Introduction

Tampering with Noise Control

System Prohibited

Owners are warned that the law may prohibit:

a)

The removal or rendering inoperative by any

person other than for purposes of maintenance,

repair or replacement, of any device or element of

design incorporated into any new vehicle for the

purpose of noise control prior to its sale or delivery

to the ultimate purchaser or while it is in use; and

b)

the use of the vehicle after such device or element

of design has been removed or rendered

inoperative by any person.

References

References to the left-hand or right-hand side given in this

manual are made when viewing the motorcycle from the

rear.

Operations covered in this manual do not always include

reference to testing the motorcycle after repair. It is

essential that work is inspected and tested after

completion and if necessary a road test of the motorcycle

is carried out particularly where safety related items are

concerned.

Dimensions

The dimensions quoted are to design engineering

specification with service limits where applicable.

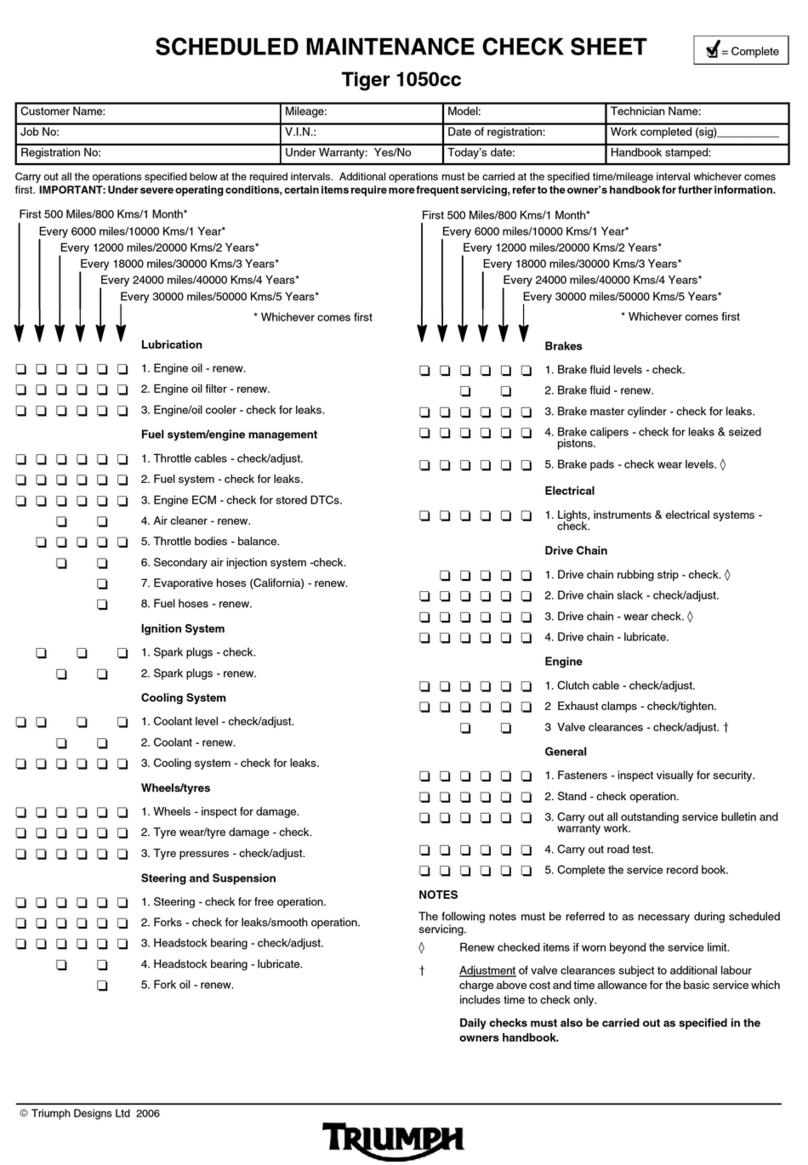

During the period of running-in from new, certain

adjustments may vary from the specification figures given

in this manual. These will be reset by the dealer at the 500

mile/800 km service, and thereafter should be maintained

at the figures specified in this manual.

Repairs and Replacements

Before removal and disassembly, thoroughly clean the

motorcycle. Any dirt entering the engine or other parts

will work as an abrasive and shorten the life of the

motorcycle. Particular attention should be paid when

installing a new part, that any dust or metal filings are

cleared from the immediate area.

Force

Common sense should dictate how much force is

necessary in assembly and disassembly. If a part seems

especially difficult to remove or install, stop and examine

what may be causing the problem. Never lever a

component as this will cause damage both to the

component itself and to the surface being levered against.

Whenever tapping to aid removal of an item is necessary,

tap lightly using a hide or plastic faced mallet.

Edges

Watch for sharp edges, especially during engine

disassembly and assembly. Protect the hands with

industrial quality gloves.

When replacement parts are required, it is essential that

only genuine Triumph parts are used.

Safety features and corrosion prevention treatments

embodied in the motorcycle may be impaired if other

than genuine Triumph parts are fitted. In certain territories,

legislation prohibits the fitting of parts not to the

manufacturer's specification.

Tightening procedure

Generally, when installing a part with several bolts, nuts or

screws, they should all be started in their holes and

ti

ghtened to a snug fit, evenly and in a cross pattern. This

is to avoid distortion of the part and/or causing gas or oil

leakage. Conversely, bolts, nuts, or screws, should all be

loosened (in sequence if specified) by about a quarter of a

turn and then removed.

Where there is a tightening sequence specified in this

Service Manual, the bolts, nuts, or screws must be

ti

ghtened in the order and by the method indicated.

Torque wrench setting figures given in this Manual must

be observed. The torque tools used must be of accurate

calibration.

Locking devices, where specified, must be fitted. If the

efficiency of a locking device is impaired during removal it

must be renewed. This applies particularly to micro-

encapsulated fixings which must always be replaced if

disturbed. Where necessary, the text in this manual will

indicate where such a fixing is used.

I

uMP

Service Manual - Daytona 675, Street Triple and Street Triple R

vii