3

48” servo wire, 1-elevator

12” Y-harness, 1-flaps in fuse, 1-ailerons in fuse, 1-rudder/steering

Battery: There are many options, the safest being 2 batteries and 2 switches, though this is generally the heaviest option.

4000 mah is necessary for 8-10 flights including start up and cool down. We recommend only the safest option which is

a 4000+ mah battery with two switch leads which has sufficient burst to power the turbine start motor (Lipoly of Li Phos

is better than Li Ion). For the SuperBee we recommend a TBM 4-cell square Li-Ion with 2 JR and 1 Multiplex leads. The

JR leads go to two MPI Miracle switches for charging and checking, and the Multiplex goes to the turbine ECU.

Switches & Regulators: We recommend 2 though the reduced vibration is much less damaging to the electronics on

board.

Loctite: Even though vibration is minimal, we recommend using a thread locker for any metal to metal screws.

Epoxy: to join the wing halves

Cable ties, Foam Rubber & Velcro: to hold the receiver and cables in place.

Do not join the fuselage together yet.

GLUE EVERYTHING AND ANYTHING WITH THIN AND THICK CA

1) As will all ARF’s, you should go over every joint. First use thin CA, then use thick Ca in every joint that you can

reach.

2) WING HOLD DOWNS IN FUSELAGE: Be sure that the balsa blocks and the plywood under the balsa blocks

which act as the wing hold down blocks in the fuselage are well glued. Add hardwood triangle, ply or square stock (not

included) as an extra precaution.

3) Look inside the wing through the inspection hole. Enlarge if necessary. If there is a visible gap between the rib

and the sheeting, contact TBM. You may not notice glue in the joint, this is typical. Only if there is a visible gap is there an

issue. It is a good idea to squirt a thin CA into the inspection hole to be sure that what you see is will glued. The center

wing spar and the first inner ply rib are important to the structure of the wing. It is better to use a little extra care to avoid

a problem later.

4) Test all the hinges by pulling on them and flexing them to see if they are loose at all. Reglue all the hinges if there is any

question as to their integrity. Use thin and thick CA as required. Usually one or two drops of thin CA and possibly one drop

of thick CA if there are any gaps is required. MF Models is not responsible for crashes due to hinge issues.

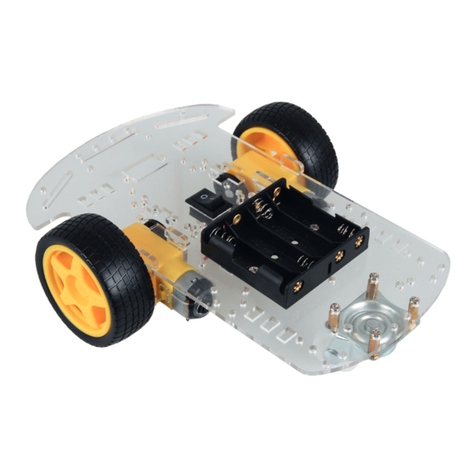

Nosewheel Installation

1) Assemble the nose wheel bracket with tire and brake as shown on the package and

the photo here. The bracket is a common part. The brake was added to the package

later.

2) Install nose wheel bracket as shown. If you have a 2 piece fuse-

lage, install the bracket before joining the 2 halves of the fuselage.

3) Install brake servo (Hitec HS-225).

4) Install steering servo

5) In the photo on the left, the nose of the plane is pointed to

the left. Use this orientation for the coil springs in the nosewheel,

brake arm and paddle.This orientation is necessary for the springs

in the nosewheel to coil up properly when the brake is used, or if an

obstruction in the runway is encountered.

6) The brake is more effective when the spinning tire comes up into the brake as shown. The Kevlar

cable is connected to the brake servo with a spring. The spring is inside the fuselage. The spring is

required to mask and irregularities and wear in the system and to reduce the strain on the servo. The

spring must be fairly strong because the force exerted onto the tire must be high enough to almost

lock the tire up completely.