TRITORC BPL 100 Operating instructions

Operating And Maintenance Manual

Air Operated Hydraulic Power Pack For Tensioner

MODEL: BPL 100

Phone No: - +1 281 5068672 / +971 65529407

Web: - www.tritorc.com

东莞 东莞赛森特流体控制设备有限公司

Dongguan Suncenter Fluid Control Equipment Co.,Ltd

Figure 1. Typical installation loop diagram

All kinds of power units and testing equipment can be made according to customer

requirements.

1. Pneumatic triplet 2. Driving gas source switch 3. Liquid filter 4. Manual four

way valve 5. Air pressure regulating valve

6.Air driven liquid booster pump 7. Silencer 8. Pneumatic unloading valve

9. Pressure gauge 14. Hydraulic cylinder 15. Unidirectional valve

2 Installation

The driving pressure connection range of liquid booster pump is (1Bar-8.3Bar max).

DANGER!

Unauthorized modification or modification of the system (mechanical, hydraulic,

pneumatic, etc.) may cause damage to personnel and systems.

4.0 Operation

4.1 The working environment requires no dust and no corrosion.

4.2 Each booster pump is equipped with two L tripod, indicating that part of the notes are

installed and the space needs size.

4.3 Air Pressure Request

Solid particles

Pressure dew point

Maximum oil content

classification

μm

classification

℃

classification

mg/m3

6

≤ 5

4

≤ +3

2

≤ 0.1

Classification standard:ISO 8573-1

4.4 Gas access

4.5 Driving interface (screw size of port) is marked, drive and pre-compressed media

are connected. It is suggested that the precision of filter device should meet our

requirements. Driving intake and oil mist device should lubricate the pump body itself.

(The oil mist device should add VG32 turbine oil, and other oil will accelerate the

aging of seal parts.)

4.6 Pipeline requirements

According to the output pressure of the pump, we must select a pipeline that can

withstand the maximum output pressure of the pump.

4.6 Start-up

a. ensures that all interfaces are fastened and the original is installed in place.

b. adjust the pressure reducing valve and transfer the pressure to O psi.

c. Open the intake switch, slowly adjust the pressure relief valve until the pump

starts (under normal conditions, the starting pressure of the pump is 15-20 psi),

continue to adjust and observe the pressure gauge, to achieve the pressure you

need.

5.0 Troubleshooting

Serial

numbe

r

Failure phenomenon

Failure analysis

Resolvent

1

The pump does not

reciprocate, and the

muffler does not

exhaust or trace

exhaust.

1. reversing valve

stuck.

2. muffler jam

1. remove the reversing valve spring,

remove the spool of the reversing

valve, remove the contaminants, and

apply proper amount of lubricating oil.

2. remove the muffler and clean it up.

2

Pump does not

reciprocate, silencers

exhaust a lot of

exhaust.

Commutation valve

spool O ring wear

seriously

Remove the reversing valve circlip,

replace the worn seal with the new

seal, and apply the appropriate grease.

3

Pump action, but the

stroke is not in place,

pump frequently

abnormal or fast.

1. firing pin stuck.

2. firing pin O ring

off.

1. screw down the firing pin and use the

sharp nose pliers to remove the firing

pin and wipe it clean.

2. screw down the firing pin and reset

the O ring.

4

The pump operates

normally, does not

pressurized, or can

pressurized and

pressurized to less than

rated pressure.

1. there is a foreign

body in one-way

valve or one-way

valve.

2. the pressure

piston seal is

seriously worn.

1. check the check valve and clean up

the dirt.

2. after removing the check valve,

replace the pressurized piston seal.

6.0 reversing valve assembly

The directional valve changes the direction of gas movement by changing the airflow

passage, so as to achieve the purpose of changing the direction of pneumatic actuator

movement.

Sketch of assembly drawing Schematic diagram

6.1 Disassemble

Maintenance, disassembly and decomposition of pneumatic directional valves are

as follows:

Figure 6-1. Remove 40 retaining rrifice

6.1.1 As shown in the figure, after cleaning the calipers with solvent, Remove the

40 retaining rings.

Figure 6-2. Remove cover and spool with

6.1.2 As shown in the figure, use a screwdriver to pass through the gas

inlet, gently push out the valve cover,take out the valve core and place

it in a clean position.

Figure 6-3. Remove the spool bush with a shaft clamp

6.1.3 As shown in the figure, clamp the valve with a spring clamp on the shaft

Inside the sleeve, gently take it out andplace it in a clean place.In general, it is not

necessary to remove the valve sleeve, but only to replace the valve core density.Sealing

rings.。

Figure 6-4. Manual removal of the spool valve sleeve seal ring

6.1.4 As shown in Figure 1, remove the spool sleeve manually Sealing ring, ensure that

the seal ring is not damaged, placed in dry The location of silence.

Table 6-5. Attribute description of parts and components of reversing valve

●Be careful

7.0 firing pin assembly

The maintenance, disassembly and decomposition of the impact pin are as

follows:

Figure 7-1. Remove pin nut

7.1.1 As shown in the figure, use 17 open wrenches orA screwdriver removes

the nut and inspects it.Whether the O-ring is damaged or not.

NO

Name

figure number

1

Valve Sleeve

VB04000-003

2

Spool

VB04000-004

3

Bonnet

VB04000-005

4

Bead flange

VB04000-006

5

O ring

ORING-19.8*2.65

6

O ring

ORING-28*2.65

7

O ring

ORING-36.5*1.8

1. In the whole process of disassembly and assembly, the driving gas source must be cut off

before the above operation can be carried out, otherwise it may cause harm to personnel.

2. The whole disassembly and assembly process of the booster pump must be careful. Seal

rings and fittings in all positions must be clean and undamaged, and appropriate amount of

silicone resin should be coated at the contact between metal and seal rings.

7.1.2 As shown in the figure, first take out the compression spring.

Then push the pin out from the back or use the pointed tongs to go out.

Pull out the firing pin.

NOTE: Clean or replace the above dismantled parts, clean up

After loading back to the original location, if not troubleshooting and then proceed

The following operations.

Fig. 7-3. dismantling guide bushing

7.1.3 Remove the guide sleeve with a screwdriver as shown in the figure.

Remove the guide sleeve.

Figure 7-4 Removal guide sleeve seal

7.1.4 As shown in the figure, use the tool to remove the bottom of the guide

sleeve.Seal, clean the sealing groove, check whether the sealing ring is

damaged.

Fig. 7-5 firing pin assembly

7.1.5 As shown in the figure, dismantle all parts and components, and use

non-corrosive.Corrosive Solvent Cleans Sealing Groove and Cleans Parts

Check whether the seals are damaged.

Table 7-6 Attribute description of parts and components of impact pin

NO

Name

Map

number /

specification

quantity

1

Guide

sleeve

FP10000-003

1

2

O ring

d4*1.8

1

3

Firing pin

FP10000-002

1

4

O ring

d5.6*1.8-90°

1

5

Compressi

on spring

D7*CS1*25-8.

5

1

6

O ring

d11.8*1.8

1

7

Firing pin

nut

FP10000-004

1

8.0 Driving body and high-pressure part

8.1 Disassembly steps

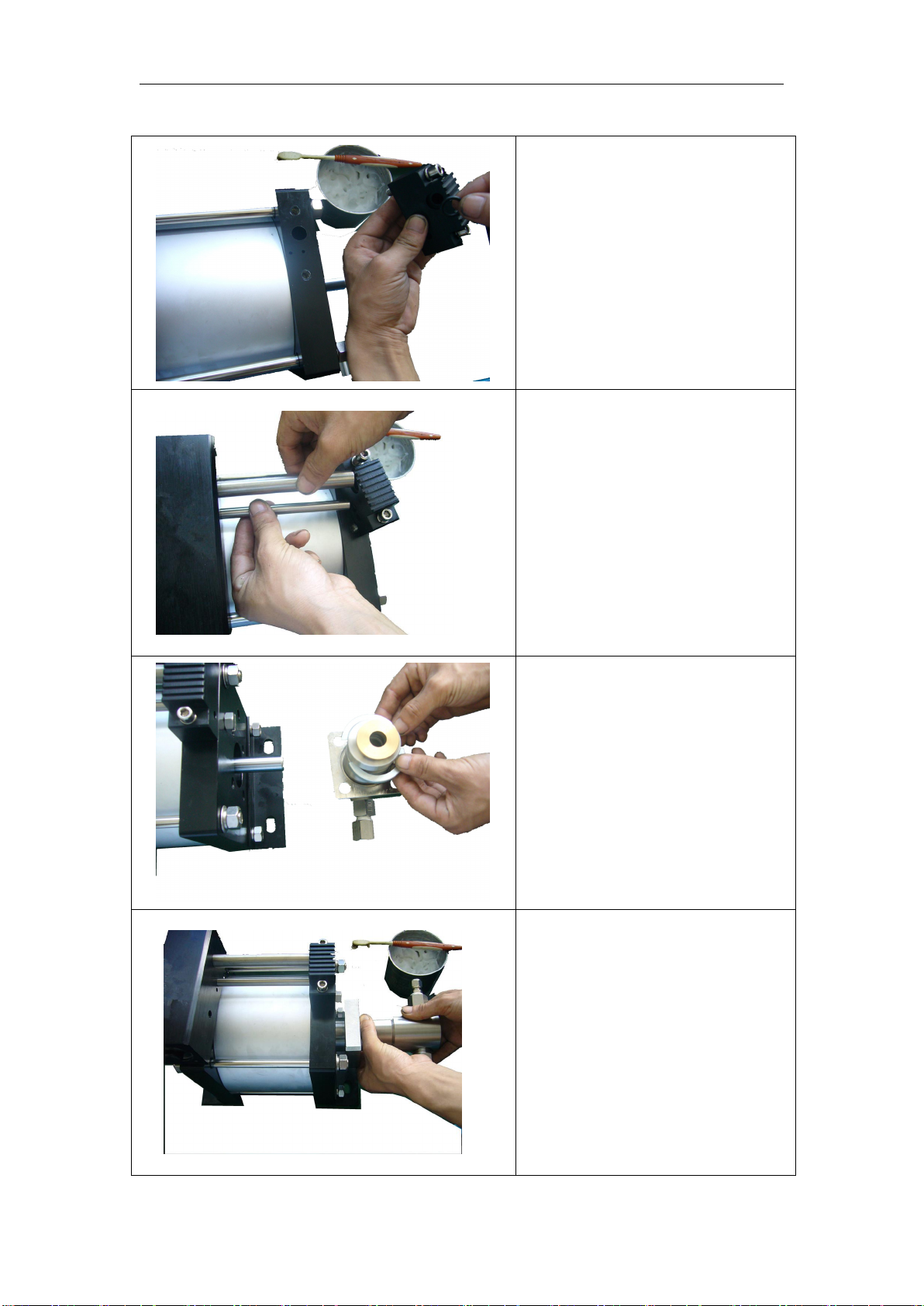

Removal of four screws for fixing

left and right high pressure

cylinders with M12 hexagonal

wrench(M12*25).

Slowly pull out the high pressure

cylinder to avoid accidental

injury to the piston rod.

The high-pressure seal in the

high-pressure cylinder can be

removed by tools. The sealing

seat can be taken out first, and

then the O-ring can be taken out.

The H605 high-pressure seal can

be taken out directly by tools to

clean the high-pressure cylinder.

The high pressure cylinder has:

high pressure seal and high

pressure guide sleeve.

High-pressure cylinder:

high-pressure seals and

high-pressure guide sleeve.。

Remove the pipes of 16 and 10.

Note that there are sealing rings at

both ends of the pipes.

(d6.9*1.8) 2 pieces

(d11.2*2.65) 2 pieces

A rubber hammer is used to strike

the edge of the end cap and

remove the end cap to separate it

from the driving cylinder.

When the seal in the end cap is

removed by the tool, the smooth

ring of the seal can be removed

first, and then the O-ring can be

removed. The UN seal can be

removed directly by the tool, and

the sealing groove can be cleaned

by non-corrosive solvent.

8.2 Installation steps

First, clean the parts and grease

the sealing parts.

High-pressure seals are

assembled in sequence.

High-pressure seals can be

installed with O-rings first, and

then into seats. H605

high-pressure seals can be

directly loaded.

Clean the shaft seal, apply grease,

assemble into the left and right

end caps. The O-ring and the

smooth ring can be separated by

the shaft package matching.

Firstly, the O-ring is loaded into

the sealing groove, and then the

smooth ring is loaded into the

groove. The 072 shaft seal can be

assembled in different directions,

and the UN shaft seal can be

directly loaded into the groove.

Assemble the pull rod of the

scaffold and place it on the marble

platform and lock the nut tightly.

When assembling the valve block,

the O-ring on the valve block

needs to be assembled first.

(d11.2*2.65) 1 pieces

(d6.9*1.8) 1 pieces

(d4.5*1.8) 2 pieces

Assemble the gas distribution

pipe and install the gas seal ring

before assembling.

(d11.2*2.65) 1 pieces

(d6.9*1.8) 1 pieces

Assemble the clasp jacket, first

put it into the clasp jacket, then

clamp the fixed groove of the high

pressure cylinder with the clasp.

When assembling the

high-pressure cylinder, when

tightening the screw of the

high-pressure cylinder, attention

should be paid to ensure that the

one-way valve at the inlet and

outlet of the high-pressure

cylinder is parallel to the scaffold,

and then tighten four pieces of

screw.

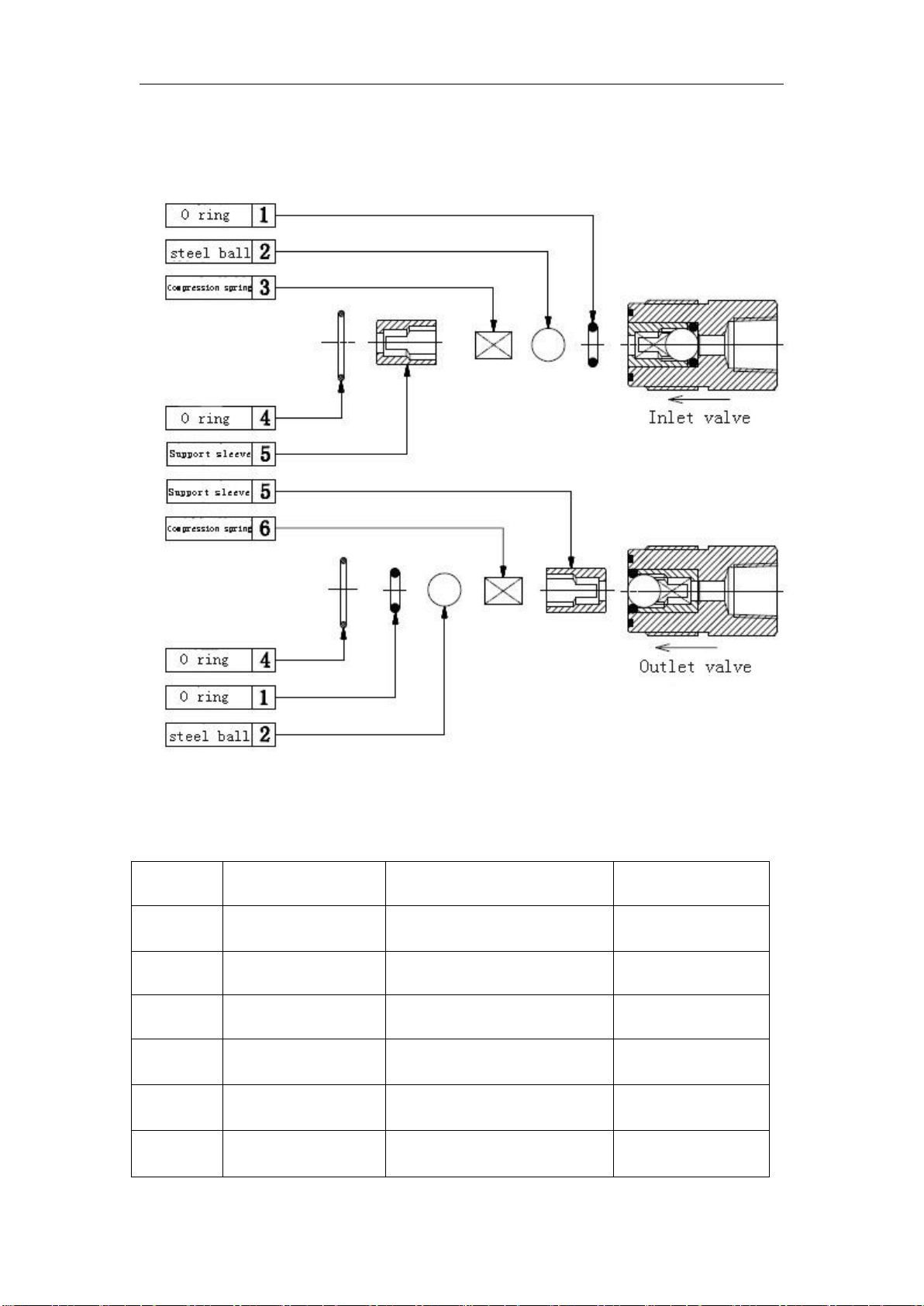

8.3 Check valve assembly

DGG10/16/28 Assembly Drawings

8.4 Attribute description of parts and components of one-way valve

NO

Name

figure number

quantity

1

o-ring

ORING-18*3.55

2

2

stainless steel ball

S¢20-001

2

3

Compression spring

D18.3*CS0.85*30-7

2

4

Support sleeve

DF 01017-001

2

5

o-ring

d30*1.8-90°

2

BPL 100 Assembly Drawing

8.5 Check valve assembly

DGG40/64/80/100/130 Series One-way Valve Import and Export Drawing Assembly

8.6 Attribute description of parts and components of one-way valve

NO

Name

figure number

quantity

1

o-ring

ORING-8*2.65-90°

2

2

stainless steel ball

S¢10-001

2

3

Compression spring

D7.6*CS0.4*17-9

1

4

o-ring

ORING-18*1.8-90°

2

5

Support sleeve

DF03006-001

2

6

Compression spring

D8*CS0.5*17-9

1

BPL 100 Series one-way Valve Import & Export Drawing Assembly

8.6 Attribute description of parts & components of one-way valve

8.7 Check valve assembly

DGG175/255/400 Series One-way Valve Import and Export Assembly Drawings

8.8 Attribute description of parts and components of one-way valve

NO

Name

figure number

quantity

1

o-ring

ORING-5*2-90°

2

2

ceramic ball

S¢6-001

2

3

Compression spring

D3.95*CS0.45*10.5-9

2

4

spool

DC06027-002

2

5

o-ring

ORING-15*1.8-90°

2

BPL 100 Series one-way Valve import & export assembly drawings

8.8 Attribute description of parts & components of one-way valve

TRITORC INC-USA

5041 Spencer Highway Suite #302, Pasedena, Texas – 77502

Web: - www.tritorc.com

Table of contents

Other TRITORC Water Pump manuals

Popular Water Pump manuals by other brands

Z.I.P.P.ER MASCHINEN

Z.I.P.P.ER MASCHINEN ZI-GP1200 user manual

Jula

Jula 731-077 operating instructions

Kamoer

Kamoer F4 user manual

Speck pumpen

Speck pumpen BADU Block Series Installation & operating manual

Samoa

Samoa LARIUS GIOTTO operating instructions

MKS

MKS Granville-Phillips 835 VQM Series instruction manual

DAB

DAB FK Series Instruction for installation and maintenance

Knauer

Knauer Azura P 4.2S instructions

PYD Electrobombas

PYD Electrobombas PC 32 8 220 instruction manual

Wilden

Wilden PS Stallion Series manual

INOXPA

INOXPA HYGINOX SE-15 Installation, service and maintenance instructions

Ulvac

Ulvac G-20DA instruction manual