苏州特鲁利电子材料有限公司

Suzhou Trojan Industry Material Co.,Ltd.

地地址:江苏省苏州市工业园区新泽路 53 号A幢

电话:0512-67580617 传真:0512-67508229

TIP: It is recommended that the head speed match or exceed the base

speed, running in the same direction. This provides flatter specimen

samples, especially for coarse grinding.

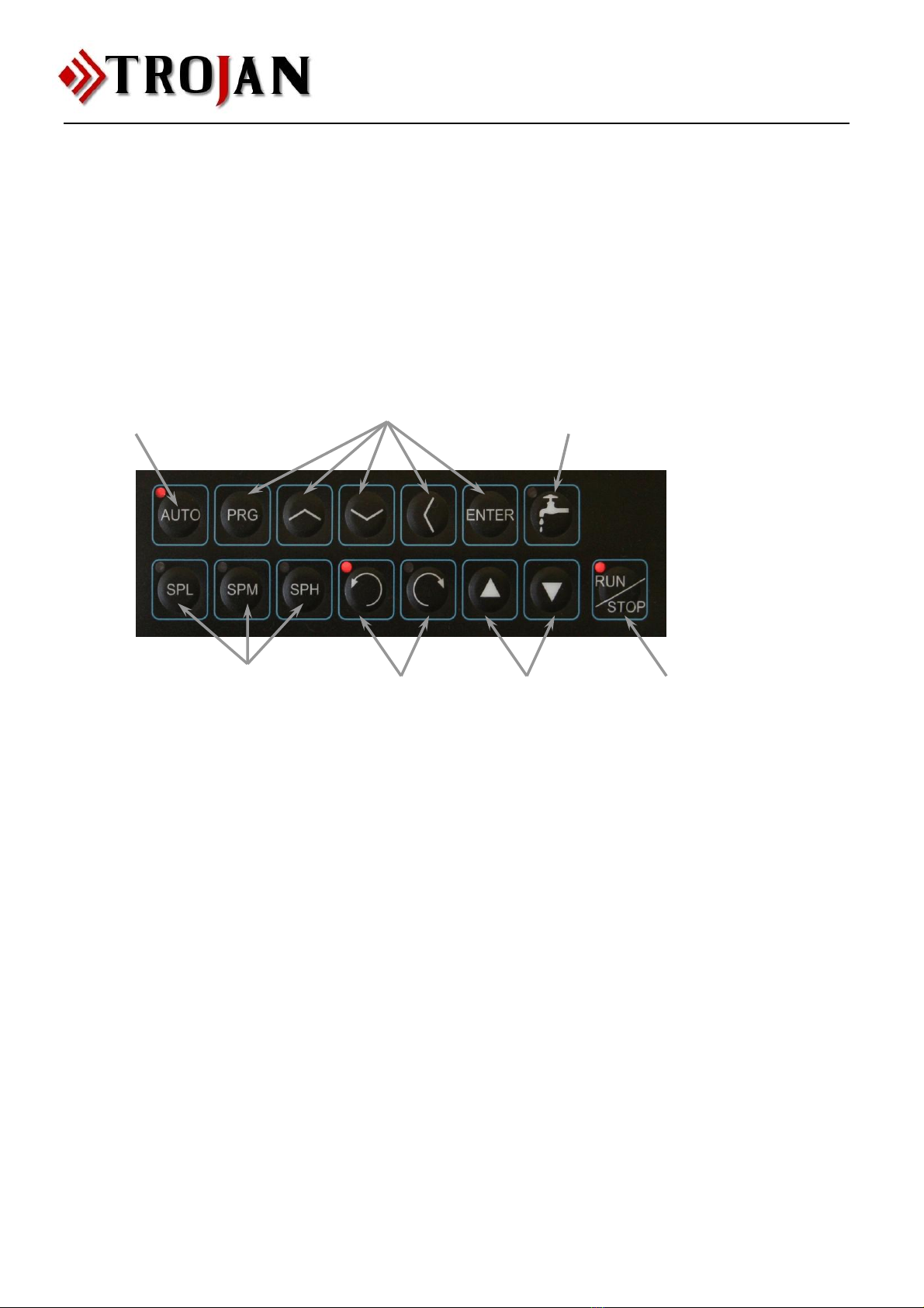

3.4 Programmable Mode

1. The programming mode can be used to pre-set the polishing speed, direction and time for automated polishing.

It can also be used to change the fast speed buttons.

2. To change the speed of the wheel:

Press the PRG button and use the up and down keys to SP1 and press ENTER. Use the up, down and < key to

change the speed. Press ENTER to save.

3. To program a grinding/ polishing time:

Press the PRG button and use the up and down keys to display t1 and press ENTER. Use the up, down and <

key to change the time (enter in seconds - displayed min-sec)

4. To operate the pre-programmed conditions:

PRESS the AUTO button and then start the program with the RUN/STOP button. The pre-programmed

conditions will be executed.

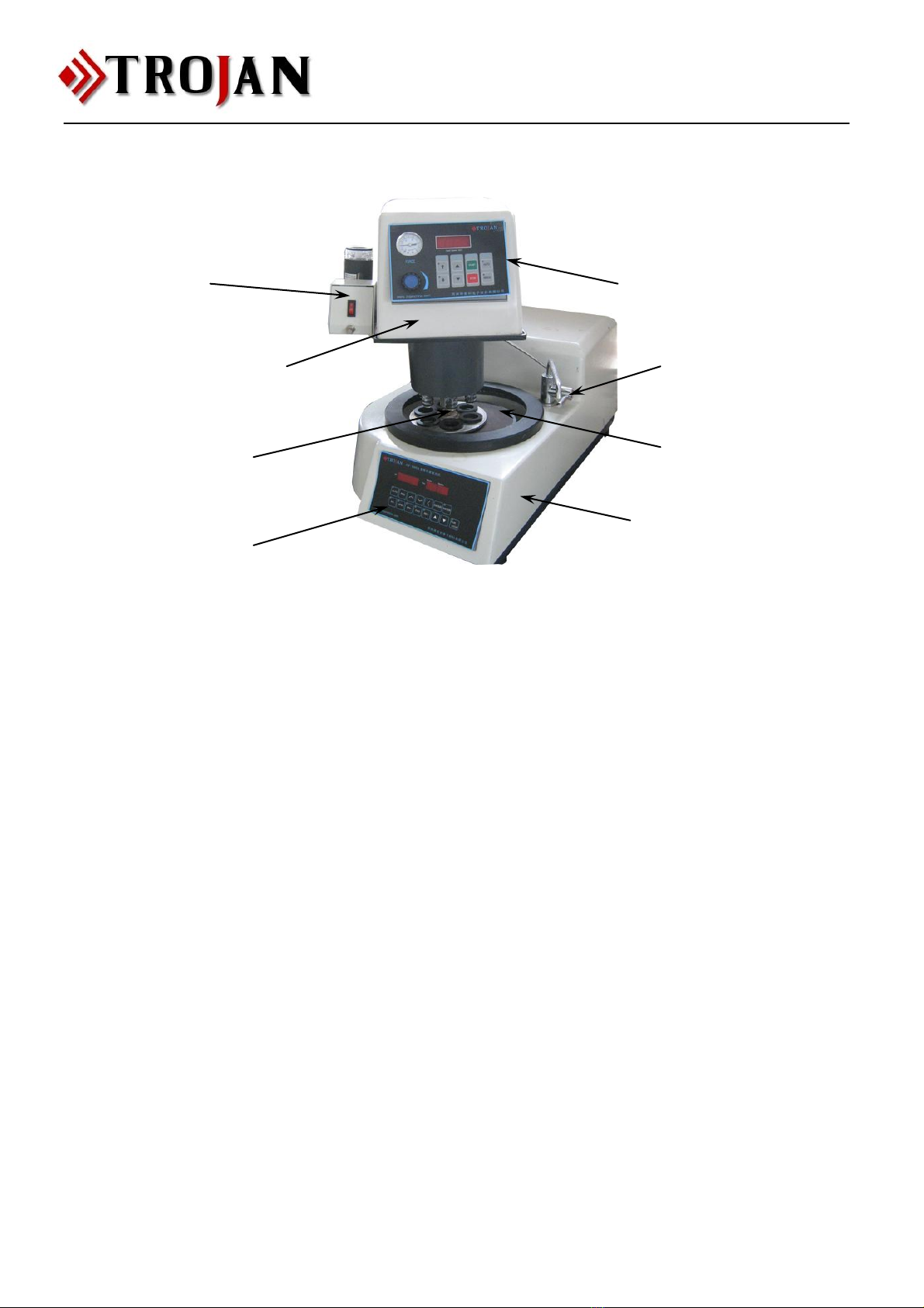

3.5 MANUAL Polishing Mode

1. Install working wheel and attach grinding papers / polishing cloths.

2. Switch on the head and the base at the back.

Set the toggle switch on the head control panel to MANUAL

Set an approximate pressure and head speed on the head.

Load samples and press the UP/DOWN key to the DOWN .

Press Start/Stop button to start the head (the base will not start automatically in this mode, it must be started

separately).

3. Start the base by using preset speeds (SPL, SPM, SPH) and pressing Run/STOP button. Note speed can be

adjusted with up and down arrow keys.

4. Position flexible water spout over working wheel. During sample preparation adjust water flow by turning water

control knob as required. Note: Initial operation of water valve may contain air in the lines. Turn water on

slowly to purge air from system.

5. Both the base and the heads need to be stopped by pressing the red button on the head and the RUN/STOP

button on the base controller.