ‘off’ the power when cleaning or servicing the unit. If not, it could cause an injury due to the high-speed

running fan or an electrical shock.

Do not continue to run the unit when there is a suspected fault.

The power supply needs to be shut ‘off’ to stop the unit; otherwise, this may cause an electrical shock or fire.

Be cautious when unpacking and installing the product.

Sharp edges could cause injury. Especially watch the edges and the fins on the heat exchanger of the product.

Always check for gas (refrigerant) leakage after installation or repair of product.

Low refrigerant levels may cause failure of the product.

Keep level even when installing the product.

This is to avoid vibration or water leakage.

Do not place hands or fingers or others into the fan, or evaporator.

The ventilator runs at high speed, this could cause significant injury.

7

OPERATING THE UNIT

Operating the unit comes down to operating the digital controller.

NEVER LET THE DIGITAL CONTROLLER GET WET. THIS MAY CAUSE AN ELECTRIC SHOCK OR FIRE.

NEVER PRESS THE BUTTONS OF THE DIGITAL CONTROLLER WITH A HARD, POINTED OBJECT.

THIS MAY DAMAGE THE DIGITAL CONTROLLER.

NEVER INSPECT OR SERVICE THE DIGITAL CONTROLLER YOURSELF, ASK A QUALIFIED SERVICE

PERSON TO DO THIS.

Features and functions

Basic controller functions

The basic controller functions are:

Turning the heat pump ‘ON’/’OFF’.

24 hours real time clock.

Timer ‘ON’ and timer ‘OFF’.

Parameter adjustment

User interface

Buttons

Unit ON/OFF button

Under unit unlock status, press this button for 1 second to switch unit ON/OFF.

Under other setting status, press this button to return to main interface.

Under locked screen status, press this button for 5 seconds to unlock screen.

Timer

Unit

‘

O

N/O

FF

’

button

Mode button

UP button

DOWN button

8

Mode button

Under main interface, press this button to check unit status

and adjust button

Turn pages up and down to check, modify parameters.

Combining with to query and change parameters.

Under unit ON status, press and to set temperature in current mode.

Timer button

Press this button for 10 seconds to set clock.

Press this button to enter Timer ON/OFF setting mode, combing with and buttons to

set 2 groups of Timer ON/OFF.

Controller operations

Parameter query and settings

User parameter query and settings (available when unit ON or OFF).

On main interface screen, press for 3 seconds to enter user parameter query interface, press

and buttons to check each parameter.

On user parameter query interface, press to enter parameter setting interface, press and

buttons to modify parameter value, press again to go back to parameter query status.

Under user parameter query or setting interface, if buttons are not pressed within 30 seconds, user

parameter query or setting interface will automatically exit and return to main operation interface.

can be pressed to go back to main operation interface.

Clock settings

Under main operation interface screen, press for 5 seconds to enter clock setting interface.

On clock setting interface screen, press on time, the “hour” digit is flashing, then press

and buttons to modify value for “hour.”

After setting “hour” digit, press again, the “minute” digit is flashing, then press and

buttons to modify value for “minute.”

After setting “minute” digit, press again to confirm clock settings and go back to main operation

interface.

Under clock setting interface, if buttons are not pressed within 30 seconds, display will automatically

confirm current clock settings and go back to main operation interface.

Under clock setting interface, press to confirm clock settings and go back to main operation

interface.

9

Timer settings

On main operation interface screen, press to enter Timer setting interface.

Then press and to set Timers, there are 4 groups of Timers.

When Time 1 is flashing, press to enter Timer 1 ON “hour” digit setting which will flash, then

press and buttons to set value for “hour” digit.

After setting Timer 1 ON “hour” digit, press again to enter into Timer 1 ON “minute” digit which

will flash, then press and buttons to set value for Time 1 ON “minute” digit.

After setting Timer 1 ON “minute” digit, press again to enter into Timer 1 OFF “hour” digit,

The setting way is same as above.

When finish setting Timer OFF time, press again to confirm current Timer settings, and enter

Timer 2 ON/OFF settings, the operation is same as Timer 1 settings, then back to main operation

interface.

On Timer setting interface screen, press for 5 seconds to cancel current Timer ON/OFF settings.

On Timer setting interface screen, if there is no press on any button for continuous 30 seconds, system

will automatically confirm current Timer settings and return to main operation interface (Timer

memory is available if power off.).

On Timer setting interface screen, press to confirm current Timer settings and back to main

operation interface.

Settings way for other groups of Timers is same as Timer 1.

Timer 1,2 are for unit ON/OFF, Timer 3 is for return water, Timer 4 is for water refilling.

Lock and unlock buttons

Under locked button status, press for 3 seconds, after a buzzer, button will be unlocked.

Automatically lock buttons if there is no press on any button within 60 seconds.

Cooling mode

Press for 5 seconds, can switch different modes: cooling, heating/hot water.

Forced defrosting

Under unit ON status, press for 3 seconds to enter forced defrosting.

Press for longer time till unit turns off, 3 minutes later the forced defrosting will exit.

Or if defrosting time reaches Parameter “H5”, the forced defrosting will exit as well.

Remove error history record

On error history query interface screen, press and for 5 seconds to remove error history

records.

Reset

Under unit OFF status, press and for 5 seconds, parameters will resume initial factory

default value.

10

PARAMETER CHECKING AND ADUSTMENT

Unit status query table

Parameter list

Some parameters can be checked and adjusted by the controller. Below is the parameter list.

User parameters (can be adjusted by users.)

Code

Pa

rameter Name

Range

Default

L2 Outlet water temperature variation

for compressor start

3

℃~

18

℃

5℃

L3 Outlet water temperature set

when heating 32℃

~

40℃

Parameter F1

40℃

L4 Outlet water temperature set

when cooling

8-32℃ 12℃

L5 Ambient temperature for

electric heater

start

0

℃~

35

℃

5℃

L6 Return water temperature 30℃

~

40℃ 40℃

L7

Allowable water

-

refill

temperature

20℃

~

40℃ 20

℃

L8 Compressor current 0

~

40A 0

(

”0” means no detection

)

Code

Parameter Name

A1

Coil

temperature

A2

Return gas

temperature

A3

Exhaust gas

temperature

A4

Ambient

temperature

A5

Outlet water

temperature

A6

Ret

urn water

temperature

A7

Reser

v

e

d

A8

Compre

ssor current

A9

O

pening of the EEV

A10

Reserved

E1

~

E6

Error code display

11

Error code table

When an error occurs or the protection mode is set automatically, the wired controller will display the error message.

Code

Protection/Failure Type

Code

Protection/Malfunction

Er01

Phase dislocation

Er23

Low outlet water

temperature

protection

under cooling mode

Er02

Phase loss

Er25

Water level switch failure

Er03 Water flow switch failure Er27 Outlet water temperature sensor failure

Er04 Anti-freeze protection in winter Er29 Compressor suction gas temperature

sensor

failure

Er05 High pressure protection Er31 Water pressure switch failure

Er06

Low pressure

protection

Er35

Compressor

hig

h curre

n

t pr

otection

Er09

Communicat

ion

failure

Er44

Low ambient temperature protection

Er12 High compressor exhaust gas

temp protection

Er45 High outlet water temperature protection

under h

eat mode

Er15

Tank

water

temp sensor failure

Er16

Coil

temp

erature

sensor failur

e

Er18 Exhaust gas temp

se

nsor failure

Er21

Ambient temp

sensor failure

Er22 Return water temperature sensor

failure

12

WIRING DIRGRAM

TRAN-PR1

N

N1

R

S

T

TRAN-SEC

13

INSTALLATION OF THE UNIT

Installation guidelines

Precautions for selecting the location

1. Choose a place solid enough to bear the weight and vibration of the unit, where the operation noise will not be

amplified.

2. Choose a location where the hot air discharged from the unit, or the operation noise will not cause a nuisance to

the neighbours of the user.

3. Avoid places near a bedroom and the like, so that the operation noise will cause no trouble.

4. There must be sufficient space for carrying the unit into and out of the site.

5. There must be sufficient space for air passage and no obstructions around the air inlet and the air outlet.

6. Locate the unit so that the noise and the discharged hot air will not annoy others.

7. The site must be free from the possibility of flammable gas leakage in a nearby place.

8. Install units, power cords and inter-unit cables at least 3m away from television and radio sets. This is to prevent

interference to images and sounds.

9. Depending on radio wave conditions, electromagnetic interference can still occur even if installed more that 3m

away.

10. In coastal areas or other places with salty atmosphere of sulphate gas, corrosion may shorten the life of the

outdoor unit.

11. Since drain flows out of the outdoor unit, do not place anything under the unit which must be kept away from

moisture.

Selecting a location in cold climates

WHEN OPERATING THE OUTDOOR UNIT IN A LOW OUTDOOR AMBIENT TEMPERATURE, BE SURE TO FOLLOW

THE INSTRUCTIONS DESCRIBED BELOW.

To prevent exposure to wind, install the outdoor unit with its suction side facing the wall.

Never install the outdoor unit at a site where the suction side may be exposed directly to wind.

To prevent exposure to wind, install a baffle plate on the air discharge side of the outdoor unit.

In heavy snowfall areas it is very important to select an installation site where the snow will not affect the

unit. If lateral snowfall is possible, make sure that the heat exchanger coil is not affected by the snow (if

necessary, construct a lateral canopy).

14

Installation space

Mounting the unit

When installing the outdoor unit, please refer to “MCS Installation guidelines” to select an appropriate location.

1. Check the strength and level of the installation ground so that the unit will not cause any operating vibration or

noise after installation.

2. Prepare 4 sets of M8 foundation bolts, nuts, and washers each.

3. Fix the unit securely by means of the foundation bolts in accordance with the foundation drawing. It is best to

screw in the foundation bolts until their length remains 20mm above the foundation surface.

15

Water pipework

Checking the water circuit

The water circuits must be installed by a licensed technician and must comply with all current regulations.

THE UNIT IS ONLY TO BE USED IN A CLOSED WATER SYSTEM. APPLICATION IN AN OPEN WATER CIRCUIT CAN

LEAD TO EXCESSIVE CORROSION OF THE WATER PIPING.

Before continuing the installation of the unit, check the following points:

The maximum water pressure is 6 bar.

Two isolation valves (not supplied) must be fitted to facilitate service and maintenance, please install one at

each water inlet/outlet. Orientation of the integrated drain and fill valves is important for servicing.

Drain taps must be provided at all low points of the system to permit complete drainage of the circuit during

maintenance.

Air vents must be provided at all high points of the system. The vents should be located at points which are

easily accessible for servicing. Do the air purge during the installation. Pls refer to the illustration on page 3

Take care that the components installed in the field piping can withstand the water pressure.

Connecting the water circuit

Water connections must be made in accordance with the diagram delivered with the unit, respecting the water inlet

and outlet connections.

BE CAREFUL NOT TO DEFORM THE UNIT PIPING BY USING EXCESSIVE FORCE WHEN CONNECTING THE PIPING.

DEFORMATION OF THE PIPING CAN CAUSE THE UNIT TO MALFUNCTION.

If air, moisture, or dust gets in the water circuit, problems may occur.

Therefore, always consider the following when connecting the water circuit:

Use clean pipes only.

Hold the pipe end downwards when removing burrs.

Cover the pipe end when inserting it through a wall so that no dust and dirt can enter.

Use a good thread sealant for the sealing of the connections.

The sealing must be able to withstand the pressures and temperatures of the system.

When using non-brass metallic piping, make sure to insulate both materials from each other to prevent

galvanic corrosion.

Because brass is a soft material, use appropriate tooling for connecting the water circuit. Inappropriate

tooling will cause damage to the pipes.

THE UNIT IS ONLY TO BE USED IN A CLOSED WATER SYSTEM. APPLICATION IN AN OPEN WATER CIRCUIT CAN

LEAD TO EXCESSIVE CORROSION OF THE WATER PIPING.

NEVER USE ZN-COATED PARTS IN THE WATER CIRCUIT. EXCESSIVE CORROSION OF THESE PARTS MAY OCCUR AS

COPPER PIPING IS USED IN THE INTERNAL WATER CIRCUIT OF THE UNIT.

WHEN USING A 3-WAY VALVE OR A 2-WAY VALVE IN THE WATER CIRCUIT.

THE RECOMMENDED MAXIMUM CHANGEOVER TIME OF THE VALVE SHOULD BE LESS THAN 60

SECONDS.

16

Charging water

1. Connect the water supply to a drain and fill valve.

NOTE

Water quality must be according to EN directive 98/83 EC.

Piping insulation

The complete water circuit, inclusive all piping, must be insulated to prevent and reduction of the heating capacity.

Field wiring

WARNING

A main switch or other means for disconnection, having a contact separation in all poles, must be

incorporated in the fixed wiring in accordance with relevant local and national legislation.

Switch ‘off’ the power supply before making any connections.

All field wiring and components must be installed by a licensed electrician and must comply with relevant

European and national regulations.

The field wiring must be carried out in accordance with the wiring diagram supplied with the unit and the

instructions given below.

Be sure to use a dedicated power supply. Never use a power supply shared by another appliance.

Be sure to establish an earth. Do not earth the unit to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

Be sure to install an earth leakage protector.

Failure to do so may cause electrical shock.

17

Pre-operation checks

Checks before initial start-up

SWITCH OFF THE POWER SUPPLY BEFORE MAKING ANY CONNECTIONS.

After the installation of the unit, check the following before switching on the circuit breaker:

1. Field wiring

Make sure that the field wiring between the local supply panel and domestic hot water tank has been carried

out according to the instructions, according to the wiring diagrams and according to European and national

regulations.

2. Fuses or protection devices

Check that the fuses or the locally installed protection devices are of the size and type specified. Make sure that

neither a fuse nor a protection device has been by-passed.

3. Earth wiring

Make sure that the earth wires have been connected properly and that the earth terminals are tightened.

4. Internal wiring

Visually check the switch box on loose connections or damaged electrical components.

5. Fixation

Check that the unit is properly fixed, to avoid abnormal noises and vibrations when starting up the unit.

6. Damaged equipment

Check the inside of the unit on damaged components or squeezed pipes.

7. Refrigerant leakage

Check the inside of the unit on refrigerant leakage. If there is a refrigerant leak, call your local dealer.

8. Power supply voltage

Check the power supply voltage on the local supply panel. The voltage must correspond to the voltage on the

identification label of the unit.

9. Water flow switch should be installed for the place where there is no constant sufficient water flow (Field supply)

10. Stop valves

Make sure that the stop valves are correctly installed and fully open.

OPERATING THE SYSTEM WITH CLOSED VALVES WILL DAMAGE THE PUMP!

MAINTENANCE

To ensure optimal availability of the unit, a number of checks and inspections on the unit and the field wiring must

be carried out at regular intervals.

BEFORE CARRYING OUT ANY MAINTENANCE OR REPAIR ACTIVITY, ALWAYS SWITCH ‘OFF’ THE CIRCUIT

BREAKER ON THE SUPPLY PANEL, REMOVE THE FUSES OR OPEN THE PROTECTION DEVICES OF THE UNIT.

MAKE SURE THAT BEFORE STARTING ANY MAINTENANCE OR REPAIR ACTIVITIES THE POWER SUPPLY TO

THE OUTDOOR UNIT IS SWITCHED ‘OFF’.

18

INSTALLATION PLAN EXAMPLE FOR COMPLETE SYSTEM

WIRING EXAMPLE

4 5 6 7

HTGHW

Room

Stat

Cylinder

Stat

321

230V

50Hz

L N E

230V

50Hz

L N E

L N

Programmer

19

TROUBLESHOOTING

This section provides useful information for diagnosing and correcting certain issues which may occur.

General guidelines

Before starting the troubleshooting procedure, conduct a thorough visual inspection of the unit and look for obvious

defects such as loose connections or defective wiring.

Before contacting your local dealer, read this chapter carefully, it will save you time and money.

WHEN CONDUCTING AN INSPECTION ON THE SWITCH BOX OF THE UNIT, ALWAYS MAKE SURE THAT THE MAIN

SWITCH OF THE UNIT IS SWITCHED ‘OFF.’

When a safety device was activated, stop the unit, and find out why the safety device was activated before resetting

it. Under no circumstances safety devices may be bridged or changed to a value other than the factory setting. If the

cause of the problem cannot be found, call your local dealer/installer.

20

Error codes and Troubleshooting

When an error occurs or the protection mode is set automatically, the wired controller will display the error message.

Protection/

Malfunction

Error code

Reasons

Co

r

rection Mode

Phase Dislocation Er01 Wrong connection of live

wire

Reverse position of two of the

live wires (3-Phase only).

Phase Loss Er02 Live wire loose, or without

power.

1)

Check if wires are loose.

2)

Check if any phase is without

power (use a multimeter to check

voltage).

Water flow switch

failure

Er03

1)

Inadequate water flow

2)

Water flow switch dam-

aged

3)

Main PCB damaged

1)

Check the pump

2)

Replace the water flow

switch

3)

Replace the PCB

Anti-freeze

protection in

winter

Er04 This function occurs when

ambient temperature is too low.

No action needed

High pressure

protection

Er05

1)

Inadequate flow rate

2)

Uncompressed gas in

refrigerant system

3)

Overcharge with

refrigerant

4)

Water temperature

setting too high

5)

Outdoor fan ventilation is

bad

6)

Poor connection of pressure

switch

7)

Pressure switch failure

8)

Main PCB damaged

1)

Check pump and water

control valve

2)

Discharge and then re-

charge the refrigerant

3)

Discharge some

refrigerant

4)

Set lower water temp

5)

Check fan ventilation

6)

Reconnect the switch

7)

Replace the pressure

switch

8)

Replace the PCB

Low pressure

protection

Er06

1)

Undercharged refrigerant

2)

Capillary or EEV blocked

3)

Poor connection of pressure

switch

4)

Pressure switch failure

5)

Main PCB damaged

1)

Add some refrigerant

2)

Replace the capillary or EEV

3)

Reconnect the switch

4)

Replace the pressure

switch

5)

Replace the PCB

Communication failure Er09 Communication failure be-

tween the LCD and PCB

1)

Check the wire connection

between the LCD and PCB.

2)

Replace LCD.

High compressor

exhaust gas

temperature

protection

Er12

1)

Refrigerant Under-

charged

2)

Reasons as Er05

1)

Add some refrigerant

2)

Similar corrections as Er05

Tank water

temperature sensor

failure

Er15

1)

Sensor open circuit

2)

Sensor short circuit

3)

Main PCB damaged

1)

Check the sensor

connection

2)

Replace the sensor

3)

Replace the main PCB

Coil temperature

sensor failure

Er16

1)

Sensor open circuit

2)

Sensor short circuit

3)

Main PCB damaged

1)

Check the sensor

connection

2)

Replace the sensor

3)

Replace the main PCB

This manual suits for next models

1

Table of contents

Other Trianco Heat Pump manuals

Popular Heat Pump manuals by other brands

Daikin

Daikin 4MXS100EV2C Service manual

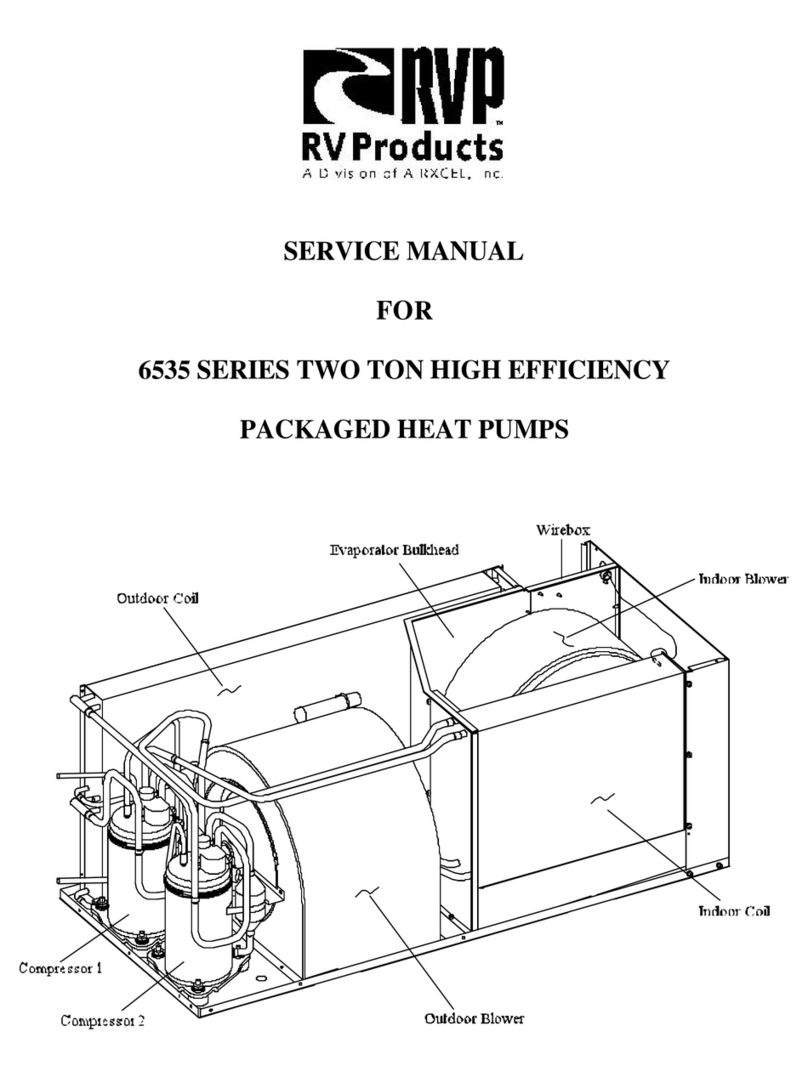

RV Products

RV Products 6535 SERIES Service manual

Viessmann

Viessmann VITOCAL 300-G manual

SOLARFOCUS

SOLARFOCUS Vampair Operation manual

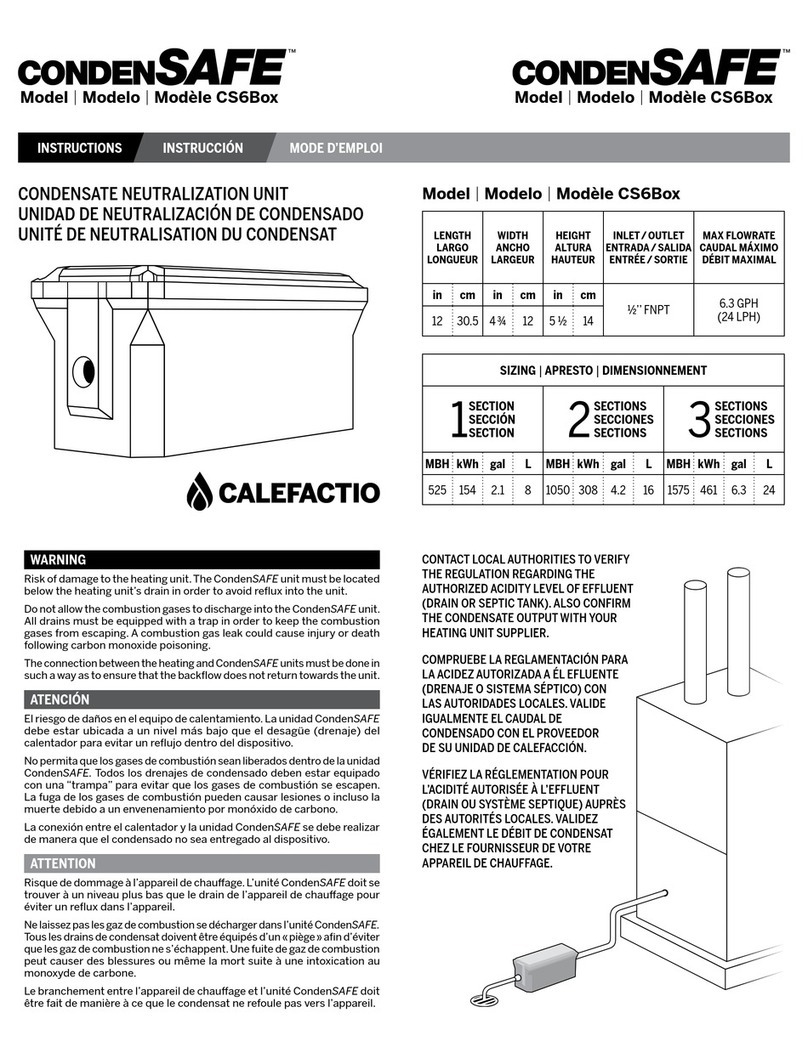

CALEFACTIO

CALEFACTIO CONDENSAFE CS6Box instructions

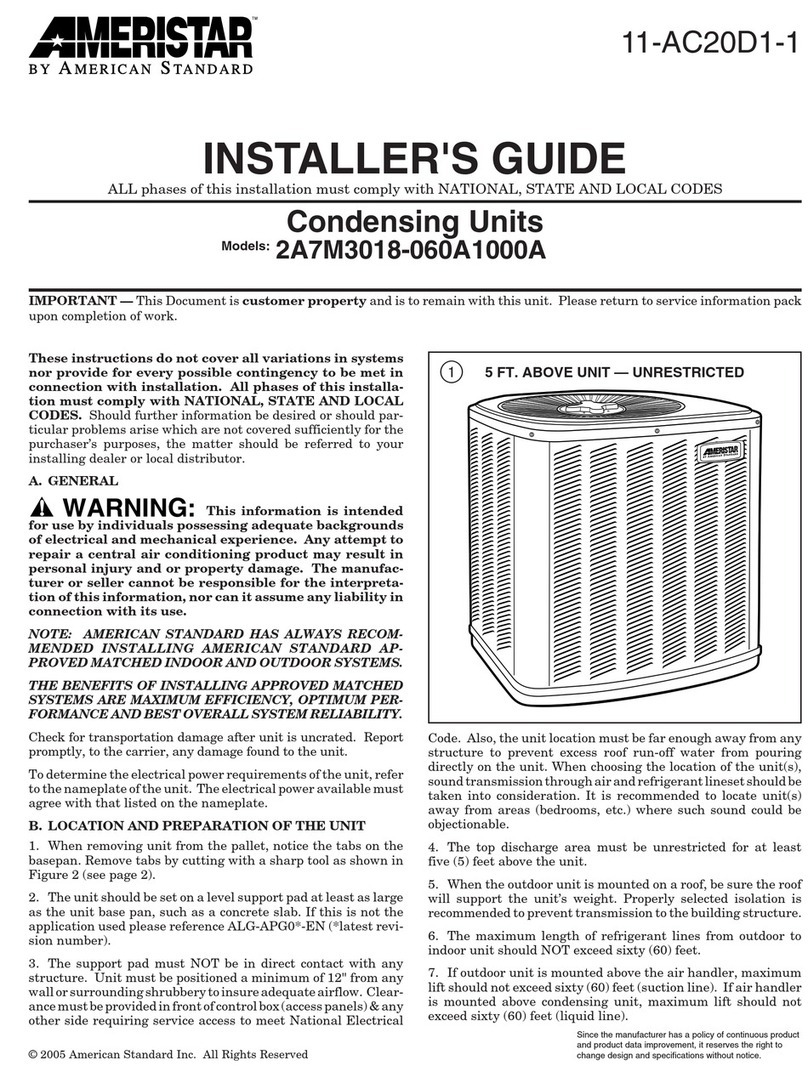

American Standard

American Standard Ameristar 2A7M3018-060A1000A Installer's guide

Emerson

Emerson COPELAND ZX Series user manual

Mitsubishi Electric

Mitsubishi Electric PUZ-WM50VHA Service manual

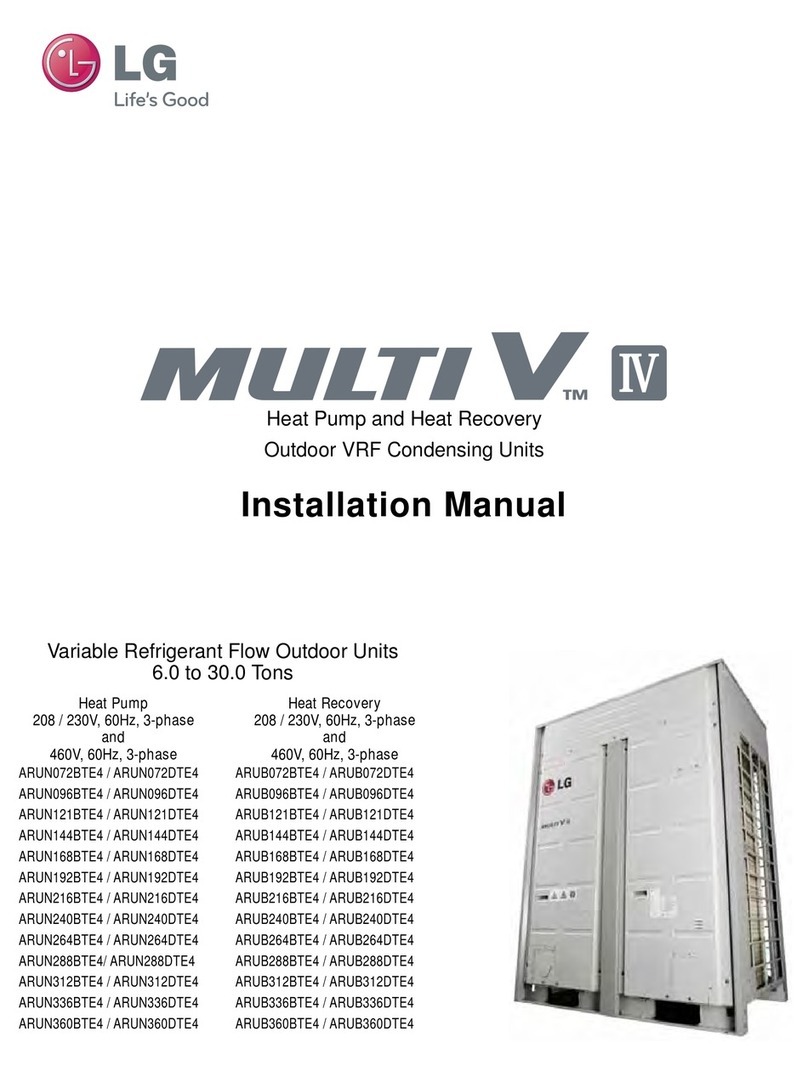

LG

LG MULTI V ARUN072BTE4 installation manual

Bryant

Bryant 548J*D Series installation instructions

Carrier

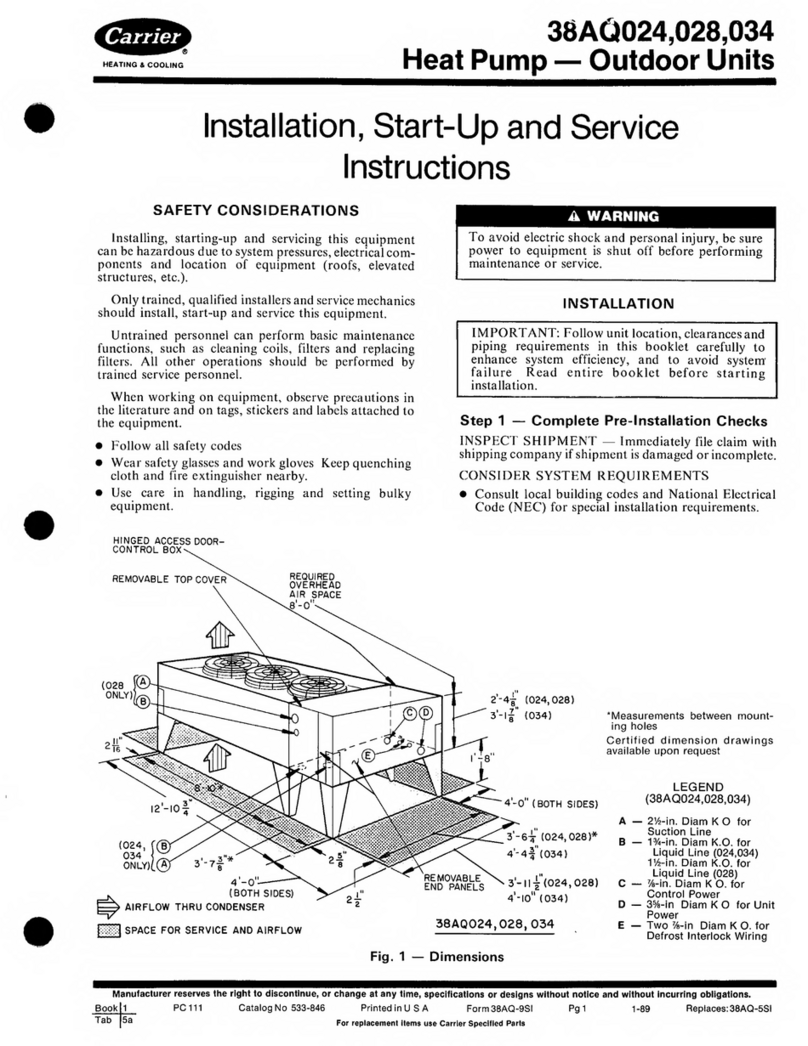

Carrier 3BAU024 Installation, Start-Up and Service Instructions

Robur

Robur K18 Simplygas Installation, use and maintenance manual