Truper Expert HILA-2000X User manual

HILA-2000X

HILA-2000X102111

2 000 PSI

ModelCode

Applies for:

CAUTION

Manual

Electric

Pressure

Washer

Read this manual thoroughly

before using the tool.

ENGLISH

ESPAÑOL

2ENGLISH

Contents

CAUTION

Keep this manual for future references.

The illustrations in this manual are for reference

only. They might be different from the real tool.

To gain the best performance of

the tool, prolong the duty life,

make the Warranty valid if

necessary, and to avoid hazards

of fatal injuries please read and

understand this Manual before

using the tool.

Technical data

Power Requirements

General Power Tool Safety Warnings

Safety Warnings for Power Washers

Parts

Assembly

Start Up

Maintenance

Troubleshooting

Notes

Authorized Service centers

Warranty Policy

3

3

4

5

6

7

9

10

11

12

13

14

FULFILL THE WORKING CYCLES.

50 min of work and 20 min of rest. Daily maximum 6 hours.

THIS MACHINE DOES NOT SUCK WATER

FROM PONDS OR TANKS.

It must be connected to a supply outlet or an elevated tank.

ALWAYS USE FILTERS AND CLEAN THEM

AFTER EACH USE.

Replace filters when they become dark brown in color.

Perform periodic MAINTENANCE to your machine (page 10).

Use and care recomendations

3

Technical data

HILA-2000X

102111

2 000 PSI

Electric Pressure Washer

174 PSI

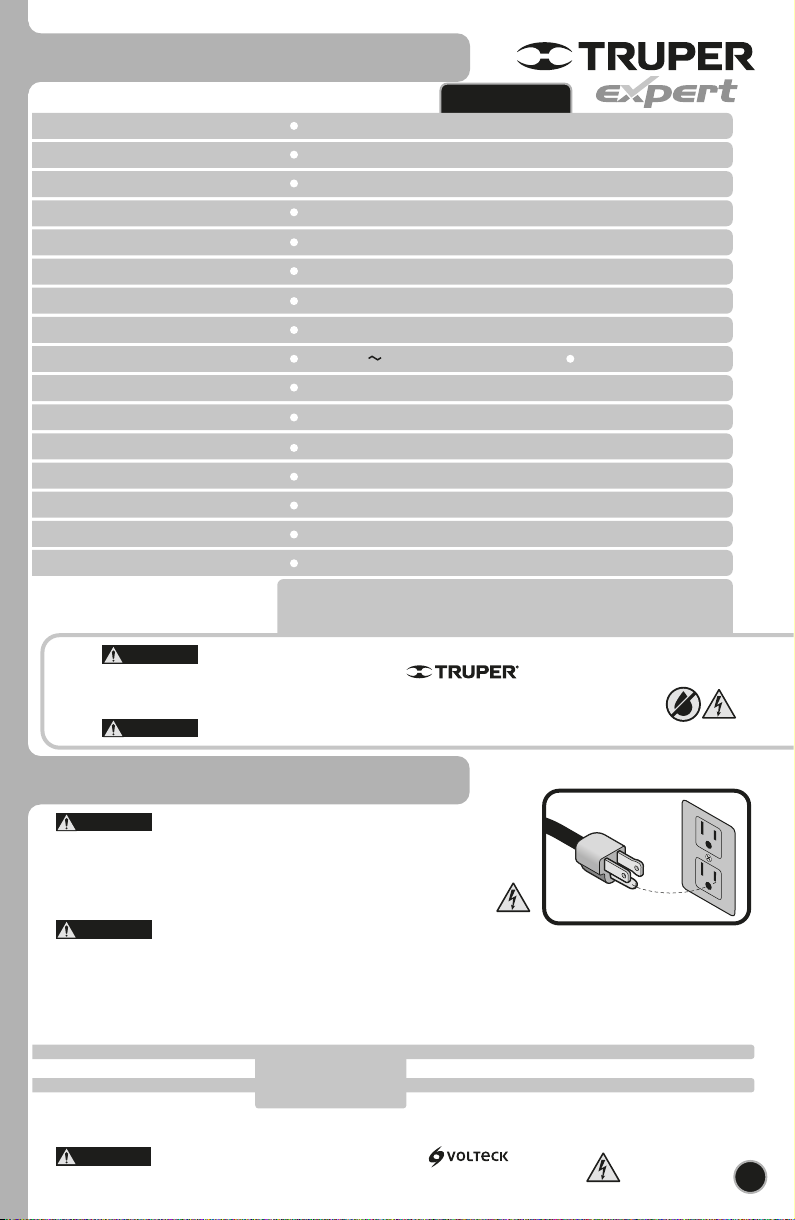

Power Requirements

In the event of faults or severe malfunction, the ground connection

delivers a trajectory with minimum resistance for power supply reducing the risk of

electric shock. This tool is built with a power cord with a connector and plug connected

to ground. The plug shall be connected into a power source installed and grounded

according to all the local codes.

When using an extension cord, verify the gauge is enough for the

power that your product needs. A lower gauge cord will cause voltage drop in the line, resulting in power loss and

overheating. The following table shows the right size to use depending on cord’s length and the ampere capability

shown in the tool’s nameplate. When in doubt use the next higher gauge.

WARNING

WARNING

ENGLISH

Code

Description

Maximum Pressure

Maximum Inlet Pressure

43.5 PSI

Minimum Inlet Pressure

Class I

60 Hz

14 AWG x 3C with 221 °F insulation temperature

50 min work per 20 min rest. Maximum 6 hours daily

16 A

16.5 ft

Frequency

26.2 ft

1.5 gpm

122 °F

127 V

Power cord grips: Type “Y”.

Washer Build Quality: Basic

Thermal insulation on motor winding: Class F

Maximum Water Flow

3.3 gpm

Input flow

Voltage

Current

2 100 W

Power

Power Supply Cable

High-Pressure hose

Duty Cycle

Conductors

Insulation

Maximum Inlet Temperature

WARNING

WARNING Avoid the risk of electric shock or severe injury. When the power cable gets damaged

it should only be replaced by the manufacturer or at a Authorized Service Center.

The build quality of the electric insulation is altered if spills or liquid gets into the tool while in use.

Do not expose to rain, liquids and/or dampness.

Before gaining access to the terminals all power sources should be disconnected.

From 0 and up to 10 A

From 10 and up to 13 A

From 13 and up to 15 A

From 15 and up to 20 A

18 AWG

16 AWG

14 AWG

8 AWG

16 AWG

14 AWG

12 AWG

6 AWG

3 (one grounded)

From 6 ft to 49 ft | Higher than 49 ft

Ampere

Capacity Number of

Conductors Extension Gauge

WARNING When operating power tools outdoors, use a grounded

extension cable labeled “For Outdoors Use”. These extensions are specially designed for

operating outdoors and reduce the risk of electric shock.

*It is safe to use only if the extensions have a built-in artifact for over current protection.

AWG = American Wire Gauge. Reference: NMX-J-195-ANCE

4ENGLISH

General Power Tools

Safety Warnings

Work area

Keep your work area clean, and well lit.

Cluttered and dark areas may cause accidents.

Never use the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Sparks generated by power tools may ignite the flammable material.

Keep children and bystanders at a safe distance while operating

the tool.

Distractions may cause loosing control.

Electrical Safety

The tool plug must match the power outlet. Never modify

the plug in any way. Do not use any adapter plugs with

grounded power tools.

Modified plugs and different power outlets increase the risk of electric shock.

Avoid body contact with grounded surfaces, such as pipes,

radiators, electric ranges and refrigerators.

The risk of electric shock increases if your body is grounded.

Do not expose the tool to rain or wet conditions.

Water entering into the tool increases the risk of electric shock.

Do not force the cord. Never use the cord to carry, lift or unplug

the tool. Keep the cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a tool outdoors, use an extension cord suitable

for outdoor use.

Using an adequate outdoor extension cord reduces the risk of electric shock.

If operating the tool in a damp location cannot be avoided, use

a ground fault circuit interrupter (GFCI) protected supply.

Using a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense

when operating a tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication.

A moment of distraction while operating the tool may result in personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as safety glasses, anti-dust mask, non-skid shoes,

hard hats and hearing protection used in the right conditions significantly

reduce personal injury.

Prevent unintentional starting up. Ensure the switch is in the

“OFF” position before connecting into the power source and /

or battery as well as when carrying the tool.

Transporting power tools with the finger on the switch or connecting power

tools with the switch in the “ON” position may cause accidents.

Remove any wrench or vice before turning the power tool on.

Wrenches or vices left attached to rotating parts of the tool may result in personal

injury.

Do not overreach. Keep proper footing and balance at all times.

This enables a better control on the tool during unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep

hair, clothes and gloves away from the moving parts.

Loose clothes or long hair may get caught in moving parts.

If you have dust extraction and recollection devices connected

onto the tool, inspect their connections and use them correctly.

Using these devices reduce dust-related risks.

Power Tools Use and Care

Do not force the tool. Use the adequate tool for your

application.

The correct tool delivers a better and safer job at the rate for which it was designed.

Do not use the tool if the switch is not working properly.

Any power tool that cannot be turned ON or OFF is dangerous and should be

repaired before operating.

Disconnect the tool from the power source and / or battery

before making any adjustments, changing accessories or

storing.

These measures reduce the risk of accidentally starting the tool.

Store tools out of the reach of children. Do not allow persons

that are not familiar with the tool or its instructions to

operate the tool.

Power tools are dangerous in the hands of untrained users.

Service the tool. Check the mobile parts are not misaligned

or stuck. There should not be broken parts or other

conditions that may affect its operation. Repair any

damage before using the tool.

Most accidents are caused due to poor maintenance to the tools.

Use the tool, components and accessories in accordance with

these instructions and the projected way to use it for the type of

tool when in adequate working conditions.

Using the tool for applications different from those it was designed for, could

result in a hazardous situation.

Service

Repair the tool in a Authorized Service Center

using only identical spare parts.

This will ensure that the safety of the power tool is maintained.

Children or people with reduced physical, sensory or mental

capabilities shall not operate the tool, neither inexperienced

people or without knowledge in the use of the tool, unless

supervised by a person responsible of their safety or if receiving

previous instructions about the tool operation.

Children shall be kept under supervision to double-check they will not play

with the tool. Tight supervision shall be used with children or disabled

persons to prevent from using or being close to any household tool.

WARNING! Read carefully all safety warnings and instructions listed below. Failure to comply with any of

these warnings may result in electric shock, fire and / or severe damage. Save all warnings and instructions for

future references.

This tool is in compliance with

the Official Mexican Standard

(NOM - Norma Oficial Mexicana).

5

ENGLISH

Safety Warnings for

Power Washers

• The washer is built with a shutdown device that detects

when the high-pressure gun trigger is released. It opens a

power circuit in the motor to stop the washer.

• If the Automatic Shutdown fails, DO

NOT USE the washer. Contact a

Authorized Service Center. Using the washer in these

conditions may damage and / or cause sever personal

injury.

• Do not store equipment with pressure in

the system. Remove the water supply and hold the trigger

for a few seconds to release any residual pressure in the

system when finished using it.

• Disconnect the power cable when the washer is not

being used and before removing the high-pressure hose.

• To prevent an accidental discharge, set

the trigger lock in the high-pressure gun when the washer

is not being used.

• Never make knots or fold the high-pressure hose. It can

get damaged.

• Do not use or store this product in

temperatures below 40 °F. The warranty does not cover

damage caused by frost.

• Bear in mind that pressure spraying is

very powerful and can be very dangerous if misused. It is

not recommended to use on painted surfaces, wood

surfaces or adhesive-pasted articles.

• This tool is built to use cleaning agents

exclusively designed for washers. Using other cleaning

agents or chemical products may seriously affect the

device safety.

• Do not use bleach, chorine, chemical products or any

other cleaning agent containing acid or that are not specific

for washers. Otherwise the machine could get seriously

damaged.

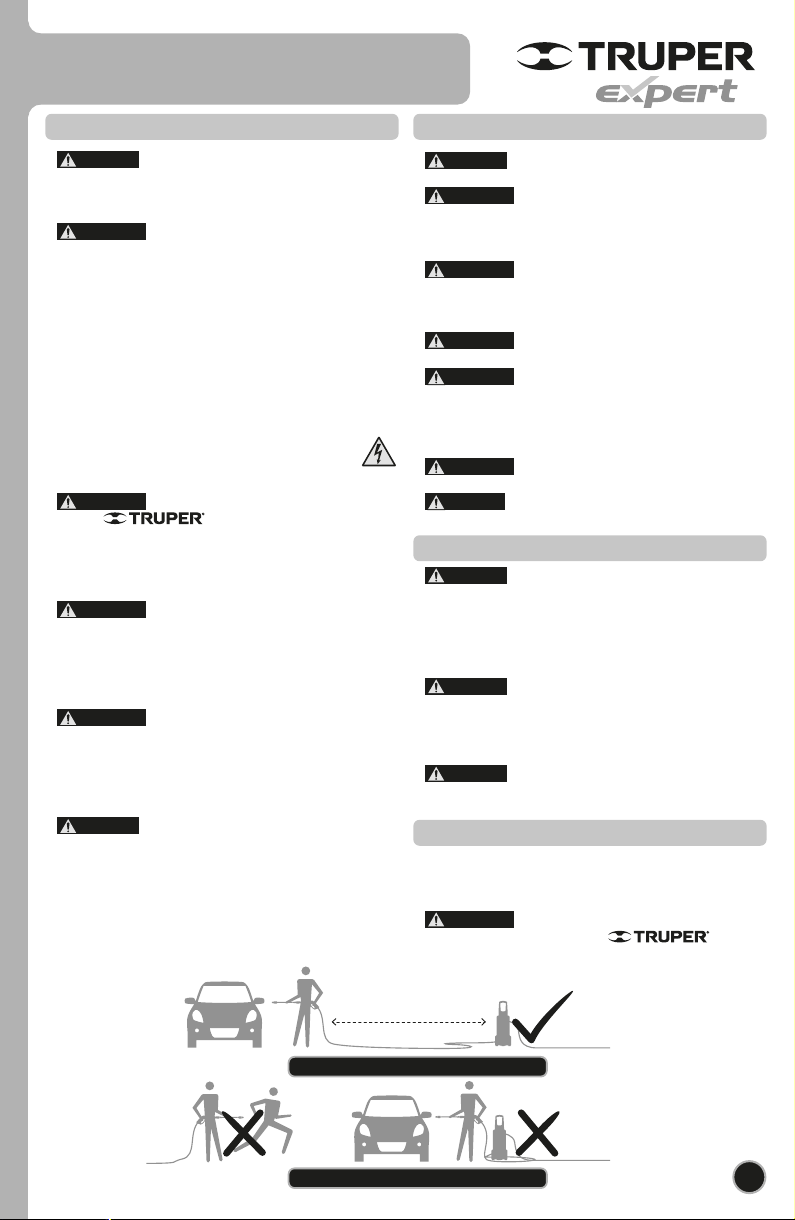

• The washer is not water proof. Set it as far away as

possible from the place to be washed.

• Have a qualified electrician to double check if the power

source where the washer is to be connected is the right

one. To prevent electric shocks, install a device to

disconnect the power supply or one that is grounded.

No more at 30 mA

• To guarantee the tool safety use only

original brand spare parts, (nozzles,

lance, gun & hose).

• Check that all the parts, components and accessories in

the washer are not damaged. When finding any type of

malfunction, replace the part before using the washer.

• Do not use the device in the presence

of people unless they wear protective clothing.

• The jet shall not be aimed directly towards any living

being, active power equipment or the device.

• Do not allow children or unexperienced people to use

the washer.

• Using a wrong extension cord can be

dangerous. If using an extension cord, the plug and power

inlet shall have the same construction against water entry.

• Do not use the machine if the power cord or important

parts show any damage for example, safety devices,

high-pressure nozzles, trigger, etc.

• The water passing through the system is

not suitable to drink.

Before Operating the Washer When Operating the Washer

After Operating the Washer

Automatic Shutdown

• Unroll the pressure hose all the way to

prevent overheating.

• Wear eye protection and waterproof

clothing.

• Use both hands when spraying to gain total control with

the high-pressure gun.

• Never touch the nozzle or the water

spray while the washer is being operated.

• Do not cover the washer when being used to allow free

air circulation.

• Never aim the water spray towards the

power cord or the washer. It may cause a fatal electric shock.

• Never discharge spray directly to people

or animals. Only people wearing the protection gear may

be close to the washer when being used. Do not aim the

water jet towards yourself or other people to clean clothes

or shoes.

• Keep all power connections dry and

above the ground.

• Do not touch the power plug with wet

hands.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Wrong Ways to Operate the Washer

Right Way to Operate the Washer

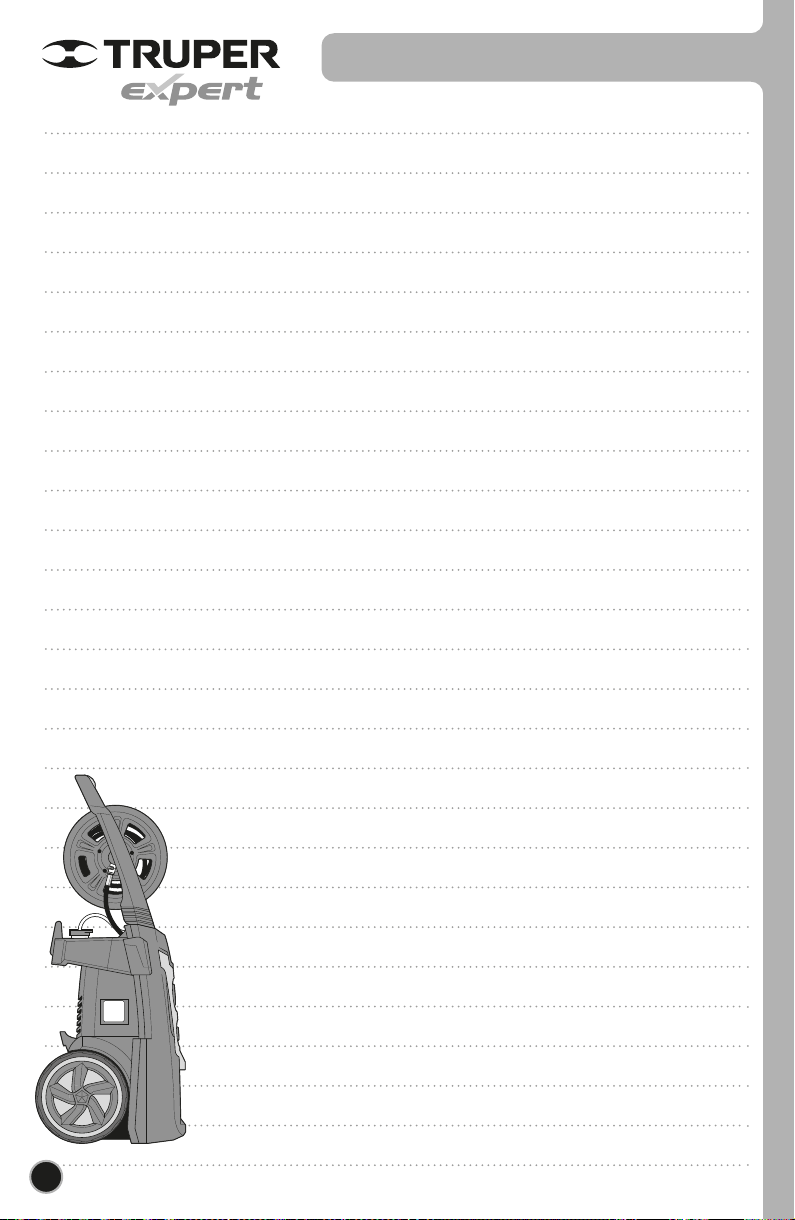

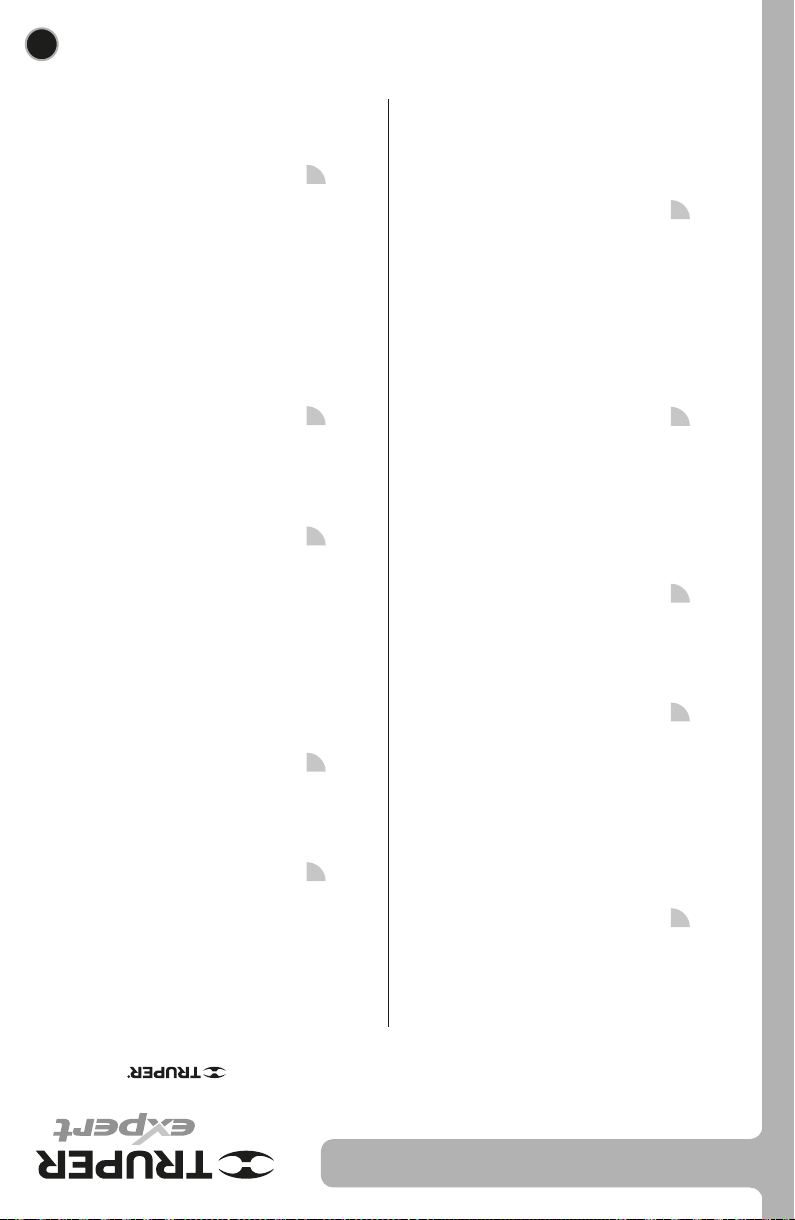

Parts

6

Handle

Hose

reel

Hose reel

Hose reel

handle

Power cord

holder Accessories

holder

Detergent

tank

Water filter

Lance tip

support

Quick hose

connector

High pressure

gun holder

Power

cord

Water

connection

High-pressure

hose

Quick coupling

for high-pressure

hoses

Transport

wheels

0°, 15°, 25°, and 40° soap nozzles

Metal lance

High pressure gun

Switch

Foam

regulator

Button for inserting

and detaching high

pressure hose

Trigger

actuator

Locking button for

high-pressure gun

Hose quick

connect

Hose comes assembled.

NOTE:

Nozzle

cleaner

Turbo nozzle

ENGLISH

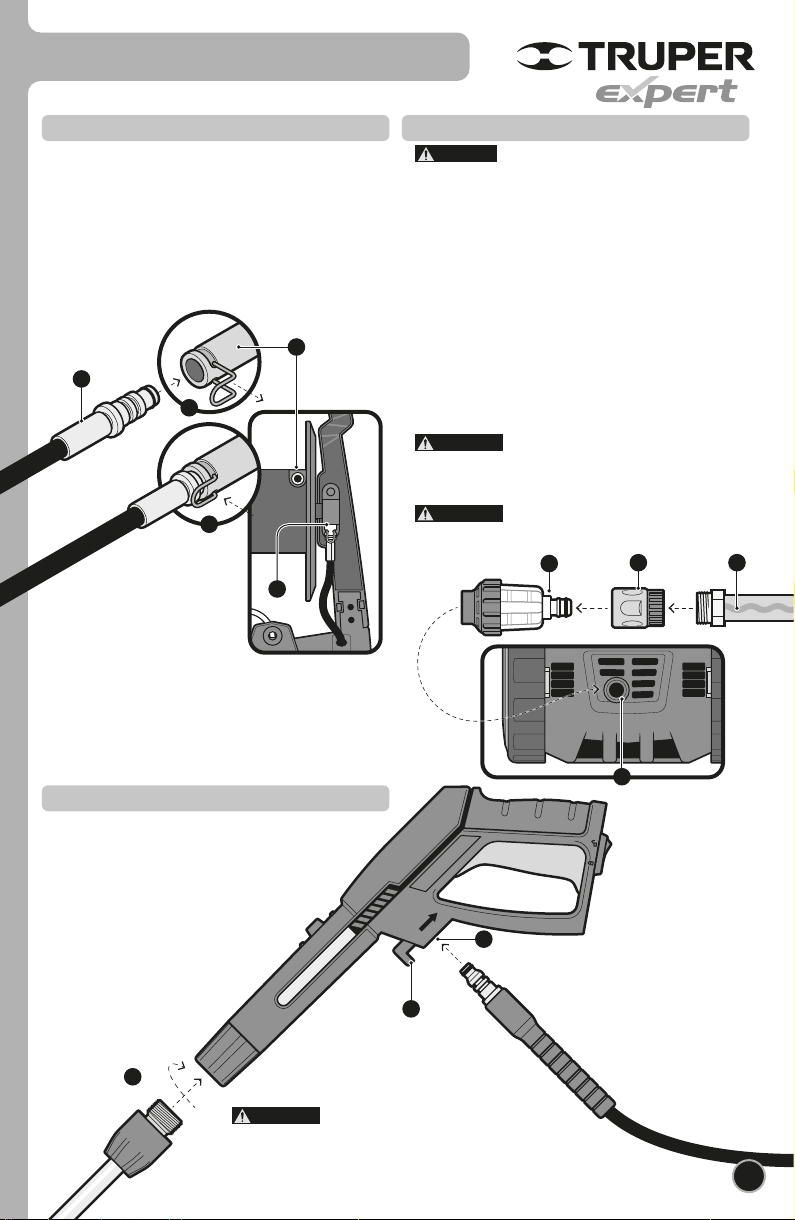

• Before connecting the garden hose (E)

to the equipment, let the water run through it to expel

any objects inside. If the water supply is a well, the length

of the hose should be a maximum of 29.5 ft and an

additional filter should be used to prevent sand from

entering the system.

• It is recommended to use a reinforced hose (not

included) with standard connection with outside diameter

of 5/8”, inside diameter of 15/32” and maximum 33 ft

length.

• Always completely untangle the garden hose and

high-pressure hose to avoid pressure fluctuations.

• Connect the garden hose (E, not included) to the quick

connector (F) and the filter (G) to the water inlet (H).

• The quick connector (F) is useful to easily connect and

disconnect the hose to the filter (G).

It is important that the connector has the

filter (G) to prevent sand, silt, stones or any impurities

from damaging the pressure washer. Using the connector

without the filter will void the warranty.

Disconnect the garden hose to prevent

damage to the filter when moving the machine from one

location to another.

• The high-pressure hose is already assembled to the reel

at the factory, the following instructions are for

replacement in case of damage:

• Connect the high-pressure hose (A) to the high-pressu-

re outlet (B) located on the inside of the reel. To connect,

pull the latch to release the padlock (C), insert the hose

connection into the outlet port as far as it will go and push

the latch to close the padlock securing the connection (D).

Assembly

7

• Connect the free end of the high-pressure hose to the

high-pressure gun orifice (I). Press the button (I1),

insert the hose connector into the gun hole as far

as it will go and release the button to secure

the connector in place and release the

button to secure the connector in place.

• Screw the lance (K) onto the tip of

the high-pressure gun.

A

C

D

H

I

I1

K

B

B1

• Check that the connection

of (B1) the pressure washer

to the reel is properly

secured. The locking system is

the same as the connection of

the high-pressure outlet.

F E

G

High pressure hose Water supply hose

High-pressure gun

To ensure the safety of the appliance, use

only original manufacturers or manufacturer's approved

replacement parts.

ENGLISH

CAUTION

WARNING

WARNING

WARNING

Assembly

8

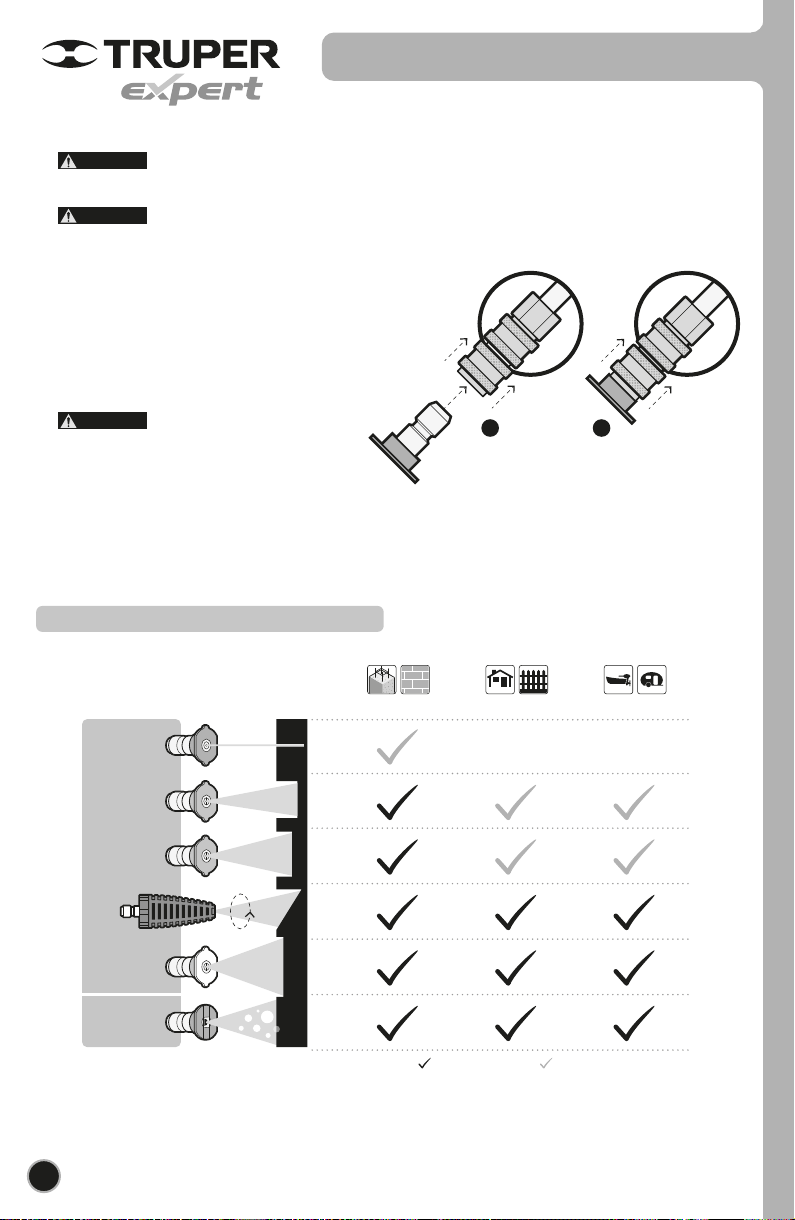

Nozzle Selection

0°

25°

40°

soap

Turbo

White

Black

15°

A B

Nozzle Flow Abrasion

• The pressure washer has different nozzles for different flow openings depending on the job to be done:

Cement, Brick, Masonry Exteriors, Hedges,

Patios, Terraces Boats, RV’s,

Gardening Gear

Red

Green

Yellow

High Pressure

Recommended Nozzle Use with Caution

ENGLISH

• Insert the nozzle into the quick connector of the lance.

• Push the nozzle until the collar of the quick connector

collar rises.

• Pull the nozzle to make sure that the nozzle is properly

secured.

• To remove the nozzle, hold the nozzle by hand and

pull the quick connect collar.

The quick connector has a

spring-loaded spring if you do not hold the nozzle

before pulling the collar, the nozzle will be ejected.

• Before mounting or removing a nozzle on the metal lance, turn off the pressure washer, shut off the

water supply, depress the trigger to release pressure, and engage the safety latch to lock the trigger. Failure to comply with

any of these points could result in serious injury.

• Do not allow the metal lance to be pointed at your face when assembling or disassembling the nozzles,

the quick connect system of the nozzles could accidentally launch the nozzle and cause injury.

WARNING

WARNING

WARNING

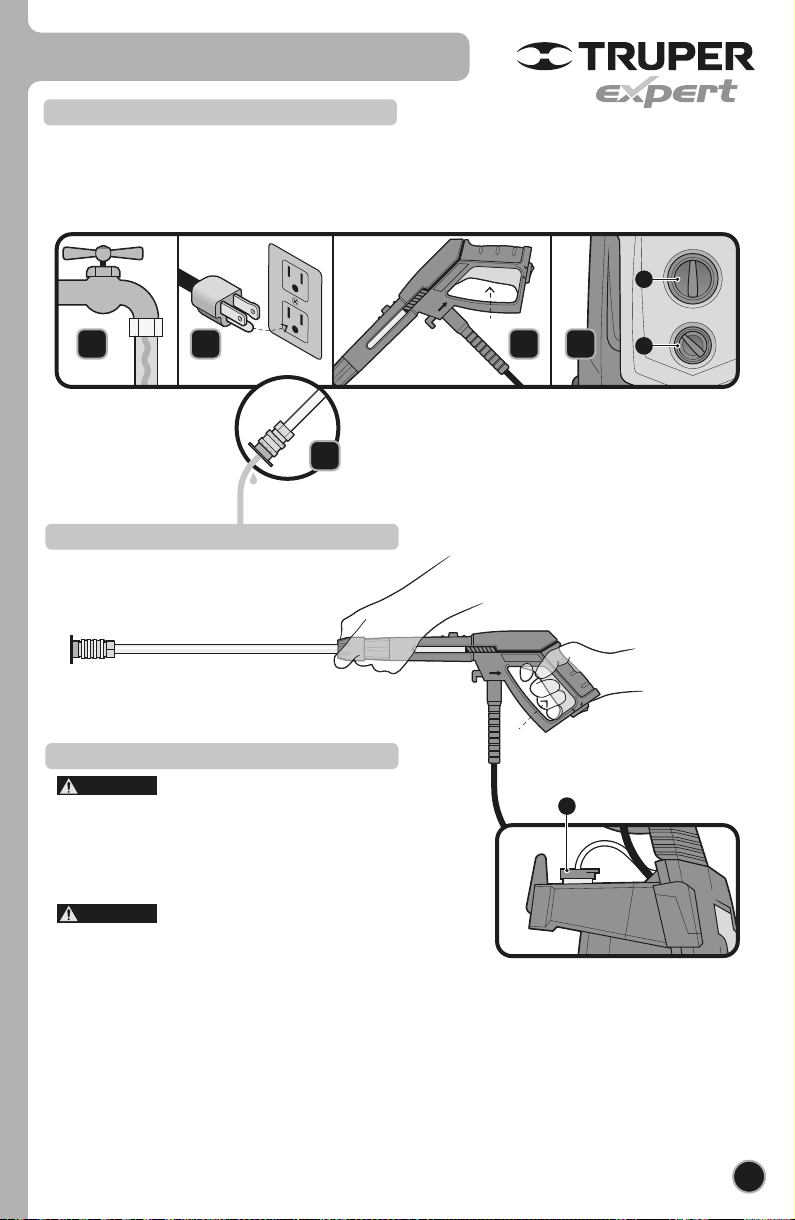

1 2 3 4

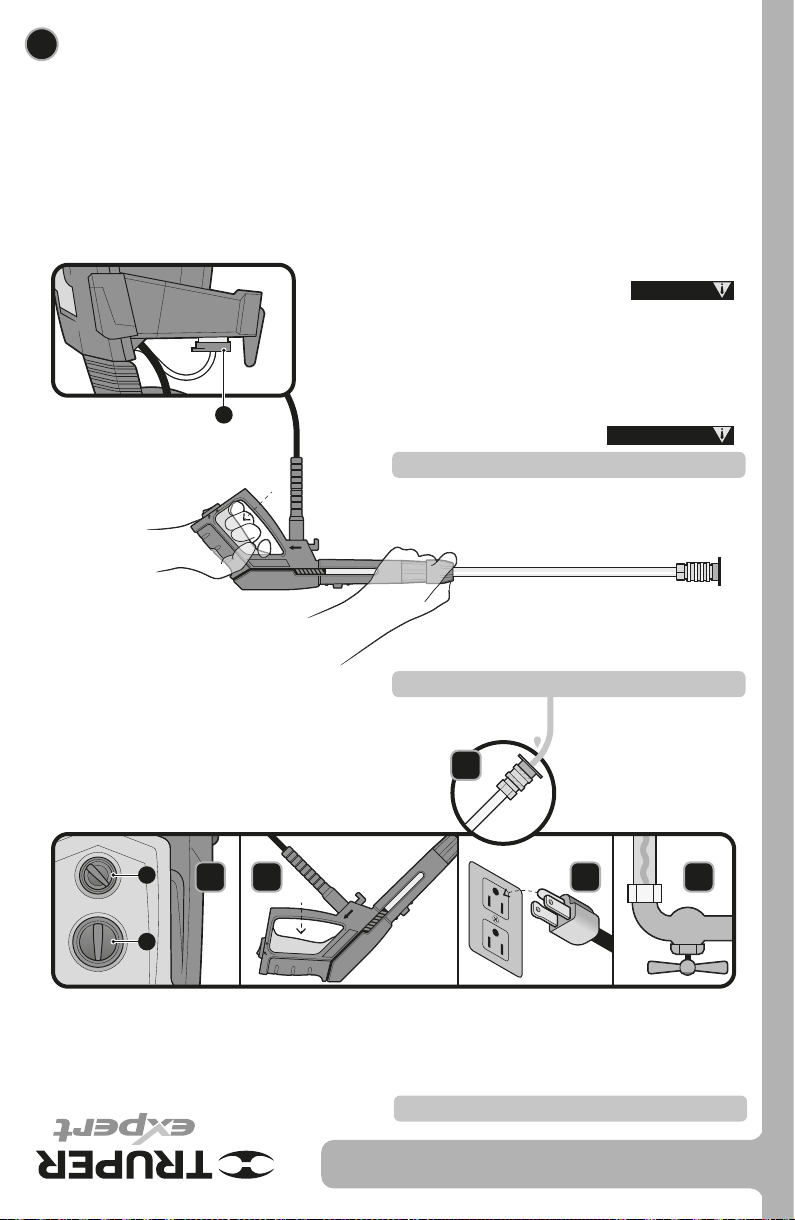

Turning On

1. Open the water faucet and keep it open all the time you are using the washer. Maximum inlet pressure: 174 PSI

2. Connect the plug into the power supply.

3. Tighten and hold the high-pressure gun trigger to release the air caught inside the washer. Release the trigger when the

water flow is constant.

4. Turn the switch (C) into the ON position. The motor will start momentarily and then it will stop.

C

D

E

9

Spraying

• Always hold the gun and lance with both hands to control

the sudden movement produced by the pressurized water.

Detergent Use

Start Up

• Aim the lance towards the floor and press

the gun trigger to start spraying.

• To stop spraying, release the trigger.

3

ENGLISH

ATE• Use only detergents designed for pressure washers.

Never use products with bleach, chlorine or other corrosive agents such

as solvents, trisodium phosphate products, ammonia or acid-based

cleaners. These products cause damage to the machine components.

• Remove the cap of the detergent tank (E)and add the appropriate

detergent. Do not add water to the detergent tank, the machine will

automatically mix the detergent with the water.

ATE NC • The machine will only suction detergent when

operating at low pressure. Mount the soap nozzle (black color) on the

lance.

• Squeeze the trigger, the detergent will come out mixed with the water.

If you need to adjust the detergent flow, turn the detergent switch (E), to

the left to decrease and to the right to increase, depending on the job to

be done.

• Apply detergent to completely cover the cleaning surface.

• Turn off the spray gun and allow the detergent to remain on the

surface to be cleaned for a couple of minutes.

• Switch to other nozzles to enter high pressure cleaning mode to rinse

and remove detergent from the surface.

WARNING

WARNING

10

Maintenance

ENGLISH

• Disconnect the power cord from the

power supply before carrying out any type of adjustment,

service or maintenance on the washer.

• Turn the washer OFF and press the trigger to release the

pressure trapped inside the unit.

• Remove both the garden hose and the pressure hose.

• Turn ON the washer and leave it running 5 seconds to

eliminate any water trapped inside the pump.

• Disconnect the washer and store the power cord.

• Store the washer and accessories in a dry environment

and with controlled temperature. Do not store the washer

and accessories where temperature may drop to 40 °F.

DAMAGES DUE TO FREEZING ARE NOT

COVERED IN THE WARRANTY.

Storing in Winter time

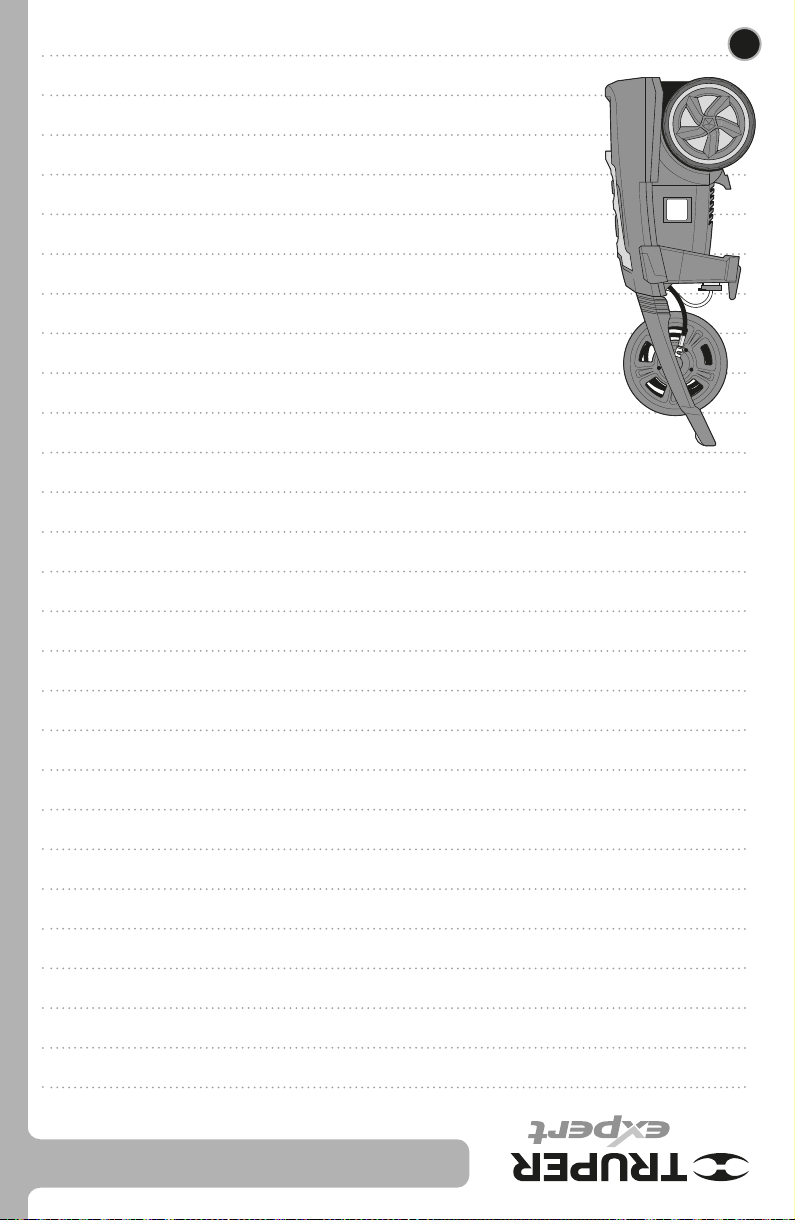

Water Filter

Cleaning and Care

Connections Lubrication

Nozzle Lubrication

Washer Lubrication

• Any foreign matter entering the washer pump may cause

damage. the washer is built with a water filter to prevent

this possibility.

• The inner screen in the washer filter shall always be kept

clean to keep a continuous flow of water into the washer

and prevent damaging the pump.

• To clean the screen, remove the filter from the garden

hose connector and unscrew to remove the screen. Handle

with care to prevent damaging the screen.

• Set back immediately both screen and connector to

prevent foreign particles entering into the pump.

Before closing the filter, make sure that the

screen (A) is assembled in the center of the seal (B) and

not over it, this to avoid leaks or damage to the filter.

• Keep the washer free of dust. Never use water or

chemical liquids to clean the washer. Clean only using a dry

and clean cloth.

• Always keep the ventilation slots clean and free of

obstructions to guarantee the proper cooling of the motor.

• Regularly inspect all the mounting screws and double

check tightness. If any of these screws is loose, tighten

immediately.

• The motor is the washer heart. Use care so that it will not

be affected by oil or water.

• Check the power cable often to detect any kind of

damage. In the event there is some damage go to a

Authorized Service Center to have it

replaced.

• The connections in the washer hoses, the high-pressure

gun and the lance shall be cleaned regularly. To prevent

leaks and damage to the seals in each connection, lubricate

using non-water soluble grease.

• The nozzles shall be regularly lubricated with non-water

soluble grease or light oil.

• A blocked nozzle increases importantly the pressure in the

pump. Clean immediately:

1) Remove the blockage in the nozzle inserting the nozzle

cleaner through the center orifice.

2) Purge the nozzle with water. Start the washer and press

the washer high-pressure gun. If the pressure is still too high

repeat steps 1 and 2.

CAUTION

WARNING

• Every six months, take the machine to a

Authorized Service Center to carry

out maintenance (lubricate valves and oil change).

• In case there is an oil leak go to a

Authorized Service Center.

CAUTION

CAUTION

A

B

11

The washer does not

start.

Pressure is not

constant.

The washer stops

while working.

The fuse blows off.

The washer is

pulsating.

The washer stops and

starts by itself.

The washer starts but

there is no water

flowing out.

• The washer is not connected.

• Faulty power outlet.

• Blown fuse.

• Faulty extension cord.

• The thermal protector of the motor

is activated.

• The pump is drawing air.

• Valves are dirty, worn or stuck.

• Worn pump seals.

• Insufficient water supply.

• Blown fuse.

• Wrong voltage supply.

• Thermal sensor is activated.

• The nozzle is partially blocked.

• The fuse ampere capacity is low.

• There is air inside the hose.

• Wrong supply of the water supply.

• Nozzle is partially blocked.

• Water filter is blocked.

• Tangled hose.

• The pump or the high pressure gun is

damaged.

• There is no water inlet.

• The pump, hoses or accessories are frozen.

• There is no water supply.

• The water filter is blocked.

• The nozzle is blocked.

• Connect the washer.

• Use a different power outlet.

• Replace fuse. Shut off other machines.

• Replace the extension cord.

• Unplug the machine from the outlet for 30 seconds

and reconnect.

• Check for leaks in the hose and connections.

• Go to a Authorized Service Center.

• Go to a Authorized Service Center.

• Increase water pressure, double check there are no

blockages, unroll hoses completely.

• Replace fuse.

• Shut off other machines. Double check voltage

supply corresponds to the specifications in this

manual.

• Allow the washer to cool down.

• Clean the nozzle.

• Change to an installation with capacity higher

than the washer’s ampere consumption.

• Try using with no extension cord.

• Turn off the equipment and press the trigger of

the high-pressure gun until the water pressure is

constant.

• Check the water supply matches the required

specifications. Avoid using long and thin hoses

(minimum ½”).

• Clean the nozzle.

• Clean the filter.

• Straighten the hose.

• Go to a Authorized Service

Center.

• Open the water inlet.

• Wait for the pump, hoses or accessories to thaw.

• Connect the water inlet.

• Clean the filter.

• Clean the nozzle.

Problem Possible cause Solution

Troubleshooting

If despite carrying out the recommended actions the problems persist,

contact a Authorized Service Center.

ENGLISH

Notes

12 ENGLISH

13

Authorized Service Centers

ENGLISH

In the event of any problem contacting a Authorized Service Center, please see our webpage

www.truper.com to get an updated list, or call our toll-free numbers 800 690-6990 or 800 0187-8737 to get

information about the nearest Service Center.

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

MEXICO CITY

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

AV. PARQUE INDUSTRIAL 1, PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257,

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

14

102111

www.truper.com

12-2021

HILA-2000X

ENGLISH

1

YEAR

Warranty

policy

Stamp of the business. Date of purchase:

Code Model Brand

This product is guaranteed for 1 year. To make the warranty valid or purchase parts and components you must

present the product in Corregidora 22, Col. Centro, Alc. Cuauhtémoc, CDMX C.P. 06060 or at the

establishment where you purchased it, or at any Truper®Service Center listed in the annex to the warranty

policy and/or in www.truper.com . Transportation costs resulting from compliance of this warranty will be

covered by

For questions or comments, call 800-690-6990. Made in China. Imported by Truper, S.A. de C.V. Parque

Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx. C.P. 54257

14 ESPAÑOL

1

AÑO

102111

Póliza de

Garantía

www.truper.com

12-2021

Sello del establecimiento comercial. Fecha de compra:

Código

HILA-2000X

Modelo Marca

Este producto está garantizado por 1 año. Para hacer válida la garantía o adquirir piezas y componentes deberá

presentar el producto en Corregidora 22, Col. Centro, Alc. Cuauhtémoc, CDMX C.P. 06060 o en el

establecimiento donde lo compró, o en algún Centro de Servicio Truper®de los enlistados en el anexo de la

póliza de garantía y/o en www.truper.com . Los gastos de transportación que resulten para su cumplimiento

serán cubiertos por

Para dudas o comentarios, llame al 800-690-6990. Hecho en China. Importado por Truper, S.A. de C.V. Parque

Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx. C.P. 54257

13

ESPAÑOL

Centros de Servicio Autorizados

En caso de tener algún problema para contactar un Centro de Servicio Autorizado

consulte nuestra página www.truper.com donde obtendrá un listado actualizado, o llame al:

800 690-6990 ó800 0187-8737 donde le informarán cuál es el Centro de Servicio más cercano.

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

CIUDAD DE

MÉXICO

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

AV. PARQUE INDUSTRIAL 1, PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257,

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

Notas

12 ESPAÑOL

Solución de problemas

La hidrolavadora no

arranca.

La presión no es

constante.

La hidrolavadora se

detiene durante el

trabajo.

El fusible se funde.

La hidrolavadora tiene

pulsaciones.

La hidrolavadora se

detiene y arranca por

sí misma.

La hidrolavadora

arranca pero no sale

agua.

• La hidrolavadora no está conectada.

• Tomacorriente defectuoso.

• Fusible fundido.

• Cable de extensión defectuoso.

• El protector térmico del motor

está activado.

• La bomba está absorbiendo aire.

• Válvulas sucias, gastadas o atoradas.

• Sellos de la bomba gastados.

• El suministro de agua no es

suficiente.

• Fusible fundido.

• Suministro incorrecto de tensión de

alimentación.

• El protector térmico del motor esta activado.

• La boquilla está parcialmente bloqueada.

• El fusible de su instalación es de baja

capacidad de amperes.

• Hay aire en la manguera.

• El suministro de agua no es el adecuado.

• Boquilla parcialmente bloqueada.

• Filtro de agua bloqueado.

• Manguera enredada.

• La bomba o la pistola de alta presión están

dañadas.

• No hay suministro de agua.

• La bomba, las mangueras o los accesorios

están congelados.

• No hay suministro de agua

• El filtro de agua está bloqueado

• La boquilla está bloqueada

• Conecte la hidrolavadora.

• Use otro tomacorriente.

• Cambie el fusible. Apague otras máquinas

• Cambie el cable de extensión.

• Desconecte la máquina del tomacorriente por

Unos minutos y vuelva a conectar.

• Revise que las mangueras y las conexiones de entrada no

tengan fugas.

• Acuda a un Centro de Servicio Autorizado

• Acuda a un Centro de Servicio Autorizado

en caso de que el problema persista.

• Aumente el flujo de agua a la entrada de la maquina, revise

que no haya bloqueos, desenrede las mangueras por completo.

• Cambie el fusible de su instalación.

• Apague otras máquinas. Revise que el suministro de

tensión corresponda a las especificadas en éste

instructivo.

• Desconecte la maquina del tomacorriente por unos

minutos y vuelva a conectar.

• Limpie la boquilla.

• Cambie a una instalación con protección más alta

que el consumo de amperes de la hidrolavadora.

• Intente sin usar el cable de extensión.

• Apague el equipo y presione el gatillo de la pistola de

alta presión hasta que la presión de agua sea

constante.

• Revise que el suministro de agua corresponda con

las especificaciones requeridas. Evite usar mangueras

largas y delgadas (mínimo de 13 mm [½”]).

• Limpie la boquilla.

• Limpie el filtro.

• Estire la manguera.

• Acuda a un Centro de Servicio Autorizado

.

• Abra o conecte el suministro de agua.

• Espere a que la bomba, mangueras o accesorios

se descongelen.

• Conecte la entrada de agua

• Limpie el filtro

• Limpie la boquilla

Problema Posible causa Solución

11

Si los problemas persisten a pesar de realizar las acciones correctivas recomendadas,

contacte a un Centro de Servicio Autorizado .

ESPAÑOL

10

Mantenimiento

ESPAÑOL

Desconecte el cable de

alimentación del tomacorriente antes de hacer cualquier

ajuste, servicio o mantenimiento a la hidrolavadora.

• Apague la hidrolavadora (OFF) y presione el gatillo para

liberar la presión atrapada dentro de la unidad.

• Retire la manguera de jardín y la manguera de presión.

• Encienda la hidrolavadora (ON) y déjela correr durante 5

segundos para eliminar casi toda el agua atrapada en la

bomba.

• Desconecte la hidrolavadora y guarde el cable.

• Almacene la hidrolavadora y accesorios en un ambiente

seco y con temperatura controlada. No almacene la

hidrolavadora y sus accesorios en un sitio donde la

temperatura baje a 4 °C (40 °F).

EL DAÑO POR CONGELAMIENTO NO

ESTÁ CUBIERTO EN LA GARANTÍA.

Almacenaje durante el invierno

Filtro de agua

Limpieza y cuidados

Lubricación de conexiones

Lubricación de boquillas

Lubricación de hidrolavadora

• Cualquier partícula extraña que ingrese a la bomba de la

hidrolavadora puede dañarla. Para evitar esta posibilidad, la

hidrolavadora cuenta con el filtro de agua.

• La pantalla interna del filtro de agua debe mantenerse

siempre limpia para mantener continuo el flujo de agua

hacia la hidrolavadora, evitando así daños en la bomba.

• Para limpiar la pantalla retire el filtro de agua del conector

de la manguera de jardín y desenrósquelo para sacar la

pantalla. Manéjela con cuidado para evitar dañarla.

• Inmediatamente vuelva a colocar la pantalla y el conector

de la manguera de jardín para evitar que entren partículas

extrañas a la bomba.

Antes de cerrar el filtro, asegúrese de

que la pantalla (A) quede ensamblada al centro del sello

(B) y no sobre de el, esto para evitar fugas o daños en el

filtro.

• Mantenga la hidrolavadora libre de polvo. Nunca utilice

agua o limpiadores químicos para limpiar la hidrolavadora.

Limpie solamente con un trapo limpio y seco.

• Siempre mantenga las ventilas limpias y libres de

obstrucciones para garantizar un enfriamiento adecuado

del motor.

• Inspeccione regularmente todos los tornillos de montaje y

asegúrese de que estén apretados correctamente. En caso

de que alguno de los tornillos esté suelto, apriételo

inmediatamente.

• El motor es el corazón de la hidrolavadora. Tenga mucho

cuidado de que no se vea afectado por aceite o agua.

• Revise periódicamente el cable de alimentación para

detectar cualquier tipo de daño. En caso de estar dañado,

haga cambiar el cable en un Centro de Servicio Autorizado

.

• Las conexiones de las mangueras de la hidrolavadora, de

la pistola de alta presión y de las lanzas, se deben limpiar

con regularidad y se deben lubricar con grasa no soluble

en agua con el fin de prevenir fugas y daños en los sellos

de cada conexión.

Las boquillas se deben lubricar con grasa no soluble en

agua o aceite ligero de manera regular.

Una boquilla bloqueada ocasiona que la presión en la

bomba de presión suba demasiado. Se debe limpiar de

inmediato.

1) Retire el bloqueo en la boquilla metiendo el limpiador de

boquillas a través del orificio central

2) Purgue la boquilla con agua. Vuelva a arrancar la

hidrolavadora y presione el gatillo de la pistola de de alta

presión. Si la presión sigue siendo alta repita los pasos 1 y 2.

ATENCIÓN

ATENCIÓN

ADVERTENCIA

Llevar la máquina al Centro de Servicio Autorizado

cada seis meses para dar

mantenimiento (lubricar las válvulas y cambiar el aceite).

En caso de fuga de aceite recurra a un

Centro de Servicio Autorizado .

ATENCIÓN

A

B

1 2 3 4

Encendido

1. Abra el grifo del agua y manténgalo así mientras utilice la hidrolavadora. Presión de entrada máxima: 1.2 MPa (174 PSI).

2. Conecte la clavija al tomacorriente.

3. Apriete y sostenga el gatillo de la pistola de alta presión para liberar el aire atrapado en la hidrolavadora. Suelte el

gatillo cuando el flujo del agua sea constante.

4. Gire el interruptor (C) a la posición ON (Encendido). El motor arrancará momentáneamente y luego se detendrá.

C

D

E

9

Rociado

• Siempre sostenga la pistola y la lanza con ambas manos

para controlar el movimiento repentino producido por el

agua a presión.

Uso de detergente

Puesta en marcha

ESPAÑOL

• Apunte la lanza hacia el suelo y apriete el

gatillo de la pistola para comenzar a rociar.

• Para interrumpir el rocío, suelte el gatillo.

3

ATE NC • Use solo detergentes diseñados para

hidrolavadoras. Nunca use productos con blanqueador, cloro u otros

agentes corrosivos como solventes, productos de fosfato trisódico,

amoniaco o limpiadores base ácido. Estos productos provocan daño en

los componentes de la máquina.

• Retire el tapón del tanque de detergente (E)y agregue el detergente

adecuado. No agregue agua en el depósito de detergente la maquina

mezclara automáticamente el detergente con el agua.

ATE NC • La máquina solo succionará el detergente

operando a baja presión. Para ello, monte la boquilla para jabón (color

negro) en la lanza.

• Apriete el gatillo, el detergente saldrá mezclado con el agua. Si necesita

ajustar el flujo de detergente, gire el interruptor de detergente (D), hacia

la izquierda para disminuir y hacia la derecha para aumentar,

dependiendo del trabajo a realizar.

• Aplique detergente para cubrir por completo la superficie de limpieza.

• Apague la pistola rociadora y deje que el detergente permanezca en la

superficie a limpiar durante un par de minutos.

• Cambie a otras boquillas para ingresar al modo de limpieza con alta

presión para aclarar y retirar el detergente de la superficie.

ADVERTENCIA

ATENCIÓN

This manual suits for next models

1

Table of contents