............ www.truemfg.com ............

True Food Service Equipment, Inc.

4 4

WARNING!

SAFETY INFORMATION

WIRING CONVERSION

At Receptacle Box

1.

2.

3.

4.

At Breaker Panel

1.

2.

3.

4.

5.

6.

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the ground prong from the power cord.

For personal safety, this appliance must be properly grounded.

USE OF ADAPTER PLUGS

NEVER USE AN ADAPTER PLUG! Because of potential safety hazards under certain conditions, we strongly recommend

against the use of an adapter plug.

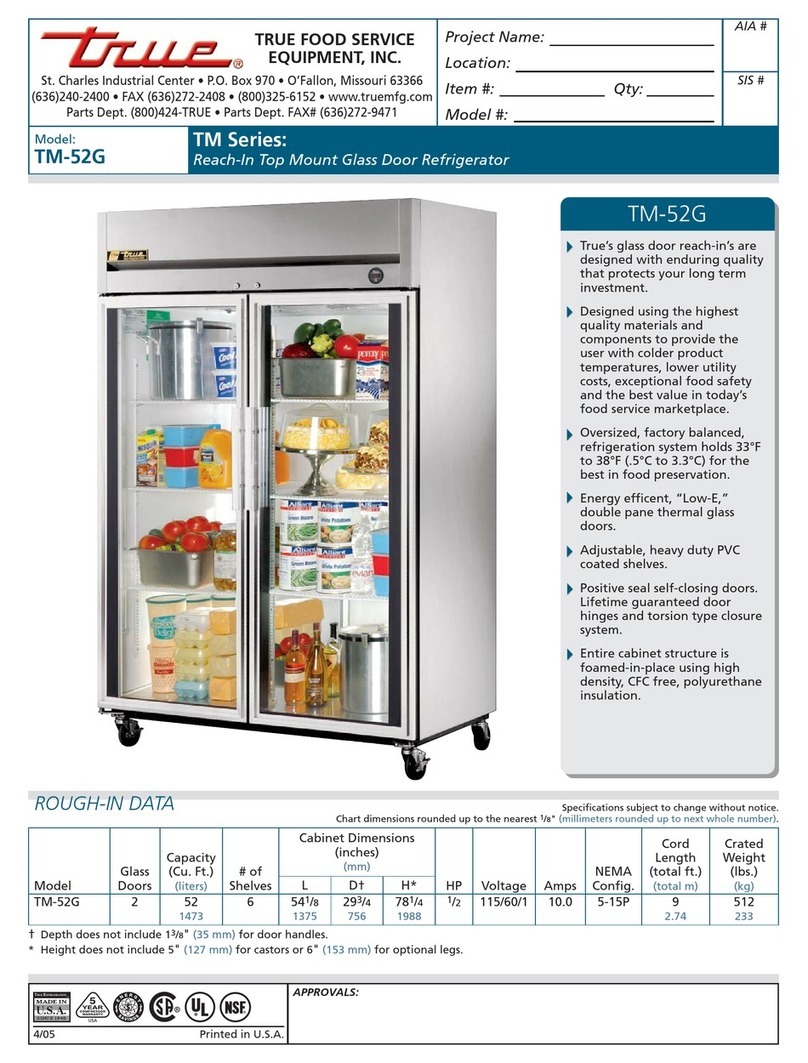

T-72F WIRING CHANGES (110V Application Only)

Previous design: 4 prong plug NEMA 14-20R - 4 wire circuit (see image 1).

Current design: 3 prong plug NEMA 5-20R - 3 wire circuit (see image 2).

(North America Use Only!)

1 2

NOTE: It is the customer’s responsibility to make sure receptacle wiring

meets all local electrical codes. TRUE recommends hiring a licensed qualified

electrician to make this change.