Trueheat RCB User manual

Trueheat RCB Infrared Gas Broiler—September 2017 Page 1 of 16

INSTALLATION & OPERATION MANUAL

RCB

INFRARED GAS

BROILER

Trueheat RCB Infrared Gas Broiler—September 2017 Page 2 of 16

CONGRATULATIONS!

Thank you for choosing Trueheat.

This product has been specifically designed by Comcater to meet a wide range of applications

and represents the best quality and highest value equipment.

Please read the instruction manual carefully to ensure the safe and reliable operation and

performance of your equipment.

Should you require service, you will be supported by Comcater’s trained and qualified service

network.

COMCATER AUSTRALIA

www.comcater.com.au

National Head Office

156 Swann Drive, Derrimut, VIC 3030

Phone: 03 8369 4600

Fax: 03 8369 4699

Email: sales@comcater.com.au

Technical Services Group

Phone: 1800 810 161

Fax: 03 8369 4696

Email:

Equipment Servicing (24/7)

service@comcater.com.au

Equipment Spare Parts

spares@comcater.com.au

Technical Support

techsupport@comcater.com.au

Comcater QR Codes

Comcater Website Log a Service Call Online Spare Parts Store

Reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorised in writing by Comcater. Comcater reserves the

right to change design and specifications without prior notice. © Copyright Comcater Pty Ltd, August 2017.

Trueheat RCB Infrared Gas Broiler—September 2017 Page 3 of 16

TABLE OF CONTENTS

INTRODUCTION

Warranty...........................................................................................................................4

Date Plate Location ..........................................................................................................4

WARNINGS................................................................................................................................ 5

GENERAL INFORMATION .........................................................................................................6

SPECIFICATIONS

Dimensions, Weight & Installation Drawings.................................................................... 7

Accessories & Optional Accessories ............................................................................... 7

Gas Configuration ........................................................................................................... 8

INSTALLATION

Gas Connection .............................................................................................................. 11

Installation Clearances ................................................................................................... 11

Levelling .......................................................................................................................... 11

CONVERSION INSTRUCTIONS ................................................................................................12

COMMISSIONING / BURNER ADJUSTMENT

Leak Test ....................................................................................................................... 12

Test Point Pressure ........................................................................................................ 12

Pilot Adjustment ............................................................................................................. 12

Target Adjustment .......................................................................................................... 12

OPERATION

First Time Use ................................................................................................................13

Daily Operation ...............................................................................................................13

MAINTENANCE

Daily Cleaning ................................................................................................................14

Recommended Service Plan .......................................................................................... 15

TROUBLESHOOTING

Burner will not light .........................................................................................................16

Broiler isn’t getting hot ....................................................................................................16

Trueheat RCB Infrared Gas Broiler—September 2017 Page 4 of 16

INTRODUCTION

GENERAL

This Trueheat RC Series is designed for commercial catering purposes only and is designed to

deliver high end performance to fulfill the busy demands within a commercial kitchen. incorporates

a wide range of design features. It is available in various appliances and configurations including:

Ranges with open burners, griddles and oven and as a top only unit.

Barbecues, salamanders, pasta cookers and deep fryers.

This versatility will satisfy a wide range of customer needs.

WARRANTY

12 months replacement of parts including labour, for goods found to be faulty due to defective

materials, manufacture and/or workmanship. This warranty is void if installation, operation and/or

maintenance of the equipment are not in accordance with manufacturer’s instructions and

recommendations.

Unauthorised modifications to the equipment will void the warranty and product certification.

All warranty work will be undertaken in normal working hours from Monday – Friday 8:00am to

4:00pm

Warranty does not extend to:

Damages caused in shipment

Damage as a result of incorrect installation

Damage as a result of incorrect operation

Damages caused by Unauthorised service and use of non-original parts

Gas supply issues to the equipment

Calibration of thermostats after 90 days

Failure resulting from improper maintenance

Failure as a result of tampering with, removal of, or changing any pre-set control or

safety device

After hours Service - Penalty rates apply for afterhours service.

Conditions as defined in Comcater terms and condition of sale, a copy of Comcater’s terms and

conditions of sale can be found at www.comcater.com.au/terms

For all warranty work, authorized service, genuine and authorized spare parts, please contact

Comcater Service 1800 810 161.

Please ensure you quote the Model and Serial Number of the unit.

The Model and Serial Number of the unit is recorded on the sales invoice, and also shown on

the top right side of the front control panel. The data plate is located behind the front control

panel.

NOTE: Data Plate is located behind the control panel

Trueheat RCB Infrared Gas Broiler—September 2017 Page 5 of 16

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE

OR MAINTENANCE CAN CAUSE INJURY OR DEATH. THE

INSTRUCTION MANUAL MUST BE READ CAREFULLY BEFORE

INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

TO BE INSTALLED ONLY BY AN AUTHORISED PERSON IN

ACCORDANCE WITH AS 5601, LOCAL AUTHORITY, GAS,

ELECTRICITY, ANY APPLICABLE STATUTORY REGULATIONS AND

MANUFACTURER REQUIREMENTS.

THIS EQUIPMENT IS DESIGNED FOR COMMERCIAL CATERING

PURPOSES AND WILL GENERATE SIGNIFICANT HEAT. HOT

SURFACES WILL CAUSE BURNS. A HAZARD AND RISK

ASSESSMENT MUST BE UNDERTAKEN BY OWNERS AND ALL

OPERATORS MADE AWARE OF THESE.

DO NOT STORE OR USE FLAMMABLE LIQUIDS NEAR THIS

APPLIANCE.

DO NOT SPRAY AEROSOLS NEAR THIS APPLIANCE WHILE IT IS IN

OPERATION.

INSTALLATION CLEARANCES AS SPECIFIED MUST BE OBSERVED.

IF YOU SMELL GAS, TURN THE UNIT OFF AND THE MAIN GAS

SUPPLY VALVE TO THE UNIT. CONTACT YOUR GAS SUPPLIER OR

AN AUTHORISED PERSON.

BEFORE TURNING ON THE MAIN GAS SUPPLY, CHECK THE UNIT TO

BE CERTAIN THAT ALL THE VALVES ARE IN THE “OFF” POSITION.

WARNINGS

Trueheat RCB Infrared Gas Broiler—September 2017 Page 6 of 16

GENERAL INFORMATION

INSPECTION

Please inspect the unit on receipt. If the unit is damaged, contact the carrier immediately

and file a damage claim with them. Save all packing materials when filing a claim. Freight

damage claims are the responsibility of the purchaser and are not covered under warranty.

OPERATOR MANUAL

This manual contains important information for your safety and the installation,

operation, maintenance and service of this equipment. Please read the manual carefully

and ensure all operators of the equipment are aware of the contents and safety

requirements. You must also assess all hazards and risks associated with the operation

of the equipment in your environment and advise all operators of these.

INSTALLATION

This equipment must be installed by an authorized person in accordance with AS 5601,

local authority, gas, electricity, any applicable statutory regulations and manufacturer

requirements.

GAS CONNECTION

The appliance must be connected by an authorized person to the gas type specified on

the unit. The gas type is shown adjacent to the rear gas connection point and on the data

plate. Connect to and use only the correct type of gas.

GAS PRESSURE

The authorized person installing this equipment must ensure that the gas operating pressure is

the same as shown on the rating plate and that there is sufficient gas volume for the appliance to

operator correctly.

COMMISSIONING

The authorized person installing this equipment must commission the equipment in accordance

with AS 5601 - gas leakage, operational checking, adjustments and instructing the owner on use

of the equipment are prescribed requirements.

Trueheat RCB Infrared Gas Broiler—September 2017 Page 7 of 16

SPECIFICATIONS

DIMENSIONS, WEIGHT & INSTALLATION DRAWINGS, OPTIONAL ACESSORIES

The following tables and drawings provide all dimension, weight and optional accessories.

DESCRIPTION RCB4 RCB6 RCB9

Weight (kg) 56 92 132

Width (mm) 400 600 900

Depth (mm) 803 803 803

Height (mm) 445 445 445

Height on stand

(mm) 1135 1135 1135

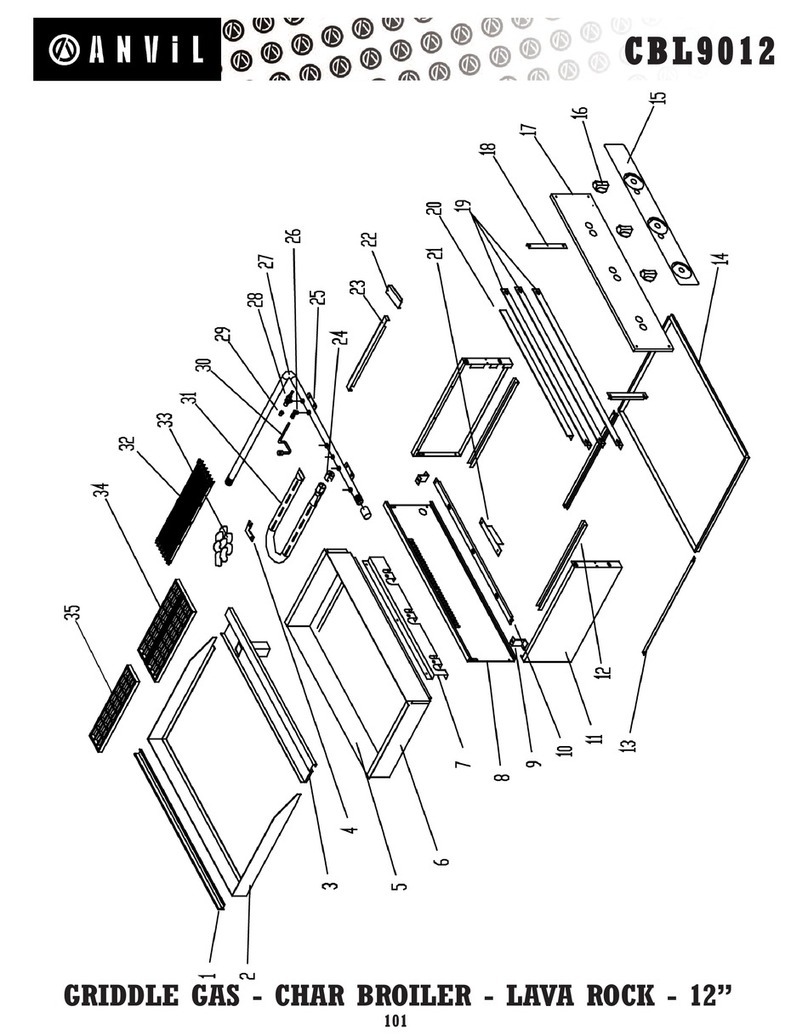

IMAGE PART NO. DESCRIPTION Qty

RCSTD4 400mm Stand complete with shelf, Suits RCB4 Counter-Top models 1

RCSTD6 600mm Stand complete with shelf, Suits RCB6 Counter-Top models 1

RCSTD9 900mm Stand complete with shelf, Suits RCB9 Counter-Top models 1

THSP-B05002 Adjustable legs for RCT Counter-Top mounting only 4

432018-900HK 900mm 3/4” flexible gas hose with quick connect fittings & restraint

1

432018-1200HK 1200mm 3/4” flexible gas hose with quick connect fittings & restraint

RCB4 RCB6 RCB9 RCB9 Shown

Trueheat RCB Infrared Gas Broiler—September 2017 Page 8 of 16

SPECIFICATIONS (cont’d)

GAS CONFIGURATION

Note: When checking gas pressure, ensure that all other equipment on the same

line is turned “ON”.

NOMINAL GAS CONSUMPTION

TO BE COMPLETED BY AN AUTHORISED PERSON.

ONLY CONNECT THE APPLIANCE TO THE GAS TYPE IT HAS

BEEN CONFIGURED FOR. THE GAS TYPE IS SPECIFIED ON

THE DATA PLATE AND AT THE REAR OF THE APPLIANCE.

DESCRIPTION NATURAL GAS PROPANE GAS

Minimum Gas Inlet Pressure 1.13 kPa 2.75 kPa

Test Point Pressure 1.00 kPa 2.50 kPa

Main Injector 1.89 mm 1.13 mm

Pilot Orifice Size 21 Size 14

Low Flame Adjustment 3 turns out from fully in 3 turns out from fully in

Commissioning

Procedure

- Regulator Adjustment

Set the gas pressure at

the main gas valve

while the burner is

running.

Set the gas pressure

at the main gas valve

while the burner is

running.

MODELS NATURAL GAS PROPANE GAS

RCB4 33 MJ/h 30 MJ/h

RCB6 66 MJ/h 60 MJ/h

RCB9 99 MJ/h 90 MJ/h

Trueheat RCB Infrared Gas Broiler—September 2017 Page 9 of 16

INSTALLATION

Note: Installation is the responsibility of the owner.

GAS INLET CONNECTION

3/4” BSP Female.

GAS CONNECTION POINT

The gas connection point is located at the

bottom rear of the Broiler as shown in the

diagram on the right.

GAS CONNECTION

The appliance must be connected by an authorised person to the gas type specified on

the unit. The gas type is shown adjacent to the rear gas connection point and on the data

plate. Only connect to and use the specified gas type that the Broiler has been set for.

Do not remove or modify any of the gas piping within the Broiler. The gas connection must

be made at the connection point provided.

Removal or modification of the gas piping within the Broiler will void the gas certification &

manufacturer’s warranty. This may also affect the customer’s insurance policy.

The authorised person installing this equipment must comply with AS 5601

requirements. Prescribed requirements include, commission the equipment, gas

leakage testing, operational checking and adjustments.

All units are tested and adjusted at the factory; however, burners and pilots must be checked at the

installed location and adjusted if necessary.

THIS EQUIPMENT MUST BE INSTALLED BY AN AUTHORIZED

PERSON IN ACCORDANCE WITH AS 5601, LOCAL AUTHORITY,

GAS, ELECTRICITY, ANY APPLICABLE STATUTORY

REGULATIONS AND MANUFACTURER REQUIREMENTS.

Trueheat RCB Infrared Gas Broiler—September 2017 Page 10 of 16

INSTALLATION ON STAND

The Broiler can be installed on a stand. The Broiler is positively

located on the stand by inserting four bolts from the underside of the

stand into nutserts in the Broiler.

WARNING: Ensure the Broiler is fastened to the stand.

Adjustable feet are included on the leg stands and

allow the unit to be levelled to the floor in the installed

location. Stands with Castors are also available

option.

INSTALLATION ON COUNTER TOP

The Broiler can be installed on a non-combustible

counter top or refrigerated cabinet with optional

100mm adjustable counter top legs. It is

recommended that the appliance is secured to the

counter to prevent unintended movement

INSTALLATION CLEARANCES

The MINIMUM clearance from combustible surfaces is

150 mm rear and 250mm on either side. See diagram

below.

Adequate clearance must also be provided for service.

LEVELLING

To adjust the legs to level the unit to the floor and/or to slightly adjust the height of the unit,

raise the front of the unit and adjust the legs (ensure safe work practices). Similarly, raise the

back and adjust the legs.

DO NOT LAY THE UNIT ON ITS BACK. ENSURE THE UNIT IS LEVELLED.

Rear Clearance Side Clearance

Trueheat RCB Infrared Gas Broiler—September 2017 Page 11 of 16

COMMISSIONING

LEAK TEST

Ensure that the valve is in the OFF position.

Turn on the main gas supply valve.

Light all pilots.

Leak test the valve and fittings using approved methods.

Correct any leaks as required and re-check.

Shut off the gas valve

TEST POINT PRESSURE

The test point is located on the gas manifold behind the control panel. The test point pressure is

shown on the appliance data plate and in the Gas Configuration Table.

LOW FLAME ADJUSTMENT

The low flame adjustment screw is located on each gas valve adjacent to the control shaft.

Low flame adjustment setting is shown in the Gas Configuration Table on Page 8.

GAS CONTROLS—BEHIND CONTROL PANEL

PRIMARY AIR SETTING

The Primary Aeration shutter setting is gas type specific. When converting between gas types

ensure that the correct Primary Aeration setting and interrupter screw are used per the

diagram below.

WARNING: IF YOU ARE NOT COMPETENT IN PERFORMING ANY

SERVICE TASK OR REQUIRE ASSISTANCE, PLEASE CONTACT:

COMCATER SERVICE

Primary Air Setting Dwg Ref Required Setting

Natural Gas

Aeration Shutter Setting A25mm

Interrupter Screw (length) C30mm

Propane

Gas

Aeration Shutter Setting BFully Open

Interrupter Screw (length) D15mm

Gas control shaft

Low flame adjustment

Primary aeration shutter

Pressure test point

Trueheat RCB Infrared Gas Broiler—September 2017 Page 12 of 16

GAS CONVERSIONS

The RCB Series of Broilers can be converted to either Natural Gas or Propane Gas.

If Gas Conversion is required, Gas conversation kits are available through Comcater Spare

Parts for either gas type. Detailed Instructions are provided with the Gas Conversion kits.

The list of components below are provided in all gas conversion kits, quantities vary per model.

NOTE: To arrange a Gas Conversion contact Comcater Service 1800 810 161

CONTENTS

ONLY TO BE COMPLETED BY AN AUTHORISED PERSON

ENSURE GAS IS ISOLATED WHILST PERFORMING CONVERSION WORK.

PERFORM A LEAK TEST BEFORE IGNITING AND CALIBRATING BURNER AND

PILOT ADJUSTEMENTS.

Image Descripon

RCB GAS CONVERSION INSTRUCTIONS

MAIN BURNER INJECTORS

BURNER INTERRUPTER SCREW

PILOT INJECTORS

SPRING FOR GAS REGULATOR

or GAS TYPE LABEL FOR REAR OF APPLIANCE

or GAS TYPE LABEL FOR DATA PLATE

Model Natural Gas Propane Gas

RCB4 THSP-RCB4-GCKIT-NG THSP-RCB4-GCKIT-LP

RCB6 THSP-RCB6-GCKIT-NG THSP-RCB6-GCKIT-LP

RCB9 THSP-RCB9-GCKIT-NG THSP-RCB9-GCKIT-LP

RCB GAS CONVERSION KIT PART NUMBERS

Trueheat RCB Infrared Gas Broiler—September 2017 Page 13 of 16

OPERATION

FIRST TIME USE

Before lighting the Broiler for the first time, ensure that all package materials including the stainless steel

protective film and moisture absorption packs have all been removed from the cooking grates and drip

trays before lighting.

Use warm soapy water and a cloth to wipe down and remove any dust or metal filings that may have

settled during manufacturing.

CORRECT ASSEMBLY

Before first time use ensure that all heat baffles, infrared hoods and cooking grates have not moved

during transport. Incorrect alignment may affect the operation of the broiler.

LIGHTING INSTRUCTIONS

1. Turn the Control knob from position “off” to “Pilot” .

2. Depress control knob and hold it down and light pilot immediately with “piezo ignitor”.

Note: The pilot can been seen through the “pilot viewing hole”.

3. Once the pilot has lit, continue to hold in the control knob for 10 seconds, before slowly releasing.

(Verify that the pilot is still lit once the control knob has been released, if not repeat step 3 & 4).

4. Turn gas control knob to the “Hi-flame” position. The burner will then ignite.

5. If the pilot becomes extinguished, repeat the above procedure.

SHUTDOWN INSTRUCTIONS

1. Turn the gas control knob to the “"off" position.

2. Allow broiler to cool down before cleaning.

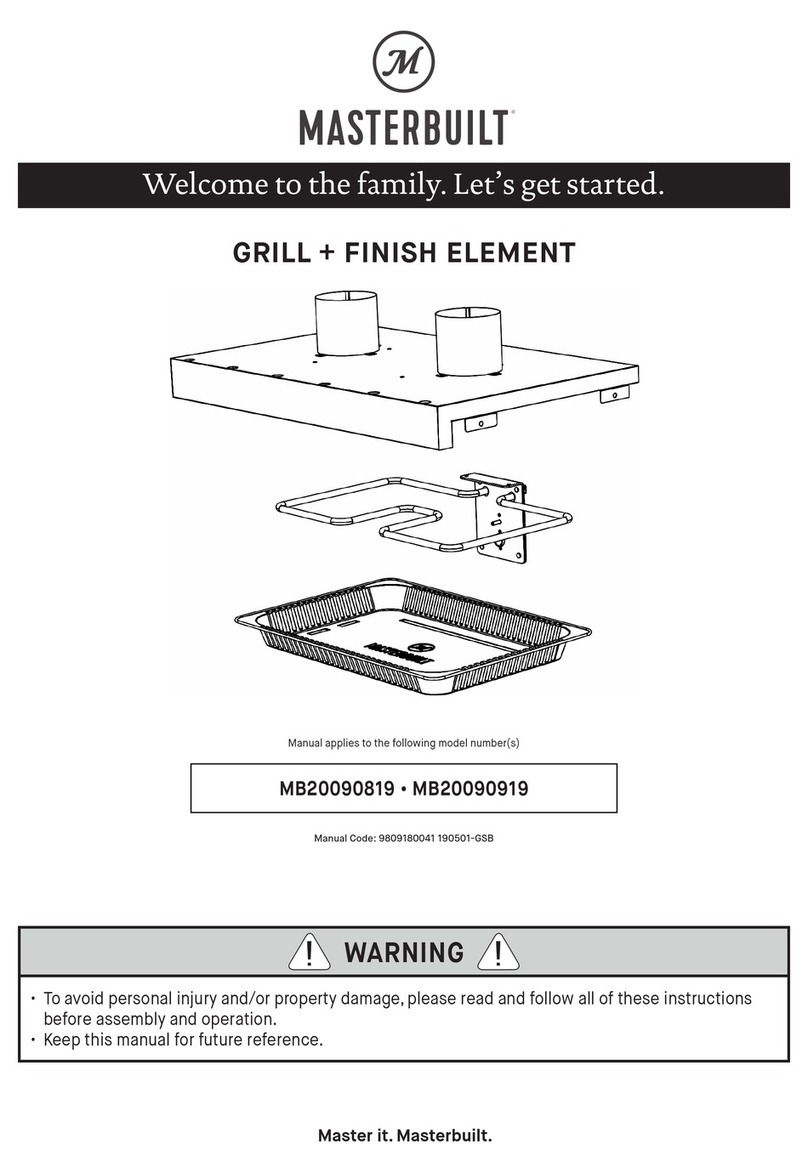

DIAGRAM - OPERATOR CONTROLS

Pilot viewing hole

Control knob marker

“Off” Position

“Pilot” Position

“Hi-flame” Position

“Low-flame” Position

Piezo ignitor

Trueheat RCB Infrared Gas Broiler—September 2017 Page 14 of 16

MAINTENANCE

DAILY CLEANING

Warning: Ensure the appliance is off and the parts are cool to touch.

Warning: Cooking by-products are collected in the channel at the front of the Broiler and drain in to a

removable grease drawer. Cooking by-products may also fall directly in to the grease drawer. Ensure the

front channel, drainage hole and grease drawer are cleaned regularly. Ensure the grease drawer is always

in position when cooking.

CLEANING BROILER GRATES, INFRARED HOODS AND BURNERS

After each use, clean the open Broiler grates with a sharp grill scraper and/or brush as necessary to

remove any excess debris.

Warning: Never use liquids to clean the Broiler grates in the installed position. Remove Broiler grates for

thorough cleaning in liquid.

Warning: Empty the grease drawer as necessary, clean, dry and replace. Ensure the grease drawer is

always in position when cooking.

Broiler grates, infrared hoods, are all positively located and may be removed (in sequence) for service and

cleaning, burners are not removable. Note: After cleaning, ensure the components are dry and re-

assemble in reverse order – ensure all items are correctly and positively located. Never operate the Broiler

without the infrared hoods & cooking grates installed.

Cleaning must be regular and thorough to ensure safe and efficient operation of the equipment and to

prevent flare-up. The amount of usage and the type of products being cooked will largely determine how

often complete cleaning is necessary - it is the operators responsibility to assess this.

To clean the items, use a suitable detergent and warm water and scrubbing brush. Repeated scrubbing

will be necessary if deposits are heavy and baked on.

CLEANING STAINLESS STEEL

Regularly wipe the surface with hot water and detergent. Rinse the washed area with a wet sponge and

clean water and wipe the area dry to prevent streaking. Follow this process and wash a small area at a

time to prevent chemical residue and streaking.

Stainless steel may discolour if overheated. These stains can usually be removed using an appropriate

powder/paste. To scrape off heavy deposits of grease and oil, use only wood or plastic tools as

necessary.

Note: Never use steel wool to clean stainless steel.

Note: Damage may occur if chemicals not suitable for stainless steel are used.

USE ONLY SUITABLE CHEMICALS AND OBSERVE ALL

MANUFACTURER SAFETY REQUIREMENTS FOR SAFE HANDLING

AND USE.

Trueheat RCB Infrared Gas Broiler—September 2017 Page 15 of 16

MAINTENANCE

RECOMMENDED SERVICE PLAN

It is recommended that your appliance be serviced by an authorised person every 12 months. This

period is for guidance purpose only and may vary based on usage of the equipment and operator care.

Prescribed service tasks include:

Functional test of all components, clean and adjusted as necessary

Inspect and clean all gas valves and lubricate with an industry approved lubricant

Inspect all gas piping

Check and adjust specified gas pressures

Leak test

Full operation, performance and safety test

For all technical queries, please contact Comcater’s Technical Support Team.

Technical Phone Support

Phone: 1800 810 161

Email: techsuppor[email protected].au

FOR YOUR SAFETY, ALL SERVICE WORK MUST BE CARRIED OUT BY

AN AUTHORISED PERSON AND USE ONLY ORIGINAL SUPPLIED AND

SPECIFIED PARTS.

TEST ALL FITTINGS, PIPES AND PIPE CONNECTIONS FOR LEAKS IN

ACCORDANCE WITH APPROVED GAS LEAK TEST PROCESSES AND

METHODS. DO NOT USE A FLAME.

Trueheat RCB Infrared Gas Broiler—September 2017 Page 16 of 16

TROUBLESHOOTING

For all technical queries regarding troubleshooting please contact Comcater Technical Support:

Phone: 1800 810 161 Email: [email protected]

Problem Probable Causes Corrective Action

Burner will not light

Pilot is not lit

Light the pilot as per

instructions shown on the

inside of the door or on Page

13 of this manual

Gas Control is set to “Pilot” Ensure that the gas control dial

is set to “Hi-Flame”

No gas supplied to unit

Verify that the gas line

connections are connected,

ensure all shutoff valves are

open, including emergency gas

shut-offs. Note: some exhaust

systems have a gas supply

interlock fitted, that will

disrupted gas supply to the

equipment if the exhaust hood

isn’t operating.

BROILER isn’t getting

Hot, (Infrared hoods are

not glowing)

Gas Control is set to the

“Low flame” setting

Ensure the gas control knob is

set to the “Hi flame” setting,

low flame is used as a standby

or rest feature only.

When the gas control is set to

the “Low flame Setting the

infrared hoods will not glow.

Large or small infrared hoods are

incorrectly aligned or haven’t

been fitted after cleaning.

When the BROILER is cool to

touch, remove the cooking

grates and ensure that all

hoods are present and

correctly positioned per

diagram on page 13.

If in doubt Contact Service

Gas pressure is too low

Isolating the problem requires

additional troubleshooting

beyond the scope of the

operator. Contact Service

Trueheat RCB Infrared Gas Broiler—September 2017 Page 17 of 16

NOTES

Trueheat RCB Infrared Gas Broiler—September 2017 Page 18 of 16

www.comcater.com.au/trueheat

This manual suits for next models

3

Table of contents

Popular Broiler manuals by other brands

Black & Decker

Black & Decker Dining-In CTO7000 Series Use and care book

Vulcan-Hart

Vulcan-Hart GHCB40C Installation & operation manual

Garland

Garland IR36-280L Installation & operating guide

Nieco

Nieco Flexi-Chef System 615 owner's manual

MVP

MVP Sierra SRRB-12 owner's manual

croydon

croydon CCR3-G0184-701 instruction manual

Southbend

Southbend SCB-24 owner's manual

Connerton

Connerton A-4F Installation, operation & maintenance instructions

U.S. Range

U.S. Range "REGAL" SERIES Installation and operation instructions

Vulcan-Hart

Vulcan-Hart ESB36 Specifications

USR Brands

USR Brands COOKLINE CCB-24 user manual

U.S. Range

U.S. Range UIRCM60 Installation and operation manual