Trufrost YC-150EW User manual

1

ICE LINED REFRIGERATOR

OPERATION MANUAL

YC-150EW

WHO/PQS certificate report No.1911-16528-WB-19-331

PQS Independent type-testing protocol: WHO/PQS/E003/RF03-VP.3

PQS performance specification: WHO/PQS/E003/RF03.4

Issuing date: 2020.3.25 Version: C

Trufrost Cooling Pvt. Ltd.

3

Content

1. Introduction.............................................................................................................................................................................. 4

2. Precautions for Safe Operation ...............................................................................................................................................5

3. Precautions for Use...................................................................................................................................................................7

4. Installation ...............................................................................................................................................................................7

4.1 Installation environment:............................................................................................................................................ 7

4.2 Installation site:............................................................................................................................................................8

4.3 Preparation before use ................................................................................................................................................. 8

4.4 First initial starting.......................................................................................................................................................... 8

4.5 Operation after power failure.........................................................................................................................................9

5. Refrigerator Components ..................................................................................................................................................... 10

6. Display panel function description......................................................................................................................................... 10

6.1 Function introduction................................................................................................................................................... 10

6.2 Function setting:........................................................................................................................................................... 12

7. Maintenance........................................................................................................................................................................... 13

7.1 Maintenance ............................................................................................................................................................... 13

7.2 Out of use......................................................................................................................................................................13

7.3 Maintenance ............................................................................................................................................................... 13

7.4 Disposal......................................................................................................................................................................... 14

7.5 Scrap and process management of the equipment..................................................................................................... 14

7.6 Condensation Draining................................................................................................................................................. 15

7.7 Steps to replace the fuse.............................................................................................................................................. 15

8. After-sale Service.................................................................................................................................................................... 16

9. Specifications ........................................................................................................................................................................ 17

10. Packing list.............................................................................................................................................................................17

11. Wiring diagram......................................................................................................................................................................18

12.Directions for safe transportation......................................................................................................................................... 18

Warranty certificate.................................................................................................................................................................... 20

4

1. Introduction

Dear Customer:

Thank you for choosing Trufrostbiomedical products! For your personal safety and better

performance of this unit, please read this Operation Manual thoroughly and save it properly for

future reference.

User can copy some chapters of this operation manual, such as instructing users how to deal

with emergencies, but only for internal use. These chapters are clearly indicated in the contents of

the manual.

If the user does not use the equipment according to the manual or the method specified by the

manufacturer, Trufrostbiomedical has no obligation and responsibility for any instrument damage

caused.

Because of our quick product update, this manual may not comply with our products fully,

please refer to the final product.

PLEASE NOTICE:

During transportation or use, it is not allowed to vibrate or collide violently or get wet. Please

store in a well ventilated and clean room with humidity less than 95%, no corrosive gas.

Ice lined refrigerators (hereinafter as equipment) can only be operated by trained and authorized

personnel.

Equipment maintenance can only be operated by Trufrostbiomedical or our authorized agent.

If the user encounters a situation not mentioned in this manual, please contact

Trufrostbiomedical or our authorized agent for correct treatment.

The equipment may be damaged if it is not used according to this operation manual.

Please use the accessories provided by Trufrostbiomedical. If users want to use other

accessories, Trufrostbiomedical will not be responsible for the adverse consequences.

The equipment must be inspected and maintained regularly to ensure the good operation.

Warm Tips:

I. Please use proper protective equipment.

II. Please keep good health habits.

III. Everyone is bound to be responsible for his/her safety.

5

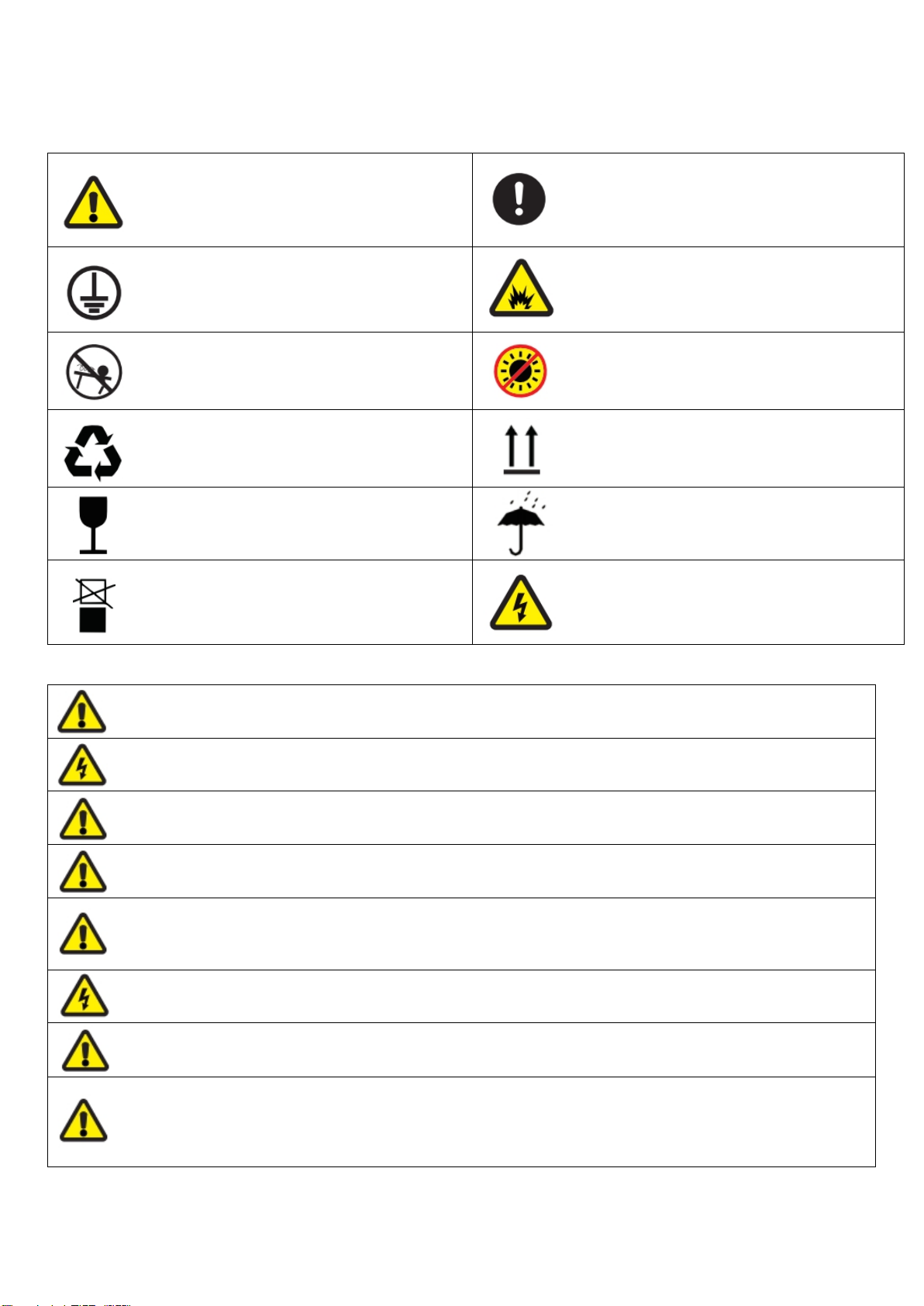

2. Precautions for Safe Operation

For the first time to use this device, please read the following warning labels very carefully, to use

the equipment safely and correctly.

CAUTION:

failure to observe the precautions may

result in serious personal injury or

death.

CAUTION.

Failure to observe the precautions may

result in personal injury, equipment

failure and property damage.

GROUNDING

Flammable and explosive refrigerants

Attention: keep away from fire!

NO TILTING

STAY OUT OF SUN

RECYCLED Package

PLAVCE UP

HANDLE WITH CARE

KEEP DRY

NO STACKING

DANGER ELECTIRC SHOCK

CAUTION: Failure to observe the precautions may result in personal injury, equipment failure and property

damage.

Do not touch any electrical parts such as the power supply plug or any switches with a wet hand.This may

cause electric shock.

Only qualified engineers or service personnel should install the equipment .

The installation by unqualified personnel may cause electric shock or fire.

Be sure to install the unit on a sturdy floor. If the floor is not strong enough or the installation site is not

adequate, this may result in injury from the unit falling or tipping over

Carefully with the power cord to avoid short circuit or open circuit.When removing the plug from the power

supply outlet, grip the power supply plug, not the cord.Pulling the cord may result in electric shock or fire by

short circuit. Don't make the power line pack and pressed by furnish or heavy goods.Also please don't close

to the compressor and heat source.

Please insert the power plug firmly to avoid leakage. After installation, the power plug must be within reach,

so that the power cord can be pulled out in time in case of emergency.

A separate special socket must be used and reliably grounded. The cross-sectional area of copper conductor

in the wall connected with the power socket must be more than 4mm2. The length of power cable shall not be

lengthened to avoid heating or fire.

Please do not use the power supply beyond the design requirements of the equipment, so as to avoid

overheating, short circuit and other faults. If 110V rated voltage products are connected to the 220 V power

supply, overheating and burning of the equipment may occur. This machine uses the AC power supply with

voltage of 220 V and frequency of 50 / 60 Hz. If the voltage is too low or too high, it is necessary to install an

appropriate automatic voltage regulator.

6

Be sure to install the unit on a sturdy floor, no shaking and tilting.

Please do not place the equipment in a dangerous area, do not run the equipment near flammable materials

to prevent explosion or fire accidents.

Do not place the equipment in the sun or rain area, to prevent short circuit or overheating and other

dangerous accidents.

Do not tilt or lie on the side of the equipment, and do not impact the equipment body; if the equipment is

equipped with refrigeration system, it is easy to be damaged by tilting or impact.

Please place the equipment in a dry and dust-free environment to avoid overheating, short circuit and other

hazards.

If there is unexpected sound, smell, smoke, etc. when the power is on, please pull out the power supply in

time and contact the manufacturer or supplier.

Please place the equipment in a dry and ventilated environment, and ensure the air vent and the surface of

the instrument are not blocked or blocked by walls or other objects; do not use the equipment in a poorly

ventilated environment to prevent damage caused by heat released from the equipment.

It is forbidden to dismantle and transform the equipment without authorization, so as to avoid potential safety

hazard. Otherwise, Trufrostbiomedical will not bear any responsibility.

It is forbidden to put inflammable and explosive dangerous goods, strong corrosive acid, alkali and other

articles not suitable in the equipment.

When storing toxic, harmful or radioactive materials, please use this equipment in a safe area.

Improper use may harm to human health or the environment

Do not insert metal objects such as iron nails or iron wire into the holes, gaps or any outlet of the equipment,

otherwise electric shock or injury may occur due to accidental contact between the above objects and moving

parts.

To ensure the normal operation and ventilation and heat dissipation of the machine, the back and left and

right sides of the box shall be at least 30cm away from the wall, and the air inlet and outlet shall not be

blocked by obstacles!

The ground wire must be connected.

Note: failure to observe the precautions may result in personal injury or equipment failure and property

damage.

It is strictly forbidden to store live animals, flowers or other items requiring highly in temperature that are not

suitable for the equipment.

When the equipment is not used for a long time, please pull out the power plug and pack it for storage.

Please check the setting value of the equipment before you restart it after power off or power failure.

Otherwise, the stored items may be damaged due to the setting change.

This equipment is for storage , which can not be used as a production equipment!

Hold the handle to close the door to prevent fingers from pinching the door.

The key should be kept properly to prevent children from getting it and open door, which may cause

accidents.

7

Please pay attention not to turn the equipment over, when moving it, to prevent equipment damage or

personal injury.

It should be lifted from the bottom when carrying it, and the inclined surface should not be greater than 45

degrees. Please pay attention to personal safety when carrying, to avoid harm to human or surroundings.

3. Precautions for Use

Before putting the items into, it is necessary to confirm in advance whether the temperature

range conforms to the required value, so as to avoid the damage due to the inconsistent

temperature setting. Please pay attention not to block the temperature sensor in the cabinet when

placing the items.

The equipment temperature display value is the temperature at the temperature sensor in the

storage chamber. There is a certain gap between the displayed temperature and the actual

temperature at the center of the equipment when the equipment just starts running, but as the

equipment enters a stable state, the displayed temperature will gradually approach the actual

temperature.

If there is a detection hole on the equipment box, it can lead out the test line in the box during the

test. After the test line is led out, it is necessary to plug the test hole with insulation material again,

otherwise the temperature in the box may not reach the temperature setting value, and

condensation will appear around the outside of the through-hole.

Please use a diluted neutral cleaner to clean the equipment, and do not use brushes, acid,

gasoline, soap powder, polishing agent or hot water to clean the equipment, otherwise the painted

surface or plastic and rubber parts may be damaged. Be careful not to wipe plastic and rubber parts

with volatile solvents such as gasoline.

A water outlet is located at the bottom of the equipment cabinet. Please be sure to drain the water

regularly, to avoid excessive moisture in the cabinet or overflow of water from the water pan which

may affect the safety of the stored items or the cleanliness of the environment. When draining is not

performed, ensure that the plug is reliably installed in the water outlet, otherwise the temperature in

the cabinet may not reach the temperature setting, causing a large amount of condensation in the

equipment to flow out of the water outlet and causing condensation near the outside of the water

outlet.

The power should be cut off while the medical refrigerator does not use for a long time.

During the storage, please do not block the sensor box to avoid damaging the performance.

4. Installation

4.1 Installation environment:

Ambient temperature:10℃ ~43℃.

Relative humidity:≤95%RH.

There is no strong vibration and corrosive gas around.

Avoid the existence of a large amount of dust.

Avoid rocking or shaking the equipment.

Elevation of the working position of the equipment: less than 2000m.

Rated voltage:220V-240V.

8

There is no direct sunlight and no other cold and heat sources and strong electromagnetic

interference, which will affect the normal operation of the control system and directly damage the

system in severe cases.

4.2 Installation site:

This unit is a precision machine. When select a location to install this unit, keep the following

conditions for perfect performance:

It should not be installed in a small confined space, the door of the room should not be less than

height of the present equipment.

Install the unit on a sturdy floor to avoid excessive vibration and noise.

Installing the unit in direct sunlight may cause malfunctioning and may shorten the life of the

unit. Keep good ventilation is necessary.

Each equipment needs to use an independent socket. Please ensure that the current should be

≥10A, and the plug and socket are firmly connected;

Checking the working voltage of the place before start the freezer. A voltage stabilizer is

suggested to be used at the place where the voltage is not stable. And the power of voltage

stabilizer should be more than 4KW, to ensure reach the input voltage requirements.

Be sure to ground the unit; If the power cord socket is equipped with grounding wire, check the

connection before use. If the power supply outlet is not grounded, it will be necessary to install a

ground by qualified engineers.

Note:

Due to the great impact of ambient temperature on the equipment, if the above

environmental requirements cannot be met, the equipment may not work normally. Please

improve the environment before using the equipment. The equipment is with intermittent

operation system.

4.3 Preparation before use

a. Remove all package components(include the protection foam inside the package)

b. Check the device, accessories and document with the device as per list of packing

c. Clean: make a clean of the device before use it.

Caution:

Do not put the packing plastic bag within reach of children as suffocation may result

4.4 First initial starting

Operate as follows for the first start:

1.After the equipment is placed stably and and cleaned, it needs to stand for more than 24 hours,

and then turn on the power, to ensure the normal operation.

2.Under no-load condition, connect the power cord to a special socket with appropriate

specifications.

3.After power on, turn on the power switch of the equipment.

9

4.Check whether the temperature reaches the required value, and then observe the equipment for

more than 24 hours. After confirming the normal performance, a small amount of items can be

placed in the storage room.

5.Try not to open the door in the cooling process, otherwise the temperature will rise.

4.5 Operation after power failure

1.The equipment has memory function for the setting value. When power is restored after power

failure, the equipment will continue the operation.

2.Once the power is interrupted, it is necessary to wait for 5 minutes before switching on again, to

avoid damaging the compressor。

3.Our company guarantees the normal operation of the equipment under certain conditions, but will

not be responsible for any loss or damage of stored items after power failure.

Caution:

The equipment can be moved by casters.

The equipment shall be in charge of special personnel, and the operation status shall be

checked and recorded every day (once every 2-4 hours). The temperature of the storage room will

rise in case of failure or shutdown, and if it can not be repaired in a short period of time, please take

out the stored items and transfer them to suitable place, to avoid damage.

Due to the refrigeration inertia, there is a certain difference between the actual display

temperature and the set temperature of the equipment, which is a normal.

The equipment is for storage , which can not be used for routine production. It is strictly

prohibited to put too many relatively hot items at one time, otherwise the compressor will burn out

after running for a long time. Items must be put in batches to ensure that the temperature of the

cabinet is stepped down until it meets the storage temperature.

Do not use unauthorized electrical appliances inside the equipment.

Do not change the set temperature frequently in a short time, otherwise, due to the large inertia

of cold and hot, the expected setting effect may not be achieved. When placing the items, make

sure that there is a certain air circulation flow space around the cabinet, especially do not block the

temperature sensor in the box (for collecting the temperature), otherwise the stability and accurate

control of the temperature will be affected.

Do not put the articles directly at the bottom of the cabinet, but on the shelf, otherwise the

refrigeration effect will be affected.

If the items too damp or too dry, it will affect the humidity in the cabinet, it is best to keep the

items sealed. The humidity of the working environment will affect the humidity change in the cabinet,

especially when the door is opened frequently or not closed properly.

Warning:

Children are not allowed to play with this equipment as game props, otherwise, the

consequences of injury or loss will be borne by themselves.

10

5. Refrigerator Components

* Due to the improvement of the products and different models, the actual products may be different

from the schematic diagram. The figure above is for reference only!

* Structure and composition: the product is composed of box body, door body, refrigeration system

and control system.

* Scope of application: the product is suitable for hospitals, pharmacies, epidemic prevention

stations, research institutions, bio-pharmaceuticals and other units refrigerated goods.

PS: The refrigerators with battery, excluding Lead, mercury, chromium, benzene, ether

6. Display panel function description

6.1 Function introduction

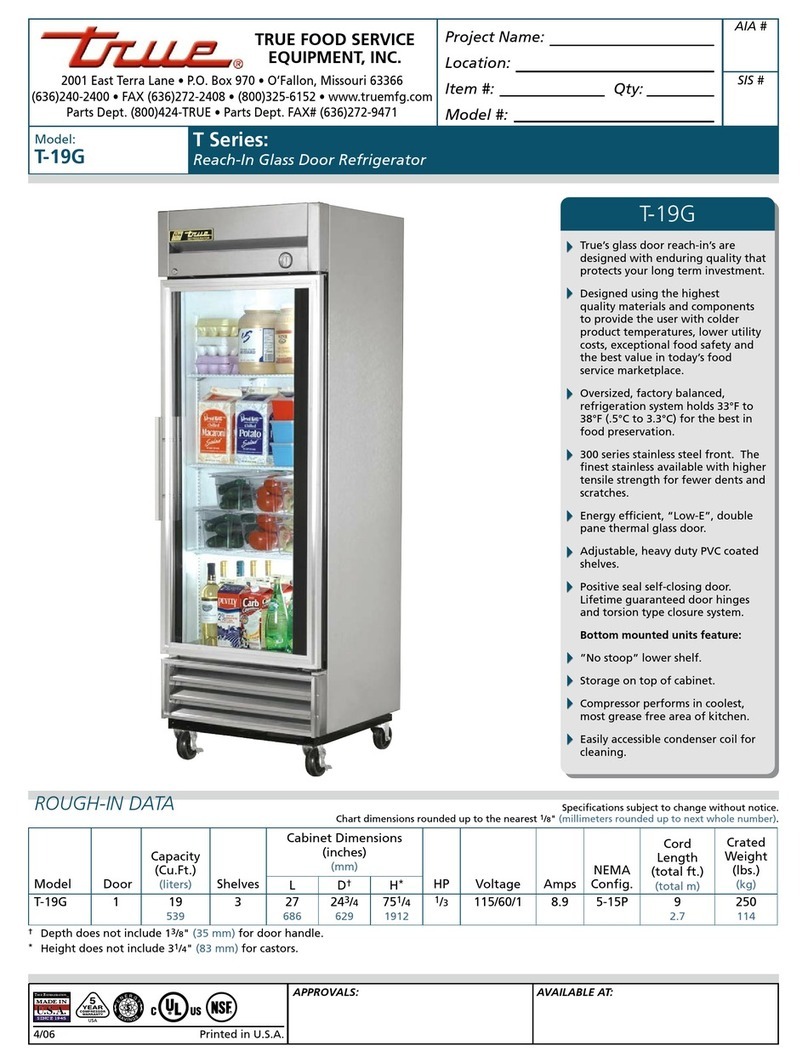

The electronic digital display can display the actual temperature in cabinet.

Indicator light

State

Significance

Refrigeration indicator light

dark

Compressor stop

blink

Compressor delay

light

Compressor working

Precooling indicator light

light

Precooling mode on

dark

Precooling mode off

Battery indicator light

light

Low power

dark

Normal power

Mute indicator light

light

Mute on

dark

Mute off

Power indicator light

light

Power on

dark

Power off,power failure alarm

Casters

Display

panel

Handle

Door

Cabinet

Power switch

Battery switch

Hinge

Outfall

11

Keyboard lock indicator light

light

Locked

dark

Unlocked

1.Control instruction

①is a digital temperature display window. Under normal operating conditions, it will

display the real-time temperature inside the cabinet, the unit is °C; in the setting state, different

prompt characters can be displayed (see below for details);

② : Under normal operating conditions, when the system alarms (the digital tube

shows that the internal temperature of the cabinet and the alarm code flash alternately), the user

can press this button to mute (temporarily turn off the buzzer), press this button again, the buzzer is

turned back on;

③ :this light is on during system operation (flashing in alarm state).

2. Function settings

①Power on/off: Under normal operation, press and hold the power button for more than 3

seconds after unlocking, the controller enters the shutdown state, the panel displays OFF, press

the power button again, the controller enters the normal running state;

②Mute operation: When the buzzer alarms (including over-temperature alarm inside the

cabinet, sensor fault alarm, etc.), press the mute button for the first time when the key is locked,

and the buzzer will stop. Press the mute button again, and the buzzer will restore the temperature

and alarm status in the display panel and continue to alarm;

③Battery switch: The battery switch is located on the back left of the cabinet: “ ” means off, “·”

means on;The power switch is located on the left of the cabinet: “0” means off, “1” means on .

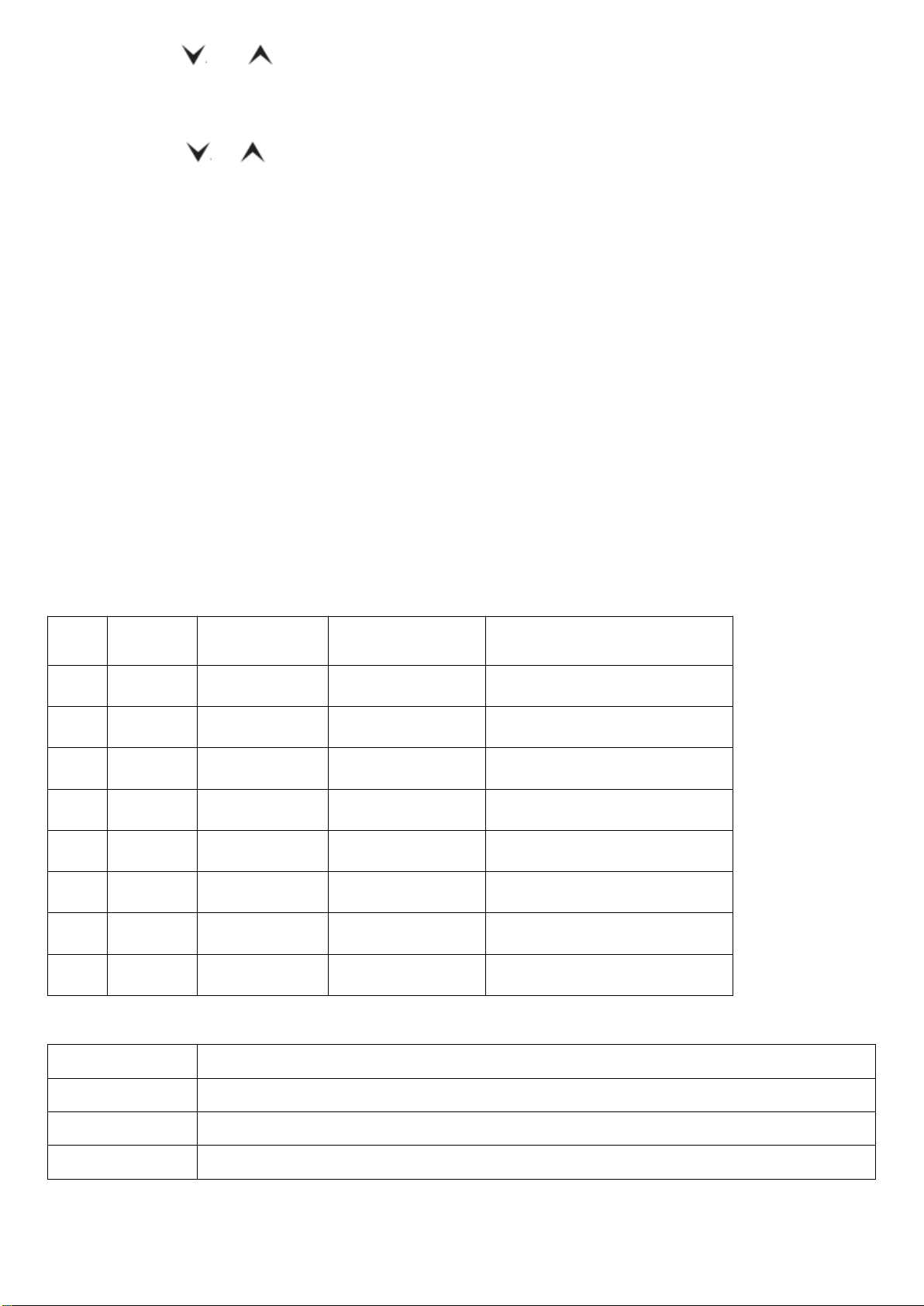

3. Operation of user menu parameters:

Unlock operation: Under normal operation, press the and for 2 seconds at the same

time, you can unlock the locked keyboard (the digital tube display is ON), or lock the unlocked

keyboard (the digital tube displays LoC); when the keyboard is locked, you cannot Operation, must

be unlocked before the keyboard can be operated. If there is no operation on the keyboard for more

than one minute, the keyboard is automatically locked.

①In the normal running state, press the function key for more than 3 seconds after the

keyboard is unlocked;

and the digital tube displays the parameter code “F01”;

12

②Use the and to roll the parameters (F01 refers to the compressor start delay, F02

refers to the time left before the power is turned off);

③Press the function key to confirm the parameter. The value of this parameter will be

displayed;

④Use the or to increase or decrease the value of the parameter;

⑤Press the function key to temporarily store the modified parameter value and return to the

parameter display page;

⑥If you modify the values of other parameters, repeat steps 3~5;

⑦Press the function key for more than 3 seconds to store the modified parameter value and

exit the parameter setting program;

⑧If you need to enable the precooling function, please press the precooling function button for

3 seconds, the precooling function indicator lights up, and the product enters the precooling mode

(please ensure that the F02 parameter ≥ 3 can successfully open the precooling mode).

Note:

The "high temperature" alarm will be triggered when the machine is started for the first time. Please

put in the items after the temperature is stable and the "high temperature" alarm removed

automatically. If the item is too damp or too dry, it will affect the humidity change in the cabinet. It is

better to keep the articles sealed.

6.2 Function setting:

1. Parameters setting:

No.

Item

Value range

Suggestion value

YC-150EW

Remarks

1

F01

0~50

3

Compressor start delay (min)

2

F02

0~24

8

Time to power failure (hours)

3

F05

0~10

0.1

Temperature setting (℃)

4

F06

1~25

1.7

Return difference setting (℃)

5

F11

-10~10

-1

Display sensor calibration

6

F07

F05~120

10

Maximum temperature setting

7

F08

-80~F05

0

Minimum temperature setting

8

F15

0~99

15

Alarm delay(min)

2. Alarm display:

Alarm code

Fault description

E1

Display sensor short circuit or open circuit

AH

The temperature exceeds the set maximum temperature value

AL

The temperature is lower than the set minimum temperature value

13

E2

Control sensor short circuit or open circuit

HH3

Ambient temperature sensor out of range

LL3

Ambient temperature sensor below lower range limit

PL

Low battery

7. Maintenance

Caution:

For personal safety, please cut off the power supply before any maintenance!

Don't inhale medications or aerosols around the device while maintaining the equipment, or

it will endanger your health.

7.1 Maintenance

Maintenance:Once in a while, the ice-lined refrigerator should be cleaned and maintained. (For the

safety, remove the power plug firstly) and wipe the inner and outer surfaces of the refrigerator with

a soft cloth.

Caution:

DO NOT sprinkle water on the faces of cabinets, which may decrease insulating property of

electric parts and rust metal parts.

DO NOT use hot water, corrosive cleanser and organic solvent!

DO NOT place heavy objects on the top of the equipment to avoid deformation under

pressure.

7.2 Out of use

Out of use: If the equipment is stored in an unsupervised area for a long time and is not used, the

power should be cut off and the inner and outer surfaces should be cleaned with a warm and soft

cloth, and then dried and sealed. The equipment must be locked to ensure that children cannot

open the door, in case of accidents such as surveillance.

Disuse: When the equipment has reached its service life, it shall be scraped by professional

qualified recycling institutions under local laws and regulations. Non-professional personnel shall

not dismantle and decompose the equipment by themselves. Disused equipment should be placed

in a designated area inaccessible to children to avoid hazards.

7.3 Maintenance

Battery installation location: inside the electrical appliance box.

Battery maintenance

14

①Regarding to the units which are not in the operation for a long time.It is better to make products

running for more than 24 hours per month to charge to prolong the service life of the battery.

②If the equipment is not used for a long time, it should be regularly (usually once a month) turned

on power and opened the power supply switch lock to run and charge, with not less than 24 hours

each time.

③When the power supply is interrupted, turn off the power lock switch of the equipment in time,

otherwise the battery will lose power and cause permanent damage to the battery;

④The main power switch must be turned off when there is long-term power failure or in

transportation , otherwise the battery will lose power or even permanent damage due to a long time

of discharge, and the display will be not normal after power is on again :

⑤The battery is consumable and has a life of about 2 years. If the battery is not properly used,

such as loss of power or reach the service life, it will cause low battery power alarm (it does not

affect the refrigeration but there is an alarm fault and impact the power failure alarms, please

contact our after-sales service personnel for replacement).

Battery replacement

①Turn off the power switch and pull the power plug from the socket;

②Remove the electrical box screws with a screwdriver; (Note: There are high-voltage electrical

components in the electrical box. Before opening, the power supply must be turned off, the power

plug must be unplugged and the power lock switch of the equipment must be turned off. The

electrical box must be opened by qualified engineers or maintenance personnel.)

③Unplug the battery connect wire; (Note: Before unplugging the battery fixed wire, please record

the wiring order of battery positive and negative. When change new battery, pay attention to the

correct wiring order in case of burning out control system due to wrong connecting. Generally, the

red wire is connected to the battery positive , and the black wire is connected to the negative.

④Remove the fixing screw from the battery fixing plate with a screwdriver and remove the battery;

⑤Battery model:DC-2600mAh-AG(3.7V) .

7.4 Disposal

Dumped Battery should be recycled and turn to local relevant administration department.Follow the

relevant laws and regulations of the host country and 2002/ 96/ EC.

Tips: In order to ensure that the battery replacement meets the requirements of the control system

and avoid the influence of improper operation on the system, please contact our after-sales

personnel for replacement or guidance.

7.5 Scrap and process management of the equipment

Caution:

If the equipment is stored in an unsupervised area for a long time and is not used, it should be

ensured that children will not get close to the equipment and the door cannot be completely closed.

15

7.6 Condensation Draining

After using the product for a period of time, there may be condensed water formed at the bottom of

the chamber, please drain away the condensed water in time to avoid damaging the storage items

such as vaccines.

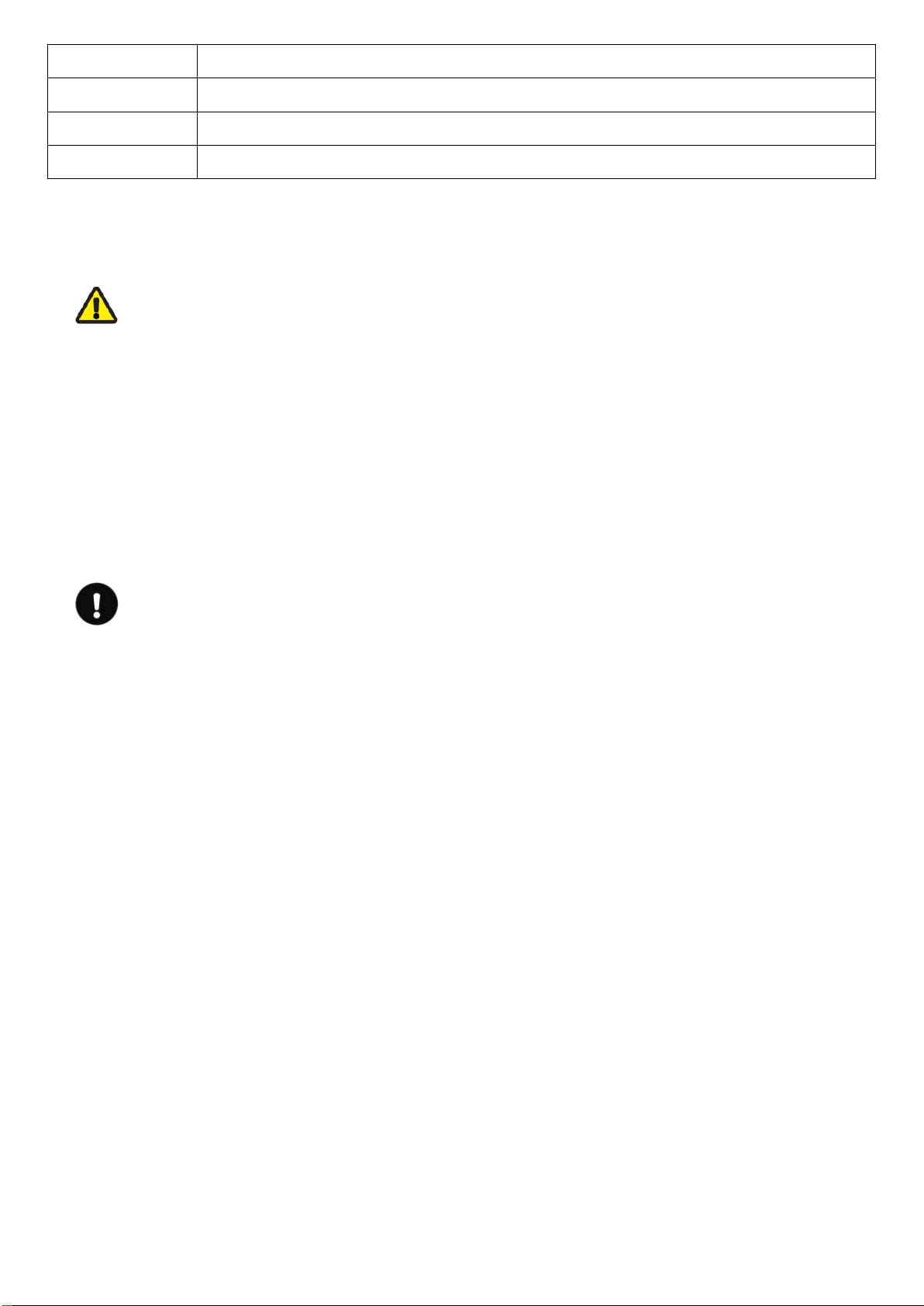

①As shown in the picture, the drain has an external plug ''2'' and an internal plug ''3''.

②Before the draining, pls prepare a water box ''1''. Taking out the plugs ''2'' and ''3'' to discharge

the condensed water.

③Install the plugs back after the draining, otherwise the performance will be damaged.

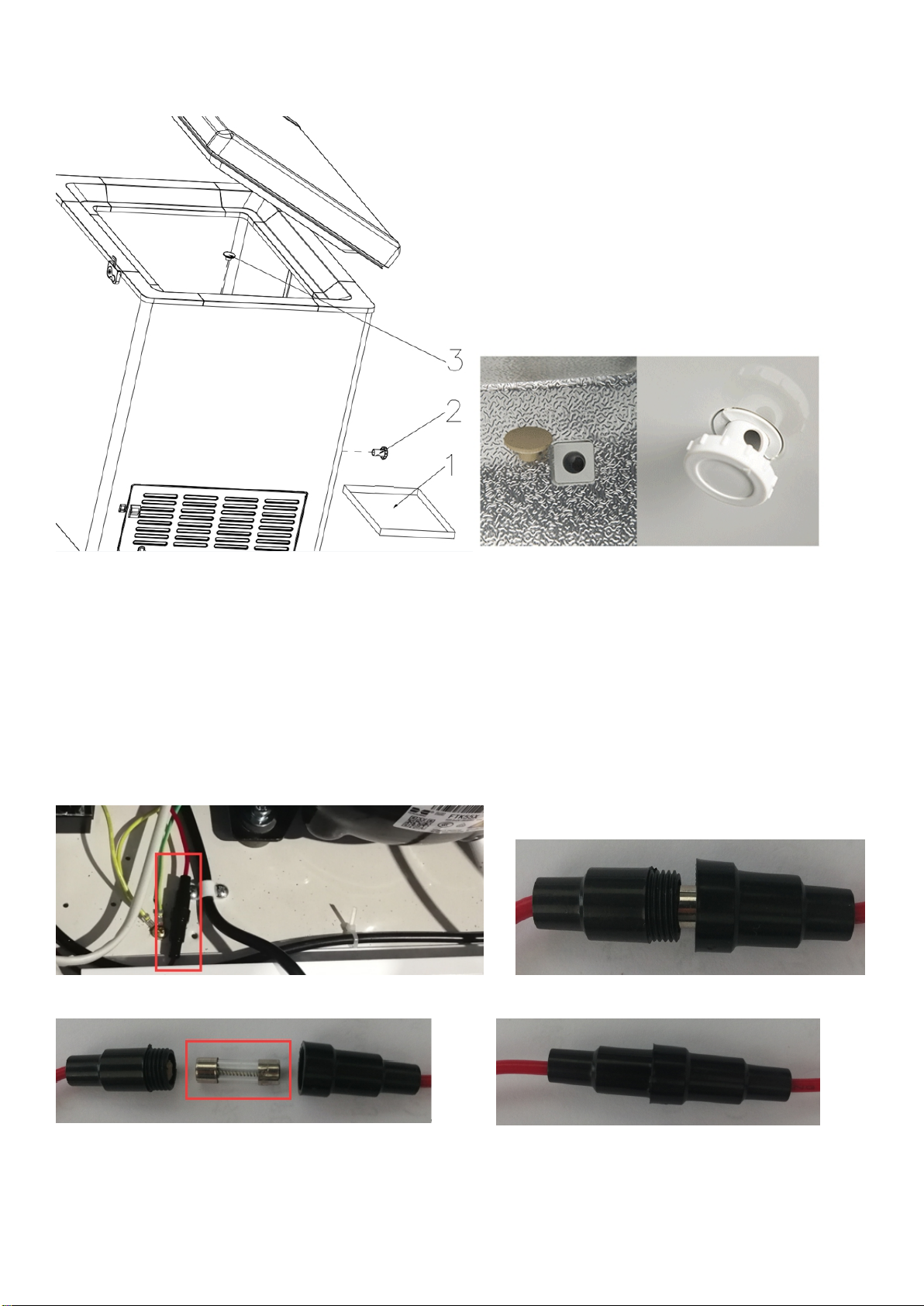

7.7 Steps to replace the fuse

①Find the fuse seat from the bundling wire harness of the wiring row and unscrew the fuse seat.

②Take out the fuse: the fuse is showed on the picture as below.

③Put in the new fuse and tighten the fuse seat.

④Ten spare fuses are placed in the enclosure bag inside the equipment.

16

No.

Special No.

Size

1

890041897

5*20 5A/250V

8. After-sale Service

Any product has the possibility of failure. Please observe the operation of the medical refrigerator

in the process of use. If there is any abnormality, please check and compare the errors with the

following table.If you can't fix the issue, Please inform our service center in time. We will serve you

wholeheartedly to avoid any losses.

Replacement time of fan motor: about 6 years;

Replacement time of temperature monitoring equipment: about 2 years;

Service life of this product: 10 years.

Problem

Possible Cause

Refrigerator does not running

●Power outage has occurred.

●The plug is bad or not securely plugged-in.

●Fuse is blown.

●Voltage is too low or high.

Compressor does not running

●Power in control panel is off.

●Temperature setting is wrong.

Temperature is lower than setting

●The door is not closed properly or is opened too frequently.

●Overfull materials are put.

●Ambient temperature is too high.

Loud noise

●Freezer is not leveled well.

●Freezer leans upon the wall.

Surface condensation of glass door

●Wet and moisture season, the door may be condensed. It belongs to normal

phenomenon, just wipe it with dry cloth.

Alarm flashing, buzz warning

●If you just put in the item, the temperature is stable and will be eliminated

automatically after running for a period of time.

●If the door is not closed tightly to cause the door open alarm.

●If the battery is low, it will be eliminated automatically for a period of time.

●Whether the temperature exceeds the standard.

● Below are normal operations:

①When the compressor starts and stops, the equipment parts will make a slight impact sound.

There is a slight sound of running water when refrigerant flows in the pipeline.

②After opening the door and put in the hot subjects, the controlling system appears high

temperature and high

humidity alarm solution:The hot subjects should be cooled by natural cooling and then put into the

cooler. Do not put too many subjects at one time. After the system is stable, the high temperature

and high humidity alarm will be relieved.

17

③When the equipment works, the surface of the equipment, especially the back, will get hot, and

the compressor even feels hotter. This is the normal condition of cooling system heat dissipation.

④The interval between two door opening should be more than 3 minutes, otherwise it will be

difficult to open the door again due to the negative pressure formed inside and outside of the

equipment.

Caution:

To ensure the normal operation of the machine and reach the corresponding safety standards,

only the engineers certified by Trufrostbiomedical can repair, maintain or improve the

equipment.Please clean and disinfect the machine before maintenance; during the warranty

period, the company will not undertake the warranty obligation for any fault or damage caused

by improper use.

Storing environment temperature:-30℃~+70℃, Relative humidity: 5%~95%.

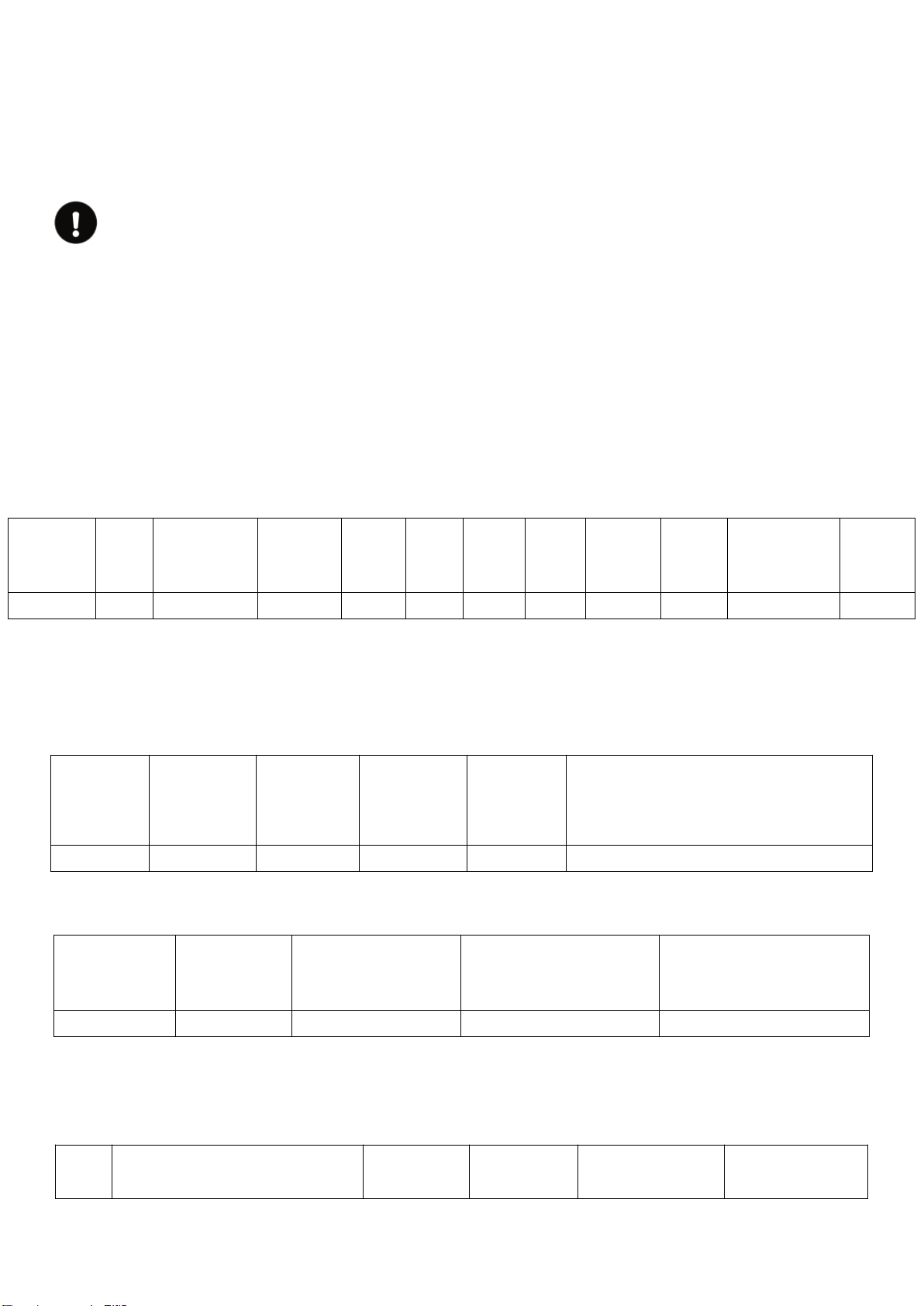

9. Specifications

Main technical parameters:

* The foaming agent is cyclopentane.

Main performance data:

10. Packing list

Model

Air

Temp

(℃)

Climate type

Refrigeration

-Qty

RV

(V~)

RP

(Hz)

Storage

Temp

(℃)

VC(L)

Input power

(W)

Weight

(Kg)

External Size

(D×W×H)(MM)

Power

connection

conditions

YC-150EW

10~43

SN、N、ST、T

R290/65g

220-240

50

2~8

150

240

76

811*775*964

Y

Model

Temperature

Zone

Cooling

performance

Power cycle

Thermal

insulating

performance

Energy consumption (stable runing,

intermittent power)

YC-150EW

Tropic (Hot)

1~3 days

8h/day

20~25h

0.934kWh/24h

Model

Lining

Refrigerator vaccine

storage capacity)(L)

Energy consumption (cool

down)

Energy consumption

(stable runing, continuous

power)

YC-150EW

Ice-Lined

120

0.897kWh/24h

0.907kWh/24h

Item

Operation manual

(with Warranty certificate)

Certificate

card

Key

Defrosting tool

spare fuse

18

11. Wiring diagram

Object / part No.

Manufacturer/

trademark

Type / model

Technical data

Mark(s) of conformity

Fan

Jiangsu Willtron Tech

Co.,Ltd

ZYD-4P-25

220-240 V, 50/60 Hz, 25/4 W,

0.19 A

VDE 40031795+

tested with appliance

Compressor

Wanbao Group

Compressor Co., Ltd.

FTK55X

220-240 V, 50/60 Hz, R290

VDE 40051763

Switch for battery

Light Country Co. Ltd.

R 19 series

250 V, 6A, 10E3, T85

VDE 40006923

Power Switch

Canal Electronic

Co.,Ltd

R series

250 V, 16(4)A, 10E3, T85

VDE 40000809

Battery

Dongguan Xintongtai

Industrial Co., Ltd.

18650

3.7V,2600mAh,9.62Wh

Tested with appliance

* If the product is improved, the technical data and circuit diagram shall be subject to the final

product nameplate and cabinet circuit label.

12.Directions for safe transportation

Products may be exposed to very high temperatures during shipping and dockside storage,

please ensure that the environment temperature range will not be out of-30℃~ +70℃and the

relative humidity is between 5%and 95%during the transportation and storage. If this security

Qty

1

1

2

1

10

19

scope is exceeded, please take proper measures to mitigate this risk and ensure the safe

transportation for the products.

The packing materials of the products do not contain ozone-depleting substances under the

“Montreal Protocol”.

Product packaging is designed to comply with export regulations and to fully protect equipment

for transport by air, sea or land to any area of the world, including remote areas with poor weather

and storage conditions and high humidity.

The packaging has an edge crushing resistance of not less than 17kN and maintains at least 60%

edge crushing resistance at temperatures of +70°C(tropical conditions) and 90% humidity.

The general specification of shipping containers will be subject to agreement with the individual

procurement agencies.

When products are transported and stored, the stack shall be no more than 2 layers.

The transportation of the temperature recorder is selected according to the customer's

requirements.

20

Warranty certificate

(Instructions)

Dear users:

Thank you for using Trufrost pharmacy refrigerators, blood bank refrigerators, ice lined

refrigerators, medical freezers, ULT freezers and other medical and scientific research equipment.

Our company will comply with the relevant provisions of the "Three Guarantees Regulations"

under the "Law of the PRC on the Protection of the Rights and Interests of Consumers'rightsandinterests".

With this warranty certificate and receipt, we will provide you with the following services:

1.Three years free warranty for the whole machine.

2. Three years free warranty for the main parts (compressor unit, filter, fan motor, temperature

controller, evaporator, solenoid valve, condenser, main control panel, electronic control display,

defrosting timer, temperature sensor, defrosting heater).

3. The following cases are not within the scope of free warranty service, but can be repaired at a

charge:

①Beyond the warranty validity;

②Unable to show warranty certificate and receipt;

③Receipt is altered;

④Damage caused by accidence and improper use;

⑤Damage caused by repair privately without permission of our company;

⑥No nameplate.

4. Notice to users

The user should show this warranty certificate,when our company's on-site maintenance or

installation personnel is in the service.

Memo: For the convenience of checking, please copy the product model, serial number and

production date on the nameplate on the back of the equipment as the following table.

Model

Serial Number

Production date

Table of contents