Tricel Duos P6 User manual

1

2

Table of contents

1.Health and safety precautions: 3

1.1 General: 3

1.2 Electrical/maintenance 3

1.3Installation: 3

2. Transporting, unloading and storage of tanks: 4

3. Introduction: 6

4. The wastewater purification process: 7

4.1 Stage 1: Existing primary settlement chamber: 7

4.2 Stage 2:Aeration (treatment) chamber: 7

4.3 Stage 3:Final settlement chamber: 7

5. Plant dimensions: 8

6. Plant drawings: 10

7.Technical drawings of Tricel pumped plant: 14

8.Lid locking points: 14

9.Manhole risers (deep inverts): 15

10. Installation: 16

10.1 Pre-installation tank inspection: 16

10.2 Quick installation guidelines: 17

10.3 Detailed installation information: 18

10.3.1 Excavation size: 19

10.3.2 Eexcavation dept: 20

10.3.3 Loadings: 21

10.3.4 Control of groundwater 21

10.4 Gravel installation: 21

10.4.1 Tank base/plinth: 22

10.4.2 Installing onto the base/plinth: 22

10.4.3 Backfilling dry site 22

10.5 Concrete installations: 23

10.5.1 Tank base/plinth: 23

10.5.2 Installing onto the base/plinth: 23

10.5.3 Backfilling a wet site: 24

10.6 Plinth and backfill specifications: 25

10.6.1 Gravel backfill specifications 25

10.6.2 Concrete backfill specifications: 26

10.6.3 Top soil 26

11. Electrical installation: 27

12. Plumbing the system: 27

13. Ancillary installation notes: 28

13.1 Ventilation: 28

13.2 Control housings: 28

13.3 Access: 28

14. Plant operation: 29

15. Disposal of treated water: 29

16. Maintenance: 30

16.1 Regular maintenance: 30

16.2

16.2.1 Yearly service (available from your supplier): 30

16.3 Production of sludge: 31

17. Operation conditions: 32

18. Troubleshooting: 33

19. Certification: 37

TTM T103 Rev04 –08 April 2014

3

It is

i

mpo

r

t

an

t

to read

t

he

full technical

and installation

guideprior to installation.

T

h

i

s

do

c

umen

t

should

be

r

e

t

a

i

ned

for

t

he

lifetime of

t

he

p

r

odu

c

t

and in

t

he

e

v

en

t

of

change

o

f

ownership

be

t

r

an

s

f

e

rr

ed

to

t

he

new

o

w

ne

r

.

Precaution

Prior to installation, please consider finished garden level when installing the plant. If you envisage that a

manhole riser/extension may be required to ensure manhole lid remains above finished ground level, the plant

must be installed with the appropriate excavation foundation and backfill to accommodate the riser. Please refer

to page 18 for manhole riser details.

1.

Health

and safety

p

re

c

au

ti

on

s

:

As safety and security are of vital importance, the following aspects are

critical.

1.1 General

:

•

Ensure the Duos plant is only installed after a functioning correctly sized septic tank

Ensure that all the information contained in this manual is adhered to at all times

•

Treated wastewater is not suitable for human consumption.

•

It’s important that locks are fitted to the lid to prevent accidental access.

•

Manholes are rated to 125kg and are for pedestrian use only

•

Never enter a tank, unless qualified to do so.

•

Naked flames shall not be used in the vicinity of the tank due to the danger of combustion.

•

The manhole covers shall never be left off an unattended tank. Always lock the cover of the

system when work is completed

•

Sewage and sewage effluent can carry micro-organisms and gases harmful to human health. Any

person carrying out work on the system must be appropriately trained. Suitable protective

clothing; including gloves, goggles should be worn at all times. Always remove contaminated

clothing and protective equipment after working with sewage treatment plants. Wash hands and face

prior to eating, drinking or smoking.

1.2 Electrical/

M

a

i

n

t

enan

c

e:

•

All electrical work to be carried out by competent persons using suitable materials for the application.

•

Do not open the Tricel® Duos cover without firstly isolating the mains power.

•

Electrical work must be carried out strictly to the manufacturer’s instructions and to the

relevant national rules for electrical installations.

•

When working with machinery / electrical equipment, proximity of water shall be noted.

Electrical equipment shall not be wet when working with it.

•

There is potential danger when de-sludging and therefore this shall never be done alone

4

1.3 Installation

:

•

Excavation work should be planned with due regard to health and safety requirements.

•

Excavation should either be shored or battered back to a “safe” angle.

•

Use appropriate lifting equipment

•

Care should be taken around grounds work machinery

•

Keep proper footing and balance at all time

2. Transportation, unloading and storage of tanks

:

1. Tanks must be held down during transportation using nylon straps, do not use cables or chains to

secure tanks. Do not over tighten straps to cause deformation of the tank shell. Do not drop or roll tanks from

the truck.

2. Move tanks only by lifting and setting, do not drag or roll.

3. Always set the tank(s) on flat smooth ground free from debris etc. To prevent movement, tanks may need to

be tied down and chocked.

4. Tanks are best lifted by a machine and webbing lifting straps –do not use chains or wire ropes in contact

with the tank. Ensure tank is empty when lifting. Care is needed to control the lift to ensure the tank is not

damaged.

5. Tanks from one to four modules (4.6m) in length should be lifted using the eyebolts on the tank.

To ensure the angle of the sling is not greater than 60o, as per option 1, the following sling lengths are

required:

Length of tank

Minimum length of sling

2.1

2.1

2.6

2.6

3.1

3.1

3.6

3.6

4.6

4.6

5

Ensure sufficient lifting height can be achieved and is available on site. If not a lifting bar as per option

2 is required.

Option 1* Option 2*

6. Tanks which are greater than 4 modules (4.6m) in length should be lifted using the slings provided

as per option 3, shown below.

Option

3*

Ensure sufficient lifting height can be achieved and is available on site available. If not a lifting bar as per

option

4 is required.

Option 4*

Ensure the slings are positioned at a joint on the tank, firmly secured and the load is evenly

balanced.

*Typical lifting examples

6

3.

Introduction

:

Tricel

Duos wastewater treatment plants are manufactured from Sheet Moulding Compound (SMC) ensuring a

durable and strong product. The Tricel Duos is manufactured in modular components and these modules are

fabricated together to make different size tanks.

The Tricel Duos Submerged aeration system is suitable for domestic and light commercial applications. These

plants use a simple, proven technology, comprising of 2 treatment zones. In each zone a different stage of

the treatment occurs. All Duos plants must be preceded by a functioning suitably sized septic tank.

7

4. The wastewater

purification

p

ro

c

e

ss

:

4.1 Stage 1: Existing

Primary

settlement

c

hambe

r

:

The wastewater is introduced into the primary chamber which must proceed the Duos system (not

included). Settlement occurs when the heavier solids, drop out of the wastewater and settle to the bottom

of the tank to create sludge and when lighter solids, like fats or oils, float to the top of the water to create

a scum. Good practice is to install a filter at the outlet of the existing septic tank to reduce suspended solids

from the effluent.

.

4.2 Stage 2:

A

e

r

a

t

i

on

(

t

r

ea

t

men

t

)

c

hambe

r

:

Stage 2 takes place in the aeration chamber where submerged aeration combines the principles of the bio

film and activated sludge processes. Masses of naturally occurring bacteria inhabit specially designed

plastic filter media. The filter media, has large surface area, and is supported within the aeration zone. As

the liquid flows slowly through the filter media the bacteria feed on the waste removing them from the

liquid. These bacteria are sustained with air, which is continuously supplied from a purpose built low

pressure, high volume air blower in the top section of the unit. The air is delivered through a diffused

aeration system, which break the air into bubbles as they are dispersed through the aeration zone. The

continuous circulation of the wastewater within the aeration zone means that the wastewater is passed

through the filter media over and over, thus ensuring very high treatment efficiency. The purified liquid is

then passed into the final settlement zone.

4.3 Stage 3:

Finalsettlement

c

hambe

r

:

As the liquid flows from the aeration zone into the final settlement zone small quantities of bacteria may be carried

with the liquid. Before discharge from the system, these solids must be separated from the liquid. With the velocity

of the liquid slowed down and the flow path maximized the bacteria settles to the bottom of the tank as sludge.

8

5.

Plant

D

i

men

s

i

on

s

:

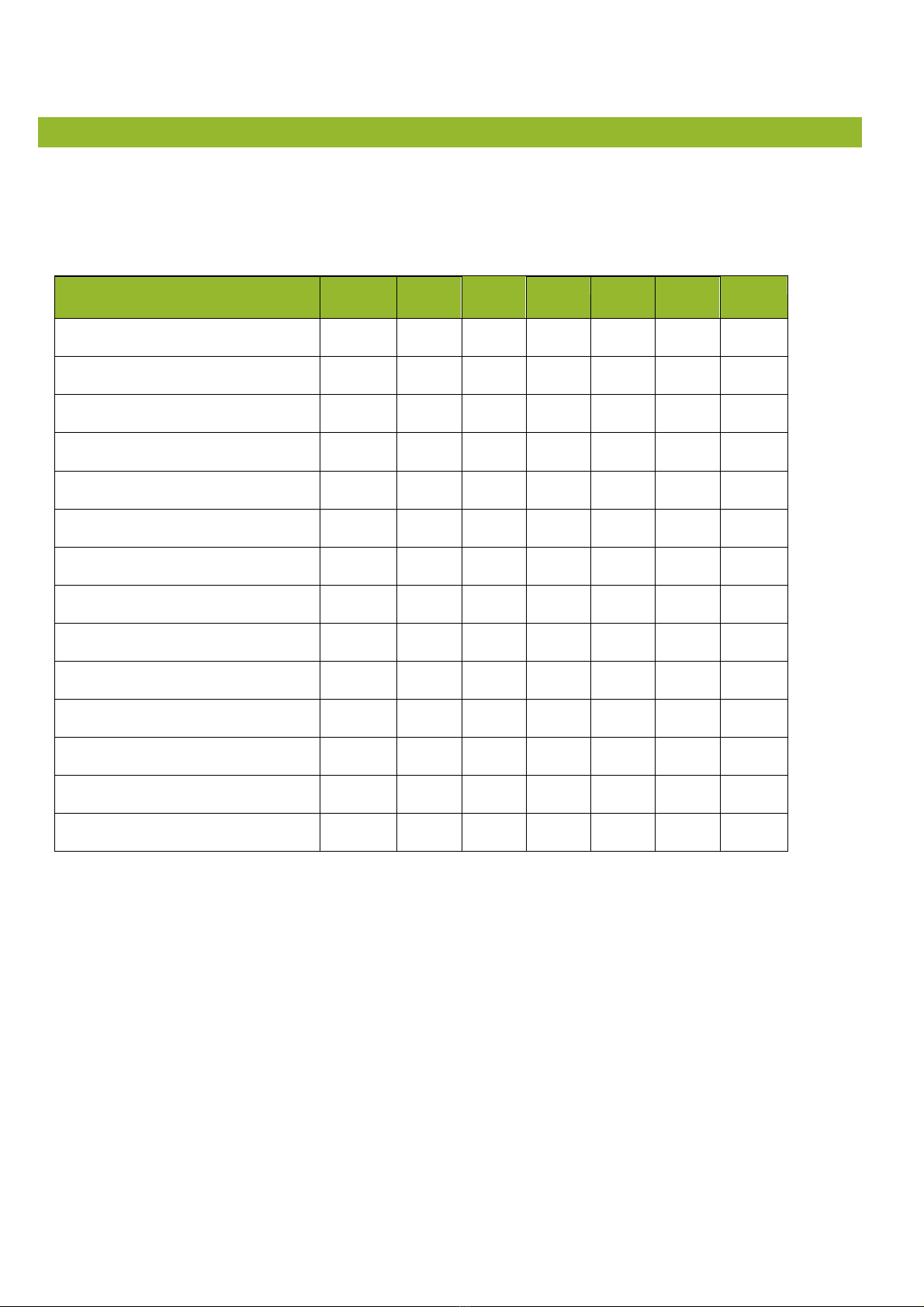

Tricel Duos wastewater treatmentplants.

Design population

6 person

8 person

10 person

12 person

18 person

24 person

Nominal inlet/outlet pipe diameter

mm

110

110

110

110

110

150

Overall length

m

1.6

1.6

2.1

2.6

3.1

3.6

Overall width

m

1.64

1.64

1.64

1.64

1.64

1.64

Overall height

m

2.24

2.24

2.24

2.27

2.27

2.27

Inlet invert to base

m

1.375

1.375

1.375

1.375

1.375

1.35

Outlet invert to base

m

1.3

1.3

1.3

1.3

1.3

1.3

Inlet invert to ground level

m

0.535

0.535

0.535

0.535

0.535

0.56

Outlet invert to finished ground level

m

0.61

0.61

0.61

0.61

0.61

0.61

Height above finished ground level

m

0.32

0.32

0.32

0.32

0.35

0.35

Weight empty**

kg

200

250

250

300

350

400

BOD Load (max)

kg/day

0.36

0.48

0.6

0.72

1.08

1.44

Design flow rate (max)

liters/day

900

1200

1500

1800

2700

3600

No of persons

2-6

3-8

4-10

4-12

6-18

8-24

Air blower rating (mean)

watts

60

100

100

100

200

200

**Allow 100kgs extra for lifting purposes

10

D

e

s

i

gn

popu

l

a

t

i

on

30

perso

n

36

perso

n

42

perso

n

50

perso

n

Nominal inlet/outlet pipe

diameter

mm

150

150

150

150

Overall length

m

4.6

5.6

5.6

6.6

Overall width

m

1.64

1.64

1.64

1.64

Overall height

m

2.27

2.27

2.27

2.27

Inlet invert to base

m

1.35

1.35

1.35

1.35

Outlet invert to base

m

1.3

1.3

1.3

1.3

Inlet invert to ground level

m

0.56

0.46

0.46

0.46

Outlet Invert to ground level

m

0.61

0.61

0.61

0.61

Height above ground level

m

0.35

0.35

0.35

0.35

Weight empty**

kg

550

650

700

750

Design flow rate (max)

liters/day

4500

5400

6300

7500

BOD load (max)

kg/day

1.8

2.16

2.52

3

No. of persons

10-30

13-36

14-42

16-50

Air blower rating (mean)

watts

200

200+ 80

200 x 2

200x2

**Allow 100kgs extra for lifting purposes

6.

Plant

D

ra

w

i

ng

s

:

T

r

i

c

e

l

Duos 6 person

g

r

a

v

i

t

y

plant

:

11

T

r

i

c

e

l

Duos 8 person

g

r

a

v

i

t

y

plant

:

TricelDuos 10 person

g

r

a

v

i

t

y

plant

:

TricelDuos 12 person

g

r

a

v

i

t

y

plant

:

12

TricelDuos 18 person

g

r

a

v

i

t

y

plant

:

TricelDuos 24 person

g

r

a

v

i

t

y

plant

:

TricelDuos 30 person

g

r

a

v

i

t

y

plant

:

13

TricelDuos 36 person

g

r

a

v

i

t

y

plant

:

Tricel Duos 42 person

g

r

a

v

i

t

y

sys

t

em

TricelDuos 50 person

g

r

a

v

i

t

y

sys

t

em:

14

7. Technical drawing of Tricel Duos pumped plant:

All plants are available with a pumped outlet option. The pump can be housed in the final settlement chamber

of the system. The standard pump option has a 1 ½”connection on the outside of the plant. Our standard

pump specification is outlined below. Other pump options are available to customer specifications.

Standard pump specification:

•

Min discharge rate 60l/min

•

Continuous duty with

35°C

liquids & fully

submerged

•

Dry motor (class F insulation)

•

IP68 protection

•

Max immersion 5m

•

Single phase 220-240 V 50 Hz 2 poles

•

0.55 to 1.1 kW for single phase

•

Rp 1 ½”delivery port (female gas)

•

Handles solids up to 35mm

F

I

N A

L

S E T T L E M E N

T

T A N K

S

8.

Lid locking

po

i

n

ts

:

All manholes should be locked for safety. Tanks are supplied with 3 optional locking points, as shown below.

All these points should be locked with a suitable locking device to prevent unauthorized access. Locking

devices are not supplied.

15

9.

M

anho

l

e

risers

–

(deep

i

n

v

e

rts

)

:

Manhole risers are available for deeper installation requirements

)r 250mm manhole risers require installation suitable for the site condition.

)r 500mm* & 750mm* manhole risers require a complete concrete installation –See section 10.5.

)r Max manhole riser is 750mm

Never place the covers

of the

tank below ground

level.

Do not allow ground

water

enter the

system

Only Tricel Duos manhole

risers

should be

used

Manhole risers are

available

as

standard

250mm

500mm

750mm

*Plants with a manhole riser of 500mm or 750mm must have a concrete installation. 500mm and 750mm

risers cannot be retrofitted unless the correct installation is in place.

16

10.

I

n

s

ta

ll

a

t

i

on:

All installations must be “fit for purpose” to suit the on-site conditions, which will vary from site to site. This is

the responsibility of the onsite contractor.

The Tricel Duos is suitable for a maximum manhole riser of 750mm which gives a maximum inlet invert of

1310mm, as

per picture. The Tricel Duos is not suitable where a deeper installation is required.

10.1

P

r

e

–

i

n

s

t

a

ll

a

t

i

on

tank

i

n

s

pe

c

t

i

on:

•

Tanks should be visually inspected for damage which may have occurred during transport prior to

installation. Any damage should be notified to the delivery driver and/or to your supplier. Do not

attempt to carry out any unauthorised repairs, as this will invalidate the warranty on the tank

•

Once the tank has been installed, we cannot accept any claims for damage

17

10.2Quickinstallation

gu

i

de

li

ne

s

:

A dry site is one where the water table never rises higher than the base of the Tricel Duos

tank. A wet site is one where the water table may rise higher than the base of the Tricel

Duos tank. The tank should never be installed where ground water can rise higher than the

inlet pipe.

Important

Inlet invert to finished ground level must be determined to ensure the correct installation

procedure is followed. See section 9.

Guidelines

Dry Site

Wet Site

The tank should be located as clode to the septic tank as possible

considering topography and pipe work levels. The tank location should

be specified by a suitably qualified person. The plant must be installed

correctly to ensure surface or ground water does not enter the system.

Never roll the tank. Tanks shall be lifted into position in accordance

with supplier’s instructions. See section 2

Dig a hole 500mm larger than the plant dimensions in plan. The depth

of the hole will be determined by the inlet pipe level.

If the plant contains more than one tank a stepped installation is

required

Remove any soft spots or boulders of significant size from the base

or sides of the excavation.

Ground water must be pumped to give a dry excavation and

excavation lined with polythene.

Determine the type of backfill by taking into account, ground

conditions (wet or dry) and finished ground level (determine if, and

height of riser required). The site engineer should specify the site

conditions.

A base is then formed using compacted gravel and this must be flat

and level.

A base is constructed of a 50mm layer of compacted gravel covered

with a 250mm layer of 25n semi dry concrete.

Ensure gravel/concrete is clean and contains no large materials.

Lift tank into position and align height for connecting pipe work.

Ensure correct inlet and outlet orientations of the plant, which may

18

Contain 1 or more tanks.

Ensure that each tank is 100% level.

Connect pipe work, as required.

Ballast the tank with water. Refer to detailed installation

Commence gravel backfilling in 300mm layers approximately up to

50mm over the cylindrical body of the tank, ensuring tank and any

pipe work is properly supported.

Commence concrete backfilling in 300mm layers approximately up to

the pipe work level, ensuring tank and any pipe work is properly

supported.

Continue backfilling with gravel up to 50mm over the cylindrical body

of the tank

Mount and seal any turret extensions.

Complete backfilling with topsoil up to the max ground level line

indicated on the plant. The surrounding finished ground level

should never be higher than the “max ground level line”.

Compact evenly around the tanks to ensure it’s is properly supported.

An access chamber should be installed before and after the tank

for sampling and to assist in clearing possible blockages

If sewage consists of high quantities of grease a grease trap should be

installed prior to the plant.

Note: The option of a reinforced concrete slabs or deadman anchor may also be used on wet sites. This should

be designed by an on-site structural engineer to suit site conditions.

10.3

D

e

t

a

il

ed

installation

i

n

f

o

r

ma

t

i

on:

The Tricel Duos should not be installed in an area subject to

flooding or

excessive water runoff. The area

around the Tricel Duos should be adequately drained, to permanently remove ground water and surface

water from the proximity of the tank. The Tricel Duos system is not suitable to be used in water logged sites,

where the ground water may rise above the inlet level.

19

10.3.1 Excavation size:

Suitably sized equipment will be required to excavate the hole and to lift the system into

place.

Installation depends on on-site conditions, water, slopes, location etc. Excavation should be planned

with due regard to health and safety requirements. The excavation should allow a minimum 250mm

clearance between the tank and the excavation wall or face of shoring. A minimum of 500mm is

also required between adjacent tanks. Unstable ground with excessive sand, peat swamps etc. may

require larger excavations. The excavation should be maintained dry by pumping or whatever suitable

means.

Total excavation: {Width. + 500mm} x {Length +

500mm} Excavation depth:

Dry Site: Allow 250mm for tank

base/plinth. Wet Site: Allow 300mm for

tank base/plinth

Please note max manhole riser is 750mm

Tank Size

Excavation

Size

Tank A (

m

)

6 person

2.1 x 2.15

8 person

2.1 x 2.15

10 person

2.6 x 2.15

12 person

3.1 x 2.15

18 person

3.6 x 2.15

24 person

4.1 x 2.15

30 person

5.1 x 2.15

36 person

6.1 x 2.15

42 person

6.1 x 2.15

50 person

7.1 x 2.15

20

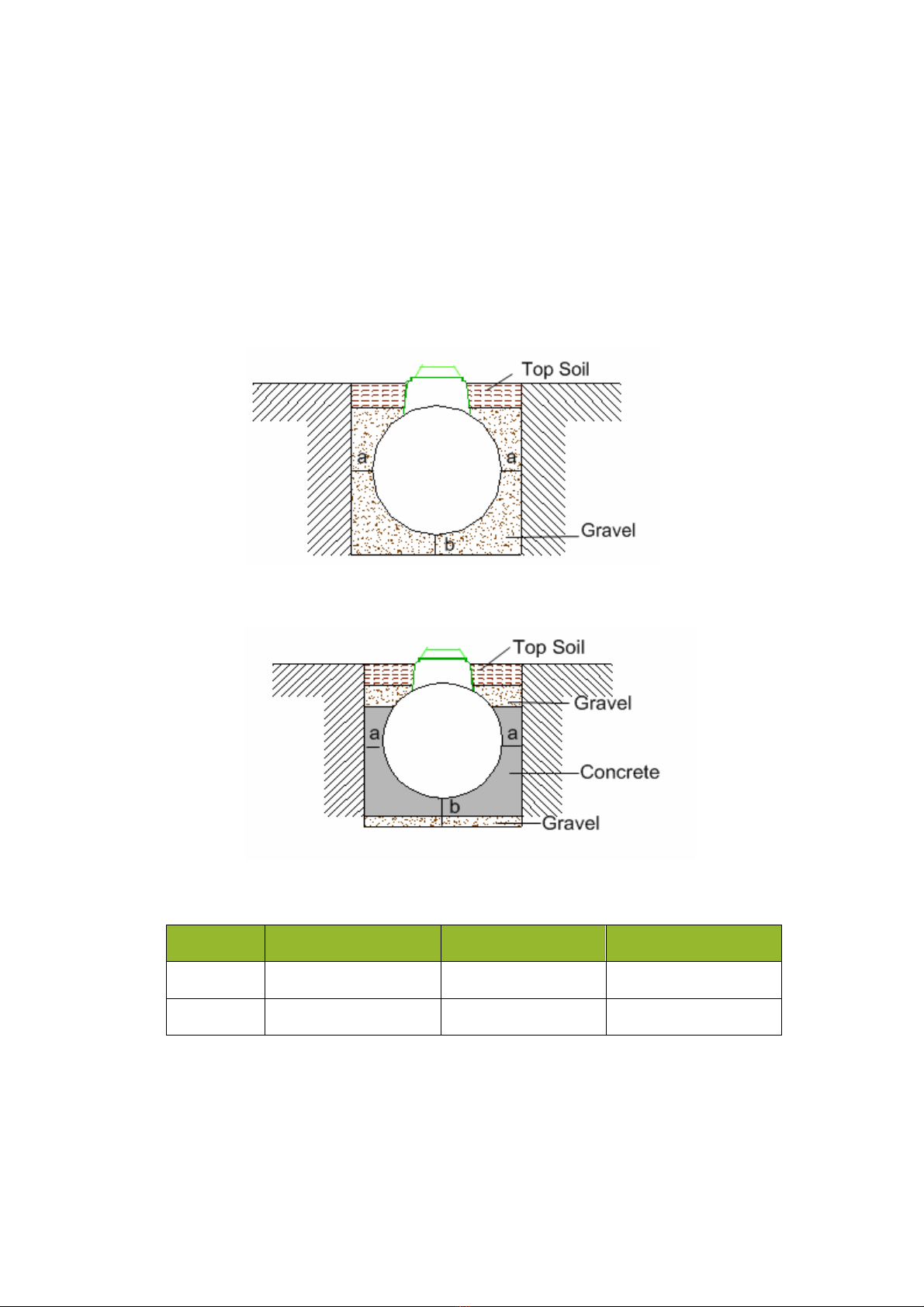

10.3.2 Excavation depth:

The excavation depth is determined by the inlet and outlet pipe, invert levels relative to the bottom of

the tank, and allowing for the minimum base thickness shown. Dimension details of the tank are shown

on the relevant drawing, given in section 6. Ground instability e.g. running sand may necessitate over-

excavation and stabilization with hard core or blinding concrete.

Dry

site

Wet

site

Tank Width. in mm

“a” minimum in mm

“b”minimum in mm

Dry Site

1650

250

250

Wet site

1650

250

300

21

10.3.3 Loadings:

If the tank is installed in an area where traffic or other superimposed loadings can be applied, consult a

structural engineer for the design of a reinforced concrete slab to prevent the load being transmitted to

the tank (or its concrete surround). If this slab is constructed immediately above the tank, it should

be separated from the concrete surrounding the tank by a compressible material. Installation guidelines

are available on www.ie.tricel.eu.

10.3.4 Control of groundwater:

During installation tanks must not be subjected to buoyant

forces.

Incorrectly installed tanks that are subject to movement, rotation or floatation may become damaged,

for which we cannot accept liability.

Contact a qualified engineer if there are difficulties on site due to adverse water

logging.

10.4 Gravel

i

n

s

t

a

ll

a

t

i

on:

A gravel surround can be used in dry site conditions if the inlet invert is less than 810mm (maximum

250mm riser).

A dry site is one where the water table never rises higher than the base of the Tricel Duos tank.

This manual suits for next models

9

Table of contents

Popular Tank Equipment manuals by other brands

JohnDow Industries

JohnDow Industries JDI-AFT106 Operator's manual

Regulus

Regulus PS 500 E Assembly, installation and operation instructions

RKI Instruments

RKI Instruments RI-215A Operator's manual

Micron

Micron Spraydome Series instruction manual

Alfalaval

Alfalaval HTC instruction manual

Kemper

Kemper FK-5 operating instructions