Body dryer

2

INTRODUCTION

This book contains all the necessary fitting and

operating instructions for your Triton Luxury

Body Dryer. Please read them carefully.

The Body Dryer installation must be carried

out by a suitably qualified person and in the

sequence of this instruction book.

Care taken during the installation will provide a

long, trouble-free life from your body dryer.

The Body Dryer has been designed for use in a

bathroom or shower room for the purpose of

personal body drying. The dryer should not be

used for any other purpose.

Never install in a shower cubicle or steam

room.

SPECIFICATIONS

Electrical

Nominal power Nominal power

rating at 240V rating at 230V

9.0kW – (40A MCB rating) 8.3kW – (40A MCB rating)

Trickle current on OFF mode is 0.04A at 240V

(9.6W) but is not isolated.

Minimum cross sectional area of supply cable is

6mm². Derating factors should always be taken

into consideration when selecting cable size.

Materials

Main unit – 20% Glass filled Polypropylene

Cover – ABS

Dimensions

Width – 335mm, Length – 625mm,

Height – 175mm

Above ceiling – 140mm

Below ceiling – 70mm (cover)

Weight – 7kg

Packed weight – 10kg

Standards and Approvals

Complies with requirements of current British

and European safety standards for household

and similar electrical appliances.

Complies with requirements of the British

Electrotechnical Approvals Board BEAB.

Meets with compliance with European

Community Directives CE. EMC

ADVICE TO USERS

The following points will help you understand

how the Body Dryer operates:

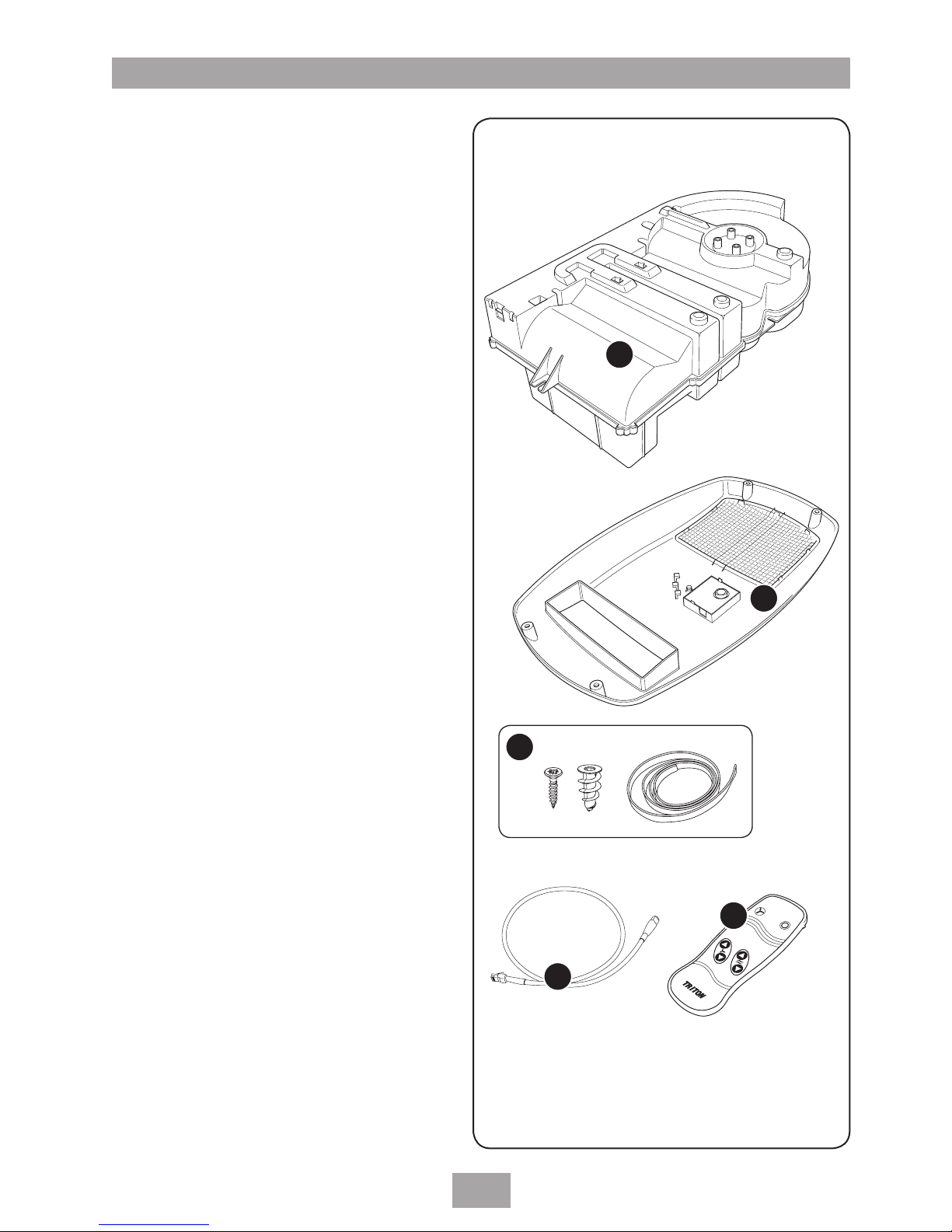

a. The unit consists of a high powered two

speed fan and 2 x 4.5kW heater elements

which are fully controllable using the hand-held

controller (supplied). Air is drawn in through

the filter, passed across the elements and then

discharged downwards.

b. DO NOT place pressurised aerosol cans in or

under the hot air flow. Always electrically isolate

the dryer or dryer/shower combination when

not in use.

c. Temperature sensors are fitted to the unit for

your safety. However, the best sensor is you. If

you find the airflow or room temperature rises

to uncomfortable levels switch off or regulate

the flow through use of the controller. Never

leave alone those unable to recognise or react to

discomfort with the dryer switched on.

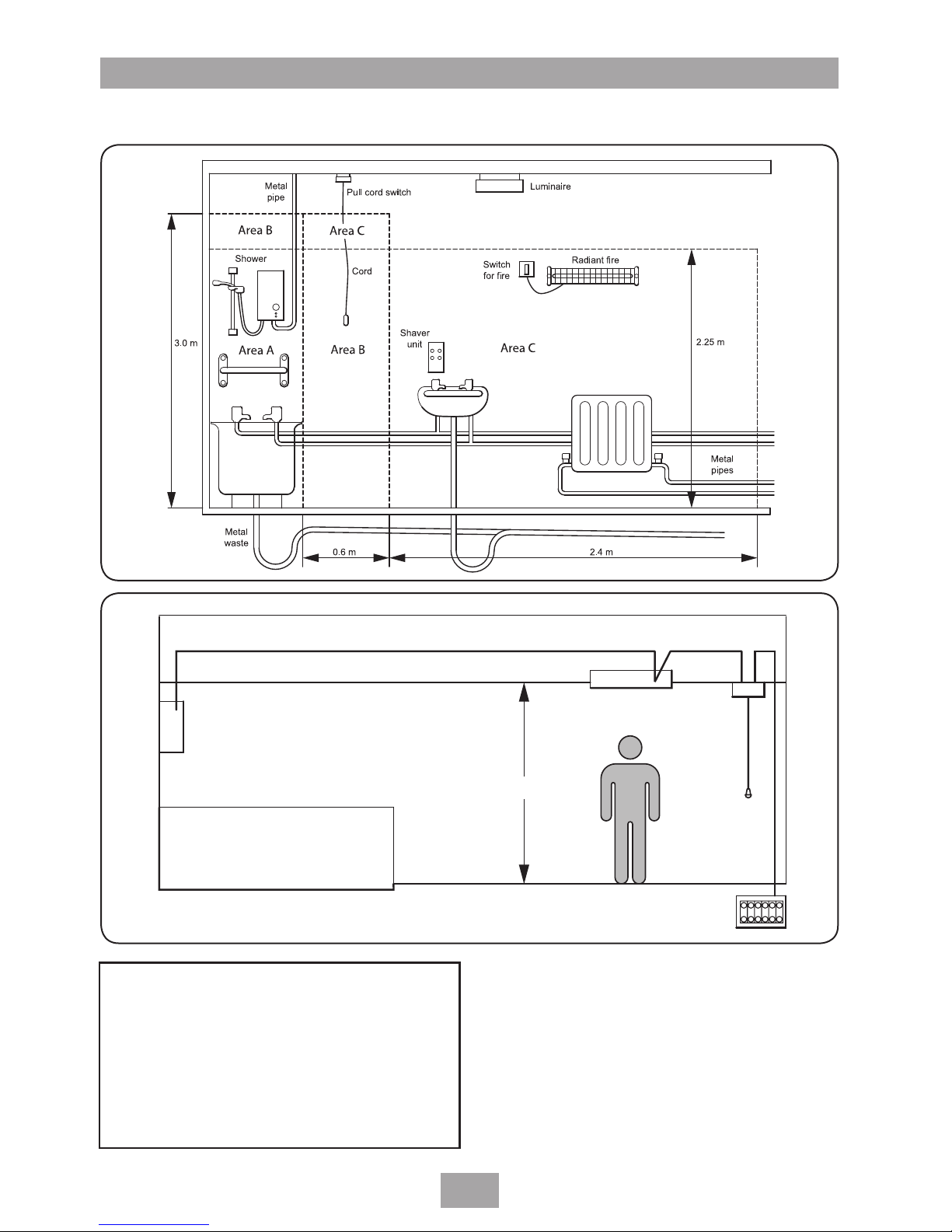

For ideal comfort and drying time the ceiling

height should be between 2.2m to 2.5m.

The dryer has a 10-minute preset cut off.

d. The unit can be connected in combination

with an electrical shower rated from 8kW

up to 10.5kW. The electrical safety features

incorporated in the unit do not allow the Body

Dryer to be operated while the shower is on and

vice versa.

e. The hand-held controller should be kept

away from sources of water.

f. The LED’s incorporated into the cover show

the operational status of the Body Dryer or

any fault condition. If you suspect the unit to

be faulty unqualified attempts to rectify the

situation should be limited to isolating and

switching on the unit via the pull cord and

operation of the hand-held controller (see

commissioning instructions). All other problems

MUST be attended to by a competent electrician

or service engineer.

Due to continuous improvement and updating,

specification may be altered without prior notice.

Replacement parts can be ordered from Customer

Service. See ‘spare parts’ for details and part numbers.