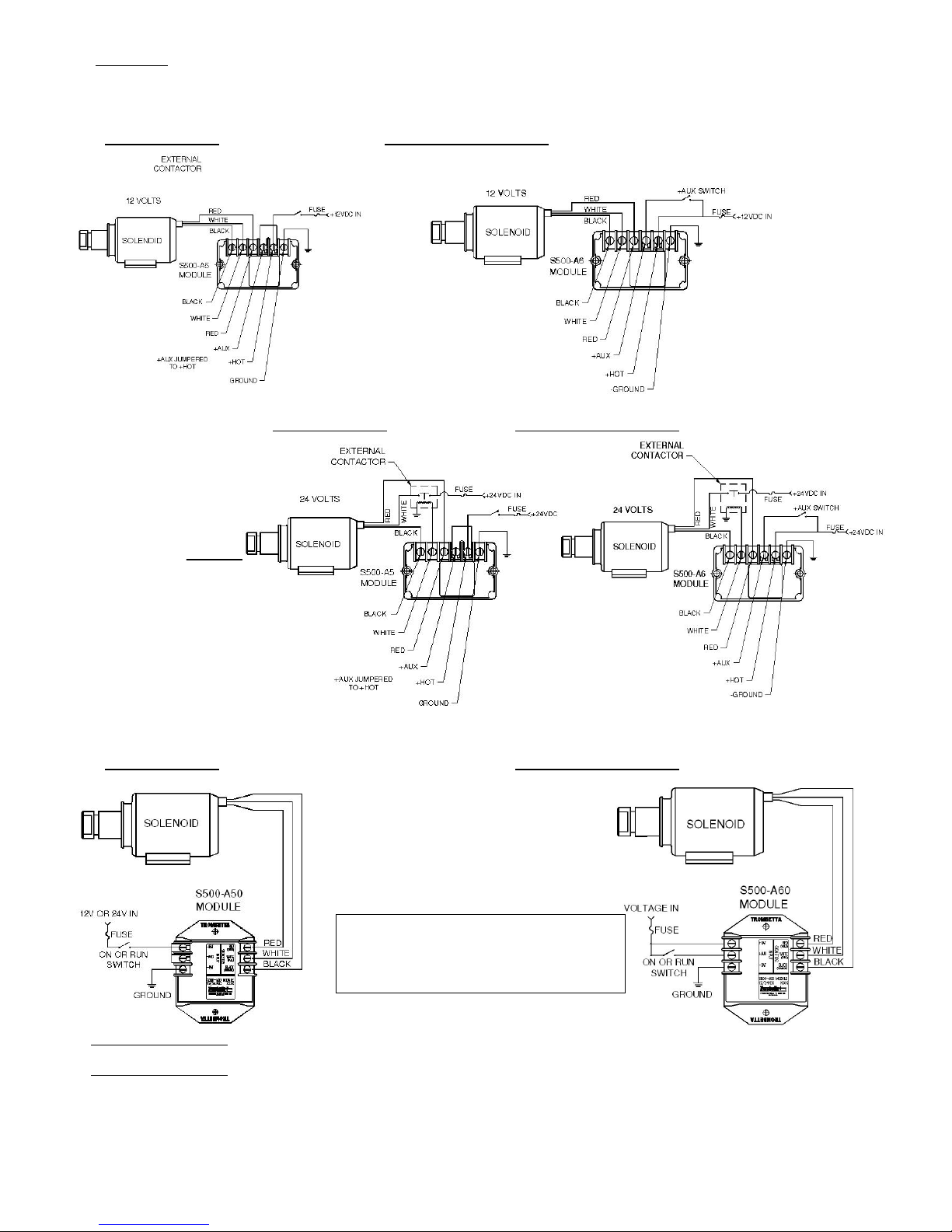

trombetta P & Q 610 User manual

Popular Power Inductor manuals by other brands

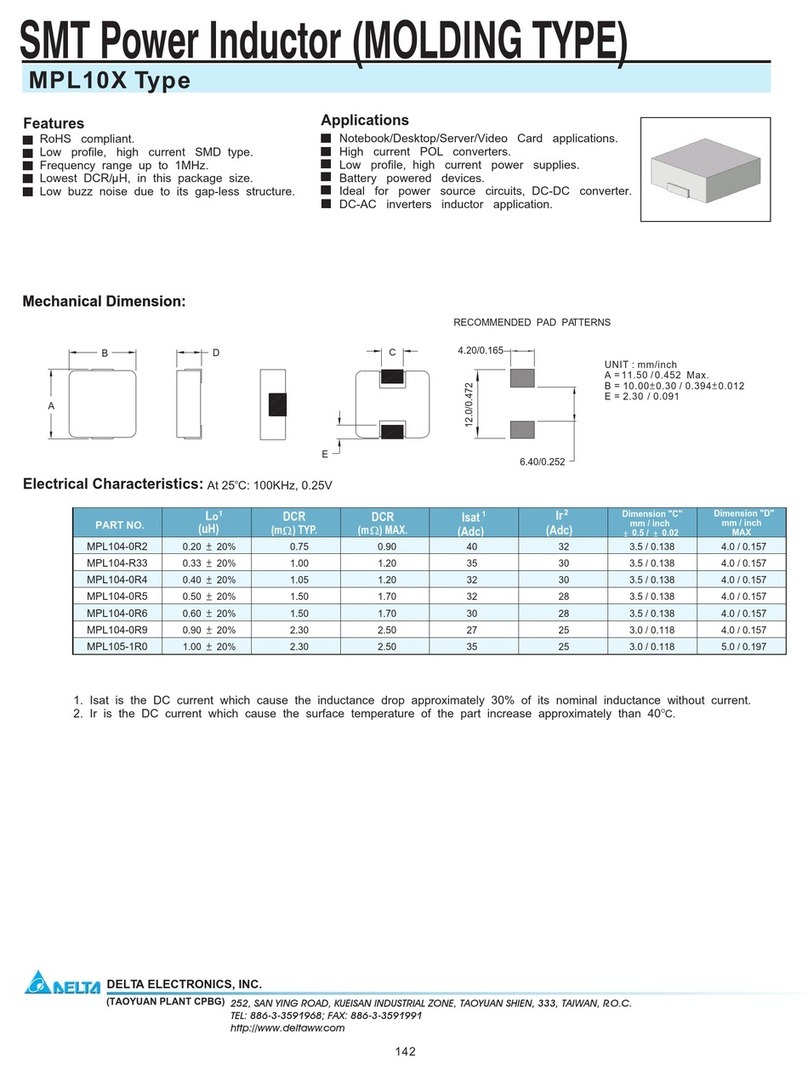

Delta Electronics

Delta Electronics SMT Power Inductor MPL10X Specifications

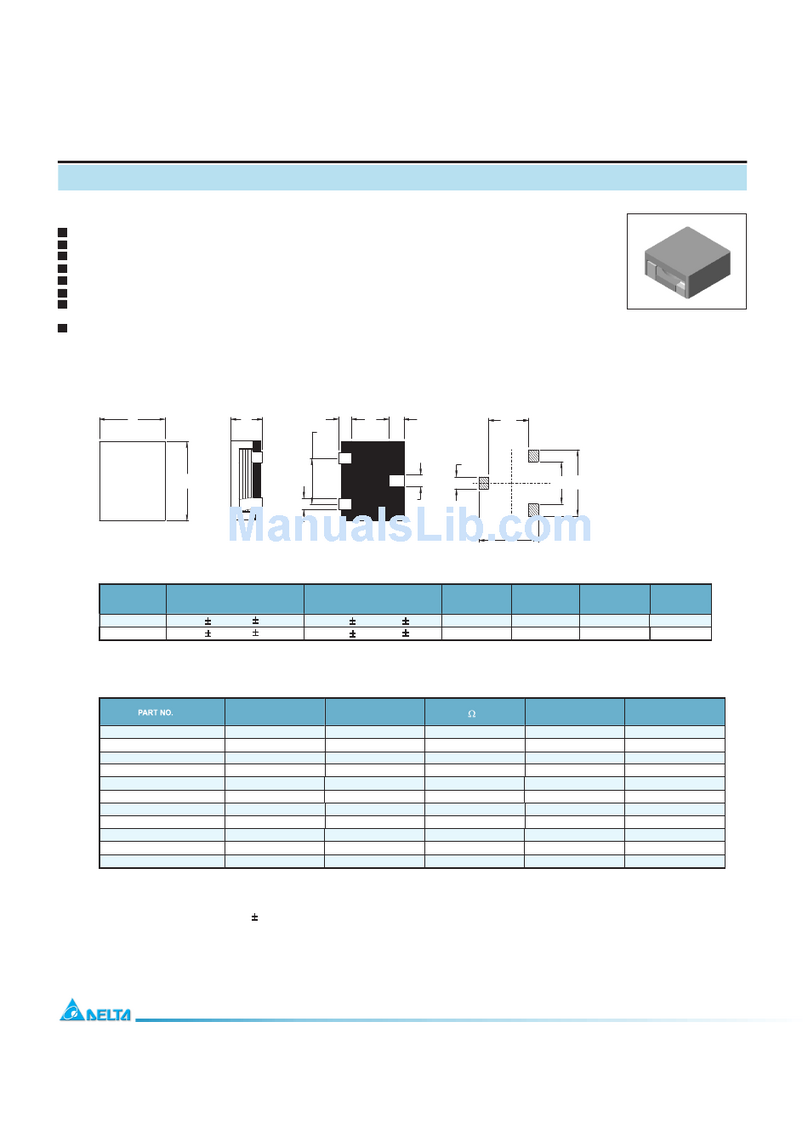

Delta Electronics

Delta Electronics HMP1350 Specifications

Delta Electronics

Delta Electronics HCB1060 Specifications

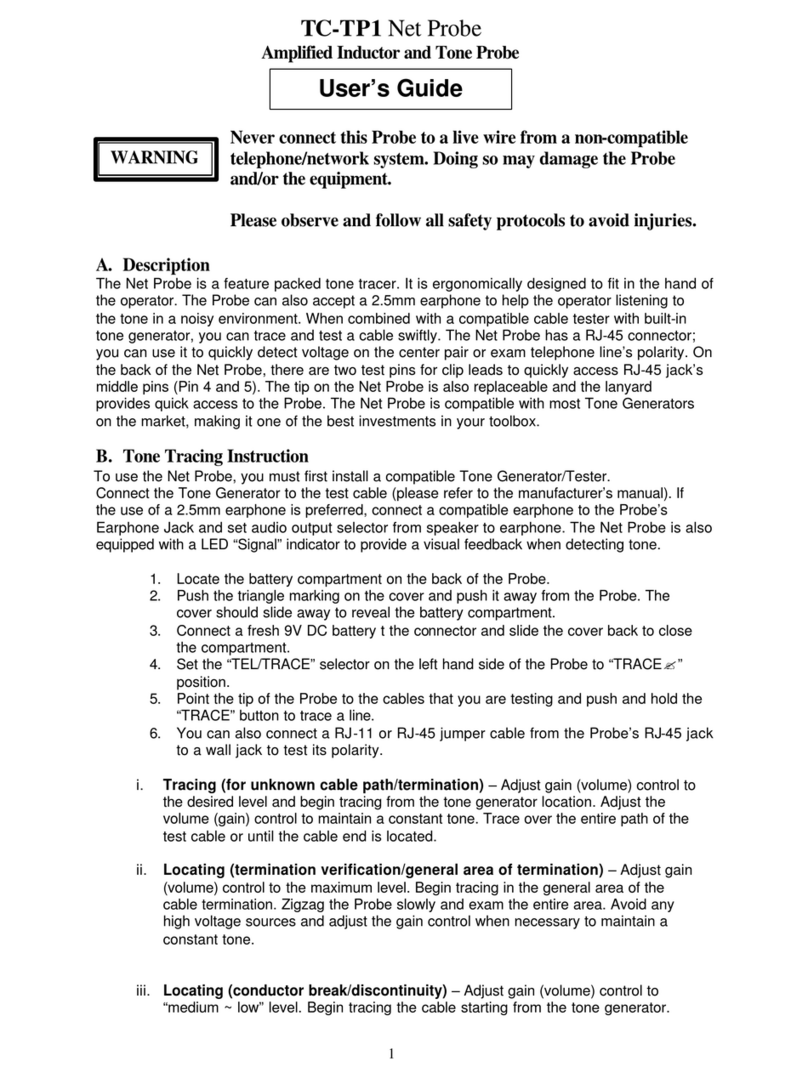

TRENDnet

TRENDnet TC-TP1 user guide

Delta Electronics

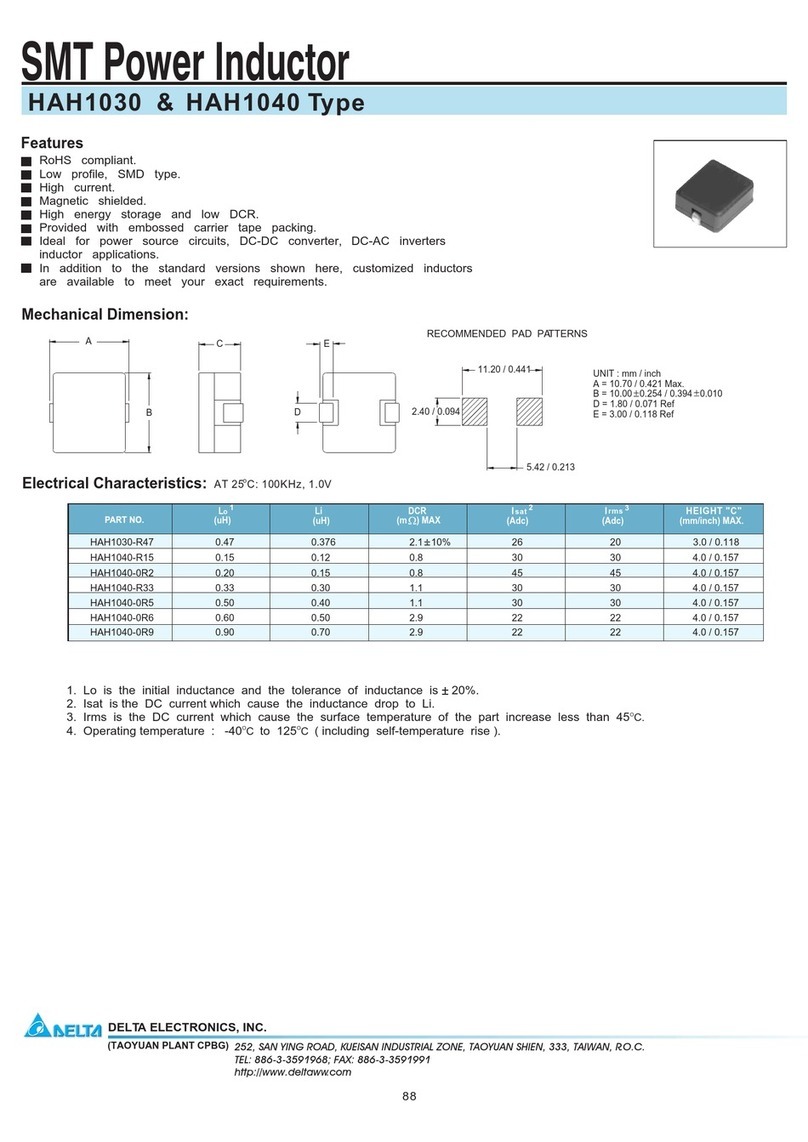

Delta Electronics SMT Power Inductor HAH1030 Product specifications

Delta Electronics

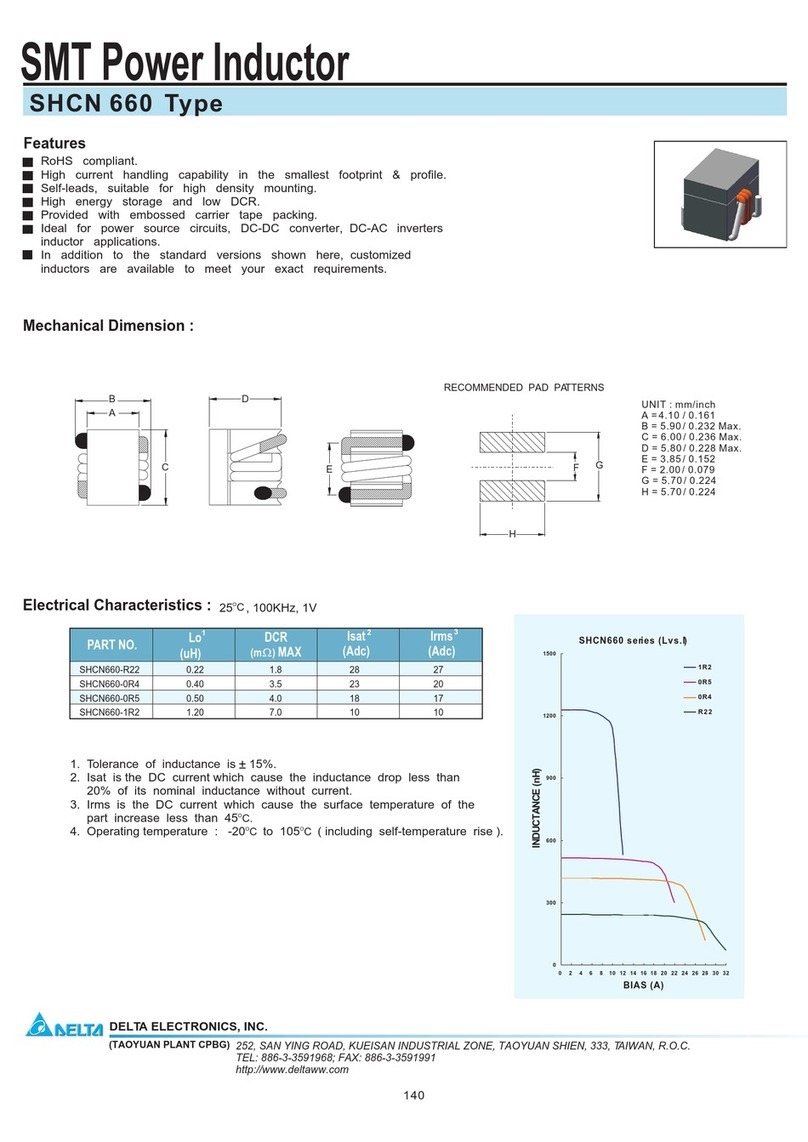

Delta Electronics SMT Power Inductor SHCN 660 Specification sheet

Delta Electronics

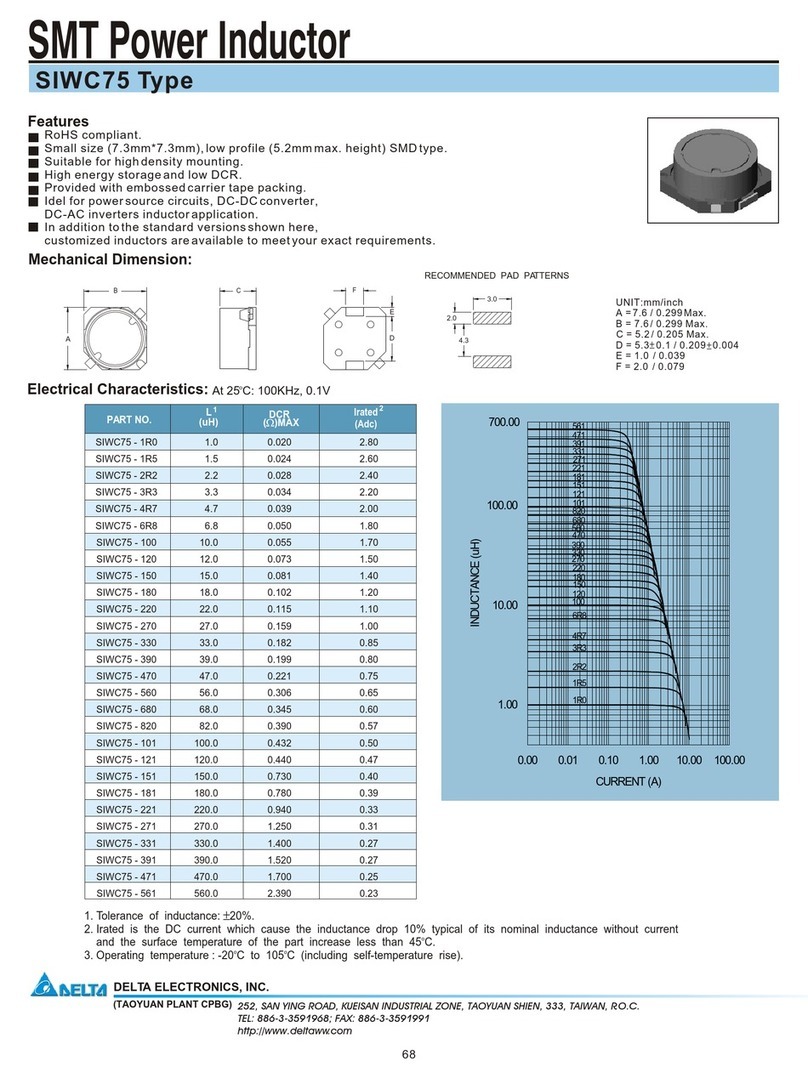

Delta Electronics SIWC75 Specification sheet

Siemens

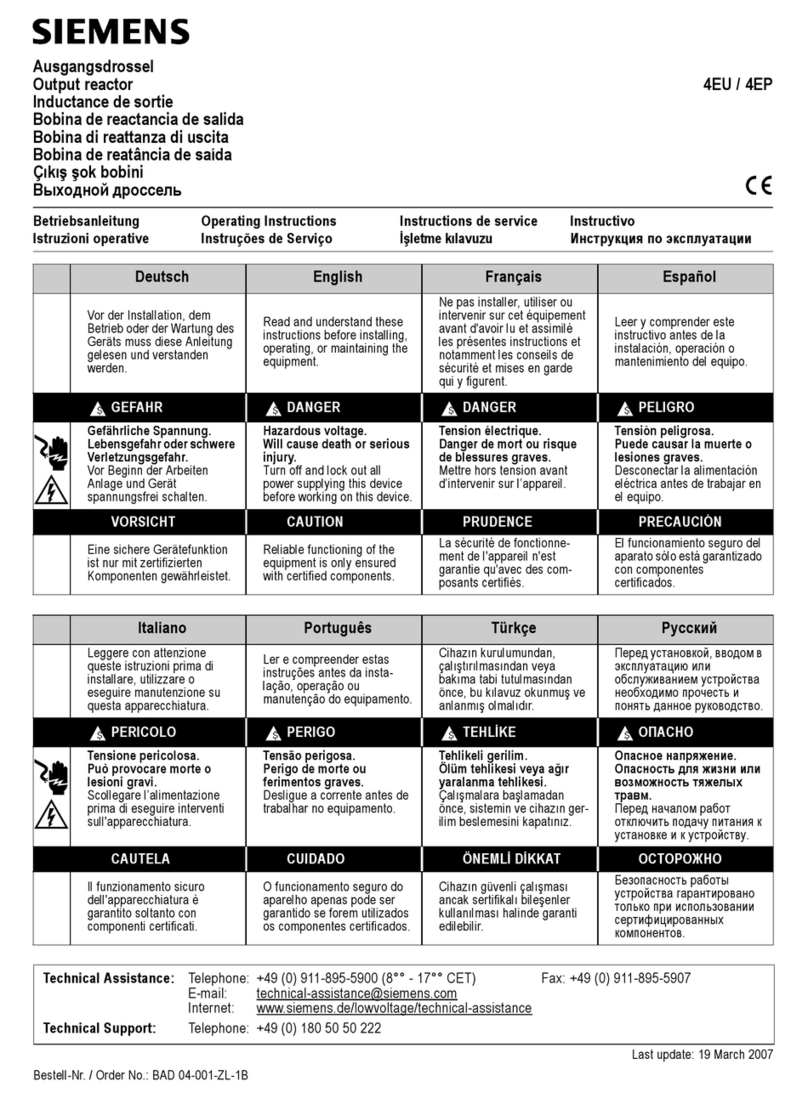

Siemens 4EU operating instructions

Delta Electronics

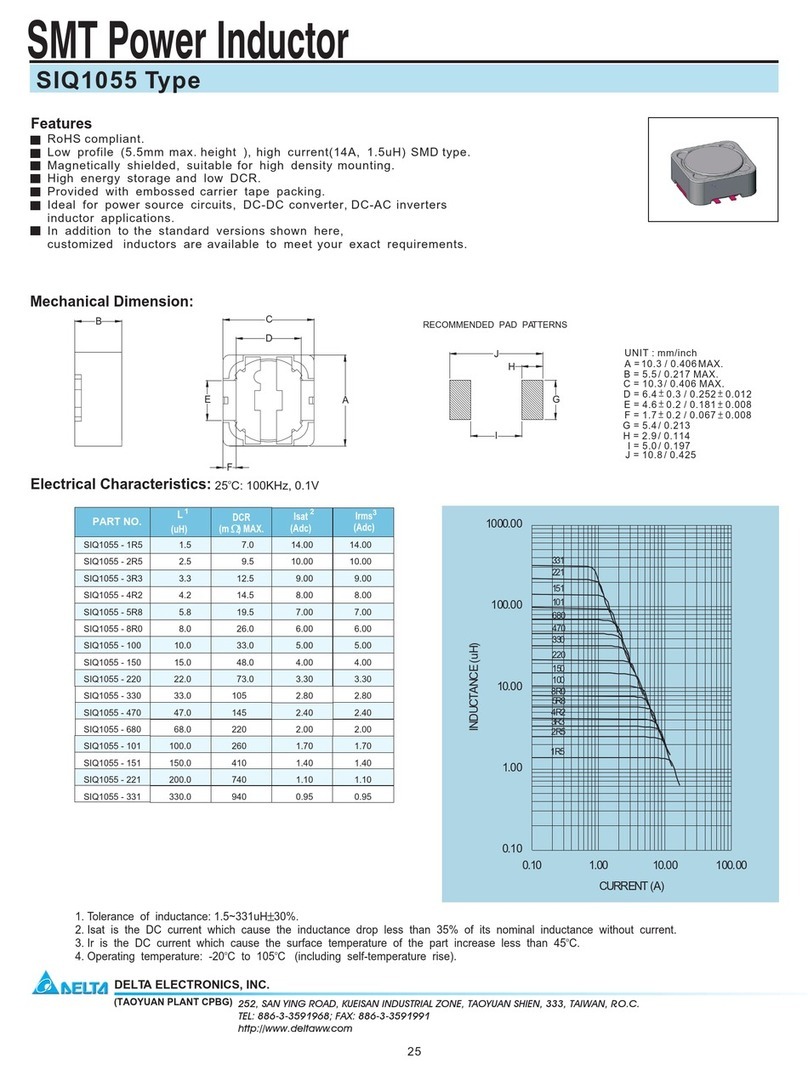

Delta Electronics SIQ1055 Specification sheet

Delta Electronics

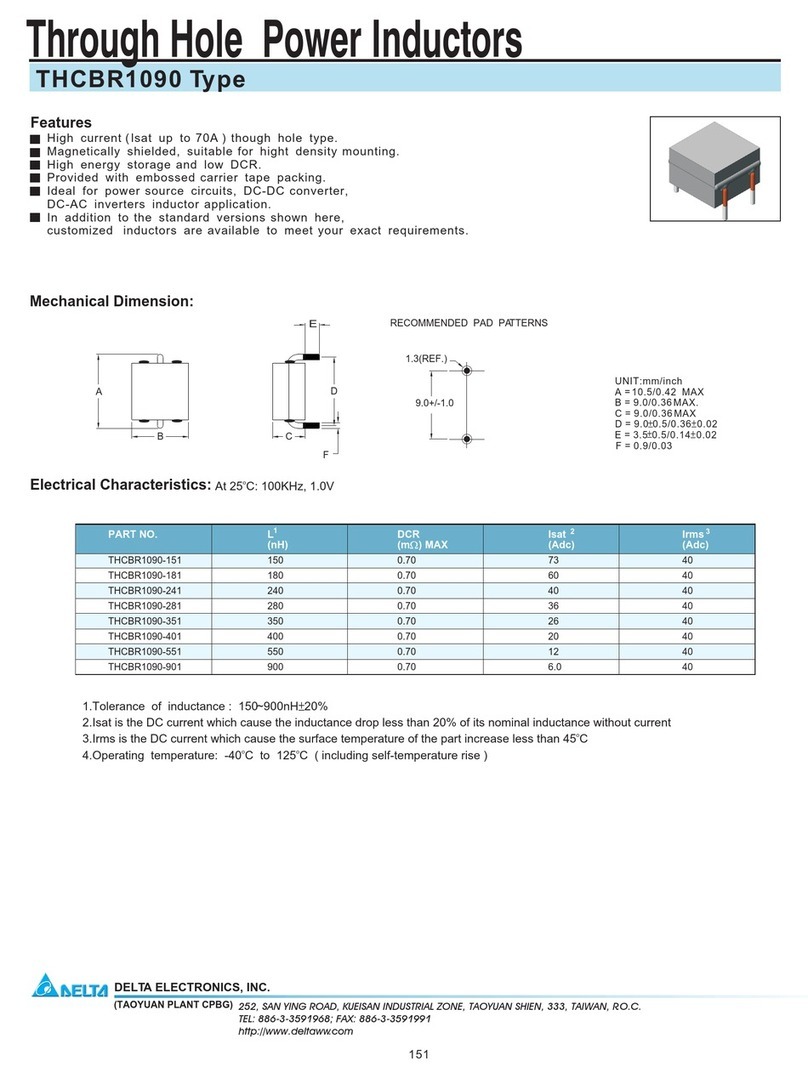

Delta Electronics THCBR1090 Specification sheet

Delta Electronics

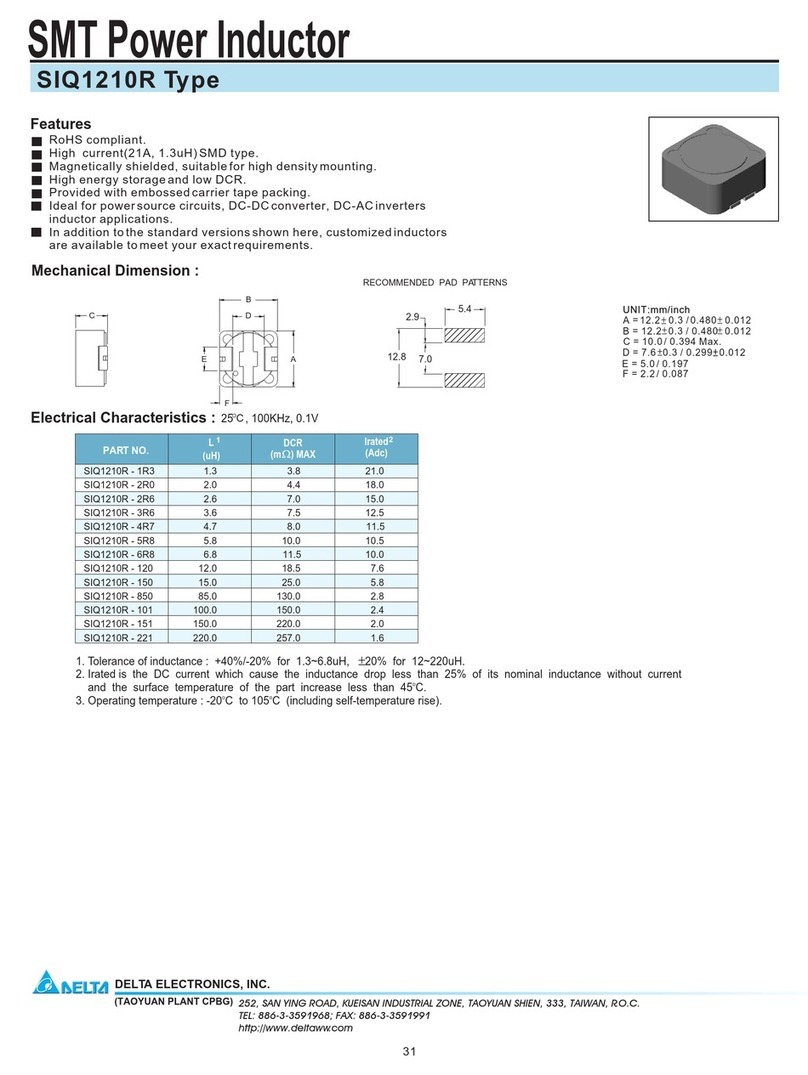

Delta Electronics SIQ1210R Specification sheet

Delta Electronics

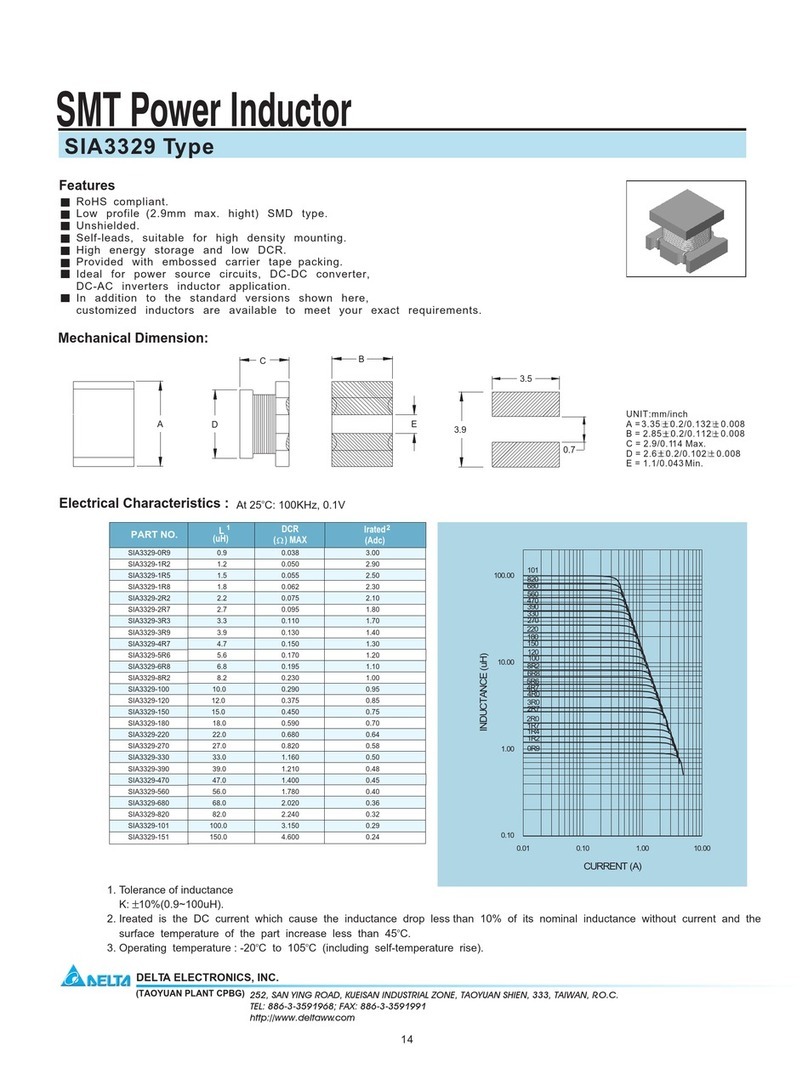

Delta Electronics SMT Power Inductor SIA3329 Specification sheet

Delta Electronics

Delta Electronics MPO135 Specifications

Delta Electronics

Delta Electronics SILM320A Specifications

Delta Electronics

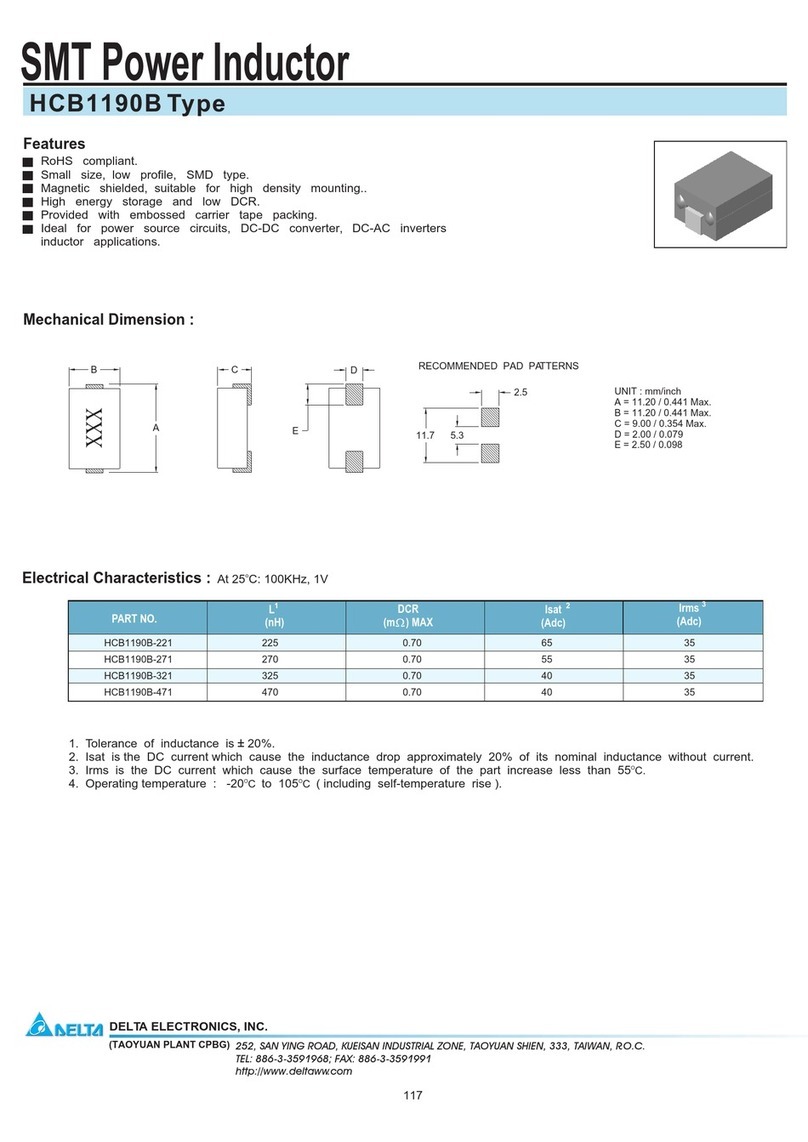

Delta Electronics SMT Power Inductor HCB1190B Specifications

Delta Electronics

Delta Electronics SIL103 Specifications

Delta Electronics

Delta Electronics HCB1175B Specifications

Delta Electronics

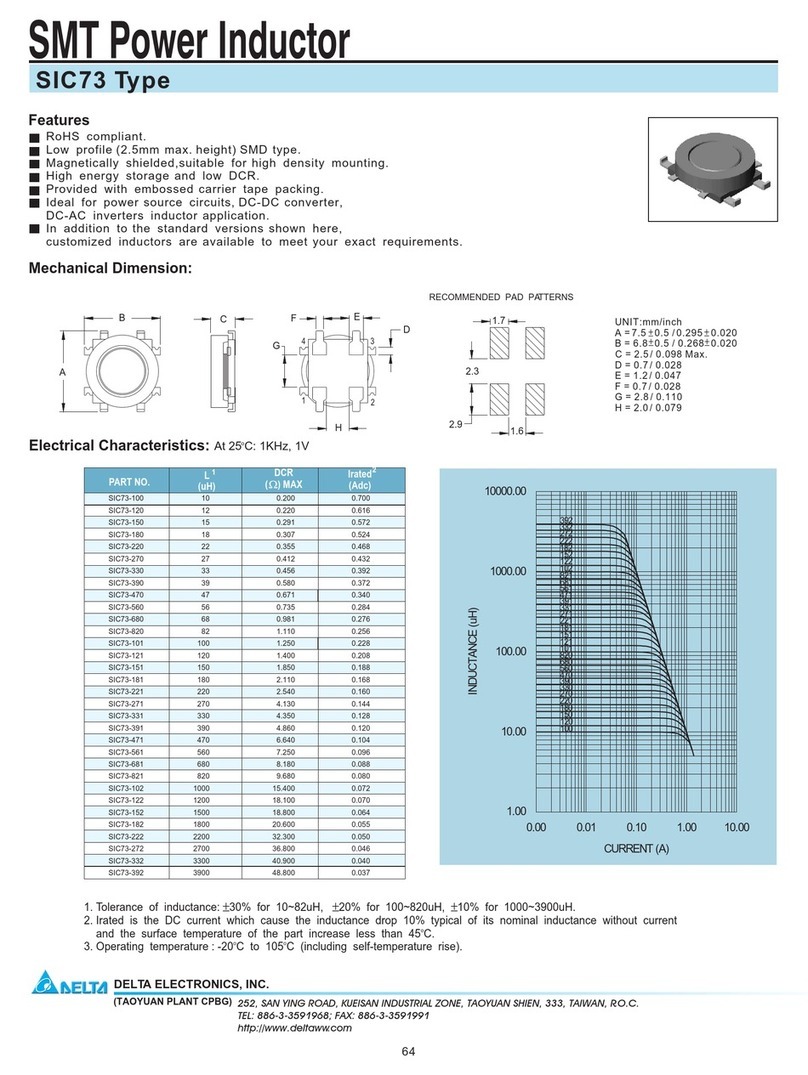

Delta Electronics SMT Power Inductor SIC73 Specification sheet