Triton advanced LADOGA 2 ADVANCED User manual

A

SSEMBLING

I

NSTRUCTION

-

T

RITON

L

ADOGA

2

ADVANCED

Touring and sea kayak

Assembly video:

2

Assembling Instruction - Triton Ladoga 2 advanced

Dear Customer,

At first: please do not be alarmed by the extent of these instructions!

The assembling instructions are very detailed and almost every step is illustrated. You will notice that it

will help you at one point or another. After a few times and with a little practice you won’t need the

manual anymore.

You have purchased a Ladoga 2 advanced - a powerful kayak with extremely high stability and

stiffness, which was awarded among others by “Kanu-Magazin” with the "Super Tip".

The Ladoga 2 advanced has been one of the best-selling folding kayaks in Europe in recent years.

The body stiffness results from the high structural performance of the frame; on the other hand the hull

is designed to fit the frame perfectly. This is why the first few setups are power intensive, since frame

and skin have to adapt to another (the hull expands a bit while/after assembling the first couple of

times). The assembling gets then easier each time.

Please take your time for the first assembling to learn about the special features. It is strongly

recommended following the single steps in the instructions carefully! Otherwise, it will be

unnecessarily difficult. After some practice you will build it up without much hassle in about 30

minutes. Always keep in mind that no one is born a master, and the individual assembling has to be

learned for each folding boat. As a "reward" of the assembling you get a fast and stiff touring kayak,

which is characterized by excellent handling and a strong hull!

Please check the assembly videos in ourt YouTube channel: https://www.youtube.com/faltbootde

If you have any questions, your dealer will be happy to assist you. Otherwise you can also contact us

directly - as an importer (call: 0049/731/4007675, mail: kontakt@out-trade.de).

Please also consider the instructions of “Care and Accessories” at the end of this manual. Especially if

you are planning extensive tours in salt water, which requires special care!

Brief overview of assembling:

1. Assembling bow: Attach 2x4x stringer elements without lock, 4x stringer elements with

lock and install cross rib #1 and #2 (#2 with ridge bar)

2. Assembling stern: Attach 4x stringer elements without lock, Attach 4x stringer elements

with lock and install cross rib #6

3. Attach the matching keel forks and the double keel elements (stern= keel ladder with riveted half

tubes), insert them into the hull and tension the keel

(Therefore take the stringer elements out the skin!)

4. Insert seats

5. Close the stringer

6. Insert and close the coaming

7. Install cross ribs #3, #5, #4

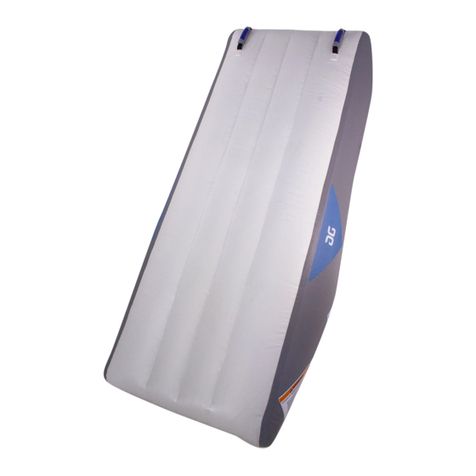

8. Install half cross rib in front of the seat and mount the rudder system

9. Inflate sponsons

This short description should provide a general overview of the basic structure of assembling. For the

first few times please consider the following detailed assembly instructions and read them

carefully before you get going:

1)

Overview parts:

Please first get all parts out the pack and spread them out. It is best to sort the parts

according to the content list.

3

1) 8x Stringer element with lock:

2) 13x Stringer element without lock

3) 4x Sleeves, small

4) Keel ladder with riveted half tube

5) Keel rod (with 2x clips)

6) Keel fork (one with open end, one

with hemispherical end)

7) 2x Bent coaming rod (wider diameter)

8) 4x Coaming rod (2x of them with D-

rings; wider diameter)

9) 2x Sleeve, big

10) 2x Ridge bar (identical)

10a) Deck rod (supports the deck

between the cockpits)

11) Bow segment

12) Stern segment

13) Half cross ribs, supporting the seats

(upper=stern seat, lower=bow seat)

14) 2x Seat, 2x back rest

15) 6x Cross ribs

16) Hull

17) Deck

18) Cover for loading hatch

19) Rudder system

20) Repair kit

21)

Backpack and waist belt (no pic)

1)

2)

3)

4

)

5)

6

)

7

)

8

)

9

)

10)

11

)

12

)

13

)

14)

15

)

16

)

17

)

18

)

19

)

20

)

#1

#2

#3

#4

#5

#6

10

a

)

14

)

4

2)

Assembling Bow

1x Bow segment

9x Stringer element without lock

4x Stringer element with lock

1x Keel rod (with 2x clips)

1x Keel fork with hemispherical end

1x Ridge bar

1x Cross rib #1

1x cross rib #2 with steel hooks on top

First clip a stringer element without lock on

each of the five elements at the bow

segment. The stringer elements will lock in

place by the snap buttons on the bow

segment.

Also clip on the keel rod to the bow

segment.

(This should result in the image on the left)

Then take cross rib #1.

The cross ribs are inserted all in the same

way:

First place the cross rib

diagonally...

Make sure, the open end

on the cross rib points

towards the open end of

the keel's "counterclip".

…then slide the clip onto the “counter clip”

on the keel rod and slowly right it up.

The cross rib is now locked and firmly

connected to the pickup element.

5

Then clip the stringer elements into the C-

clips of the cross rib.

Also clip in the centered stringer element

(arrow) on top of the cross rib. This will use

as an extension to the ridge bar

Now insert another stringer element without

lock to each of the side stringer (4x), and

then again one stringer element with lock

(4x).

Attach the keel fork with hemispherical ends

onto the keel rod, with the clips facing

upwards.

Take cross rib #2 and one of the two

identical ridge bars.

Hook the cross rib to the ridge bar.

Join the cross rib diagonally with the hooks

pointing forwards to the openings at the

ridge bar.

(see left images)

Now, the cross rib #2 is simultaneously (the

wider of two cross ribs with steel hooks at

the upper end) connected to the keel rod.

The ridge bar is inserted into the extension.

(If you have clipped the extension into the

upper clip of cross rib #1, release it again for

the step above!)

snap button

6

The connection of the cross rib #2 and the

insertion of the ridge bar into the extension

element have to be done simultaneously.

Then clip the extension element on the

upper clip of cross rib #1

Ensure, that all snap buttons face inside

the kayak:

The bow element is fully assembled and

should result in the image on the left.

3) Assembling stern

You need:

1x Stern segment

4x Stringer element without lock

4x Stringer element with lock

1x Keel fork with open end

1x Keel ladder with riveted half tube

1x Cross rib #6 (the smaller of two

cross ribs with steel hooks)

1x Ridge bar

First clip a stringer element without lock

on each of the four side ward elements at

the stern segment, then one stringer

element with lock.

The keel fork with the open end is

attached to the keel of the stern segment.

Then put the keel ladder with riveted half

tube to the keel fork.

snap button

7

The cross rib #6 is inserted similar to the

cross rib #2.

Which means, that the remaining ridge

bar is joined to the cross rib and then,

while pushing it to the pickup element on

the keel rod, it is inserted to the pickup at

the stern segment.

Then clip the stringer elements to the

cross rib #6.

Ensure, that all snap buttons face inside

the kayak!

The stern element is fully assembled and

should result in the image on the left.

3) Inserting bow and stern element / tensioning the hull / Inserting the seats

Spread out the hull.

Open the hatch at the bow and open the

waterproof roll closure.

Then insert the bow element into the hull.

Make sure to place the frame centered

Now push the frame flatly into the bow.

It is best to kneel inside the boat and

take the frame at the back ends of the

stringer elements.

8

Try to orientate at the ridge bar and the

reinforcement strip on the deck to insert

the frame centrally. Also, a look through

the hatch can help.

Push the frame firmly into the bow as far

as you can.

Make sure, the two pickup elements at the

ridge bar are pointing towards the center

of the kayak (this is where the coaming is

inserted later on).

On the left you see the insertion of the

stern section.

Proceed likewise with the stern.

Push the frame flat into the bow and as

far as you can.

Make sure to take the filling tubes for the

sponsons between the stringer elements.

Now bow and stern are getting connected

and tensioned. In order to do this, remove

the split pin on keel ladder.

And then proceed exactly as described.

Please read through the following

section before going to work:

The keel fork of the bow with its

hemispherical ends is mounted to the

riveted half-tubes of the stern’s keel

ladder.

9

That means pulling up stern and bow

("stern over bow"). Hang the keel fork

under the keel ladder (with the riveted

half-tube) and gently push the whole thing

down.

IMPORTANT:

Prior to this operation take the stringer

elements out the skin. This will relieve

the keel and will avoid any blockage.

You can pull up bow and stern without any

problem. The skin can flex and the frame

won’t jam.

(You see this very clearly on the pictures

on the left).

If the stringer elements are not removed

from the skin, an unfortunate pressure on

the keel rods is created, which may

damage them.

After joining keel fork and ladder, slowly

press them both down.

Put the stringer elements back into the

hull (see the left picture).

Slowly press the aligned keel rods down.

Especially the first time a high tension

occurs. This is normal and will decrease

with further assembling.

Then insert the split pins back through the

holes and wrap the rubber around it.

10

Installation of the hanging seat

The filling tube to inflate the seat always

faces forwards, towards the bow.

The front seat is a bit more narrow in the

front, than in the back.

The back seat (the other way around)

wider in the front than in the back.

(see arrows in the left picture).

The seats reproduce the boat's shape.

(Front: narrow to wide; back: wide to

narrow)

Take the Front seat and insert the lower

stringer elements (closest to the keel).

Then push it far towards the bow.

It might help to slightly press the two

stringer elements inside the boat, in order

to place the seat easier.

Proceed identically with the back seat and

push towards the stern.

It should result in the image on the left

(the inflating tubes always point towards

the bow).

Connecting the stringer

The connecting of the stringer elements is

a process that you have to learn.

Especially the precise alignment of the

"locks" to another is crucial to prevent

jamming. This connection technology

adds a lot to the overall stiffness of the

boat.

For one, you "press" the excess length,

the two stringer element with lock of bow

and stern have, "into the boat length" and

on the other hand, this connection is

stable, both on pressure and on tension.

A huge advantage on the water!

front seat

back seat

11

Note: You can connect the stringer

elements both by pushing them into the

boat, or by pulling them into the boat from

the opposite side.

Give it a try, what suits you better.

Work your way from the bottom up. Start

with the lower stringer elements.

First take one of the four small sleeves

and slide it onto one of the stringer

element (see top picture).

Then take the stringer element (as in the

second picture) and align the locks

exactly to another.

The mouths have to "look at each other".

This is crucial, otherwise it will be

unnecessarily difficult.

Push both stringer elements towards the

boat's center. This requires some strength

(especially for the first few times). The

process can also be done - as mentioned

earlier - from the other side, by pulling the

stringer elements to yourself.

Then connect the two locks. You must

align the locks exactly to another, in

order to prevent jamming.

Do the whole process - especially the first

few times - as slowly as possible and

without hassle.

Let the stringer then slowly come back

and make sure that the two elements

form a straight line.

This is very important, too. Once there is

no straight line, the stringer elements will

jam.

If they form a straight line, you still can

adjust some little imprecision, by pressing

with your thumb.

12

Then slide the sleeve over the connection.

Repeat the process with the remaining 3

stringer elements, from bottom to top.

Especially at the beginning you have to

practice a bit until you find the right way.

But then it is surprisingly easy. The

gratitude is an extremely stiff and strong

connection that contributes a lot to the

performance of your folding kayak.

4) Installation of the coaming

For the coaming you need:

2x bent coaming rod

(with D-rings

)

4x straight coaming rod

(2 of them with D-rings)

Connect one of the bent rods with one of

the straight rods with D-ring.

Insert these with the bend part ahead into

the coaming channel. And that into the

part with the largest gap in the rear third

(see the left picture).

Then slide this first half of the coaming

through the channel to the front.

Especially at the first assembly you have

to make sure, that the rod runs through

the channel.

13

It is much easier to push the coaming rod

“from the inside of the boat”, rather than

“from above”. This creates a “straight line”

and prevents jamming inside the channel.

Thus, the rods are much easier to push

into the channel!

Then connect the coaming rod with the

pickup element in the bow by sliding it

onto it. Just pull the flexible part a bit

toward you, so that there is also a straight

line. Thus the connection of coaming rod

is much easier.

Proceed likewise on the other side.

NOTE:

You can also insert the coaming rods

separately (before you connect them).

First the bent rod, then the straight one

and connect them inside the channel.

Proceed how it suits you best!

Then insert the two remaining coaming

rods without D-rings in the channel

towards the stern.

Connect them with the pickup element in

the stern.

Take one of the two bigger sleeves and

put it onto the coaming rod.

The connection of the coaming rods is

done similarly to the connection of the

stringer.

14

Align both locks exactly on another. Then

press the rods slightly downward or

upward - depending on how the

connection works better.

Snap the locks and return rods. Then slide

the sleeve over it.

Important:

Again, it is crucial to form a straight line

and then slide the sleeve over the locks.

You can also pull the two rods towards

you, if you want to do it from the other

side.

NOTE:

Some customers proceed in reverse

order, connecting stringer and coaming.

That is, they connect bow and stern,

THEN connect the stringer elements first

and insert the coaming afterwards and

connect it.

Try that variation, if you want and proceed

how it suits you best!

15

5) Installation of the cockpit cross ribs and final installation of the seats

Please also follow the exact order in

the next step!

At the top you see cross rib #5, which is

the lowest one and sits behind the back

seat.

In the middle is cross rib #4 with a clip on

top (to clip on the ridge bar)

At the bottom cross rib #3 with a steel

pickup element on top.

Push the front seat as far as possible

towards the bow.

Then take cross rib #3 and join it

diagonally as usual.

Support a little by pulling the cross rib to

the pickup elements with the other hand

(see picture)

Raise the cross rib slowly.

Please make sure, not to snag the cross

rib on the coaming channel

Then clip the stringers into the cross rib's

clips.

Best is to grab the cross rib from the

opposite side with your thumb above the

clip. Then press the stringer from the

bottom into the clip. (see picture)

Thus, you get the best leverage and need

less power.

Please do not clip in the coaming, yet!

#3

#4

#5

grab with your thumb above

the clip

press from bottom to top

16

Pull the seat backwards. Grab from

behind to the front part of the seat

(as on the picture).

Pull as far until the seat is located

approximately 8 cm in front of the cross

rib #3.

(you will find out, what position suits you

best quickly).

Now push the back seat towards the

middle (close to the sleeves).

Then install cross rib #5.

Try to lead the two top clips on the side

into the stringer while joining the cross rib.

That will save you from having to push up

the stringer elements into the clips

afterwards.

Then pull back the seat towards cross rib

#5 (until app. 8cm).

Install cross rib #4 in the same way.

Then clip the coaming into the big top C-

clips of the cross ribs.

17

If this is a bit difficult, "push" the coaming

with your palm over the cross rib.

(as shown in the left picture)

Now take the two half cross ribs. They use

as support for the seats and ensures that

the weight of the paddler does not press

on the stringer element.

It is therefore essential to install!

The lower one is for the back seat, the

more bent one for the front seat.

First place he half cross rib diagonally and

then push it into position! Otherwise is not

possible to install.

Clip one end onto the stringer right in

front of the seat. Place the other end

diagonally on the lower stringer and a

bit further to the front.

Then slide the half cross rib into position.

The half cross ribs then sits directly in

front of the seats.

half cross rib for

the back seat

half cross rib for

the front seat

18

Now install the back rest.

Lead the upper strap through the D-ring

on the coaming, then lead it back through

the clip.

Set the desired position.

The lower straps are fixed on the cross rib

behind the seat.

Now inflate the sponsons by using the

filling tubes. These are then connected

with the connecting pipe. By connecting

the tubes you will provide a pressure

equalization, which guarantees an ever

symmetrical underwater hull.

It is best to inflate the sponsons with the

mouth. When you notice, that it gets

harder to inflate, it is usually the right

pressure.

19

6) Deck lining / Deck / Rudder system

In the repair kit you will find the deck lining

and other parts for the rudder system.

The deck lining can be installed in

different ways.

One suggestion is, to form a loop, lead it

through the middle D-ring and lead the

two ends back through the loop.

(as shown in the left picture)

But you are free to attach the lining as you

want.

Cover for the loading hatch:

ATTENTION: At first the tension is very

high! Please put the cover over the hatch

and leave it there for a while. So the

elastic strap can extend a bit and it gets

easier the next time. A certain tension is

normal, though for the cover staing in

position.

Please secure the hatch cover at the first

assembling to the deck lining on the fore

ship. It can stay there, and you won't

loose it.

Lay it "on the back", run one hanger under

the lining…

20

...and then the whole cover through it.

Now the hatch cover is securely

connected to the lining and stays on

board.

Now attach the deck.

The deck is attached by Velcros.

Begin at the top of the cockpit fix it.

You can also paddle your Ladoga 2

advanced "open", if you like.

If you use the deck, though, clip in the

ridge bar (10 a) in the overview) to

support the deck between the cockpits.

Your boat is now fully assembled. Have fun on the water!

Other Triton advanced Boat manuals