Trycom Technology TRP-C28 User manual

TRP-C28

4-channel isolated digital input and 4-channel power relay output

RS485 module, Support ASC and Modbus Protocol.

User’s Manual

Printed May. 2011 Rev 1.3

Trycom Technology Co.,Ltd

1F, No.2-11,Sihu street ,Yingge Township, Taipei, Taiwan ROC

Tel: 886-2-86781191 , Fax: 886-2-86781172

www.trycom.com.tw

Copyright

Copyright Notice: The information in this manual is subject to change without prior notice in order to improve reliability, design and function and

dosed not represent a commitment on the part of the manufacturer. No part of this manual may be reproduced, copied, or transmitted in any

form without the prior written permission of manufacturer. Acknowledgment roducts mentioned in this manual are mentioned for identification

purpose only. roducts manes appearing in this manual may or may not be registered trademarks or copyright of their respective companies.

1

1. ntroduction

TR -C28 provides with 4 optical isolated digital input channels and 4 power relays output. All

channel features screw terminals for convenient connection of field signals as well as LED’s to

indicate channel status. Input channels are equipped with 3750Vms DC isolation, and surge

protection on RS485 data lines that protect the module and devices against high power voltage

input and ground potential differences. For easy user access, TR -C28 can enter configuration

mode and self-test mode with outer dip-switch. TR -C28 support both ASCII and Modbus

protocol, with a full set of command, dual watch-dog, and auto reset function the module can be

bi-directionally remote controlled by C in ASCII or Modbus RTU protocol.

1-1.Features

Wide input range DC power supply.

Support ASCII and Modbus RTU protocol.

Supports baud rates from 1.2Kbps to 115.2 Kbps.

All 4 channels digital input ca be used as counter.

Digital input signal with 3750Vrms isolation protection.

Dual watchdog: Module’s firmware, host computer traffic.

LED for each channels working status.

DIN rail and panel mount support.

Configured and self-test by outer dip-switch.

Support screw terminal and external DC power adaptor.

1-2.Specifications

Input channel: 4 digital input channels.

Input optical isolation: 3750 Vrms.

Input logical level 0: ±1V (max).

Input logical level 1: ±4.0V ~ ±30V.

Communication interface: RS485.

Communication speed: Baud rate from 1.2kbps to 115.2Kbps.

Input impedance: 3Kohm.

Distance: 500M (max).

Digital Input can be used as counter channel: 4.

Counter frequency: 100Hz.

Output channel: 4 channel power reply outputs.

Relay type: 2 Form A (RL1,RL2) , 2 Form C (RL3,RL4).

Contact ratting: 6A/24V DC , 6A/120V AC , 5A/250V AC.

Relay surge strength: 4000V.

Relay operating time: 6ms.

Relay operating life: 1 X 10(7).

Dual watchdog: Hardware reset circuit, module and host operating status.

2

Signal LED: ower on, all channels.

ower supply: Screw terminal, or external DC adapter.

Connection type: Screw terminal, accepts AWG #12~32 wires.

ower consumption: 2.7W.

Operating environment: 0 to 65C.

Storage temperature: -20 to 65C.

Humidity: 10-90% Non-condensing.

Dimension: 151mm X 75mm X 26mm.

Weight: 400g.

1-3. Panel Layout

1-4.Block Diagram

3

1-5. Pin Definitions

2. Communication Wiring

3. Wire Connection

4

4. System Configuration Switch

The TR -C28 support the Modbus RTU and ASCII communication protocol, It has a two pins

external dip-switch that allow user to select protocol between Modbus/RTU and ASCII. The dip-

switch also provides “back to default” function when user forget the configuring information

stored in EE ROM such as ID (RS-485 Module address), baud rate and data format.

Default setting:

D Address: 01,

Baud Rate: 9600,

D O Mode Type: 40,

Checksum: Disable,

RS485 Communication data format: N, 8, 1.

Modbus Protocol (Factory)

5

Modbus Communication rotocol.

Back to N T for Modbus

1. Adjust the switch to “off off” position

2. Adjust the switch to “on off” position

3. Reboot.

ASC Protocol

ACSII communication protocol.

Back to N T for ASC

1. Adjust the switch to “on off” position

2. Adjust the switch to “on on” position

User may adjust the switch in power on

status, no system reboot require.

Enter self- test mode

Adjust the switch to on on then reboot.

*INIT: ID=00, Baud-Rate: 9600, Data format: 00, Checksum=disable.

5. Function description

Power on mode: When power fail, system reset or host watchdog timeout will cause the

module reboot then into power on mode, the module’s digital output value will return to the

before setting.

And module can accept the host’s command to change the digital output value.

Dual Watchdog: Module self watchdog: The module’s watchdog is a hardware reset circuit

while working in harsh or noisy environment, the module may be down by the external, The

circuit may let the module to work continues and never halt.

Host watchdog: The host watchdog is software function to monitor the module's output states to

prevent the module from communication problem or system halt due to unexpected situation,

It’s purpose is to prevent the RS485 network from communication problem or host halt. When

the timeout interval expired, the module will turn all output to predefined safe value. This can

6

prevent the controlled target from unexpected situation.

Safe mode: If the user install the watch-dog enable on the RS485 line, The host will send the

reset module’s watchdog command one by one, when the host is not send the command (May

be is RS485 off line or host halt), the module will watchdog timeout then into the safe mode, if

the module into the safe mode, the digital out will not be changed until the watchdog disable.

6. TRPCOM Command Protocol Description

Command Format :”Leading Code”+”ID Address”+”Command”+”CHK”+(cr).

Response Format :”Leading Code”+”ID Address”+”Data”+”CHK”+(cr).

7. How to Calculate the Checksum

1. Calculate all characters of the command string to get the ASCII sum, except the character

return.

2. Mask the sum of string with 0FFH.

Example:

Send the command is “$06M”.

Sum of string is “$”+”0”+”6”+”M”=“24H”+”30H”+” 4D“=“A1H”……The checksum and [CHK]=“A1”.

Response string with checksum is:” A1 “.

7

8. Command List

Command List Function Description age Index

%IDNN BBDD(CHK)(cr) Set the module’s configuration See 8-1 ~ 8-3

#ID FD(CHK)(cr) Digital output data See 8-4

#IDN(CHK)(cr) Read digital input N channel counter value See 8-5

#IDCN(CHK)(cr) Clear digital input N channel counter value See 8-6

#IDCW(CHK)(cr) Clear all digital input counters value See 8-7

#IDCS(CHK)(cr) Save all digital input counters value to EE ROM See 8-8

$IDLS(CHK)(cr) Read digital input latched See 8-9

$IDC(CHK)(cr) Clear digital input latched See 8-10

$ID6(CHK)(cr) Read digital input/output status See 8-11

$ID2(CHK)(cr) Read the TR -C28M configuration See 8-12

$IDRS(CHK)(cr) Reset the module status See 8-13

$IDM(CHK)(cr) Read the module’s name See 8-14

$IDF(CHK)(cr) Read the module’s firmware version See 8-15

$ID5(CHK)(cr) Read the module reset status See 8-16

~IDONN(CHK)(cr) Change the module’s name See 8-17

~IDLEDA(CHK)(cr) Set the module’s LED operating mode See 8-18

~IDWENN(CHK)(cr) Enable watchdog and set the timeout value See 8-19

~IDWD(CHK)(cr) Disable watchdog See 8-20

~IDWR(CHK)(cr) Read watchdog timeout value See 8-21

~**(CHK)(cr) System stand by (Host OK!) See 8-22

~ID4V(CHK)(cr) Read power on/safe value See 8-23

~ID5V(CHK)(cr) Save current digital output status to power on or safe mode See 8-24

#**(CHK)(cr) Save current digital input status See 8-25

$ID4(CHK)(cr) Read synchronized data See 8-26

*We offer the utility to guide you to configure the module; the utility is with on-line RS485

modules scanning and searching function. You can find the utility in the CD which bundled in

TR -C28 standard package.

8

8-1. Configure TRP-C28

Command %IDNN BBDD(CHK)(cr)

Syntax

Description

% First leading code

ID Address of setting module 00-FF(HEX)

NN New address of setting from 00-FF(HEX)

The Digital I/O module type define to 40

BB Set new baud rate (See 8-2)

DD Data format (See 8-3)

CHK Checksum

(cr) Carriage return

Response !ID(CHK)(cr) Command valid

?ID(CHK)(cr) Command Invalid

8-2 Baud rate setting (BB)

8-3 Data format setting (DD)

Example:

Send command:”%0001400600”…If you turn on the system setting switch, the ID will be reset

to “00”,

New ID is “01”,D I/O type is “40” ,Bard-Rate:9600 ,Checksum setting disable is “00”,

Response:”!01”.

Example:

Send command:%000340054

New ID=“03”,Bard-Rate=“4800”,Checksum=“Enable”,Response:”!03”.

9

8-4. Digital output data

*Multi-Channel mode (Output control for one BYTE)

Example:

Send command :”#010A0F”…..Data=”0F”:DO0-DO3=“1111”, (RL1/RL2/RL3/RL4= ON).

Response:”>”……. Command valid.

Example:

Send command:”#010008”…..Data=”08”:DO0-DO3=“0001”,(RL1/RL2/RL3:OFF/RL4:ON).

Response:”>”……. Command valid.

Example:

Send command:”#01000G”…Data=“0G”…….Data error!.

Response:”!01”……. arameter error!.

*Single-Channel mode( Output control for one BIT)

Example:

Send command:”#011001”….. Data=”01”:DO0=“1”.

Response:”>”……. Command valid.

Send command:”#011201”….. Data=“01”:DO2=“1”.

Response:”>”……. Command valid.

Send command:#011300……Data=“00”:DO3=“0”.

Response:”>”……..Command valid.

10

8-5. Read digital input N channel counter value

Example:

Send command:”#012”…..Read the TR -C28M channel 2 counter value.

Response:”!0100023”…..The digital input have been trigger 23 times.

*Unless you save value to EE ROM by using the command “#IDCS”. The counter’s value will

reset to 0 if power fail or send command “$IDRS”.

8-6. Clear digital input N channel counter value

Example:

Send command:”#01C2”, Clear DI2 counter value to 0.

Response:”!01”.

*If counter’s value already been reset to 0 you must use command “#IDCS” to save the new

value in EE ROM again, or the module will load old value if power fail or reset.

11

8-7.Clear all digital input counters value

Example:

Send command: ”#01CW”, Clear DI0-DI3 counter value to 0.

Response:”!01”.

* After the command “#IDCW” you must save new value in EE ROM again, or the module will

load old value if power fail or reset.

8-8.Save all digital input counters value to EEPROM

Example:

Send command ”#01CS”, Save DI0-DI3 counters value to EE ROM.

Response:”!01”.

Then after power fail or reset

Send command:”#010”……..Read DI0 counter value.

Response:”!0100187”………..Last time save value is “187”.

12

8-9.Read digital input latched

Example:

Send command:”$01L0”…….Read digital input logic 0.

Response:”!010200 ”……… DI1 have been latched.

*Digital input latch: User key in a digital signal to the module and want to read the response of

key stoke. However the user will lost the stoke information because the key input is pulse digital

input. If user read by the command “$ID6” in time A and time B, the response is that no key

stoke. Use command $IDLS can solve this problem, user may read the key stoke in time

position A and B.

8-10.Clear digital input latched

Example:

Send command:”$01C”…….Clear digital input latch .

Response:”!01 ”……………. …Latch have been clear.

13

8-11. Read digital input/output status

Example:

Send command:$016…….Read digital I/O status .

Response:”!01060C”…….”6”: Relay (RL1,RL4:OFF,RL2,RL3:ON).

“C”: Input DI0 ,DI1 for logic “0”.

8-12.Read the TRP-C28M configuration

Data format table

14

Example:

Send command:$012…Read configuration .

Response:”!01400640”……. DIO type=40,Baud-Rate=9600 (See 7.2) ,Data format=40 Input

counter :rising ,Checksum= Enable, Model=0….TR -C28M (See Data format table),

8-13.Reset the module status

Example:

Send command:”$01RS”…….Reset TR -C28M.

Response:”!01 ”……… …………..Have been reset.

*Reset will clear all digital output status.

8-14.Read the module’s name

Example:

Send command:$01M…Read the TR -C28M’s name.

Response:”!01TR C28”……. The module’s name is “TR C28”.

15

8-15.Read the module’s firmware version

$IDF(CHK)(cr)

Syntax

description

$ First Leading code

ID Address of setting module 00-FF(HEX)

F Command for leading module’s version

CHK Checksum

(cr) Carriage return

Response !IDMODYYMMDD Mod: The module type

YY: Year

MM: Month

DD: Date

?ID(CHK)(cr)

Example:

Send command:”$01F”…Read the TR -C28M’s version.

Response:”!01C28M070412”……. The TR -C28M’s version date is “04/12/2007”.

8-16. Read the module reset status

Example:

Send command:$015…Read the TR -C28M’s reset state .

Response:”!011”……. The TR -C28M has been reset.

*If the module is system halt or detect abnormal voltage, the module will restart and reset the

flag to “1”.

16

8-17.Change the module’s name

Example:

Send command:”~01OABCDE”….. Change the TR -C28M’s name become to “ABCDE”.

Response:”!01”……. . Command valid.

Then send the command “$01M”…read the TR -C28M’s name.

Response:”!01ABCDE”……. .The TR -C28M’s name is “ABCDE”.

8-18.Set the module’s LED operating mode

~IDLEDA(CHK)(cr)

Syntax

description

~ First Leading code

ID Address of setting module 00-FF(HEX)

A A=0 Turn on all LED when DIO enable off.

A=1 Turn off all LED when DIO enable on.

CHK Checksum

(cr) Carriage return

Response !IDON/OFF Command valid

?ID(CHK)(cr) Command invalid

Example:

Send command:”~01LED0”….. Turn off all LED, when logic “1” ON.

Response:”!01OFF”……..Command valid.

8-19.Enable watchdog and set the timeout value

17

Example:

Send Command:”~01WEFF”….. Set the watchdog time for 25.5 Sec.

Response:”!01”……. . Command valid, When module count to 25.5 Sec the watchdog will into

safe mode ,then WR LED will flash, before timeout if host send “~**”, the watchdog will re-

counted!.

*When the module is in safe mode, any digital output command are invalid, you will get the

response “!IDWE” , which means the system is in safe mode, you can't change output status.

*Reset and power fail will not affect watchdog mode.

8-20. Disable watchdog

Example:

Send Command:”~01WD”….. Watchdog disable!.

Response:”!01”……. . Command valid, System LED will stop flashing!.

8-21. Read watchdog timeout value

18

Example:

Send Command:”~01WR”…. Read watchdog timeout value.

Response:” !01WD0F”……. . Command valid, set the watchdog timeout is “0F”..1.6 Sec.

8-22.System stand by (Host OK!)

*If watchdog is in enable , send the Host Ok!”command before watchdog timeout (B) the

watchdog will re-count, WR LED will flashing after watchdog timeout.

8-23.Read power on/safe value

19

Command ~ID4V(CHK)(cr)

Syntax

description

~ First Leading code

ID Address of setting module 00-FF(HEX)

4 Read power on or safe mode I/O status

V V= : ower on mode I/O status

V=S: Safe mode I/O status

CHK Checksum

(cr) Carriage return

Response !IDABCD A=0 B:DO0~DO3

B=0 D:DI0~DI3

?ID(CHK)(cr) Command invalid

Example:

Send Command:~014S……….Read safe mode digital output status.

Response:” !01080F”………. . Command valid, safe mode digital IO status is ”080F”.

8-24. Save current digital output status to power on or safe mode

Example:

Send Command:”#010A0F”…Relay output RL1~RL4= ON/ON/ON/ON

Response:” !01”……. . Command valid!

Then Send Command :” ~015 ”….Set the relay output for power on ,.After power fail or reset ,

The module will load current DO status.

8-25. Save current digital input /output status

20

Other manuals for TRP-C28

1

Table of contents

Popular Switch manuals by other brands

HAI

HAI 38A00-3 Installation and operating instructions

Vetra

Vetra MegaSwitch USB- 802 Series User instructions

Hama

Hama 102193 Operating instruction

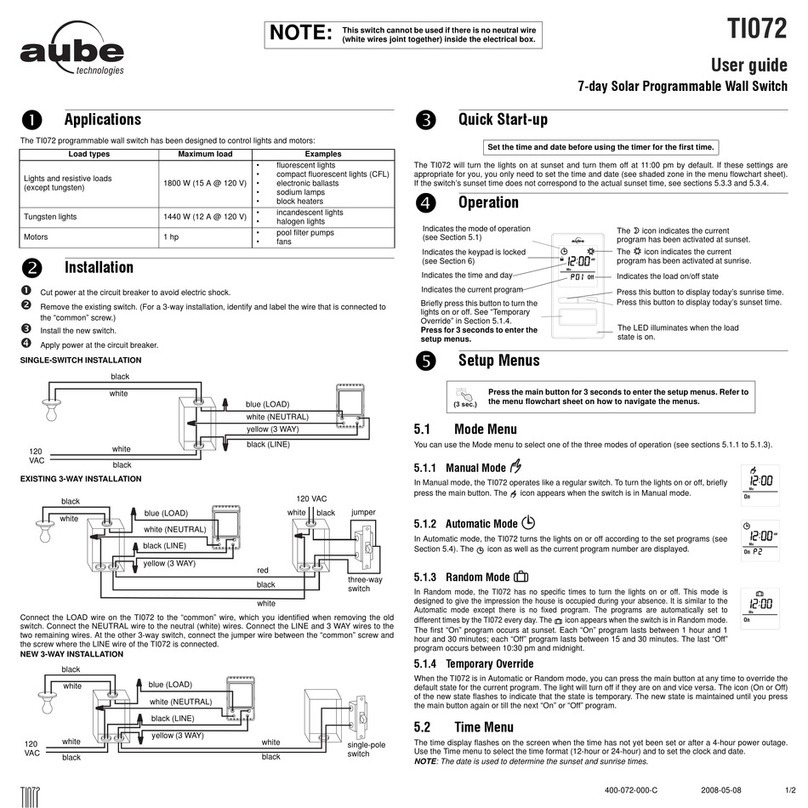

Aube Technologies

Aube Technologies TI072 user guide

Cabletron Systems

Cabletron Systems SmartSwitch 6500 Overview and setup guide

Cisco

Cisco SG350XG-2F10 quick start guide