Forced Aeromotive Technologies FAA-STC SA10232SC User manual

Forced

Aeromotive

Technologies

DOCUMENT NO. 22001-05

REV G, August 21, 2020

PAGE 1 OF 11

Instructions for Continued Airworthiness

FAA-STC SA10232SC

Supercharged O-470-L, -R, -S, and -U Engines Installed On

Cessna Models 182B, C, D, E, F, G, H, J, K, L, M, N, P, Q and R Aircraft

NOTICE

This document must be referenced on Block 8 of FAA form 337 and added to the aircraft

permanent record as required by 14 CFR Part 91, §91.417(a)(2)(vi) when the reference

FAA-STC modification is accomplished on eligible aircraft. This document complies with

the requirements of 14 CFR Part 23, §23.1529, in accordance with 14 CFR Part 23,

Appendix G.

Model No. _________________

Aircraft Serial No. __________________

Aircraft Registration No. __________________

ForcedAeromotiveTechnologies

FAA-STC SA10232SC

Supercharged O-470-L, -R, -S, and -U Engines in

Cessna Models 182B, C, D, E, F, G, H, J, K, L, M, N, Q, and R Aircraft

Instructions For Continued Airworthiness

DOCUMENT NO. 22001-05

REV G, August 21, 2020

PAGE 2 OF 11

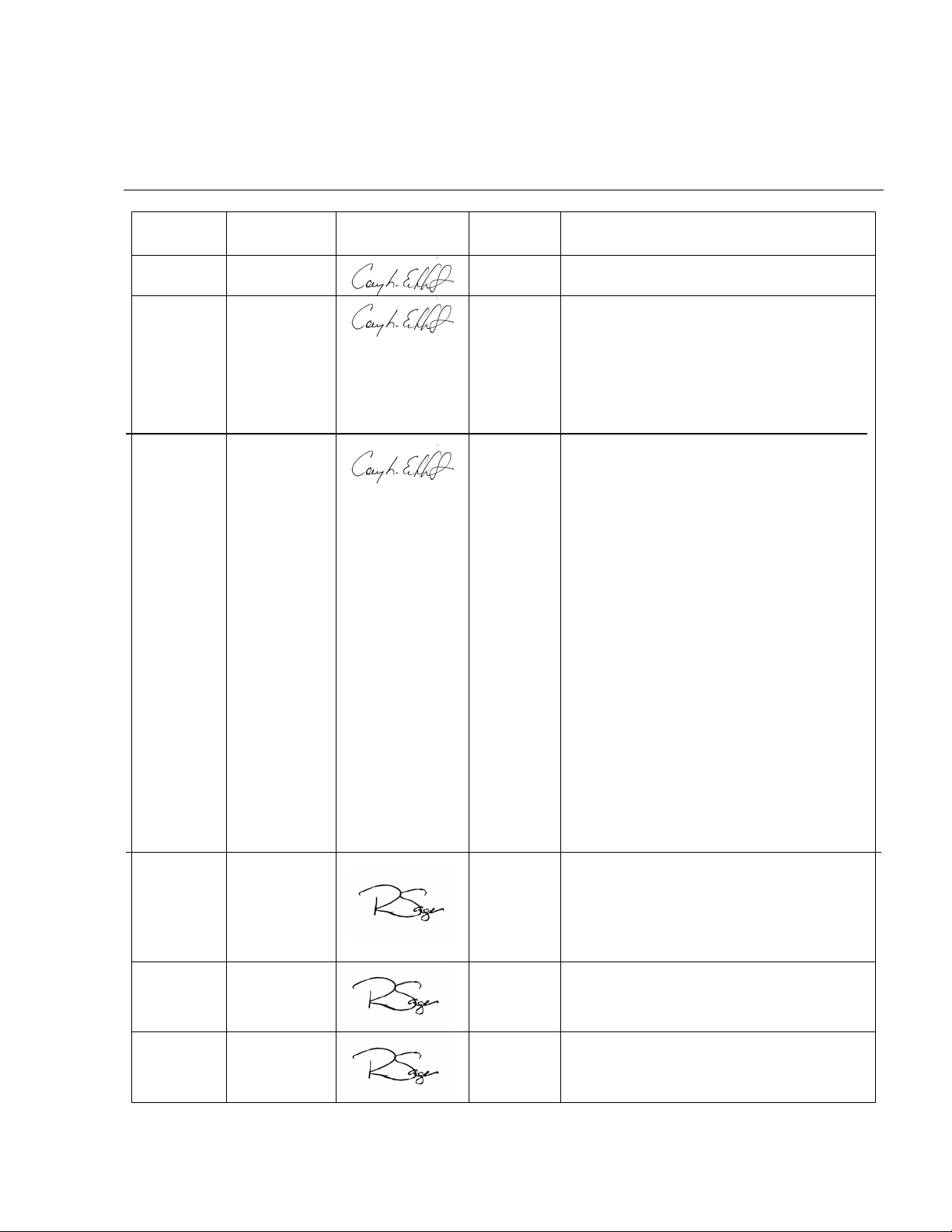

LOG OF REVISIONS

Revision

Number

Revision

Date

Approval Affected

Pa

g

es

Description of Revision

IR 03/05/2004 All New

A

B

C

08/06/2004

01/04/2005

06/17/2006

6

10 11 12

13

All

5, 8

9

10

13

11

13

5.3, para 2. Alignment marks for

boost cutoff closed position

changed to match installation

instructions, II-182.

Parts list added.

Cessna 182 Q and R models and

O-470-U engines added to header

Cessna 182 Q and R models and

O-470-U engines added to

section 2 and 15.

O-470-U added to section 15,

engine operation

Kit # changed to match PMA

Cessna 182 Q and R models and

O-470-U engines added to

eligibility list

O-470-U pulley added

Heat shields added

Weldon fuel pump P/Ns A8164A

and A8164B added to parts list.

Editorial correction

Belt added

D 12/21/2008 5

10

13

Multi-groove belt replacement

Added item 5, 6, 18.

Added item 103, 104.

E 2/27/2013 10-13 Removed kit list.

ForcedAeromotiveTechnologies

FAA-STC SA10232SC

Supercharged O-470-L, -R, -S, and -U Engines in

Cessna Models 182B, C, D, E, F, G, H, J, K, L, M, N, Q, and R Aircraft

Instructions For Continued Airworthiness

DOCUMENT NO. 22001-05

REV G, August 21, 2020

PAGE 3 OF 11

F 10/30/2014

7 Oil change, self oiled

superchargers

G 8/21/2020

6 Belt tension settings

ForcedAeromotiveTechnologies

FAA-STC SA10232SC

Supercharged O-470-L, -R, -S, and -U Engines in

Cessna Models 182B, C, D, E, F, G, H, J, K, L, M, N, Q, and R Aircraft

Instructions For Continued Airworthiness

DOCUMENT NO. 22001-05

REV G, August 21, 2020

PAGE 4 OF 11

Table of Contents

1. Introduction .......................................................................................................... 5

2. General Description ............................................................................................. 5

3. Control, Operation Information, Special Procedures ............................................ 5

4. Servicing Information ........................................................................................... 5

5. Maintenance Instructions ..................................................................................... 6

6. Troubleshooting Instructions ................................................................................ 8

7. Removal and Replacement Information ............................................................... 8

8. Diagrams .............................................................................................................. 8

9. Special Inspection Requirements ......................................................................... 8

10. Application of Special Treatments ........................................................................ 9

11. Data ..................................................................................................................... 9

12. Special Tools ........................................................................................................ 9

13. Additional Information for Commuter Category Aircraft ........................................ 9

14. Recommended Overhaul Period .......................................................................... 9

15. Airworthiness Limitations .................................................................................... 10

16. Revision ............................................................................................................. 11

17. Assistance .......................................................................................................... 11

ForcedAeromotiveTechnologies

FAA-STC SA10232SC

Supercharged O-470-L, -R, -S, and -U Engines in

Cessna Models 182B, C, D, E, F, G, H, J, K, L, M, N, Q, and R Aircraft

Instructions For Continued Airworthiness

DOCUMENT NO. 22001-05

REV G, August 21, 2020

PAGE 5 OF 11

1. INTRODUCTION

This document outlines the compliance with 14 CFR 23.1529 “Instructions for

Continued Airworthiness” for Forced Aeromotive Technologies, Inc.

Supplemental Type Certificate (STC) No. SA10232C.

NOTICE:

Section 15, titled “Airworthiness Limitations” is FAA approved and specifies

maintenance required under 43.16 and 91.403 of the Federal Aviation

Regulations unless an alternative program has been FAA approved. To remain

in compliance with the STC, the aircraft shall be maintained in accordance with

these limitations.

This document supplements or supersedes the Cessna “Service Manual”, part

numbers D138-1-13, revision 1, D637-1-13, revision 1, and P2006C3-13, change

3, or later approved revisions only in those areas listed herein.

2. GENERAL DESCRIPTION

STC SA10232SC installs supercharged Teledyne Continental Motors Model No.

O-470-L, -R, -S, or -U engines in the appropriate Cessna Models 182E, F, G, H,

J, K, L, M, N, P, Q and R aircraft. This STC also installs dual electrical fuel

pumps, fuel pump circuit breakers and switches, a fuel pressure gage, low fuel

pressure and alternator inop annunciators, a cockpit controlled boost cutoff push-

pull cable, and various placards.

This STC cannot be incorporated unless STC SA10233SC has been performed

on either the appropriate O-470-L, -R, -S, or -U engine which installs the belt-

driven Vortech VS-1 supercharger on the engine, alters the inductions system for

the supercharger, and installs a boost cutoff control valve.

3. CONTROL, OPERATION INFORMATION, SPECIAL PROCEDURES

Refer to basic Cessna Maintenance or Service Manual, basic Pilot’s Operating

Handbook and Airplane Flight Manual Supplement 22001.

4. SERVICING INFORMATION

Refer to basic Cessna Maintenance or Service Manual.

Table of contents