Trumpf quicksharp User manual

quicksharp

DK

DGB FE

INL

Betriebsanleitung

Operator's manual

Manuel opérateur

Istruzioni per l'esercizio

Manual de operatión

Driftsvejledning

NL

Gebruiksaanwijzing

Ersatzteilliste

Spare parts list

Liste des pièces de rechange

quicksharp

06/2000

Operator's manual

quicksharp

06/2000

Ordering information Please state title of document, desired language and date of

edition.

TRUMPF GmbH + Co KG

D-71254 Ditzingen

Johann-Maus-Straße 2

Phone (0 71 56) 303-0

Telefax (0 71 56) 303-540

Internet: http//www.trumpf.com

e-mail: [email protected]

This document has been drawn up by the Technical Documentation Dept. of

TRUMPF GmbH + Co.

All rights to this documentation, especially the right of reproduction and

distribution as well as translation, reserved to TRUMPF GmbH + Co., also in the

case of applications for industrial rights. Without the prior written consent of

TRUMPF GmbH + Co., no part of the documentation, in any form whatsoever,

may be reproduced or processed, copied or distributed using electronic systems.

Errors and technical modifications excepted.

TRUMPF GmbH + Co KG

TRUMPF GmbH + Co. cannot be held responsible for possible mistakes in this

documentation. Any warranty for direct and indirect damages, arising in

connection with the delivery or the use of this documentation, is excluded, as far

as this is legally permissible.

Table of Contents

1. For your safety 4

1.1 Overview of dangers 6

2. Description 7

2.1 Technical data 8

2.2 EC Declaration of Conformity 8

3. Installation 9

3.1 Hydraulic oil container 9

3.2 Grinding coolant container 9

3.3 Power supply 10

4. Operation 10

4.1 Regrinding dies 10

4.2 Regrinding flat punches 12

4.3 Regrinding punches with shear (Whisper Tools) 13

5. Maintenance 15

5.1 Sharpening the grinding wheel 15

5.2 Changing grinding wheels 15

5.3 Adjusting the locating stop 16

5.4 Setting the feedrate 16

5.5 Maintenance 17

5.5.1 Utilities 17

5.5.2 Maintenance intervals 17

6. Troubleshooting 18

B60E Table of Contents 3

1. For your safety

With the quicksharp you have at your disposal a grinding machine

which, in terms of safety, is state-of-the-art and safe in operation.

With the declaration of EC conformity and the CE label on the

machine, we confirm that the quicksharp complies with the relevant

regulations on occupational health and safety as stipulated in EC

Machinery Directive 89/392/EEC.

6840-H 3

1,7

16

M achine N °.

20

Nameplate and CE marking Fig. 24072E

The nameplate, together with the CE marking, is affixed to the rear of

the machine.

Despite all these provisions, however, the machine may still represent

a source of danger if incorrectly operated by untrained personnel or if

used for unauthorized application.

☞In addition to the guidelines provided in this manual, the

general guidelines governing safety and accident prevention

must also be observed!

Authorized application The quicksharp is designed for grinding dies, flat punches and

Whispertools.

Liability voided in the Any application beyond and above this shall be construed as

event of unauthorized unauthorized application. The manufacturer shall not be held liable for

application! any damages resulting therefrom; the entire risk rests solely with the

user.

4quicksharp B60E

Modifications to the Unauthorized changes or modifications to the machine by the owner

machine or the operator are strictly prohibited; the manufacturer shall not be

held liable for any injury to persons or material damage resulting

therefrom.

Instructing the Only authorized, trained and suitably instructed personnel may be

personnel entrusted with the operation, maintenance and service of the machine.

This personnel must receive specialized instruction regarding possible

hazards.

Reading the The complete technical documentation on the machine should be

documentation made available for study to all persons charged by the owner with the

operation, maintenance and service of the machine. It is

recommended that the owner obtain written confirmation from his staff

that they have studied and understood the documentation.

Maintenance work The mains plug must always be disconnected before undertaking any

adjustment, maintenance and service work on the machine unless

indicated otherwise.

Using original parts Original parts and accessories have been designed especially for the

machine. Replacement parts for these original parts and accessories

other than those supplied by the manufacturer of the machine are not

inspected and approved by the manufacturer. The incorporation

and/or use of such products may, therefore, have an adverse effect on

the function of the machine and diminish its safety.

Liability disclaimer The manufacturer shall not be held liable for any damage incurred

through the use of non-original parts and accessories or through

improper installation or exchange of original parts and accessories.

Notes on work safety The technical documentation on the machine provides information on

working safety that is of vital importance for the prevention of injuries

ensuing from hazards to health and life. The symbol on the left calls

your attention to this type of information.

☞For your safety: These statements must be observed without

fail!

B60E quicksharp 5

1.1 Overview of dangers

The following overview is a summary of the potential dangers that the

machine may pose to life and health, and of possible injuries. The

design and construction of the machine, coupled with the safety

equipment installed in compliance with EC machinery directive

89/392/EEC, eliminates danger to persons. Any measures that can be

taken by the user to reduce any residual dangers are indicated in the

overview below.

Type of danger Danger point Danger Extra measures*

Mechanical danger

•Being caught or rolled up •Rotary tool holder Danger of injury -

•Grinding wheel Danger of injury -

•Fluids and gases expelled

under high pressure •Hydraulic hoses Danger of injury -

•Parts ejected at high speed •Workpiece Danger of injury -

Electrical danger

•Due to electrical contact •Direct contact with normally Lethal danger -

live parts

•Indirect contact with parts Lethal danger -

that are live when faulty

Danger from noise emission

•Hearing loss •During the grinding process Health hazard -

Danger from material

•Through contact with or by •Grinding coolant Health hazard •Provide for adequate

inhaling toxic fluids, gases, ventilation

mist, vapors and dust •Use grinding coolants as

specified in operator's

manual (non-chlorinated)

Danger due to faults or

malfunctions •Drives Danger of injury -

•Power supply faults •Control voltage Danger of injury -

•Faulty installation •quicksharp Danger of injury •Note operating instructions

Thermal danger - - -

Danger from vibrations - - -

Danger from radiation - - -

*Extra measures the customer can take to reduce any danger remaining despite the

safety equipment of the machine

6quicksharp B60E

2. Description

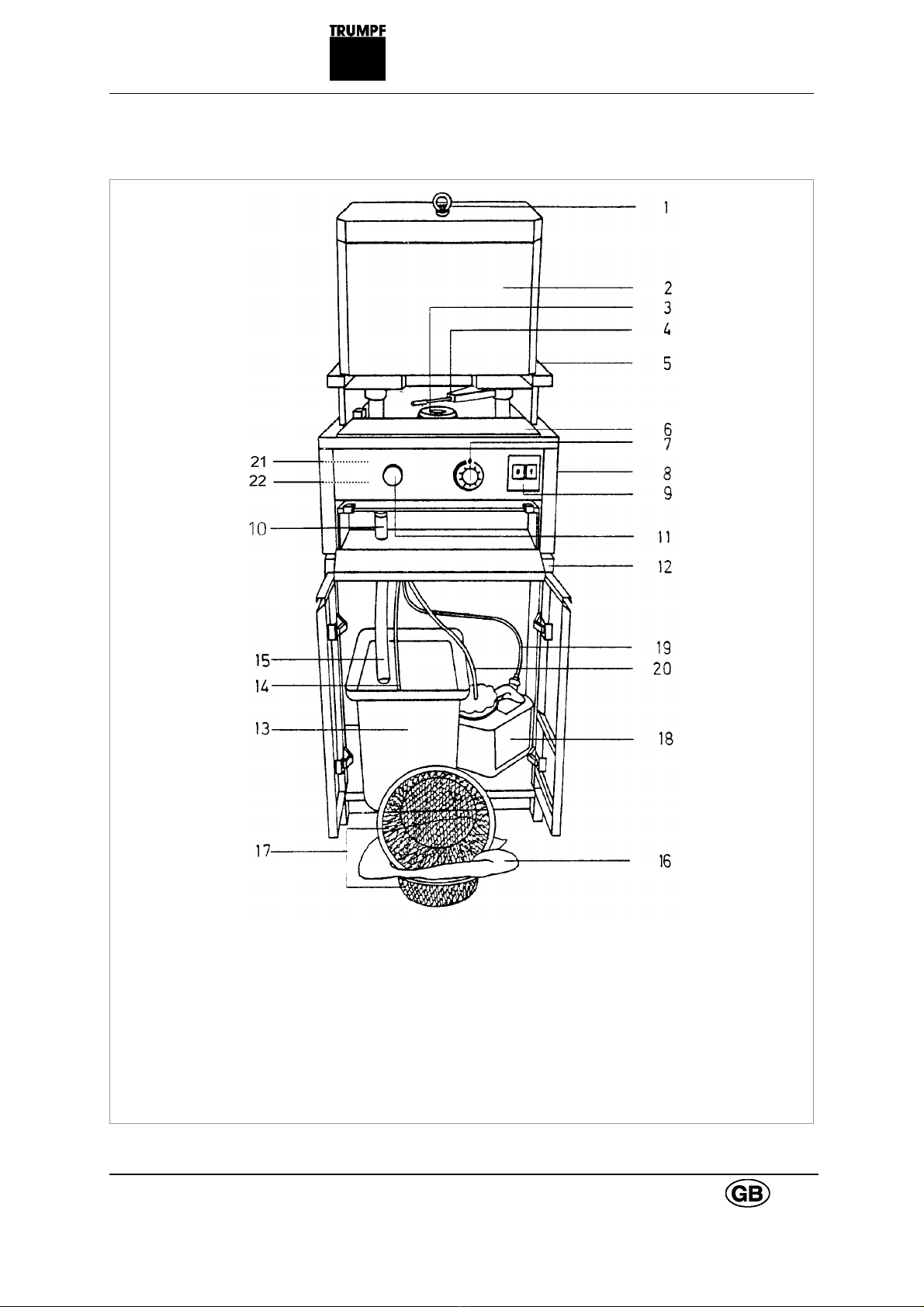

1 Lifting eyebolt 8 Indicator pin 17 Filter screens

2 Enclosure/top 9 Main switch OFF/ON 18 Hydraulic oil container

3 Rotary tool holder 10 Return flow pipe 19 Return hose for hydraulic oil

4 Locating stop 11 Feed button 20 Intake hose for hydraulic oil

5 Hole for brake 12 Base 21 Throttle valve

release 13 Grinding coolant container 22 Relief valve

6 Flap 14 Grinding coolant intake hose

7 Rotary knob for setting 15 Return flow/grinding coolant

the regrind amount 16 Filter paper

quicksharp Fig. 9885

B60E quicksharp 7

2.1 Technical data

quicksharp

Workpiece:

Clamping diameter 150 mm

Min. height 25 mm

Max. height 130 mm

Wheel motor:

Speeds 2800 - 3360 min-1

Voltages 200 - 265 V/350 - 460 V

Cycles 50/60 Hz

Power 1.1 kW

Grinding wheel diameter 125 mm

Grinding wheel height 23 mm

Cutting speed 20 m/s

Workpiece speed 40 min-1

Feedrate 0.1 mm/min

Regrind amount per grinding

operation 0 - 0.5 mm

Dimensions 600 x 600 x 1780 mm

Weight 300 kg

Hydraulic oil - container volume 5 l

Grinding coolant - container volume 20 l

Noise emission The typical A-effective sound level of the

unit is lower than 70 dB(A).

2.2 EC Declaration of Conformity

as defined by EC Machinery Directive 89/392/EEC, Annex IIA

We herewith declare that the machine indicated below, owing to its

engineering concept and construction and the model as introduced on

the market, complies with the relevant essential safety and health

provisions stipulated in the EC directive.

This declaration shall lose its validity if any changes are made to the

machine without our authorization.

Machine designation: Tool Grinding Machine

Machine type: quicksharp

Applicable EC directives: EC Machine Directive 89/392/EEC;

91/368/EEC, 93/44/EEC

EC Low Voltage Directive

(73/23/EEC)

EC-EMC Directive (89/336/EEC)

Applied harmonized stan-

dards, in particular: EN 292-1, EN 292-2, EN 60 204-1,

EN 55022, EN 55014

Hans Klingel

Director of Development

TRUMPF GmbH + Co.

D-71254 Ditzingen

8quicksharp B60E

3. Installation

•Check consignment for completeness and for any signs of damage

incurred during transit

•Use the lifting eyebolt (1) when lifting the unit (screw the bolt in all

the way). For safety reasons, the grinding machine and the base

should be transported separately

•Take care not to damage the hoses (14, 15)

Installation:

•Run the power cable to the rear of the machine

•Run the transparent return hose (15) through the base and clamp

to the return pipe (10) with a hose clip

•Run hoses (14, 15, 19, 20) through the cabinet top to the

containers (see connections below)

•Remove the lifting eyebolt after transport has been completed

•Open flap (6), release brake (5) (insert a hexagon screwdriver

SW6 in the tapped hole to push the pin back)

•Lift the top (2) and remove the transport safety (Styrofoam)

•Lower the top (2) approximately 50 mm, swing locating stop (4) to

the right and close the flap (6)

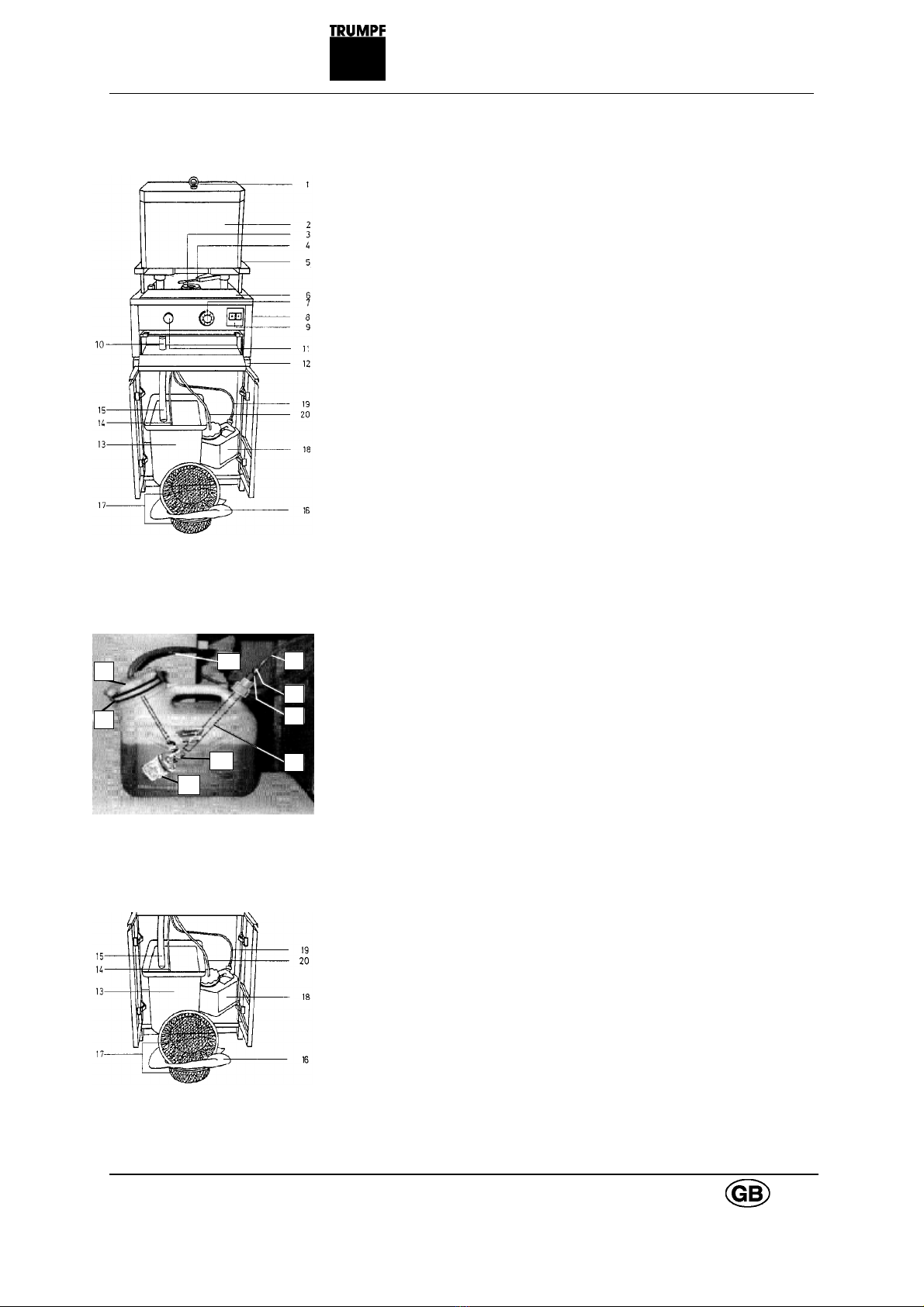

3.1 Hydraulic oil container

54

7

1

8

9

6

3

2

Connection:

•Unscrew the nut (7) and remove the cap (1)

•Attach the hose (4) and tighten the nut (7)

•Open lid (2), remove end plate (3)

•Insert hose (5) without filter (6) through lid (2)

•Mount filter (6) on hose (5)

•Add hydraulic oil as specified in "maintenance"

•Replace the lid (2)

3.2 Grinding coolant container

Prepare the grinding coolant:

•Mixture ratio: 1 : 30 (0.6 - 0.7 liters of Henkel P3-MULTAN 41-3 to

20 liters of water)

•Clean container (13) and fill it with grinding coolant

•Run intake hose (14) with filter (6) into the container

•Insert the filter paper (16) between the filter screens (17)

•Hang the filter screens into the container; the return flow/grinding

coolant must reach into the filter screens

B60E quicksharp 9

3.3 Power supply

The power supply plug should be attached to the connection cable by

an electrician in compliance with local regulations. Voltage is factory-

set by the manufacturer for the requirements in the country of

operation.

Check direction of rotation of the hydraulic pumps:

•Remove enclosure (2)

•Main switch (9) ON

•Both pumps must rotate in direction of arrow (clockwise)

•Pull the feed button (11) - the green indicator pin (8) must pop out

4. Operation

Basics Sharpen your tools regularly

Recommended regrinding amount: 0.1 - 0.2 mm

Approximate values The approximate values below serve as an aid for correct setting:

Punch*Die

∅(mm)/Size 30 76 I II

Scale value 1-2 2-3 2-3 3-4

*not Whispertools

4.1 Regrinding dies

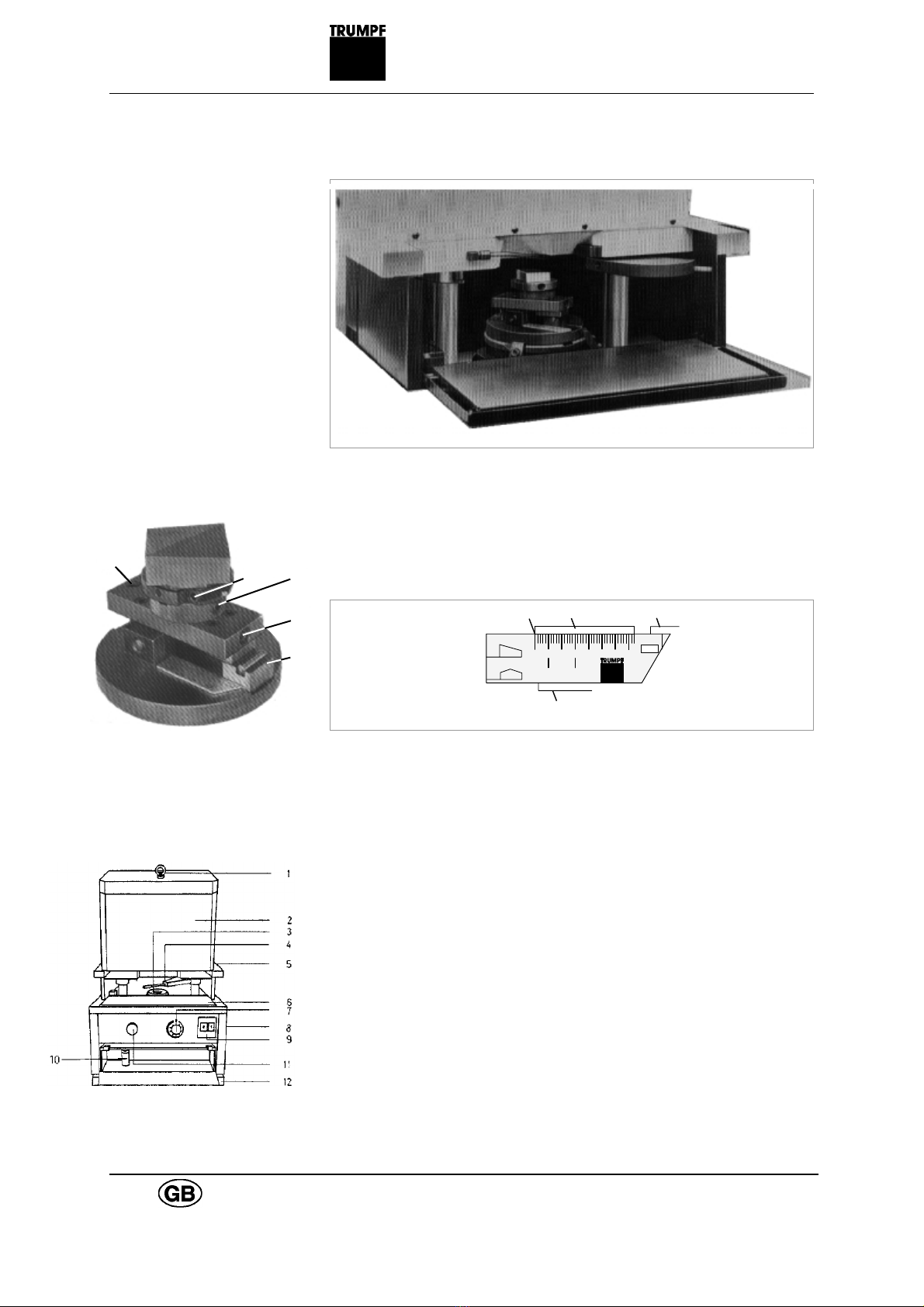

Regrinding dies Fig. 9892

Procedure •Insert die in a suitable adapter ring.

•Lock die in adapter ring onto the rotary tool holder with the

clamping jaws (loosen hex. screw on jaws and tighten)

10 quicksharp B60E

•Swing the locating stop (4) to the left; a certain amount of

resistance must be overcome when doing so

•Lower the top until the locating stop rests on the die - then swing

the stop back to the right

•Close flap (6); the machine cannot be started with the flap open

•Set the desired regrind amount at the rotary knob (7)

•Main switch (9) ON

•First pull, then press the feed button (11)

•Grinding takes place automatically. The quicksharp switches off

automatically when the grinding process is finished.

Regrinding Multitool In preparation for grinding, Multitool dies must be raised and shimmed

dies in the die holder.

☞Automatic grinding can be interrupted any time by pulling the

feed button (11).

As a visual aid, the green indicator pin (8) becomes visible at

the end of the automatic grinding cycle. The quicksharp

switches off automatically when the grinding process is

finished.

Suitable die clamping fixtures (see spare parts list) must be

used when sharpening dies from other manufacturers.

B60E quicksharp 11

4.2 Regrinding flat punches

Regrinding flat punches Fig. 9893

Procedure •Insert punch (with alignment ring) into the punch grinding fixture

•Tighten screws (1, 2 and 5)

4

2

3

1

5

•Loosen screw (4)

•Position slide (3) with red marker to the scale section for flat

punches (3):

50 60 7040

10080

12 3

4

Sine rule Fig. 9894

•Tighten screw (4)

•Swing the locating stop (4) to the left; a certain amount of

resistance must be overcome when doing so. Raise the top (2).

•Lock the punch grinding fixture on the rotary tool holder (3) with the

clamping jaws (loosen hex. screw on jaws and tighten)

•Lower the top until the locating stop rests on the punch - then

swing the stop back to the right

•Close flap (6); the machine cannot be started with the flap open

•Set the desired regrind amount at the rotary knob (7)

•Main switch (9) ON

•First pull, then press the feed button (11)

•Grinding takes place automatically. The quicksharp switches off

automatically when the grinding process is finished.

12 quicksharp B60E

☞Automatic grinding can be interrupted any time by pulling the

feed button (11).

As a visual aid, the green indicator pin (8) becomes visible at

the end of the automatic grinding cycle. The quicksharp

switches off automatically when the grinding process is

finished.

Suitable clamping fixtures must be used (see spare parts

list) when sharpening punches from other manufacturers.

4.3 Regrinding punches with shear

(Whisper Tools)

Differentiation Punches may have a shear on one or both sides:

•up to 72 mm outer circle diameter (corner dimension, diameter):

shear on one side

•outer circle diameter over 72 mm: shear on both sides (roof-

shaped).

Procedure •Insert punch (with alignment ring) into the punch grinding fixture

•Loosen screw (4)

4

2

3

1

5

•Position slide (3) with red marker to the scale section for punches

with single or roof-shaped shear. Set the values in the scale

section according to the outer circle diameter (corner dimension,

diameter) of the punch in mm:

50 60 7040

10080

12 3

4

Sine rule Fig. 9894

B60E quicksharp 13

•Scale section (1): for Whispertool punches max. 35 mm outer circle

diameter

•Scale section (2): for Whispertool punches with shear on one side

(35 - 72 mm outer circle diameter)

•Scale section (4): for Whispertool punches with roof-shaped shear

(outer circle diameter over 72 mm)

4

2

3

1

5

•Tighten screw (4)

•To make sure the punch face you want ground is exactly level, use

a height gauge

•Tighten screws (1, 2 and 5)

•Swing the locating stop (4) to the left; a certain amount of

resistance must be overcome when doing so; raise the top (2)

•Lock the punch grinding device on the rotary tool holder (3) with

the clamping jaws (loosen hex. screw on jaws and tighten)

•Lower the top until the locating stop rests on the punch - then

swing the stop back to the right

•Close flap (6); the machine cannot be started with the flap open

•Set the desired regrind amount at the rotary knob (7)

•Main switch (9) ON

•First pull, then press the feed button (11)

•Grinding takes place automatically - Roof-shaped punches must be

turned 180˚in the grinding device; to do so, loosen screw (2, top

Fig.), turn by 4 notches, tighten screw (2)

•Main switch (9) ON

•First pull, then press the feed button (11) - grinding takes place

automatically. The quicksharp switches off automatically when the

grinding process is finished.

☞Automatic grinding can be interrupted any time by pulling the

feed button (11).

As a visual aid, the green indicator pin (8) becomes visible at

the end of the automatic grinding cycle. The quicksharp

switches off automatically when the grinding process is

finished.

14 quicksharp B60E

5. Maintenance

For safety reasons, the mains plug must always be disconnected

before undertaking any maintenance work on the machine unless

indicated otherwise.

5.1 Sharpening the grinding wheel

☞Sharpen the wheel regularly!

When? If the grinding noise increases, the ground surface shinier and the

workpiece hotter than when the grinding wheel is sharp, the later

should be sharpened.

Procedure •Clamp the sharpening device (with corundum block protruding at

least 3 mm) onto the rotary tool holder

•Slide the locating stop to the left; a certain amount of resistance

must be overcome when doing so, and lower it carefully onto the

top of the corundum block

☞Caution: The corundum block may fracture!

•Then slide the stop to the right

•Loosen attachment of corundum block - pull it out upward 10-15

mm - clamp corundum block

•Close flap. The machine cannot be started with the flap open

•Main switch ON

•First pull, then press the feed button

•Pull the feed button once the visibly rapid descent of the top stops;

this improves sharpening results!

•To switch off: Main switch OFF

5.2 Changing grinding wheels

Attachment The wheel is attached with 3 screws and has 3 free tapped holes.

Dismantling the old •To dismantle, loosen the 3 fastening screws, thread them into the

grinding wheel free tapped holes and press the wheel out by applying uniform

pressure.

Mounting the new •Clean the flange faces

grinding wheel •Screw the new grinding wheel on

•Make sure the 2 small coolant tubes are directed straight onto the

wheel face (clearance: approx. 1 mm)

•Set the locating stop

B60E quicksharp 15

5.3 Adjusting the locating stop

When? The locating stop must be reset every time the grinding wheel is

replaced or sharpened:

2

1

3

1 Setting screw

2 Grub screw

3 Handle

Locating stop Fig. 9898

Procedure •Loosen grub screw (2)

•Insert hex. screwdriver SW6 into one of the holes on the setting

screw (1) - then turn setting screw to the left until the locating stop

rests lightly against the grinding wheel

•With hex. screwdriver SW6 turn to the right by 1 mark of the scale

on the setting screw (1)

•Using a feeler gauge, make sure there is a 1/10 mm gap between

grinding wheel and locating stop; if necessary, readjust the setting

screw (1)

•To lock: Tighten grub screw (2) using an Allen key

5.4 Setting the feedrate

The feedrate is correctly set at the factory and should not be re-

adjusted. (Cycle time approx. 3 1/2 - 4 1/2 min).

If no other recourse is available, the feedrate can be set - at working

temperature - at the throttle valve located behind the back cover of the

machine using a spanner SW32.

16 quicksharp B60E

5.5 Maintenance

5.5.1 Utilities

Lubrication point Quantity Recommended lubricant Designation Viscosity

Hydraulic oil container 5 l ARAL Vitam GF 32 or Vitam DE 32 HLP/HLPD ISO VG 32

BP Energol HLP 32 DIN 51525

CASTROL Hyspin AWS 32

ELF ELFOLNA HMD 32

ESSO TERESSO 32

FUCHS RENOLIN MR 10

MOBIL DTE 24 or 25

SHELL Tellus Oil DO 32 or DO 46

Grinding coolant 0.7 l / Henkel P3-MULTAN 41-3

container 20 l CASTROL Syntilo 81-E

(oil for grinding coolant)

5.5.2 Maintenance intervals

Interval Work to be done

After 8 h •Take the dirt bowl out of the rotary tool holder and rinse it out

•Check the hydraulic oil and grinding coolant

•Replace filter paper in coolant container as soon as filtration

effect diminishes

After 40 h •Clean the entire machine

•Lubricate locating stop using a grease gun

After 160 h •Clean the grinding coolant container

•Change the coolant, assure proper disposal of waste grinding

coolant

After 500 h/ •Remove hood, raise the motor bridge and

half-yearly lubricate ball bearings with slideway oil

•Check the fittings on the pumps for proper seating

After 4000 h •Replace the hydraulic oil and bleed the system at

the throttle valve, assure proper disposal of waste oil

B60E quicksharp 17

Table of contents

Popular Grinder manuals by other brands

Performance Tool

Performance Tool W50003 owner's manual

BW Manufacturing

BW Manufacturing DG-16 Operating & maintenance instructions

Ryobi

Ryobi P420 Repair sheet

Hitachi

Hitachi G 13VA Handling instructions

Parkside

Parkside 90983 Operation and safety notes translation of original operation manual

Parkside Performance

Parkside Performance PWSAP 20-Li B2 Operation and safety notes translation of the original instructions