6

2.2 IndoorUnits

2.2.1 Placementconsiderations

Placementofindoorunitsshouldtakeaccountofthefollowingconsiderations:

Sufficientspacefordrainpipingandforaccessduringservicingandmaintenanceshouldbeallowed.

Toensureagoodcooling/heatingeffect,short‐circuitventilation(whereoutletairreturnsquicklytoaunit’sairinlet)

shouldbeavoided.

Topreventexcessivenoiseorvibrationduringoperation,suspensionrodsorotherweight‐bearingfixingsshould

typicallybeabletobeartwicetheunit’sweight.

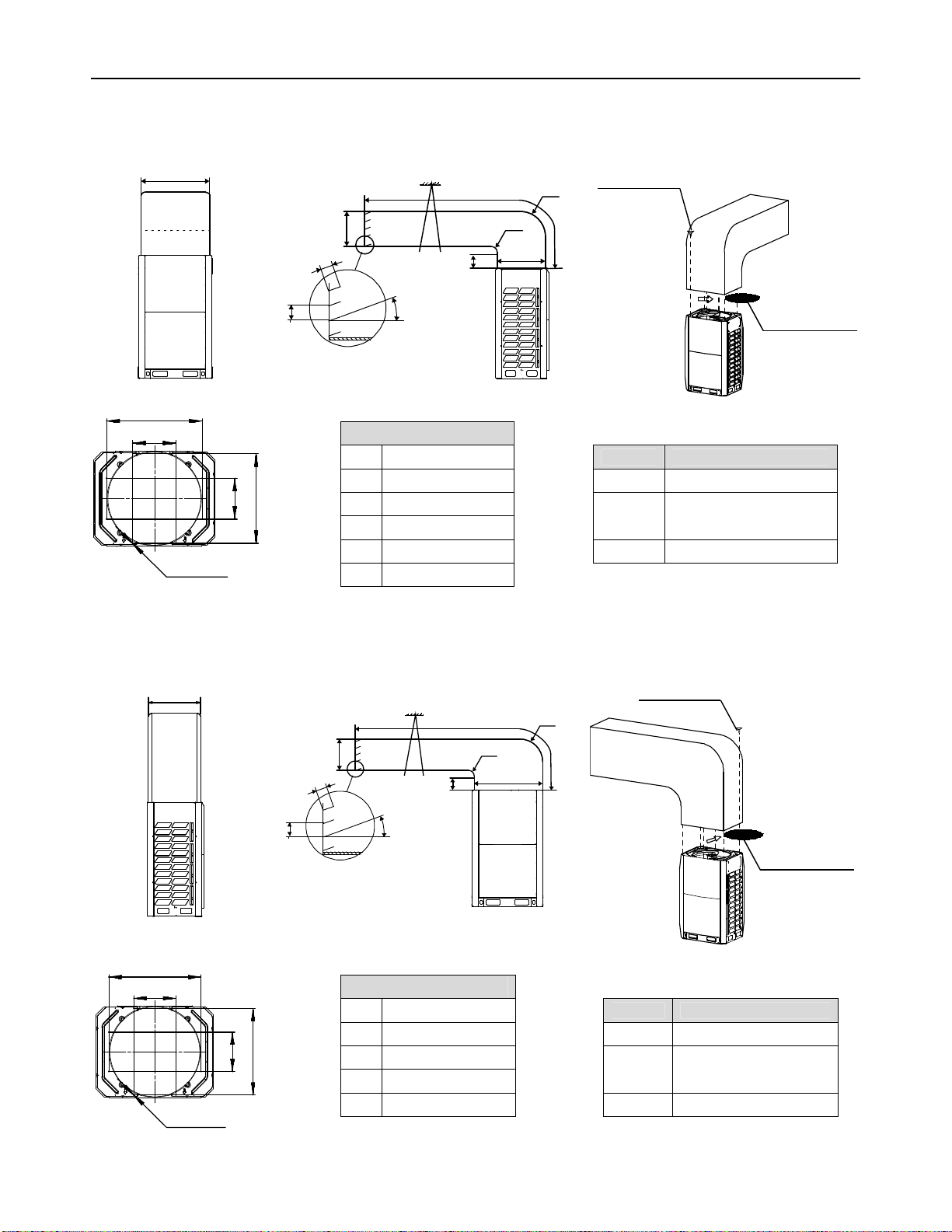

3 OutdoorUnitDuctingandShielding

3.1 DuctingRequirements

Dependingontheheightofadjacentwallsrelativetotheheightoftheunits,ductingmayberequiredtoensureproperair

discharge.InthesituationdepictedinFigure3‐3.1,theverticalsectionofductingshouldbeatleastH‐hhigh.

Figure3‐3.1:Top ofunitbelowtopofadjacentwall

3.2 DesignConsiderations

Outdoorunitductingdesignshouldtakeaccountofthefollowing:

Eachductshouldcontainnomorethanonebend.

Vibrationisolationshouldbeaddedtotheconnectionbetweentheunitandtheductingtoavoidvibration/noise.

Installinglouversisnotrecommendedasdoingsodecreasesairflow,impactinguponcooling/heatingperformance

andenergyefficiency.Iftheinstallationsituationnecessitateslouvers,theyshouldbeinstalledatananglenogreater

than15°tothehorizontal,tominimizetheimpactonairflow.

hh-H

H

Beforeinstallinganindoorunit,checkthatthemodeltobeinstalledisasspecifiedintheconstructiondrawings

andconfirmthecorrectorientationoftheunit.

Ensurethatunitsareinstalledatthecorrectheight.

Toallowsmoothcondensatedrainageandtoensureunitstability(topreventexcessivenoiseorvibration),

ensurethatunitsareleveltowithin1°ofthehorizontal.Ifaunitisnotleveltowithin1°ofthehorizontal,water

leakageorabnormalvibration/noisemayoccur.

Notesforinstallers