True-Surface Vibe V User manual

1

2

3

TABLE OF CONTENTS

Serial Number Reference Form ….....................................................................................................4

Vibe V Introduction .........................................................................................................5

Warranty Information .........................................................................................................6

Fact Sheet .........................................................................................................7

Tips for Safe Operation/Consistent Greens .........................................................................................................8

Select-A-Vibe Dial Procedure .........................................................................................................9

RSM Replacement Notice .......................................................................................................10

Counterbalance/Pulley Notice .......................................................................................................11

TRUE-SURFACE®VIBE V ROLLERS SCHEMATICS AND INSTRUCTIONS

Vibe V Base Schematic/Parts Listing .......................................................................................................12

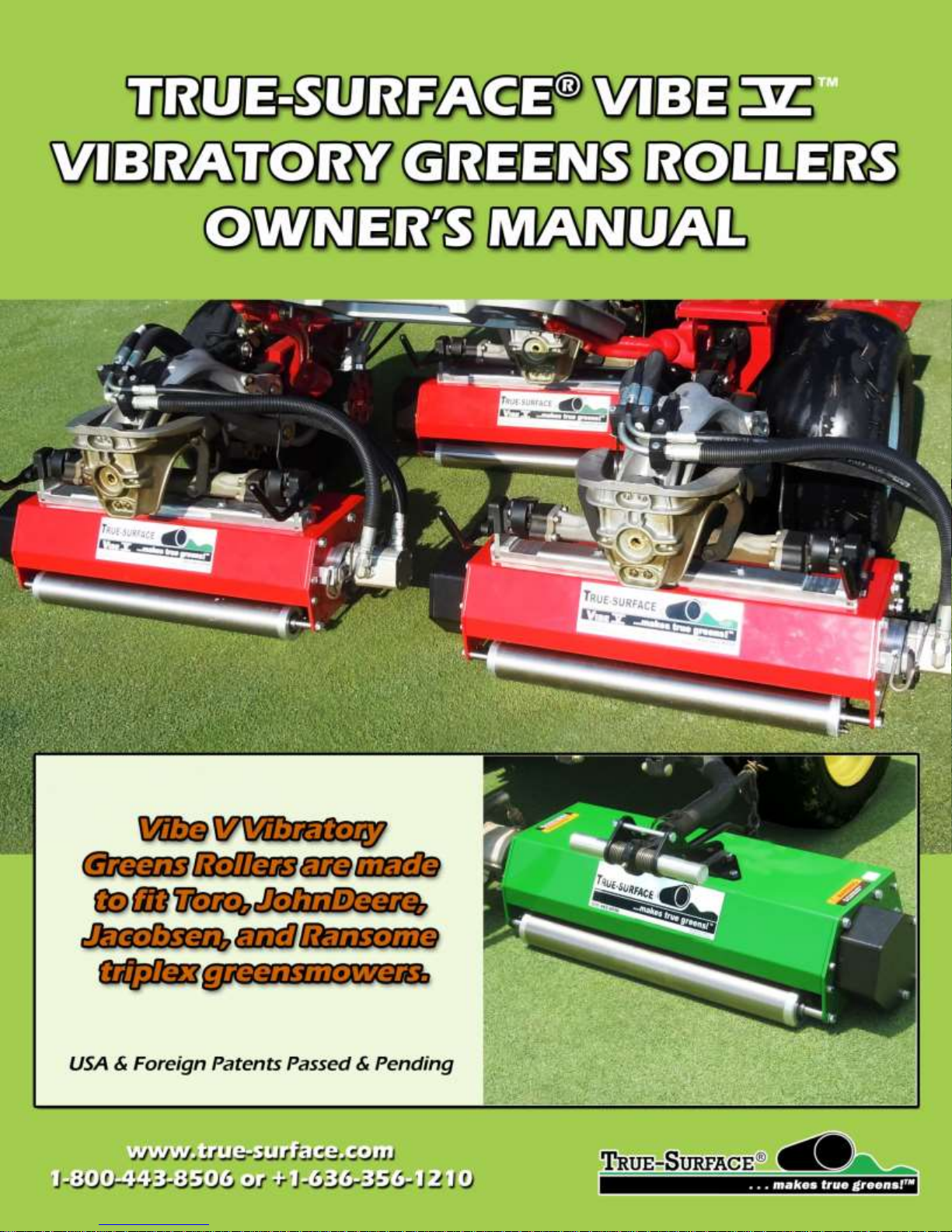

True-Surface®Vibe V to fit Toro Models .......................................................................................................15

True-Surface®Vibe V to fit Jacobsen Models.......................................................................................................33

True-Surface®Vibe V to fit John Deere Models...................................................................................................51

True-Surface®Vibe V to fit Ransome & G-Plex Models......................................................................................65

ADDITIONAL INFORMATION

Adaptation Kit Instructions .......................................................................................................72

Frame End Removal Instructions .......................................................................................................73

Drive-End Reversal Instructions .......................................................................................................73

Vibe V Upgrade Kit Schematic/Instructions .......................................................................................................74

Warranty Registration Form .......................................................................................................83

Copyright © 2007 by Turfline, Inc.

4

INFORMATION ABOUT YOUR TRUE-SURFACE®

VIBRATORY GREENS ROLLING SYSTEM:

DATE PURCHASED: __________________

SERIAL NUMBER: __________________

OPERATION NOTES: ______________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

___________________________________________________

This page is for your reference only. To activate the warranty on your new rollers, please fill out

and fax the warranty card located in the back of this manual.

For parts and/or service, please call 1-800-443-8506; or if you are calling internationally, please

call +1-636-356-1210.

Orders placed before Noon CST can be shipped the same day via UPS.

5

VIBE TM Introduction

Congratulations on the purchase of your new True-Surface®VIBE TM Vibratory Greens Rolling System from

Turfline, Inc.

Please review this owner's manual before unpacking the rollers.

It is imperative to complete the warranty form in the back of this manual and return it to Turfline, Inc. via mail or

fax. Doing this will activate your product’s two year warranty.

Maintenance of the rollers is minimal. Clean Sand and dirt from rollers using air. Pressure washing units is not

advised because it could damage the bearings.

The proper belt tension is 1/4" deflection, and is preset at the factory. If you need to adjust the belt tension, loosen

the three nuts that secure the roller bearing to EACH end plate and adjust accordingly in the slotted holes. Retighten

all of the six nuts, and replace the belt guard.

In the enclosed manual are the following:

Installation Instructions

Parts Drawings and Numbers

Mounting Kit Conversions

Adaptation Kits

Warranty and Safety Information

If you have any technical questions or need to order parts, please call

Turfline, Inc. at 1-800-443-8506

Orders received by Noon CST will be shipped the same day via U.P.S. ground to anywhere in the continental United

States.

Thank you for choosing the best set of American-made rollers available!

Certificate & Declaration of Conformity for CE Marking

Hereby, Turfline, Inc. declares that the True-Surface®Vibratory Greens Roller and all of its

components are in compliance with the essential requirements and other relevant provisions.

The True-Surface®Vibratory Greens Roller is classified within the following EU Directive: EU

Machinery Directive 98/37/EC & 2006/42/EC, and further conform with the following EU

Harmonized Standards: EN 12100-1:2003 EN 12100-2:2003 EN ISO 214121-1:2007 EN ISO 4254-1:2005.

© 2009 Turfline, Inc. All rights reserved.

Reproduction, transfer, distribution, or storage of part or all the contents in this document in any form without the

prior written permission of Turfline, Inc. is prohibited.

US & Worldwide patents pending.

Turfline, Inc. operates a policy of ongoing development. Turfline, Inc. reserves the right to make changes and

improvements to any of the products described in this document without prior notice.

Table of contents