DIXIE GRINDERS 11-10 User manual

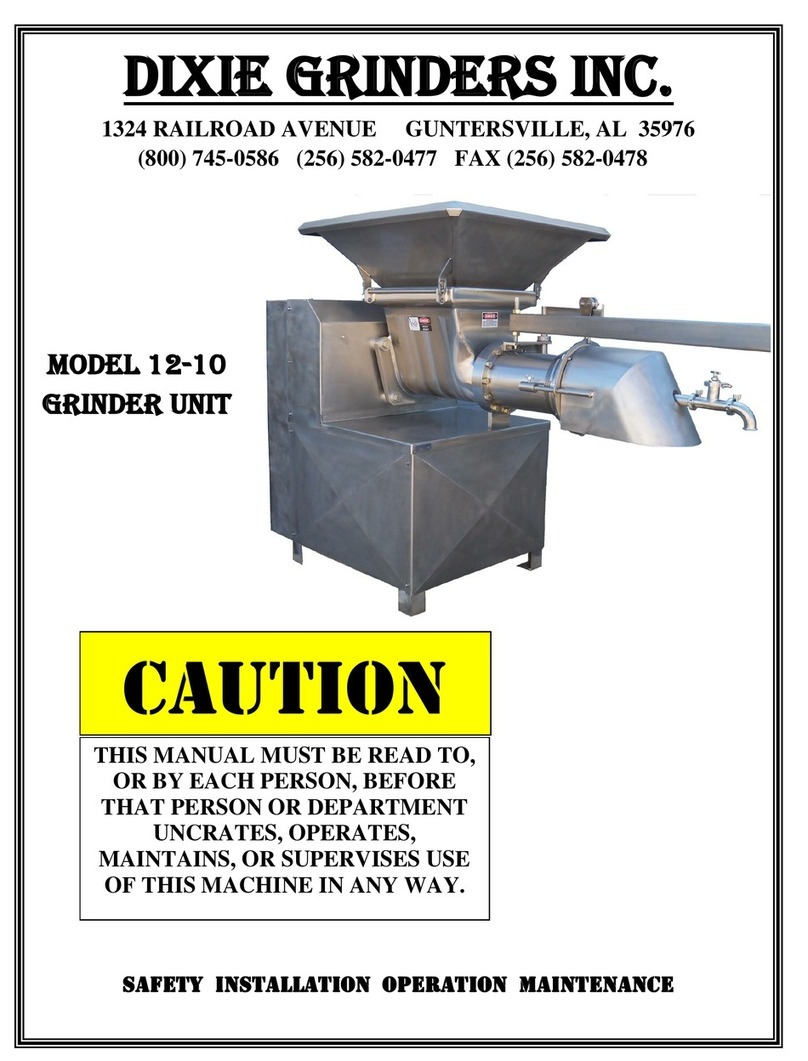

DIXIE GRINDERS INC.

1324 RAILROAD AVENUE GUNTERSVILLE, AL 35976

(800) 745-0586 (256) 582-0477 FAX (256) 582-0478

MODEL 11-10

GRINDER UNIT

SAFETY INSTALLATION OPERATION MAINTENANCE

THIS MANUAL MUST BE READ TO,

OR BY EACH PERSON, BEFORE

THAT PERSON OR DEPARTMENT

UNCRATES, OPERATES,

MAINTAINS, OR SUPERVISES USE

OF THIS MACHINE IN ANY WAY.

CAUTION

1

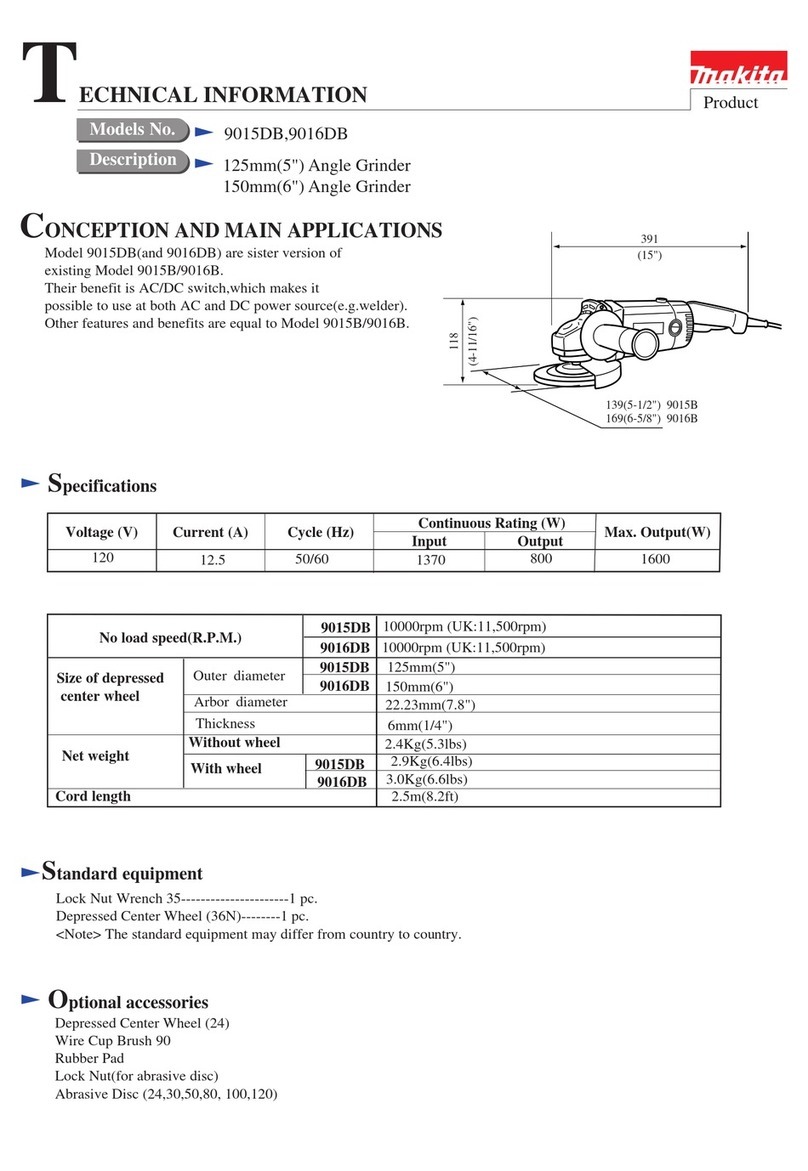

DIXIE

GRINDERS

INC.

TRIPLE

PLATE

ASSEMBLY

2

IMMEDIATE HAZARDS

WHICH WILL RESULT IN

SEVERE PERSONAL INJURY

OR DEATH.

HOPPER GUARD

LISTED BELOW IS THE DEFINITION OF THE HAZARD

LEVEL USED ON THE SAFETY STICKERS.

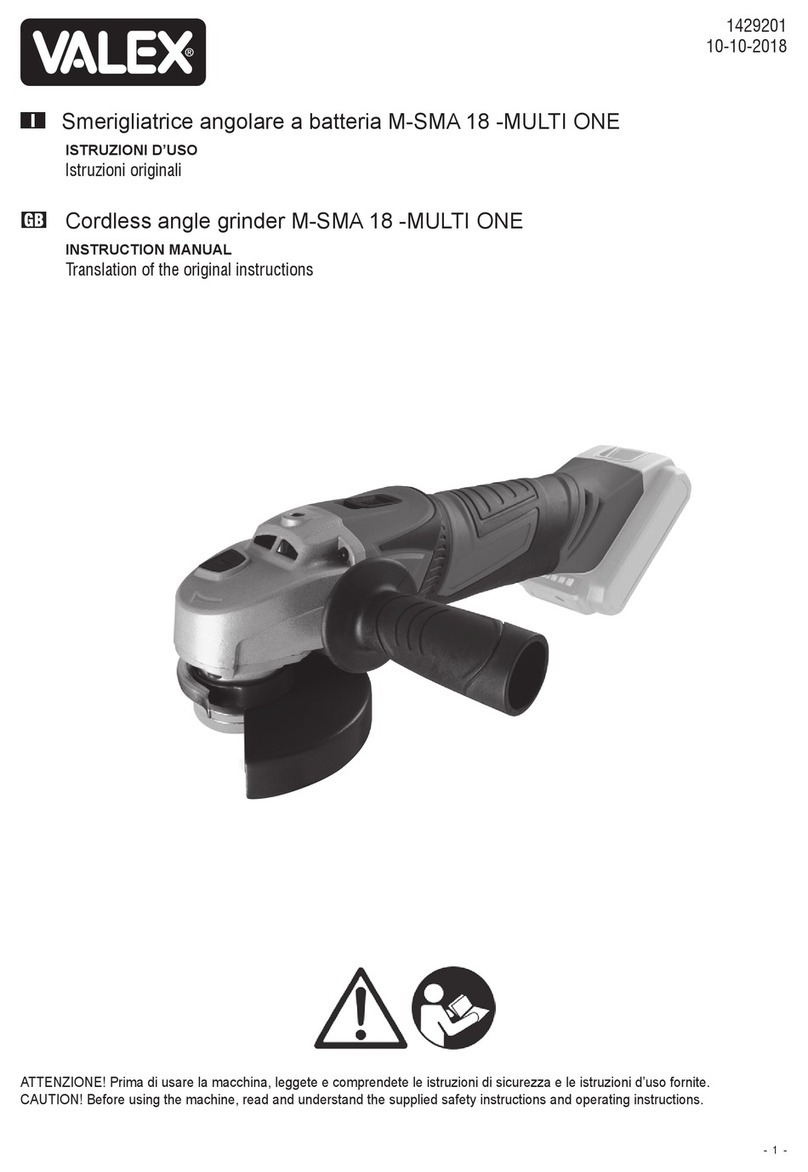

TYPICAL DIXIE 11-10 GRINDER UNIT

FRAME

MOTOR

COVER

PANELS

SERIAL

NUMBER

HOPPER

RING

BELT

GUARD

HEAD

GEARBOX

SAFETY TAG

ORIFICE

PLATE

GUARD

GEARBOX

TAG

3

INTRODUCTION

A Grinder Unit is a type of size reduction

machine. Its primary purpose is to grind

meat, meat by-products, and other similar

products.

The primary grinding components are a plate

retaining ring, orifice plate, plate bushing,

knifeholder with knife inserts, centering pin,

spring or springs, head, feedscrew, hopper,

gearbox, and drive pulleys. In most instances

an electric motor drives the grinder unit.

This unit is mounted on a undermount frame

(as shown on cover) or sidemount frame.

Standard safety equipment includes a belt

guard, a hopper guard, and a plate guard. If a

transition funnel is used, the plate guard is not

required.

It is important that your application, and/or

installation does not render these guards

ineffective. If for any reason you believe these

guards are not adequate, do not use the machine

and call Dixie Grinders Inc. at once. (256) 582-

0477 OR (800) 745-0586.

This machine was sold for a specific application.

If you are not familiar with the application that

this unit was sold for, check with Dixie Grinders

Inc. before using the machine.

All operators and sanitation personnel should

read this manual and understand it.

TAG D 1 EA. (ON GEARBOX)

TAG C 2 EA. (ON FRONT OF

HOPPER AND FRONT OF FRAME)

TAG B 2 EA. (ON BELT GUARD

TAG A 2 EA. (ON SIDES OF HOPPER) AND ON HOPPER FRONT) 4

THE HOPPER GUARD AND PLATE

GUARD MAY NOT BE ATTACHED

FOR SHIPPING!

THE HOPPER GUARD IS

PROVIDED TO RESTRICT

ACCESS TO THE ROTATING

FEEDSCREW!

THE PLATE GUARD IS

PROVIDED TO RESTRICT

ACCESS TO THE PLATE, THE

KNIFEHOLDER, AND THE

FRONT END OF THE

FEEDSCREW!

THE BELT GUARD IS

PROVIDED TO RESTRICT

ACCESS TO THE V BELTS

AND THE ROTATING

PULLEYS!

4.84B

192

11-10

08-023

FAILURE TO USE GUARDS WHILE THE

GRINDER UNIT IS IN OPERATION MAY

RESULT IN SEVERE INJURY OR DEATH!

REPLACE SAFETY TAGS WHEN

NECESSARY! CALL DIXIE GRINDERS

INC. FOR REPLACEMENT SAFETY TAGS.

SITE CONSIDERATIONS:

It is important that the permanent position of

the grinder unit provides clearance of several

feet behind, to either side, and approximately

eight feet or more in front of the grinder unit.

If the grinder is set on a stand, or leg extensions

are attached, an adequate platform must be

provided to provide safe access to the grinder

unit. It will be necessary to have an approved

platform or device to provide access so the unit

can be properly sanitized, disassembled,

assembled, and maintained. Consideration

must be given to allow for complete service to

the grinder unit.

Platforms should be so designed not to make

the hopper guard, or other guarding,

ineffective. The hopper guard is not a hopper

for holding a large amount of material, it is

designed to keep the operator away from the

feedscrew. If the location of this grinder unit

compromises this feature, special guarding may

be necessary. Consult your Safety Engineer,

Plant Engineer, and O.S.H.A. for all regulations

related to the guarding of this machine.

Only the feedscrew puller and ring lift can be

attached to the grinder unit directly. Do not

use the grinder frame to support other

equipment without prior approval from Dixie

Grinders Inc. The grinder frame is not to be

used as a personal stand, and under no

circumstances should anyone be allowed to

climb on it or use it as a platform. Remember

to Work Safely!

"THE GRINDER HAS ARRIVED"

LIFT EQUIPMENT REQUIRED:

We recommend using a 5,000 pound capacity

fork lift with 48" or longer forks. Do not

attempt to unload the grinder unit from a

commercial van from ground level! Only

authorized and properly trained equipment

movers should attempt to unload the grinder

unit. Remember to Work Safely!

PRE-UNLOADING INSPECTION:

Before the grinder unit is unloaded, inspect the

unit for any damage before unloading. If the

machine is damaged consult your management,

the trucking company, and Dixie Grinders Inc.

before unloading the machine!

UNLOADING GRINDER UNIT:

With the commercial van properly chocked and

secured to the loading dock, and using only

approved and adequate dock plates should any

attempt be made to unload this machine. Lift

only under the grinder frame, never attempt to

pick up a grinder from the hopper or gearbox.

The forks should be long enough to extend

beyond the end of the frame a safe distance.

Unload the grinder unit and all parts that have

been shipped with the grinder unit. Consult the

packing slip to insure that all pieces have been

unloaded.

UNPACKING:

When the grinder has been properly unloaded it

should be placed in a suitable location for

unpacking. The belt guard protector and the

shipping skids may be removed. Remove any

spare parts that may have been shipped in the

grinder hopper. Use appropriate equipment

and appropriate personal safety equipment in

this process. Remember to Work Safely!

5

UNIT CONTROLS.

Dixie Grinders Inc. does not supply motor

controls, starters, stop/start stations,

disconnects, or other related equipment that is

required to control the function of the grinder

unit.

INSTALLATION:

The machine can be installed in its permanent position

after the skidding has been removed. Use only

adequate equipment and properly trained personnel to

install the grinder in its permanent position. Use great

care in moving this equipment, it is heavy and must

not be tipped, tilted, jarred or jammed into position.

We recommend a 1° slope to allow water to drain from

the grinder unit.

We recommend serious consideration is given

to the location of the start/stop station.

We strongly recommend that additional stop

stations are located where deemed appropriate.

Disconnects that can be locked out should be so

located that employees that have to operate,

service, and sanitize the unit can lock the unit

out. Each employee that has to work on this

machine should be given a lock and key and

trained in proper procedures for LOCK

OUT/TAG OUT!

Please consult with your Safety Engineer, your

Electrical Engineer, and O.S.H.A. for all

regulations related to the controls and wiring

for this machine.

We do not recommend the use of wye-delta or

star delta starters. In some areas this is

required. If your machine must be wired this

way the operators must understand that they

cannot begin to grind product until full power

is supplied to the grinder feedscrew. If there is

product in the grinder hopper before the unit is

turned on, the grinder may not have enough

torque to start grinding in the reduced torque

condition.

Frequency controllers are very useful, but with

the exception of a grinder connected directly to

a pump unit or mechanical deboner, the use of

a frequency controller on a grinder unit is

usually not necessary. We do recommend a

frequency controller or some form of speed

control is used to feed the grinder, and often to

take the product away from the grinder.

We do not recommend remote operation of any

grinder unit unless special precautions are

taken, and that all possibilities of employee

injury are eliminated.

6

DISASSEMBLY TOOLS:

If the grinder is not located on floor level

make no attempt to disassemble the grinder

unit without an adequate platform or

provisions provided by the installation

contractor, plant engineer, or plant safety

officer. The grinder has many parts that

have square edges and cutting edges.

Adequate safety equipment should be used

at all times!

After the grinder has been installed in its

permanent position, it can be disassembled.

The tools described below are for both

disassembly and assembly of the grinder

unit.

The end of the ring wrench fits into the end

of the feedscrew and it can be used to

engage the feedscrew to the drive spline.

Plate Lifter

This is used to

remove the plate

and bushing from

the grinder unit, or

on assembly to

install the plate and

bushing into the

grinder unit.

Note:

Wear appropriate safety equipment and

remember to always "Work Safely".

7

Ring Wrench / Worm insertion tool

The Ring Wrench fits over the lugs of ring and

is used to loosen the ring (counter clockwise),

or tighten the ring (clockwise)

When the grinder unit has been properly

secured, disassembly can begin.

Dropping the ring on the end of the pin will

damage the threads each and every time. There

is no maybe, the threads are damaged and they

need to be fixed. Trying to screw a damaged

ring or chamber ring onto the head or the next

chamber ring will destroy the mating threads

making the mistake a bigger one, now costing

over twice as much to fix.

With the grinder unit properly secured,

disassembly can begin.

Step 1. Using the ring wrench, loosen the ring

by exerting downward pressure, as shown,

turning the ring counter clockwise.

GRINDER UNIT DISASSEMBLY:

READ AND UNDERSTAND THE

FOLLOWING TAG.

Use the ring wrench only to loosen the ring.

When the ring can be turned by hand,

discontinue using the ring wrench.

When the ring has been loosened, turn it off

by hand. Depending on the ring type, the ring

may weigh up to 65 lbs. If this is more than

you can lift, get help. Use the ring remover if

your machine has been equipped with one. Do

not attempt to remove the ring if you are out

of position, or if the ring is higher than the

center of your chest, or if you cannot lift this

much on your own!

8

Step 2. Remove the 1453 slip in bushing from

the final plate. You may use the plate

remover or carefully use a screw driver. Do

not, under any circumstances, bump the

grinder on to remove the last plate and

bushing. The power should be locked out and

remain locked out during grinder

disassembly!

Step 3. Remove the third or final plate.

Use plate remover if necessary.

Step 4 continued, removing 3rd knifeholder,

#1978.

Step 4. Remove the 3rd knifeholder. The

inserts are sharp so be carefull. If necessary

wear gloves.

9

Step 5. Remove the third set of washer

springs, #2578.

Step 3 continued. It may be necessary to

wiggle or rock the #1118 X 1/8" plate in

order to remove it.

For 1/8" spacing this

side out.

Check for nicks, dings, and dents caused by

tramp metal in your product. Notice the nice

sharp corners on the new 10026 impeller,

pretty isn't it?

Step 6. Remove the #10026 impeller. Edges

may be sharp, wear protective gloves if

necessary.

Step 7. Remove the impeller spacer, #10118.

This may not be in the machine at all times, see

assembly instructions. The impeller spacer is

used to keep the impeller spaced away from the

second plate.

For 1/4" spacing this

side out.

10

Note what direction the impeller spacer is on

the pin if you will be using the same

knifeholders and plates. The impeller spacer

can be placed over the square shoulder to

provide 1/8" spacing, or place flush with the

shoulder to provide 1/4" spacing. Neat huh!

Step 11. Remove the #10035 springs.

Step 9. Remove the second plate, #1118 x

3/16". The second bushing #10031 slides into

the plate from the back side. Notice the recess

in the face of the knifeholder that provides

clearance for the bushing.

Step 10. Remove the #10032 4-bladed

knifeholder.

11

Step 8. Remove the first chamber ring.

Using the ring wrench, loosen the ring until it

can be turned by hand. If you are out of

position, or cannot lift heavy items, get help.

As mentioned with the ring, dropping the

chamber ring on the centering pin will

damage the threads.

Step 12. Remove the #2579 impeller.

Step 14 continued. Remove the first plate,

#1115 x 5/16". The first bushing #2573 slides

into the plate from the back side. Notice the

recess in the face of the knifeholder that

provides clearance for the bushing.

12

Step 13. Remove the second chamber ring,

#2577. I won't say don't bang up the threads

this time around, ok? Or hint that it might be

to heavy for you and you might need help

lifting it.

Step 15. Remove the #2572 four-bladed (or

#2991 two bladed) knifeholder. The #1991

inserts may be sharp so be carefull. You may

wish to wear gloves to protect your pinkies.

Step 14. Remove the #1115 x 5/16" plate.

Step 16. The hand is removing the #2938

springs, notice that these also have one spring

facing inward and one facing out.

OUTWARD

FACING

SPRING

Step 17. Remove the #2937 spacer collar.

It may be necessary to hold the feedscrew in

while pulling the pin out.

Step 18. Remove the pin, notice how the pin

key was caught with the other hand!

INWARD

FACING

SPRING

13

With the feedscrew removed from the grinder unit, it can now be wired. Dixie Grinders Inc. does

not supply motor controls, disconnects, or stop/start stations. Please consult your Electrical

Engineer, your Safety Engineer, OSHA, and other Federal, State, and local regulations.

With the pin out of

the feedscrew, you

can now remove

the feedscrew from

the rest of the

grinder unit.

Step 19. REMOVE THE FEEDSCREW FROM THE GRINDER UNIT.

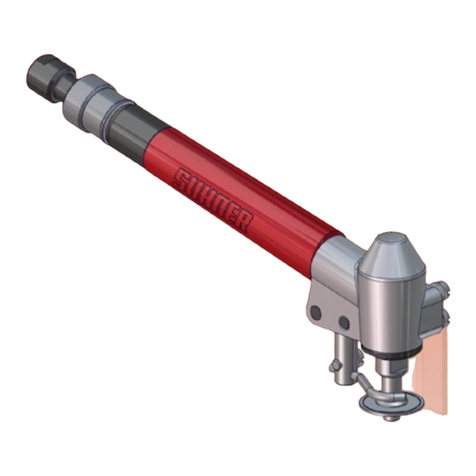

We recommend using our Model FSP2005 to remove the feedscrew (see next page). If you do not

have a FSP2005 feedscrew puller, we recommend using a feedscrew cart, chain hoist, or other

suitable lifting device.

The feedscrews are heavy, 300 to over 400 pounds. Do not attempt to remove the feedscrew by

hand.

The feedscrew needs to be handled carefully so that the outside diameter is kept free of nicks and

burrs. Be careful, the feedscrew has sharp corners that can cut, the cupping is sharp!

Wear appropriate safety equipemnt and remember to always "Work Safely".

14

ROTATION: When the grinder unit has

been disassembled, and then wired

according to all applicable codes and

regulations, rotation can be checked. Do

not turn the unit on until you are positive

that no one is in harms way! The grinder

feedscrew should turn counterclockwise!

After the rotation has been checked

LOCK OUT THE POWER!

SANITATION: Appropriate clothing

should be worn, and all safety precautions

should be taken before cleaning any

equipment. Typical grinder units have tin

plated feedscrews, heads, rings, and often

the grinder hopper is also tin plated. Before

you begin to clean your machine, make sure

any commercial cleaning agents are

approved for cleaning tin plated surfaces.

If no mention of tin is on the label but the

cleaner is not recommended for aluminum

do not use it unless you have contacted the

cleaner manufacturer for their

recommendations. Do not use high pressure

streams of water to clean a grinder unit. It

is possible to drive water past the oil seals

and damage the gearbox.

Do not allow any cleaning agent to sit on the

tin plated surfaces for an extended period of

time. Apply the soap, and rinse it off

immediately!

After cleaning, rinse the unit with large

quantities of hot water. We strongly

recommend drying the unit and applying a

liberal amount of mineral oil to all tin plated

surfaces. If the machine is not going to be

used for an extended period, apply a coat of

edible grease to all surfaces and wrap the

grinder in plastic.

SANITIZERS: Iodine sanitizers. Iodine

reacts with tin. If the Iodine is in sufficient

strength and has been on the tin plated

surfaces long enough it will turn anything

that touches the surface deep purple. Other

sanitizers also may react with tin plated or

stainless steel surfaces. Check label

instructions before using. If you notice that

the tin plating is coming off of your grinder

unit contact Dixie Grinders Inc.

UNIT ASSEMBLY: Please study all of the

grinder parts shown on the exploded view

before you attempt to assemble the grinder

unit. The exploded view is at the rear of the

maintenance instructions. (These instructions

assume that the grinder unit has not been

disassembled any further than the instructions

already given.)

MAKE SURE THE POWER IS

STILL LOCKED OUT BEFORE

ASSEMBLY.

Step 1. INSTALL FEEDSCREW.

Using the Model FSP2005 feedscrew puller,

or other device, install the feedscrew into the

grinder unit. Do not attempt to install the

feedscrew by hand, or by yourself. You will

notice that when using the FSP2005 the

feedscrew usually engages on the drive spline

with little effort. If you are not using the

FSP2005 it will be necessary to use the

handle end of the ring wrench.

15

If the feedscrew does not slide up on the

spline, it may be necessary to push down

and in, while turning the feedscrew slightly

to engage the drive spline. Never reach into

the hopper to engage the drive spline. The

feedscrew will jump in another inch when it

is seated on the spline. Check the head

space!

3/4"

FEEDSCREW

HEAD The head space should be checked on a

weekly basis. The head space is 3/4" on

all DGI grinder units. This should be

done with the excluder seal removed.

Spacers should be added if the

measurement is more than 3/4". Spacers

should be removed if less than 3/4".

When using the ring wrench to install the

feedscrew, lift the feedscrew slightly while

pushing it in.

NOTE: THE FEEDSCREW

SHOULD NEVER RUB THE HEAD

FLUTES!

16

2 1 UNIT ASSEMBLY:

Please study all the grinder parts shown on

the exploded view before you attempt to

assemble the grinder unit. (The exploded

view follows the Maintenance section.)

(These instructions assume that the grinder unit has

not been disassembled any further than the

instructions have already given.)

Step 1. Inspect the excluder seal. It should

be clean and free of nicks, cracks, or tears.

If the excluder seal is damaged it should be

replaced.

It may be necessary to tap the excluder seal

in position. Use a rounded punch and soft

taps to help it in its proper position. Do not

use a screw driver or other pointed objects.

Push only around the center of the seal, do

not push on the soft lip. Apply force at the

hub of the seal, as shown. The lip of the

excluder seal faces out, and contacts the

hopper flange.

HEAD SPACE ADJUSTMENT.

Item 1 is our Adjustment Washer #10409

(1/16" thick) and/or Adjustment Washer

#10408 (1/8" thick). These are used with an

Adjustment Bolt #10407. Add or subtract

washers to obtain the 3/4" head space

dimension.

NOTE: This step is necessary when changing

feedscrews, heads, hoppers, or if the gearbox

has been rebuilt. Failure to set the proper

head space may result in serious damage to

the unit. If the feedscrew is allowed to rub

the head, metal particles may contaminate

your finished product!

When the Head Space has been adjusted,

remove the feedscrew so that the Unit can be

assembled for operation.

LIP OUT

Step 2. Apply a small amount of edible

grease, vegetable shortening, tallow, lard,

chicken fat, bear fat, or some other lubricant

to the face of the seal. (Check with your Quality

Control Dept. and your USDA representative for

approved materials.)

Step 3. Apply a liberal amount of this same

lubricant to the female drive spline teeth!

1

17

Step 4. INSTALL FEEDSCREW.

Using the Model FSP2006 feedscrew puller,

or other device, install the feedscrew into the

grinder unit. Do not attempt to install the

feedscrew by hand, or by yourself. You will

notice that when using the FSP2006 the

feedscrew usually engages on the drive

spline with little effort. If you are not using

the FSP2006 it will be necessary to use the

handle end of the ring wrench.

When using the ring wrench to install the

feedscrew, lift the feedscrew slightly while

pushing it in.

If the feedscrew does not slide up on the

spline, it may be necessary to push down,

in, while turning the feedscrew slightly to

engage the drive spline. B drives engage

much easier than the older A drives. The

feedscrew will jump in another inch when it

is seated on the spline.

Place the pin key into the slot in the

centering pin. Then place the pin in the

feedscrew.

Inspect the pin to make sure it is clean and

free of nicks and burrs. Replace the pin

when it shows wear grooves, checks, or is

worn.

Step 5. INSTALL CENTERING PIN.

Check adjustment bolt to make sure it is in

the pin. The pin is supplied with four

washers, start with two and the 3/4-10 x 3/4"

long hex head cap screw. This bolt is used

to space the first impeller away from the

outside of the first plate.

18

Step 6. Install

the #2937 spacer

collar over the

pin. This part

can go in either

side up.

When these springs are new the uncompressed

height of the two springs is over 1/4" as shown

above. This is how they are to be installed,

touching at the center, a gap at the outside.

One spring facing in, one facing out.

Step 7. Install the #2938 springs. Note, these are the largest of the three sets of springs.

19

Other manuals for 11-10

1

This manual suits for next models

1

Other DIXIE GRINDERS Grinder manuals

DIXIE GRINDERS

DIXIE GRINDERS 11-7 User manual

DIXIE GRINDERS

DIXIE GRINDERS 12-10 User manual

DIXIE GRINDERS

DIXIE GRINDERS 11-7 User manual

DIXIE GRINDERS

DIXIE GRINDERS 7-7 User manual

DIXIE GRINDERS

DIXIE GRINDERS 11-10 User manual

DIXIE GRINDERS

DIXIE GRINDERS 16-10 User manual

DIXIE GRINDERS

DIXIE GRINDERS 8-7B User manual

DIXIE GRINDERS

DIXIE GRINDERS 1666D User manual