Trixy Aviation G 4-2 User manual

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 1

Maintenance manual

Trixy Aviation

Series

G 4-2

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 2

Maintenance Manual for

Gyrocopter G 4-2

This manual contains information for basic maintenance and forms to

document the performed maintenance, repairs and alterations done on

the gyrocopter. The extent and state of revision of this manual may be

obtained from the index and the revision index.

Maintenance for the gyrocopter G 4-2 is to be performed ONLY by an

authorized persons and/or aviation workshop in accordance with the

instructions and intervals given in this manual as well as the manuals

for engine and propeller.

This manual does not substitute the education of an aviation

technician or the authorization of an aviation maintenance

workshop. IT is to be used in addition to the maintenance manuals

of engine and propeller.

Revision: 05A Date issued: 03.05.2017

Sticker with individual gyrocopter date here!

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 3

REVISIONS TO THIS MANUAL

No.

Description

Page

Date

Name

01

Previous manual Rev. 3.0

All

03.05.17

R. Farrag

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 4

INDEX

1.

GENERAL REMARKS

6

1.1

Introduction

6

1.2

Certification and Registration

7

1.3

Warnings and precautions

7

1.4

Description

8

1.5

Technical data

8

1.6

Side view, top view and front view

9

2

COMPONENTS

12

2.1

Introduction

12

2.2

Frame

13

2.3

Rotor

15

2.4

Rotor head

17

2.5

Rotor controls

31

2.6

Prerotator system

36

2.7

Propeller

41

2.8

Nose wheel and steering

45

2.9

Main gear

49

2.10

Main wheels and breaks

51

2.11

Empennage

52

2.12

Rudder controls

53

2.13

Dashboard

58

2.14

Engine

60

3

SYSTEMS

62

3.1

Introduction

62

3.2

Engine oil circuit

63

3.3

Engine coolant circuit

64

3.4

Engine ignition system

64

3.5

The fuel system

65

3.6

Electrical system

67

3.7

The hydraulic brake system

91

3

PERIODIC PREVENTIVE MAINTENANCE

94

4.1

Introduction

94

4.2

Maintenance after the first 25 hours

95

4.3

50 hour interval maintenance

96

4.4

100 hour interval maintenance

97

4.5

500 hour interval maintenance

98

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 5

4.6

Recommended overhalls

99

5

MAINTENANCE SERTIFICATES

100

6

DAMAGE OR ACCIDENT REPORTS

116

7

CERTIFICATES OF REPAIR AFTER DAMAGE

120

8

MODIFICATION CERTIFICATES

124

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 6

1 GENERAL REMARKS

1.1 Introduction

This manual contains information and instructions of the gyrocopter

manufacturer, which must be made available to the operator of the

gyrocopter to perform proper maintenance in accordance with the

German regulations stated in (BUT).

More details on engine and propeller maintenance are to be found in

the manufacturer’s Maintenance manual for each item. Such details are

very important and must be followed.

The operator is only permitted to exchange defective parts and/or

components using original parts and/or components in an authorized

aviation workshop after consulting the manufacturer of the gyrocopter.

The operator must perform an annual inspection according to the

German regulations. Such inspections must be approved and

documented by an authorized inspector. DAeC as a German authority is

currently overlooking these regulations and must be officially informed

about annual inspections. Regulations in other countries must be taken

in consideration, in case that the gyrocopter is registered in countries

other than Germany.

The warranty provided by the manufacturer of the gyrocopter is only

valid when maintenance is performed by an authorized person or

authorized aviation workshop.

Technical defects, which may signal weak points in the design or the

construction of the gyrocopter, must be reported without delay to the

manufacturer of the gyrocopter.

Reporting incidents and accidents according to § 5 Luft VO in Germany

or regulations in other countries are also to be reported to the

responsible authority and the manufacturer of the gyrocopter.

Please use the forms at the end of this manual to report such defects.

All warranties provided by the manufacturer of the gyrocopter are void,

in the event that one or more of the instructions in this manual are

ignored.

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 7

Attention: means that the disregard of the corresponding procedure

leads to a reduction of flight safety over time.

Warning: means that the disregard of the corresponding procedure

leads to an immediate or major reduction of flight safety.

Note: attends to special issues which are not in direct relation to

flight safety, but are important or unusual.

1.2 Certification and Registration

The statutory basis for the operation of an ultra-light gyrocopter (ULG) is

regulated in air traffic laws. Details are to be obtained from associated

documents. All rules and regulations contained in these documents

must be obeyed.

The G 4-2 is constructed, manufactured and tested according to the

construction regulations for ultra-light gyrocopters (BUT 2001) and Nfl II

13/09 dated 12.02.2009 and is registered under the identification

number 61218 by the responsible German authority (DAeC).

1.3 Warnings and precautions

The following definitions are used for warnings, precautions and notes

in this manual:

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 8

1.4 Description

•Gyrocopter with nose wheel steering

•Stainless steel frame welded in gas-shielded process

•Two seats in tandem configuration inside an open fuselage

(model Liberty) or enclosed fuselage with removable hard top

(model Princess). The fuselage and the canopy are made of

carbon fiber composite.

•Main undercarriage strut, equipped with hydraulic brakes

•Rotor made of extruded aluminum profile

•Rotor head steering via push rods

•Rudder steering via steel wires

•Rudder and stabilizers made from CFC

The series G 4-2 includes 2 models: Liberty and Princess.

Liberty is an entry-level model, which is designed to basically operate

with an open cabin. However, this model can be converted with an

optional kit to a closed version.

Princess is a top model, which is designed to basically operate with a

closed cabin. This model can be converted with an optional kit to an

open version.

1.5 Technical data

Length 4.90 m

Width: 1.85 m

Height: 2.80 m

Empty weight: 265 - 310 kg (as equipped)

Load capacity: 190 - 280 kg (as equipped)

Max. Take-off weight: 500, 530 or 560 kg (as equipped)

Tank capacity: 34 l / 68 l (as equipped)

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 9

Note: The three views are not to scale!

1.6 Side view, top view and front view (2 models)

The model Liberty

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 10

Note: The three views are not to scale!

The model Princess

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 11

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 12

Warning: This manual does not substitute the education of an

aviation technician or the authorization of an aviation maintenance

workshop. IT is to be used in addition to the maintenance manuals of

engine and propeller.

Attention: Only persons authorized by the gyrocopter manufacturer

are allowed to perform maintenance and repair works on the

gyrocopter. Persons to perform maintenance and repair works on

either engine or propeller must be authorized by the respective

manufacturer.

Note: All warranties are void in case that the instructions in this

manual are not carefully followed.

2 COMPONENTS

2.1 Introduction

The components used in the gyrocopter series G 4-2 are illustrated and

documented in this section of the maintenance manual.

Bolts and nuts are to be tightened and inspected in accordance with the

data provided in this manual and the tightening torque in the

corresponding tables is to be used as a reference. In doubt, the

maintenance technician or the aviation workshop performing the

maintenance or repair works must contact the manufacturer of the

gyrocopter, the engine manufacturer or the manufacturer of the

propeller for further information.

Engine maintenance must be performed according to the instructions of

the engine manufacturer. Maintenance, repairs or adjustments to the

propeller must be conducted by authorized persons in accordance with

the instructions provided by the propeller manufacturer.

Only original parts and/or components are to be used as spare parts.

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 13

Note: All warranties are void in case that the instructions in this

manual are not carefully followed.

Attention: Cracks or damage to the frame are dangerous and

reduce flight safety. Repairs on the frame may only be carried out by

persons who are authorized by the manufacturer of the gyrocopter.

Cracks and damages to the frame are to be reported to the

manufacturer of the gyrocopter with no delay.

Warning: The gyrocopter is not to be operated once cracks,

bends, dents or any other damages are detected in the frame and/or

the engine mounts.

2.2 Frame

The frame is the structure carrying the gyrocopter and connecting all its

components together. It is made of a special stainless steel and welded

under inert gas protection against corrosion. It is tested and passed the

load requirements in BUT (the German specifications for type

certification of ultra-light gyrocopters). Such high loads never occur in

normal flight conditions. However, the gyrocopter may be exposed to

higher loads and forces during taxiing, take-off and landing on rough

terrain. This may cause damage to the frame and/or other components

of the gyrocopter. It is, therefore, recommended to visually inspect the

frame before every flight and to thoroughly inspect it by authorized

persons in every scheduled maintenance.

To be overhauled: 500 h

To be exchanged: 2000 h

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 14

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 15

Attention: Cracks or damage in the rotor system are dangerous and

reduce flight safety. Repairs on the rotor may only be carried out by

persons who are authorized by the manufacturer of the gyrocopter.

Cracks and damages to the rotor are to be reported to the

manufacturer of the gyrocopter with no delay.

.

Note: All warranties are void in case that the instructions in this

manual are not carefully followed.

Warning: The gyrocopter is not to be operated once cracks,

bends, dents or any other damages are detected in the rotor system.

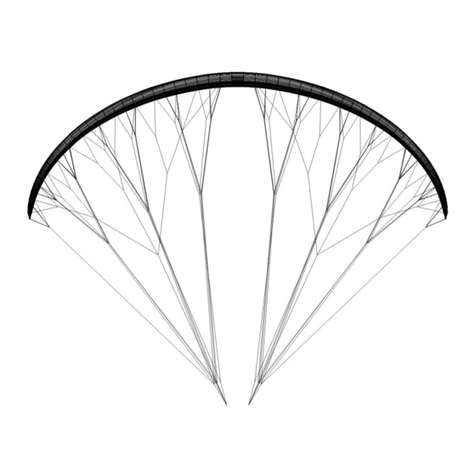

2.3 Rotor (2 sizes)

Air foil: NACA 8H12

Manufacturer: Averso Aviation

www.averso.info

Rotor diameter: 8.40 or 8.60 m

Rotor circle area: 55.4 or 58.1 m²

Max. rotor load: 10.1 or 9.64 kg/m²

To be overhauled: 500 h

To be exchanged: 1500 h

Rotor bridge for Rotor head type KK-1

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 16

Pos.

Description

Qnt.

Tightening torque

7-1

Hexagon bolt M10x90 8.8

4

40 Nm

7-2

Hexagon bolt M10x70 8.8

16

40 Nm

7-3

Self-locking Hexagon nut M10 ISO 7042

20

7-4

Washer 10,5 DIN 125-B

36

25-109

Hexagon bolts

4

40 Nm

Rotor bridge for Rotor head type TS-1

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 17

Attention: Cracks or damage in the rotor head are dangerous and

reduce flight safety. Repairs on the rotor head may only be carried

out by persons who are authorized by the manufacturer of the

gyrocopter. Cracks and damages to the head are to be reported to

the manufacturer of the gyrocopter with no delay.

.

Note: All warranties are void in case that the instructions in this

manual are not carefully followed.

Warning: The gyrocopter is not to be operated once cracks,

bends, dents or any other damages are detected in the rotor head.

2.4 Rotor head (2 types)

2 Rotor head types (KK-1 and TS-1) are certified for the series G 4-2:

Type KK-1 is a tilt head design. It is designed and manufactured by

Trixy Aviation. It is made of high quality materials and has passed all

tests required under the German rules and specifications for type

certification of ultra-light gyrocopters. It is made of aircraft aluminum

and stainless steel. The bolts, bushings and axes are of special design

and must not be replaced by standard parts.

To be overhauled: 500 h

To be exchanged: 1500 h

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 18

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 19

Maintenance manual G 4-2 Revision 05A –03.05.2017 Doc. No.: TA-M-D-002-EN 20

Table of contents

Popular Aircraft manuals by other brands

Piper

Piper PA-28-181 Archer II manual

Forced Aeromotive Technologies

Forced Aeromotive Technologies FAA-STC SA10232SC instructions

Piper

Piper Arrow IV Turbo Maintenance manual

Niviuk

Niviuk PEAK 6 user manual

Bruce Goldsmith Design

Bruce Goldsmith Design WASP Ownersmanual

Dancing Wings Hobby

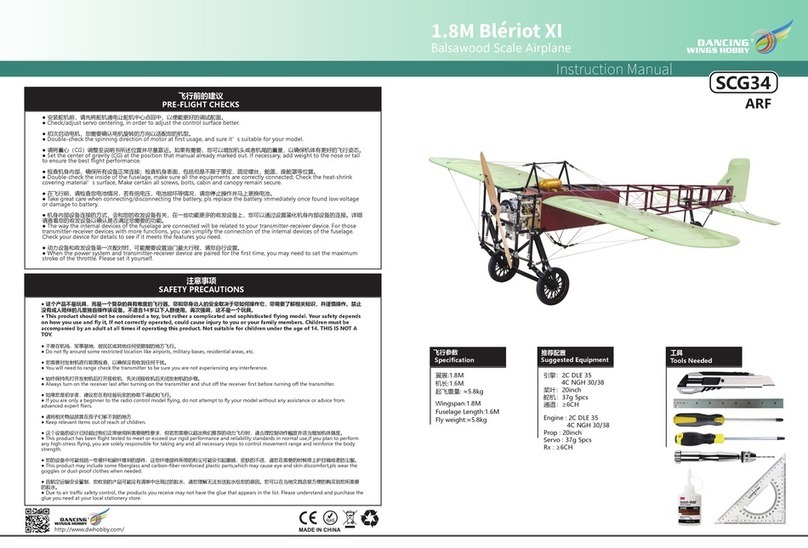

Dancing Wings Hobby 1.8M Bleriot XI instruction manual