Trueshopping 5 in 1 Petrol Installation and operating instructions

5 in 1 Petrol Multi Tool

Assembly / Owner’s Manual

©Trueshopping LTD Issue 01 mc-rt

Original Instructions

CONTENTS

GENERAL

Model Guide 3

Safety instructions a,b,4

Protecting yourself 4

Fuelling 4

Vibrations 4

Protecting others 4

Protecting the machine 5

Minimum Age 5

Recommended use 5

Emergency action 5

Safe operating instructions 5

Fuel Safety 6

What’s in the box? 6

Contents list 6

The multi tool engine driving unit 6

The engine 7

ASSEMBLY/OPERATION

Attaching the handle 7

Pole attachment 8

Shoulder harness assembly 9

Starting the multi tool 9

The hedge cutter

Hedge cutter parts 10

Hedge cutter assembly 10

Strimmer / brush cutter assembly

General operation advice 11

Adjusting the strimmer cord 11

Strimmer parts 11

Brush cutter parts 11

Attaching the guard / line cutter 11

Attaching the brush blade 14

Attaching the bump head 16

The Pruning saw

Guide rail / chain mounting 17

Tensioning the chain 18

Filling with oil 18

Operation advice 18

Adjusting the idle screw 19

MAINTENANCE

Fuel pipe / grommet exchange 19

Fuel filter exchange 21

Changing / checking the spark plug 24

Air filter cleaning / exchange 25

Carburettor exchange 26

Refilling the strimmer head 28

General maintenance

The engine 30

Guide rail (chain pruner) 30

Chain maintenance 30

The strimmer / brush cutter 31

Maintaining the bevel gear 31

The hedge trimmer 31

FAULT FINDING

Online help 32

Specifications 33

THIS GUIDE COVERS THE FOLLOWING

MODEL NUMBERS –

MT260 /MT260O

BC3304IN1 / BC3304IN1O

HLMP4304IN1 / HLMP4304IN1

HYM524IN1 / HYM524IN1O

MT550 / MT550O

MT580 / MT580O

MT620 / MT620O

MT650 / MT650O

MT680 / MT680O

*While every effort is made to ensure the

accuracy of the information in this

manual,occasionally minor design

changes can occur, ifin doubt please

visit the manufacturers website for the

most up to date version of this guide .

3

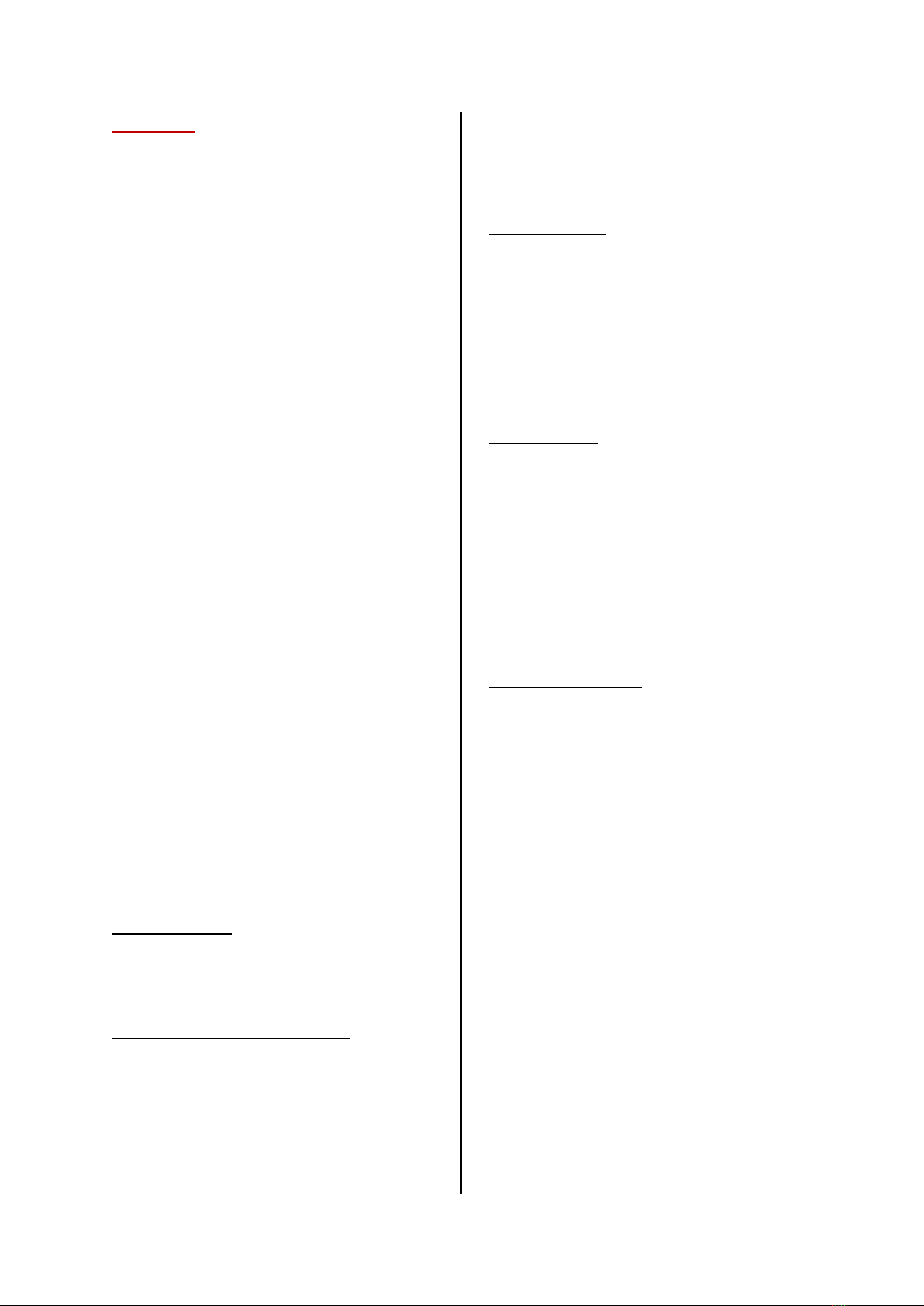

Warnings on the Machine and their

Meanings

Information on the long reach hedge and

pruner attachments

Model Information

(location differs by model)

CAUTION! HOT EXHAUST

DO NOT USE NEAR

NAKED FLAMES

Machine Noise

information

Clockwise from left -

Danger of kickback

Keep feet away from

guard and blade

Watch your step

Beware of thrown

objects

Keep working area

clear of pedestrian

traffic

Ensure you have adequate

space to work

a.

Important

information

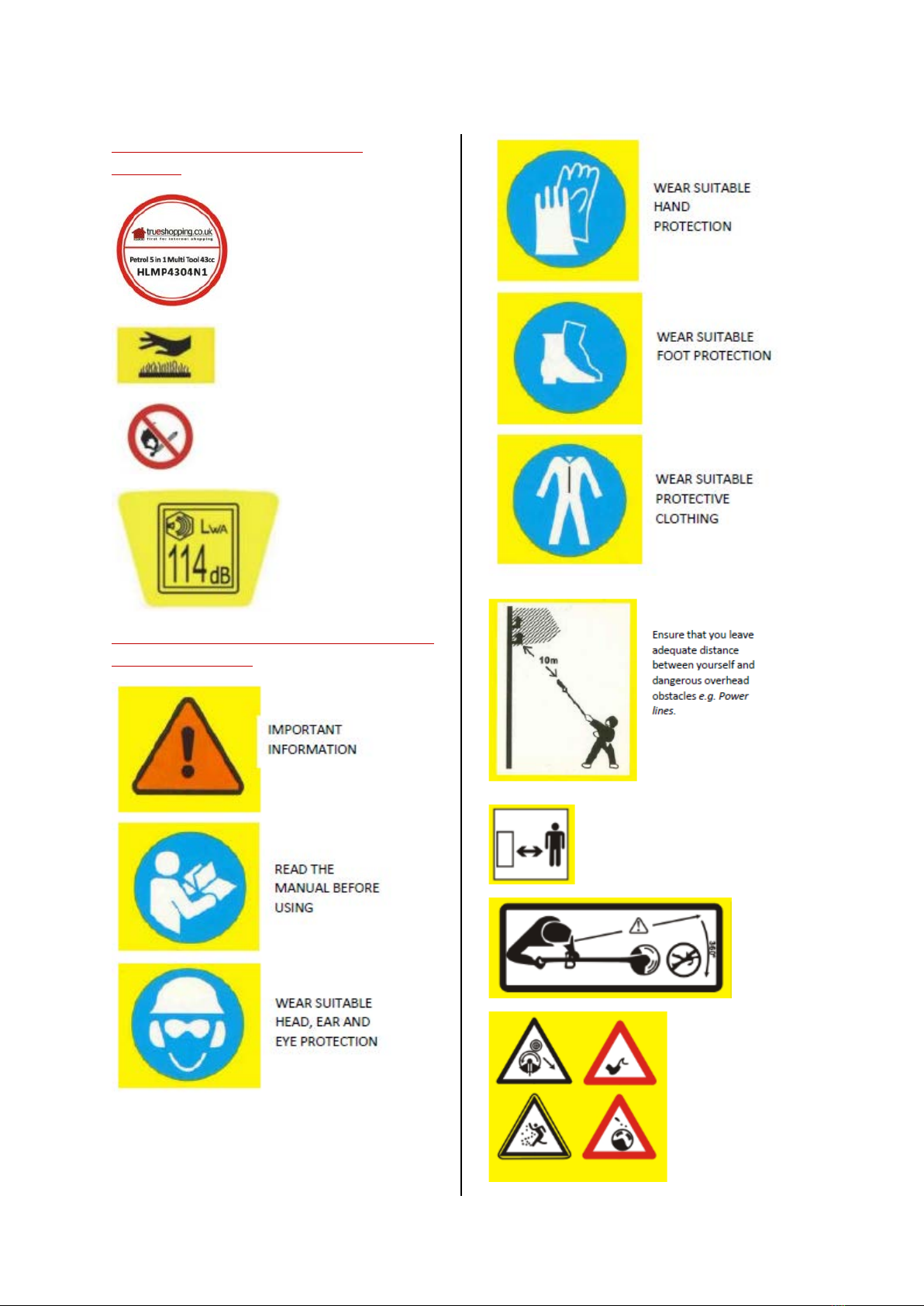

IMPORTANT SAFETY INFORMATION

•Please note that the cutting blade

continues to run for a short period

after you let go of the throttle trigger

–This is called the flywheel effect.

•Do not lend or rent your power tool

without the instruction manual. Be

sure that anyone using your power

tool understands the information

contained in this manual.

•Persons with pacemakers only: The

ignition system of your power tool

produces an electromagnetic field of a

very low intensity. This field may

interfere with some pacemakers.

Consult your doctor if you have

concerns.

•Do not use a pressure washer to clean

your power tool. The solid jet of water

may damage parts of the power tool.

•Do not spray the machine with water.

•Work calmly and carefully – in

daylight conditions and only when

visibility is good. Stay alert so as not

to endanger others.

•Your power tool produces toxic

exhaust fumes as soon as the engine

is running. These fumes may be

colourless and odourless and contain

unburned hydrocarbons and benzoyl.

Never run the engine indoors or in

poorly ventilated locations.

•The dusts, vapour and smoke

produced during operation may be

dangerous to health. If the work area

is very dusty or smoky, wear

appropriate safety equipment.

•If your power tool is subjected to

unusually high loads for which it was

not designed (e.g. heavy impact or a

fall), always check that it is in good

condition before continuing work

•When working at heights:

–Always use a lift bucket

–Never work on a ladder or in a tree

–Never work on an insecure support

–Never operate your power tool with

one hand.

Be alert and cautious when wearing hearing

protection, your ability to hear warnings

(alarms, etc.) is restricted.

TUV IDENTIFICATION

LABEL

b.

Attachment information

Safety Instructions

Read this manual in full before operating the

machine for the firsttime. If you have any

questions regarding the operation ofthe

machine, please contact the manufacturer.

CAUTION! In order toensure your safety you

must follow the safety, installation and

operation instructions. Any person who uses

this machine should be fully aware of the

potential risks.

!You must be 18orover to operate this

machine. Children must notoperate this

machine.

! The manufacturer shall not be held liable if

the unit is altered outside of the information

printed in this guide.

! Always turn the engine off before

performing any maintenance

!Some components will become hot

during use, specifically – the engine, bump

head, brush cutter blade, hedge trimmer

and pruning saw.

Protecting Yourself

!Donotusethis machine in areas with poor

ventilation or indoors, when switched on,

the machine produces carbon monoxide!

!Donotoperate this machine in adverse

weather conditions orin situations where

sure footing is not guaranteed.

! Exercise common sense when operating

this machine, do not operate when under the

influence of alcohol or medication which

may impair judgement and concentration.

FUELLING

! Always switch the engine off before

fuelling.

Open the tank cap slowly to avoid spillage due

to internal pressure. If the unit has recently

been in use, allow to cool down first. Not

allowing the unit to cool could cause the fuel

to ignite.

When replacing the fuel, be careful not to

over fill the tank. Any spillages should be

cleaned up immediately.

After filling ensure that the cap is secured

properly and that it will not work loose while

the machine is switched on.

VIBRATIONS

Vibrations from the machine make it difficult

to hold for long periods of time, this time can

be prolonged by wearing suitable gloves.

Protecting others

! Do notallow anyone toapproach the

machine while in use, ensure the working

area isclear.

! Avoid jamming the blade as this can make

the machine suddenly difficult to control.

! WEAR EAR PROTECTION!

! SAFETY BOOTS MUST BE WORN

WHILE OPERATING THE MACHINE!

! WEAR SUITABLE EYE

PROTECTION!

! WARNING, PETROL IS

FLAMMABLE, TAKE

APPROPRIATE CARE!

4

! Never use the brush cutter or strimmer

bump head without the guard attached as

objects can be thrown up.

!Donotusethe machine for any purposes

other than outlined in this manual.

!Itis good practise to clearly mark your

working area.

! Turn the machine off when moving

location.

Protecting the Machine

! Only use recommended parts, consult the

manufacturer to obtain these.

! Always use the correct tool for the correct

job. Use the tool only for its designed

purpose.

! Only use non-metallic fibre in your

strimmer.

! Ensure that the machine is stored in a dry

area in a secure place. Parts of the tool are

sharp and should not be left within reach of

children / pets.

! Inspect the machine for damage before use,

and ensure all components are properly

aligned.

! Use of third party strimmer heads can

potentially cause damage to the machine

Minimum Age

Only persons over 18 years of age are legally

allowed to operate this machine unless under

training supervision.

Recommended use

The unit is recommended for general use in

agriculture, forestry and gardening.

Emergency Action

In the event of injury, seek qualified medical

assistance and apply first aid to the injury. If

you are the responder, protect the injured

person from further injury.

! The user is responsible for any material /

personal damage resulting from improper

use.

! Please note that if not properly used, the

following injuries can be caused –

Contact with an uncovered Strimmer head –

Laceration

Reaching into the running scythe –

Laceration

Hearing problems if proper ear protection

not used

Carbon monoxide poisoning if used in an

enclosed area.

Safe Operating Instructions

! Do not operate the machine if you suspect

the machine has a problem.

•Always visually inspect tosee that the

blades and bolts are secure. Ensure

the engine vents are freefrom any

dirt or remnants.

•Operate the machine at the lowest

possible engine speed to do the job.

•Keep your hands and feet clear of the

attached tool when the machine is

running.

•Keep both hands firmly on the

machine at all times.

•Always use the machine with the

supplied carry strap.

•Always wear appropriate hand, feet

and hearing / eye protection when

operating the machine.

•Do not use metal cutting coils.

•Pay attention, the machine will

continue to run for five seconds after

the engine has stopped.

5

Fuel safety

! Petrol is highly flammable. Take the

following precautions:

•Store fuel in containers specifically

designed for this purpose. DO NOT store

in the mixing bottle.

•Refuel outdoors only and do not smoke

while refuelling.

•Add fuel before starting the engine. Never

remove the fuel cap when the engine is

running or the engine is hot.

•Avoid spillage. If petrol is spilled, do not

attempt to start the engine, move the

machine away from the spillage to avoid

any danger of petrol vapours igniting.

•Tighten the fuel tank cap tightly.

What’s in the box?

This is a universal tool which will enable you

to care for your garden. With this machine

you can cut the lawn,hedgerowsand lop tree

limbs .This machine is powered byan easy

starting,reliable air cooled single cylinder 2

stroke engine.Using a fuel/oil mix of25:1 and

producing 1.2hp at11,000rpm itmakes easy

work ofmost garden tasks. Afoam air filter

prolongs engine life and the centrifugal clutch

automatically engages, driving the tools only

when required.

All of the incorporated tools are easy to

attach to the main engine unit as required.

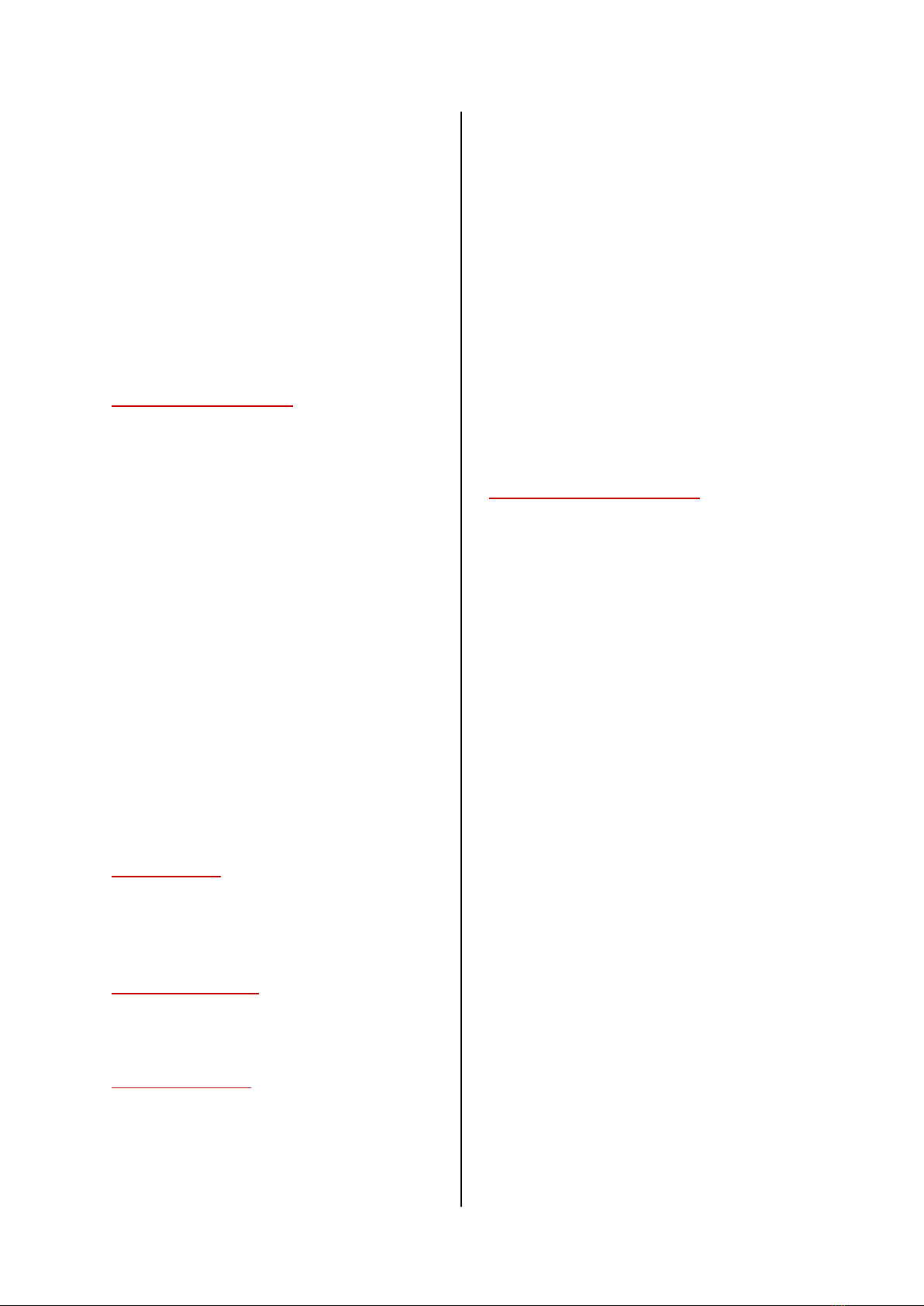

Contents list

•Main engine with handle attached

•Strimmer

•Tools

•Strimmer/cutter Guard

•Extension handle

•Handle to chain pruning saw

•Pruning saw blade

•Hedge trimmer

•Cutter blade

•Strimmer spool

•Carry strap

•Petrol mixing bottle

The multi tool engine driving unit

1. Handle

2. Harness loop hole

3. Stop switch

4. Throttle lockout

5. Air filter

6. Start handle

6

7. Fuel tank

8. Throttle trigger

9. Shoulder Harness

10. Unit attachment locking screw

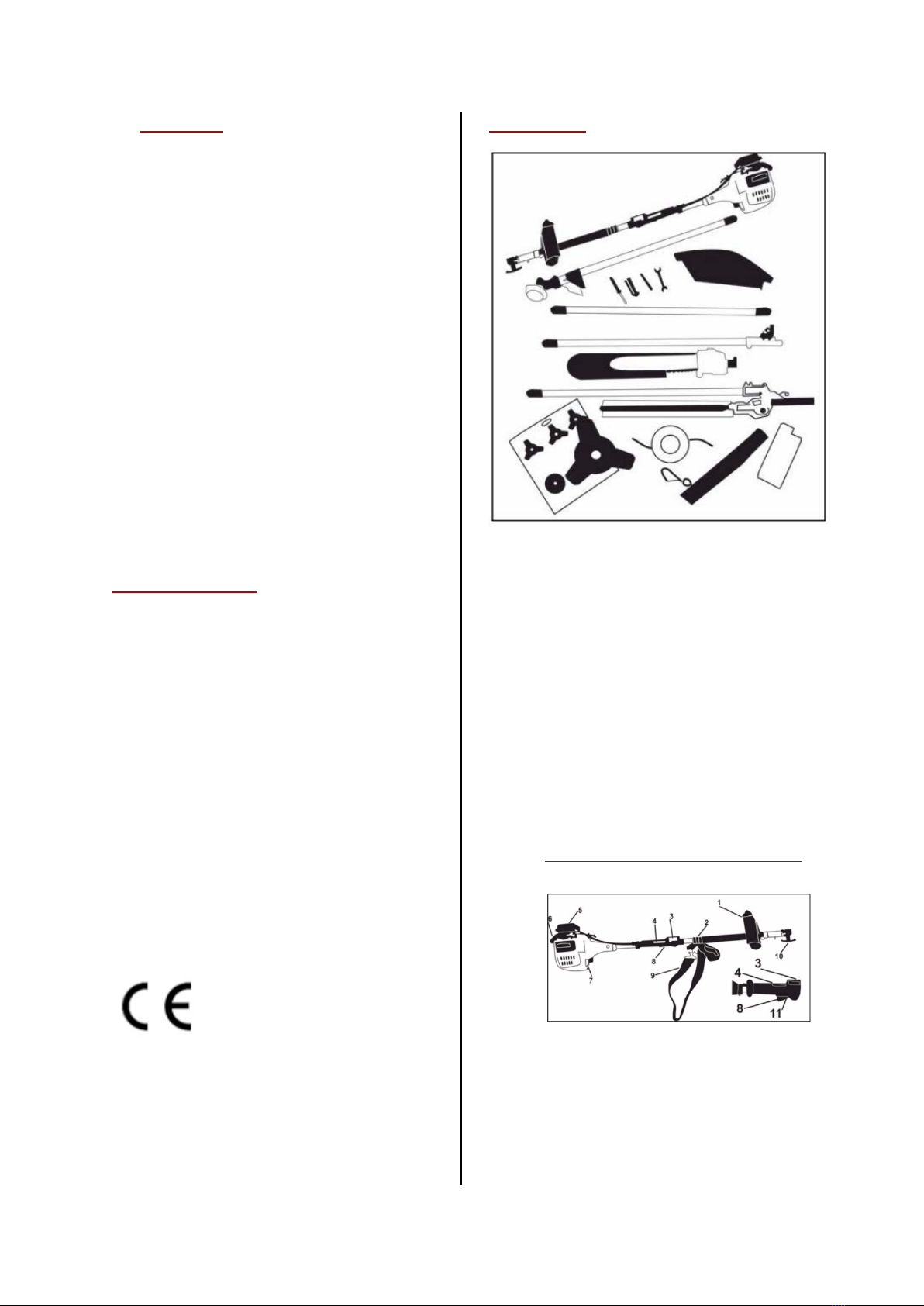

The Engine

1. Filler cap

2. Choke lever: Facilitates the engine

starting.

3. Fuel Pump: increases fuel supply

when cold starting.

4. Carburettor screw: For adjusting the

idling speed.

5. Engine support : For supporting the

machine when on the ground

6. Fuel tank: For storing a fuel mixture

comprising of petrol and engine oil.

7. Exhaust (with spark arrestor):

Reduces operating noise and directs

the exhaust gas away from the

operator.

Attaching the handle

•The handle fits over the plastic mounting

bracket which is already attached to the

upper pole.

•The handle consists of two parts ( 1 & 2 )

•Place part 2 onto the underside of the

mounting bracket and hold it in place with

your hand. Push four hex nuts into the

recesses beneath part two and hold them

in place with your fingers.

1

2

7

•Place part 1 onto the mounting and line

the holes up with the holes on part 2.

Then fix the four Allen bolts through the

top of part 1 to fix in place.

Pole Attachment

To attach the different attachments to the

machine, you need to connect them to the

coupling on the end of the fixed engine pole.

1. Open the coupling and turn the retaining

handle to loosen the connection.

2. Line up the hole on the required tool

pole as shown below and push firmly

into the coupling.

3. Close the coupling again, tighten the

retaining handle, and pull and twist

the pole to ensure that it is secure.

8

Shoulder harness assembly

The shoulder harness clips to the handle of the

main engine as shown below.

Starting the Multi tool

! Please be aware that a certain degree of

effort is required to successfully start the

multi-tool, please persevere if you are

struggling to start the engine.

•Pull the switch into the on “I” position and

hold the throttle lockout and then pull the

throttle trigger.

•While still holding the above, press in the

switch next to the on/off switch .

•Slowly release all three and you should

note that the switch stays pressed in.

•Now we need to prime the engine with

fuel for use. Press the priming bulb on the

unit several times (8-10) to prime the

machine.

•To start the engine, push the choke lever

upwards and pull the starter cord.

9

•Do this until you hear a splutter or cough

from the engine. Once this has happened,

push the choke lever down and pull the

starter cord and the engine will start. You

can then pull the throttle trigger to start

the tool working.

**Please note that it can take several

attempts at pulling the starter cord to

start the machine.

•To turn the machine off push the on/off

switch to “O”.

The Hedge cutter

The hedge cutter is ready assembled and just

needs to be attached to the main engine unit.

Refer to the “Pole attachment” guide on how

to do this.

When you are ready to use the hedge cutter

ensure that the unit is switched off and then

remove the plastic guards from the blades

**TAKE CARE WHEN HANDLING THE HEDGE

CUTTER AS THE BLADES ARE SHARP **

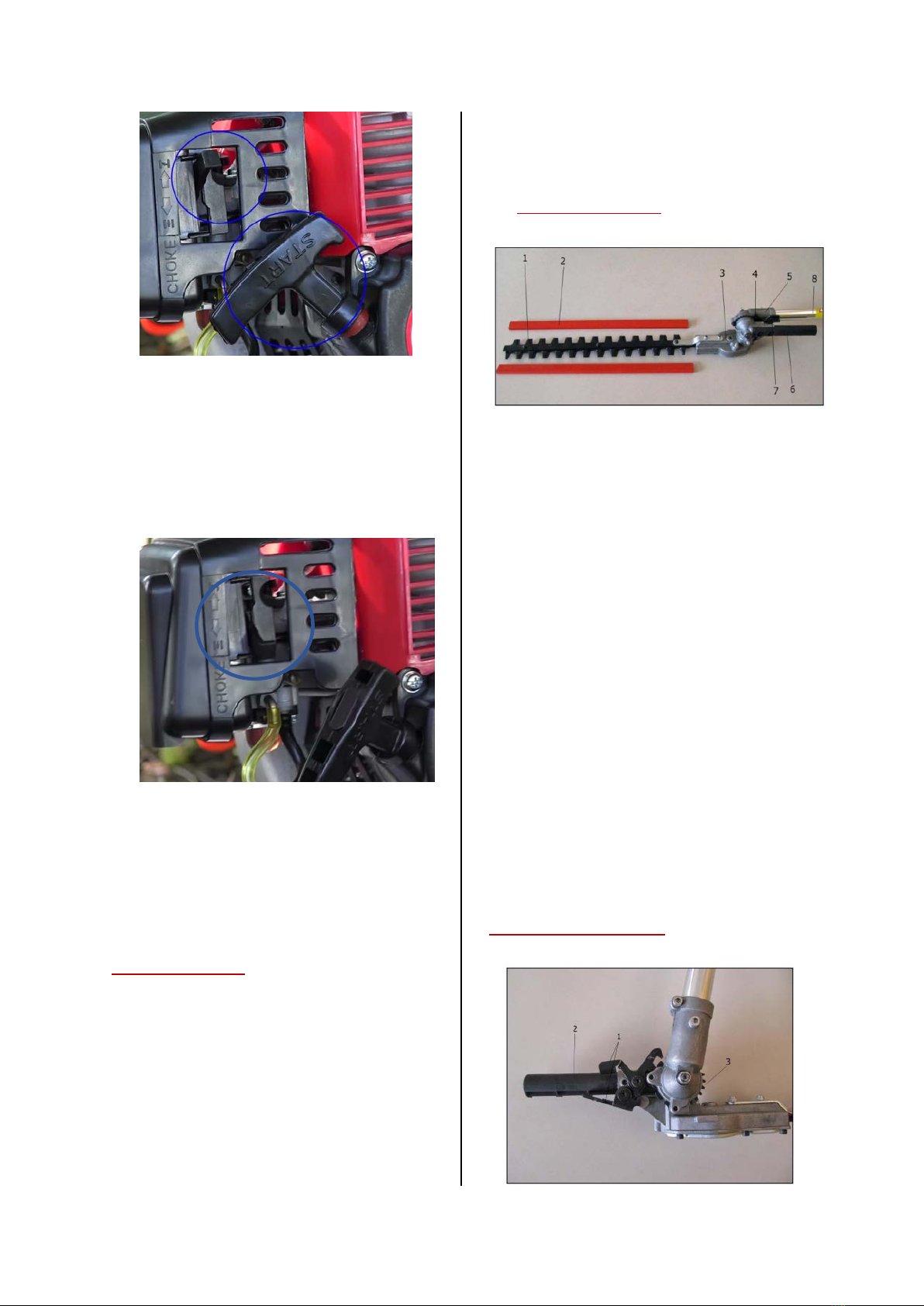

Hedge cutter parts

1. Cutting blade: Steel blade for cutting

hedges and bushes.

2. Blade Guard: Protect the cutting rail

when the tool is not in use.

3. Blade gear: Convert the rotation of

the angle gear when the cutting blade

moves back and forth.

4. Locking mechanism: Holds the cutter

in the desired position.

5. Angle Gear: Transmits the rotational

movement of the drive axel to the

blade gear.

6. Adjusting lever: Adjust the cutting rail

to the desired angle.

7. Locking lever : Lock and unlock the

cutting rail

8. Drive shaft tube: Surrounds and

protects the drive shaft between the

coupling sleeve and gear.

Hedge cutter assembly

10

1. Unfold the hedge cutter

attachment by pressing the two

locking levers (1)

2. While still pressing the locking

levers rotate the adjusting lever

(2) to the desired angle, then fix

the locking lever to the gear ring.

Strimmer / brush cutter assembly

General operation advice

!Any hard objects e.g. Stones, metallic and

plastic objects should be removed from the

area before operation. Otherwise they can

be thrown up and cause damage tothe

machine and Injury.

! Grass height in the working area should not

exceed 15cm due to the danger of hidden

Debris.

!Only for useon grass, weeds and low

shrubbery.

! When the unit is running, never put the

strimmer / brush cutter on the ground.

! Never cut above shoulder height and

ensure you have firm footing at all times.

! If you are unsure about any of the

procedures outlined, please contact the

manufacturer.

Adjusting the strimmer cord

! The strimmer head will still run for a short

time after switching off the machine. Wait

until the machine comes to a complete stop.

When the strimmer cord becomes too short

after use, tap the spool head on solid ground

several times. This will unlock the spool head

and extend the cord through centrifugal force.

The line cutter will automatically trim it to the

correct length.

Strimmer parts

Brush cutter parts

12. Blade

13. Line cutting knife

14. Mounting screw and washer

15. Mounting washer

16. Blade protection

17. Locking nut

18. Spacer disc

Attaching the guard / line cutter

! Be careful when handling the line cutter, it

is sharp.

!The guard must be attached when using

either the strimmer orbrush cutter

The following parts are required to fit the

guard and line cutter

4 x locking bolts

4 x locking nuts

4 x washers

1 x 4mm Allen key

1 x spanner

•Loosen the metal mounting bracket using

the 4mm Allan key and spanner

11

•Once loosened, pull the metal bracket

away from the plastic mounting on the

pole.

•Place the blade guard uptothe mounting

bracket.

•Make sure that the holes on the mounting

bracket and blade guard line-up.

•Insert the locking bolts through the plastic

retaining bracket on the main pole.

•Fasten them both together using the Allen

key, locking nuts and washers.

12

Now that the guard is attached, we will now

fix the line cutter in place. To do this you will

need –

1 x Line cutter

2 x Phillips screws

1 x small Philips screwdriver

•Locate the mounting block on the guard.

•Place the line cutting blade upto the

mounting block asshown.

•Fix the blade to the mounting block using

the two Philips screws.

13

The line cutter is now attached.

Attaching the brush blade

! Please be careful during this procedure, the

brush blade is sharp.

The following parts are required for fitting the

brush blade –

1 x Brush blade

1 x 4mm Allen key

•Remove the nut on the head assembly by

rotating it clockwise.

•Once the nut is removed, pull the bell

shaped washer away from the head

assembly.

•Now lift and remove the flat spacer

washer from the head assembly.

•Line up the hole on the side of the large

washer with the hole in the side of the

head assembly.

Insert the 4mm Allen key through both holes

(This will prevent the head from rotating

while you attach the blade).

•Now carefully remove the brush blade

from the packaging.

14

•The blade must be mounted with the

directional arrow on the blade and the

directional arrow on the guard pointing in

the same direction.

•Next we mount the blade onto the large

washer on the head assembly as shown.

! The blade must sit correctly onto the head

assembly, an improperly mounted blade can

cause damage / injury.

•Now re-fix the small spacer washer onto

the central spindle, ensuring the recessed

side of the washer faces the blade.

•Re-attach the bell shaped washer and

locknut while holding onto the Allen key.

15

•Finger tighten the locknut anti clockwise

and then tighten fully with the socket

tool.

•Finally, remove the Allen key.

•The blade in now ready for use.

Attaching the Bump head

This instruction shows you how to attach the

strimmer bump head to your multi tool.

•Remove the nut and large bell washer

from the head assembly (as shown in the

brush blade instruction)

•Rotate the large washer until the hole in

the side lines upwith thehole on the

head assembly. Then insertthe 4mm

Allen key through the two holes to

prevent the assembly frommoving.

•Pick up the bump head and place the

threaded connection on the bump head

onto the threaded connection point in the

centre of the head assembly.

•Screw the bump head onto the central

fixing by rotating it anti clockwise, it is

important that you hold the Allen key

16

while doing this otherwise the head will

turn indefinitely.

•The unit is ready for use once the bump

head stops turning.

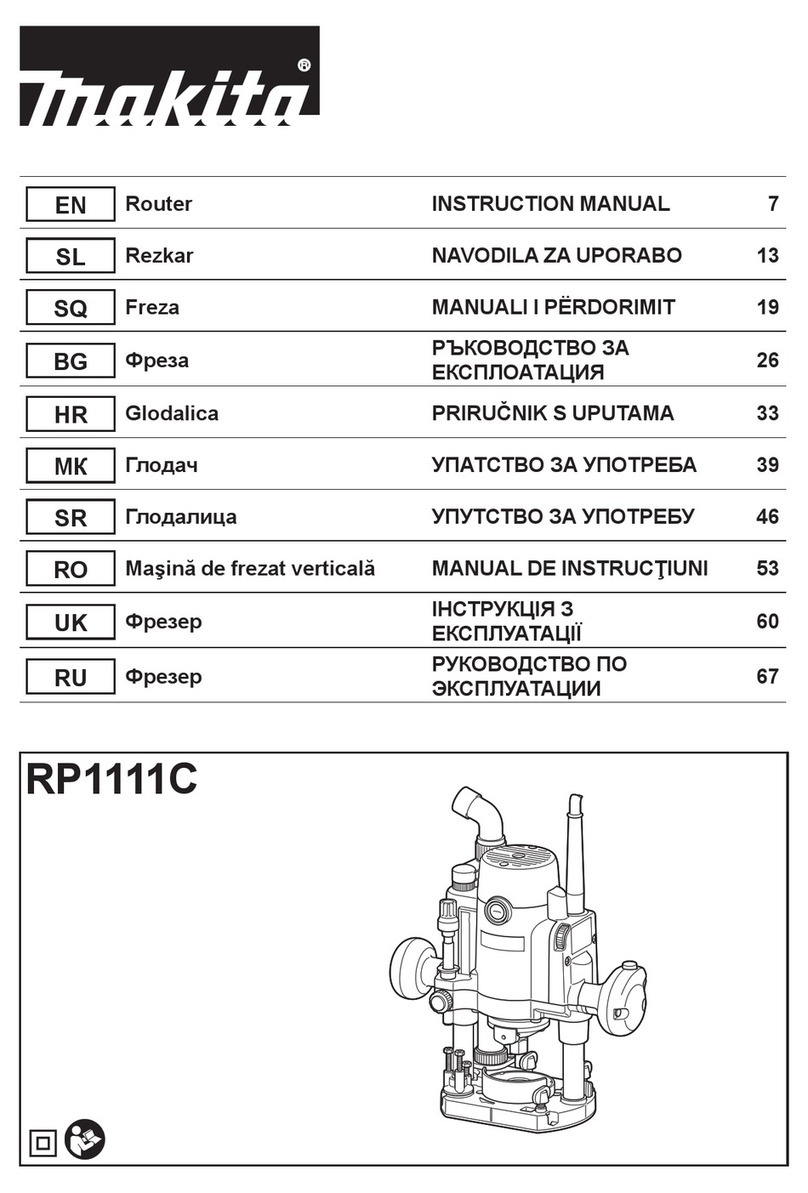

The Pruning Saw

The pruning saw is designed for cutting

hard to reach branches. It is not designed

to be used in the felling of trees.

The extension pole can be used with the

pruning saw, see the section “pole

attachment” for advice on attaching to

the main engine unit.

**When you are ready to use the pruning

saw, carefully remove the protective

cover. Ensure that the engine is off and

take care when handling as the saw teeth

are sharp **

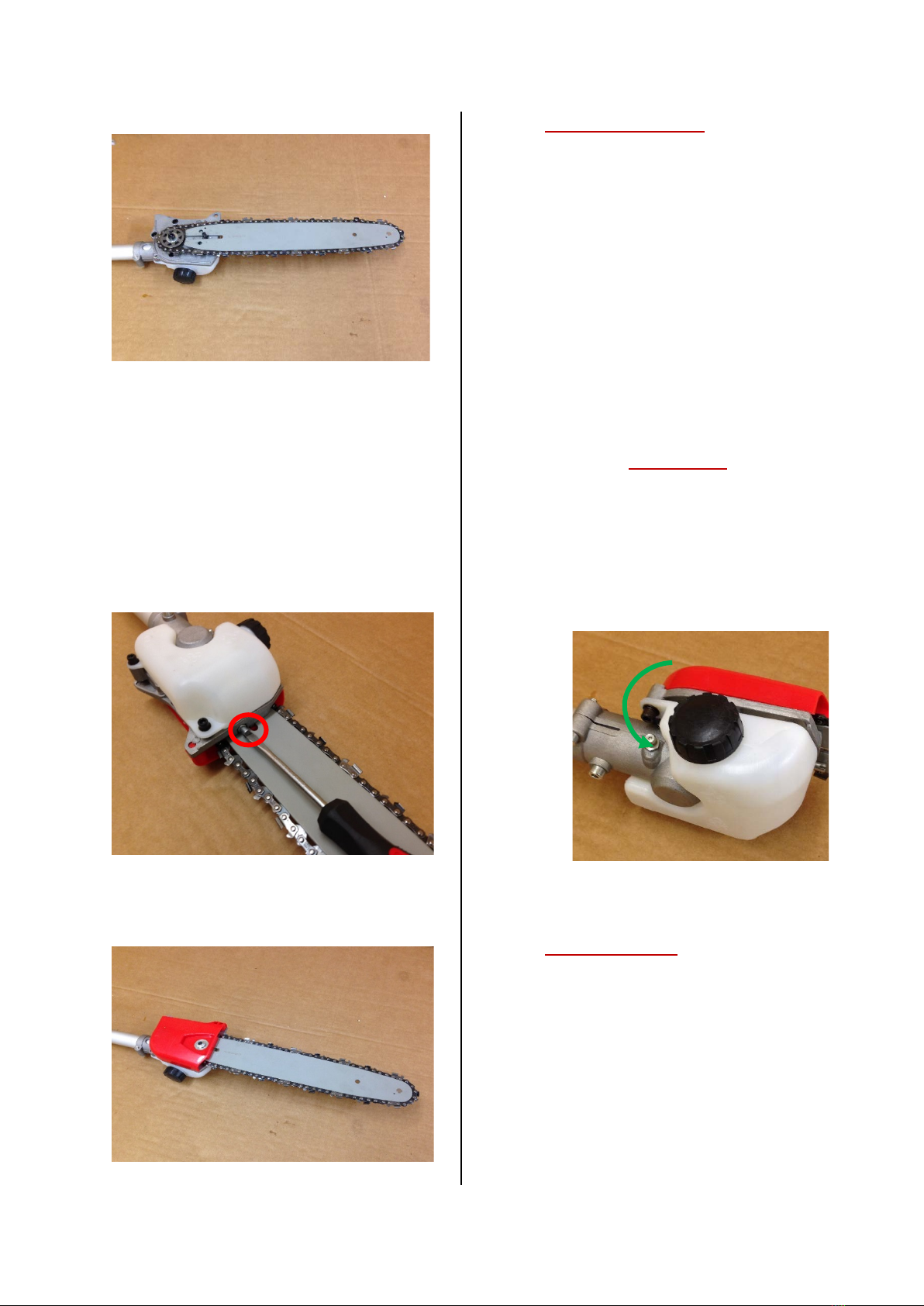

Guide rail / chain mounting

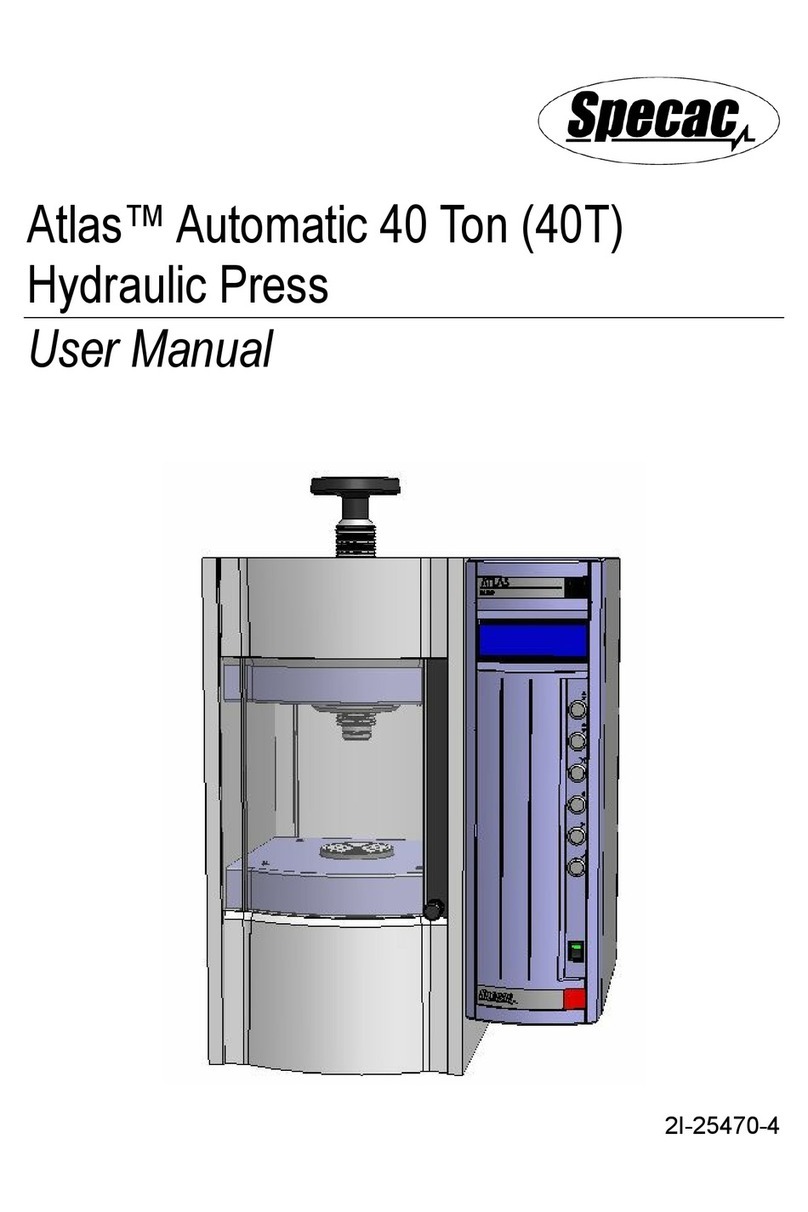

•Loosen the nut and remove the

chain guard.

•Tighten the adjuster with a

screwdriver so that it is all the

way to the right (circled) then sit

the bar in position.

•Put the chain in place and start

from the top end of the rail,

ensuring that the chain teeth go

around the bar as pictured.

17

•Place the plastic cover onto the

assembly and loosely screw the

nut on. (DO NOT TIGHTEN)

•Turn the tightening screw

(Circled) clockwise until the chain

on the underside of the rail is

slightly hung up and the links are

located into the groove of the

guide rail.

•Refit the chain guard and tighten

the nut by hand.

Tensioning the chain

A new chain has to be tensioned

frequently remember to check the

chain tension regularly.

To do this –

1. Stop the engine and loosen the

guard nut.

2. Keep the guide rail tip pointing

upwards.

3. Use a screwdriver to tighten the

clamping screw clockwise until the

chain once again rises tightly against

the underside of the rail.

4. Retighten the nut.

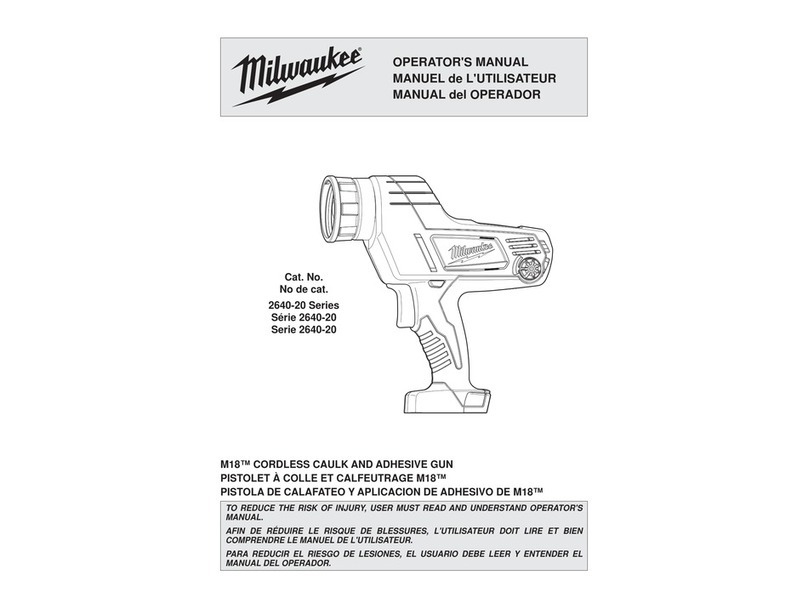

Filling with oil

To fill the chain pruner with oil.

•Remove the black plastic cap on

the chain pruner by turning it anti

clockwise.

•Fill with oil and then replace the

cap.

Operation advice

•Beware of falling branches and

branches that many spring back

•You must use the extension to get

to hard to reach areas, do not

lean.

•Do not use the pruning saw while

standing on a ladder, ensure you

have firm footing at all times.

18

Table of contents

Languages:

Popular Power Tools manuals by other brands

Specac

Specac Atlas Automatic 40 Ton user manual

Makita

Makita BTM40 instruction manual

Chicago Pneumatic

Chicago Pneumatic CP86150 Operator's manual

Pattfield Ergo Tools

Pattfield Ergo Tools E-PST 800 L operating instructions

Makita

Makita RP1111C instruction manual

Milwaukee

Milwaukee M18 2640-20 Series Operator's manual