-

,

. 4A

-

. 4B.

-

() .

4C.

-

4D ( )

() .

13 mm (1/2

) .

.

-

40°C (98°F).

10 bar (145 psi).

!

.

.

- "0".

- (Volt/Hz)

. 3B

- ,

.

-

IEC 364.

30 mA 30 ms

.

!

.

-

, 2-3

. ""

- .

-

5 , ,

.

- ,

.

5

- ,

.

TSS:

- TSS, ( 5C)

:

- ,

.

- ,

.

- TSS,

4-5

.

-

TSS,

15 .

-

( 0,5 ).

- "JET",

. 5D

-

.

-

,

. 5D.

( )

- ,

:

-

-

.

-

.

-

Ferm 91

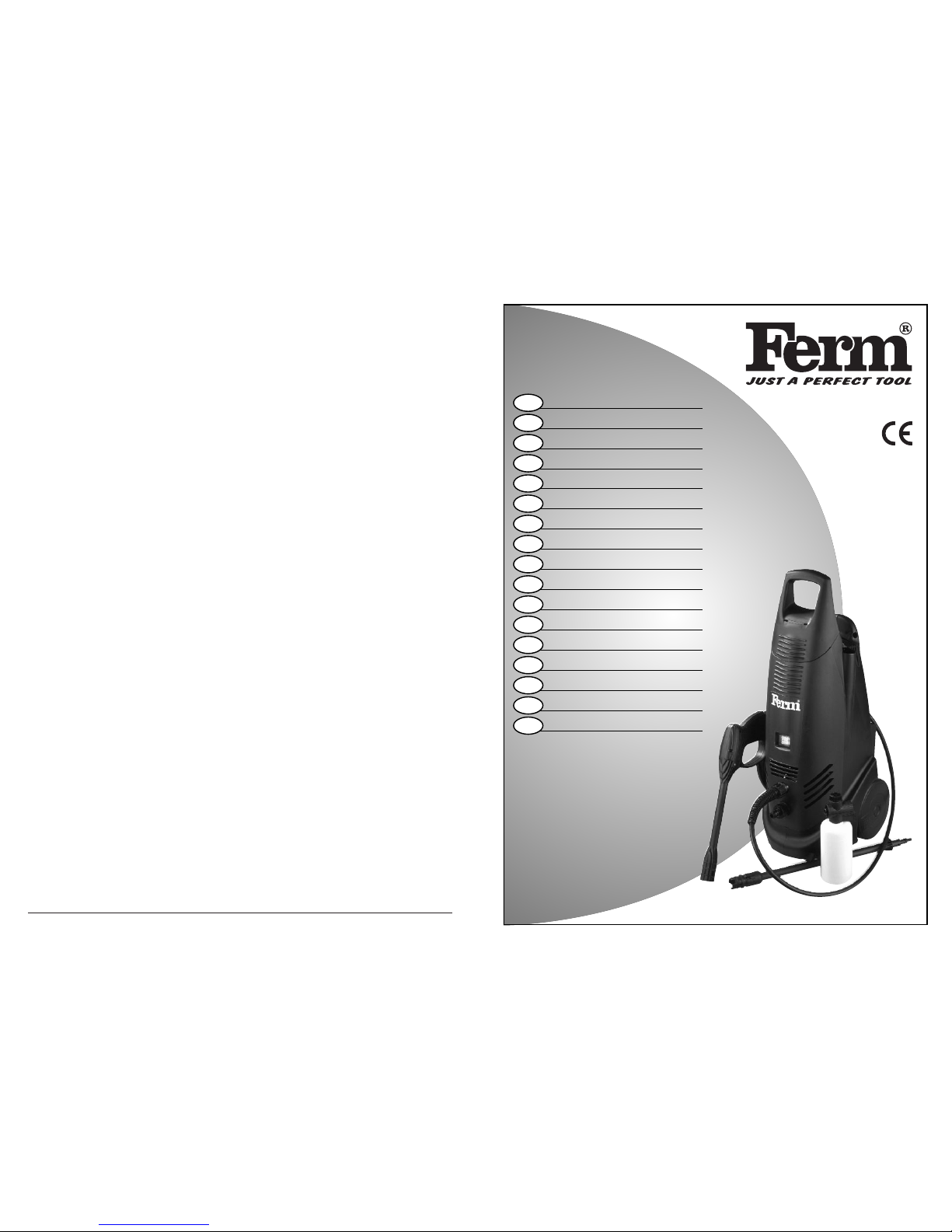

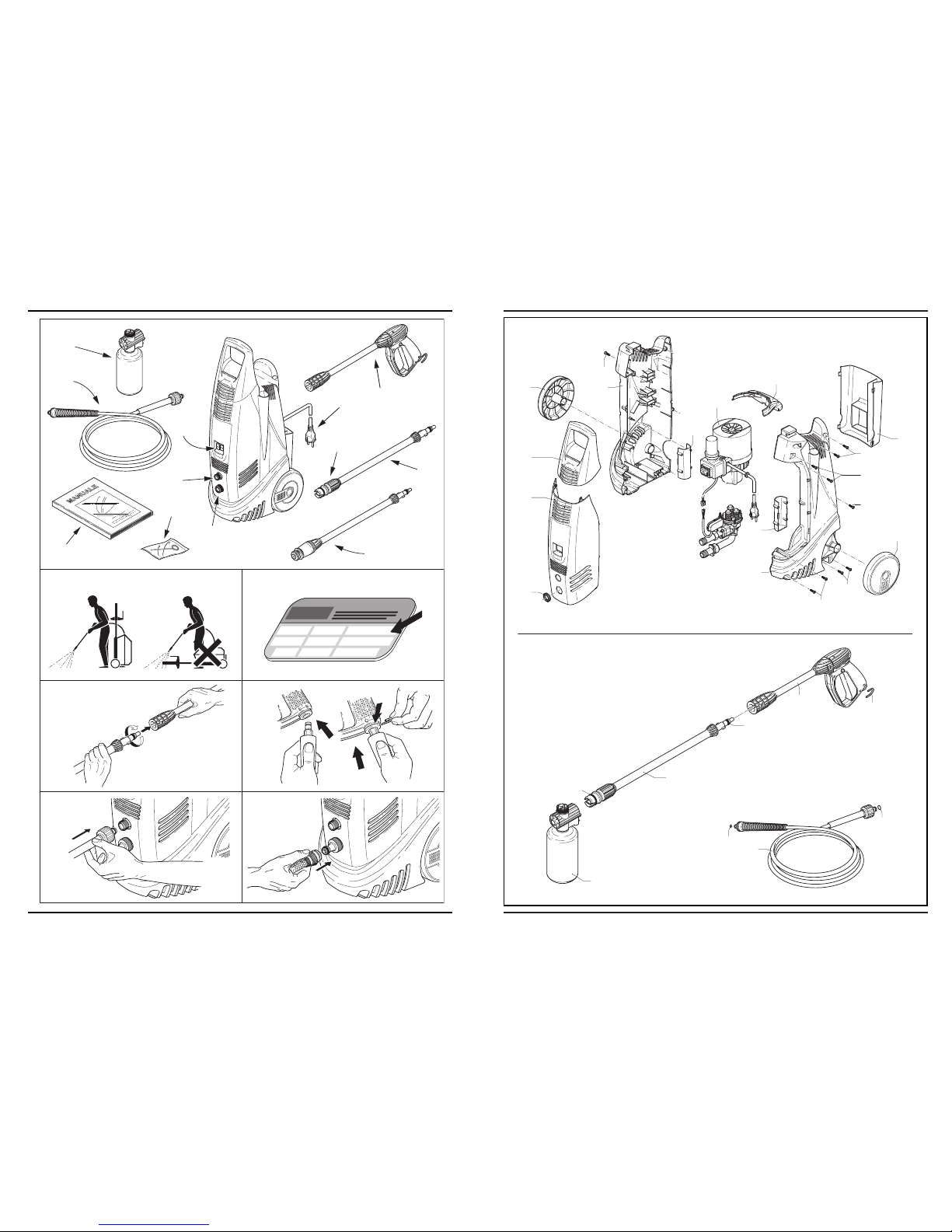

INSTALLATION

-Fitthelance into thegunby rotating andpushinguntil

thetwoparts are completelylocked.FIG.4A

-Connectthegun to thehighpressure hose. FIG.4B.

-Connectthehigh pressure hosetothe water

(OUTLET)onthe cleaner. FIG.4C.

-Connectthewater supply hoseFIG.4D(not

supplied)tothe water (INLET)ofthe cleaner. The

supplyhosemust have aninternaldiameter of atleast

13mm(1/2 in.) andmustbe reinforced. Thewater

supplymustbe at leastequalto the cleanerdelivery

capacity.

-Theintakewater temperature mustNOTexceed

40°C(98°F).The water supplypressuremust NOT

exceed10bar (145 psi).

CAUTION!Thecleaner must onlybeused with

cleanwater;use of unfilteredwateror corrosive

chemicalswilldamage the cleaner.

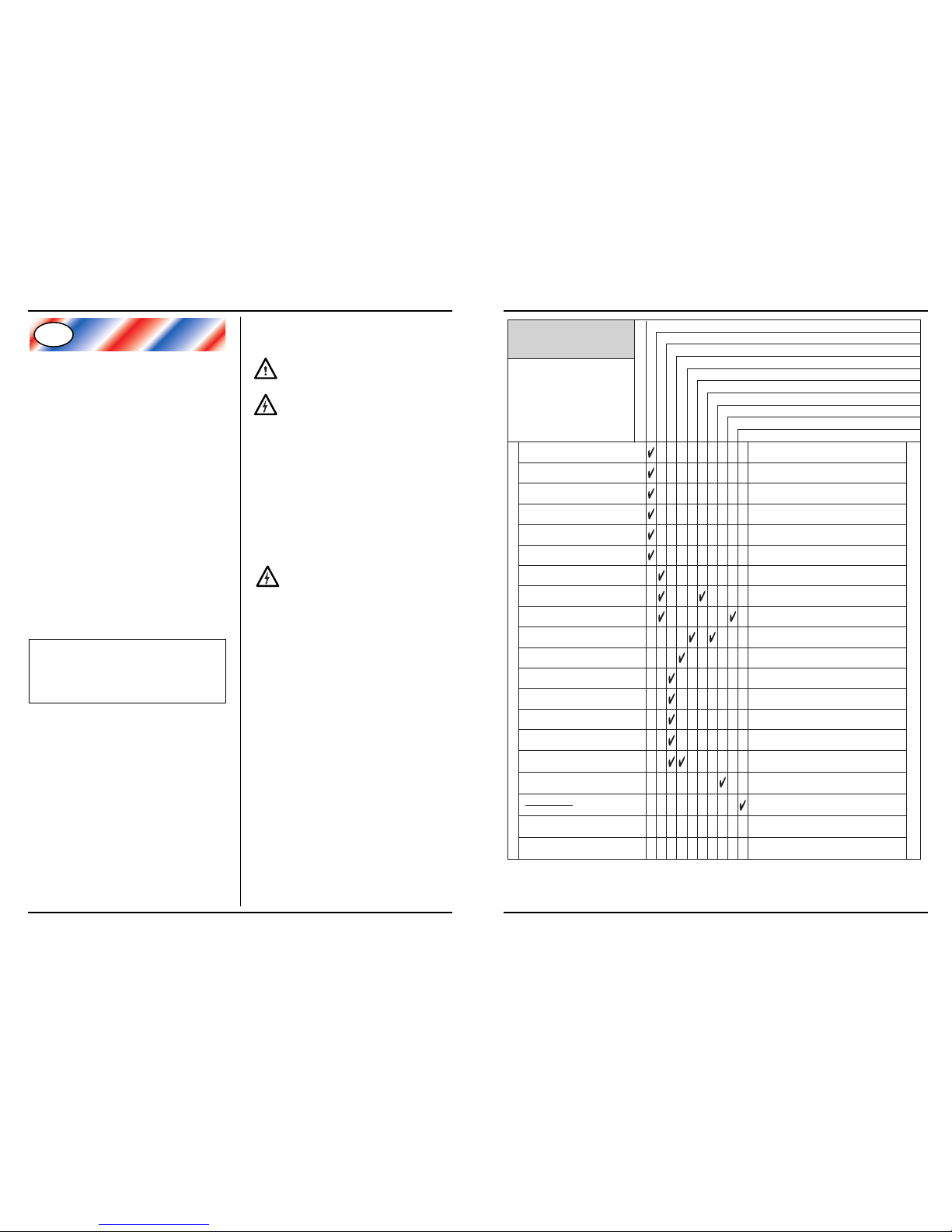

-Turnthemotor switch tothe"0" position.

-Checkthatthe electrical supplyvoltageand

frequency(Volts/Hz)correspond to thosespecified

onthecleaner data plate.Fig.3B

-Ifthepower supply iscorrect,you may nowplugin

thecleaner.

-Theelectricsupply connection shallbemade by a

qualifiedelectricianand comply withIEC364. It is

recommendedthatthe electric supplytothis

applianceshouldinclude either aresidualcurrent

devicethatwill interrupt thesupplyif the leakage

currenttoearth exceeds 30mAfor 30 msora device

whichwillprove the earthcircuit.

CAUTION!Themachine may causeelectrical

disturbanceswhenstarting.

-Ifthemotor stops andfailsto restart, wait2-3

minutesbeforerestarting. THERMAL CUTOUT

TRIPPED

USE

-Turnonthe water supplytapFULLY.

-Releasethesafety catch FIG.5A,thenpress the

triggerfora few secondstoallow air toescapeand to

dischargeresidualpressure in thepipes.

-Keepingthetrigger pressed, pushtheswitch to start

themotor.FIG.5B

-Whenre-startingthe motor, alwayskeepthe trigger

pressed.

TSSModels:

-InTSSmodels, (FIG. 5C)withautomatic delivery

flowcut-off:

-Whenthetrigger is released,thedynamic pressure

automaticallycutsout the motor.

- Whenthetrigger is pressedthepressure drop

automaticallystartsthe motor andthepressure is

restoredwitha very slightdelay.

- Forcorrectoperation of theTSS,once the trigger

hasbeenreleased it mustnotbe pressed againforat

least4-5seconds.

-Forcorrectuse of theTSSmodel cleaner, donot

leavetheunit in automaticcut-offstatus for more

than15min.

USINGDETERGENT

-Fillthefoam unit tankwithdetergent (capacity about

0.5lt.).

-Settheadjustable head inthe“JET” position, thenfit

thefoamunit on headandfix it inposition.FIG. 5D

CORRECTUSEOF STANDARD

ACCESSORIES

-Thecleaneris equipped withanozzle for adjustment

ofthejet from concentratedtofan. FIG. 5E

-Itisalso equipped withthefoam unit fordetergent

distribution,withadjustment of thequantityof

detergentusingthe knob M.FIG.5D

CORRECTUSEOF THE ROTARYNOZZLE

(Wherefitted)

-Forincreasedwashing power, usetherotary nozzle

kitasfollows:

-Turnoffthe high pressurecleaner

-Unscrewtheadjustable head andfitthe rotary

nozzleontothe lance.

-Turnthehigh pressure cleanerbackon.

RECOMMENDEDCLEANINGPROCEDURE

-Dissolvedirtby applying detergentwiththe fan jetto

thedrysurface. On verticalsurfaces,work from the

bottomupwards.Leave the detergenttoact for 1to

2minutes,but do notallowto dry out.Applythe high

pressurejet,keeping the nozzleatleast 30 cm(10in.)

fromthesurface, working fromthebottom upwards.

Avoidallowingthe rinsing watertorun on to

unwashedsurfaces.

STORAGE

-Switchoffthe cleaner. Turnoffthe water supplytap.

-Dischargeresidualpressure by pressingthetrigger

untilnomore water comesoutof the adjustable

nozzle.

-Engagethegun safety catch.

-Removetheplug from thesocket.

-Operatethecleaner with noncorrosive/non-toxic

antifreezebeforestoring for thewinter.

6Ferm