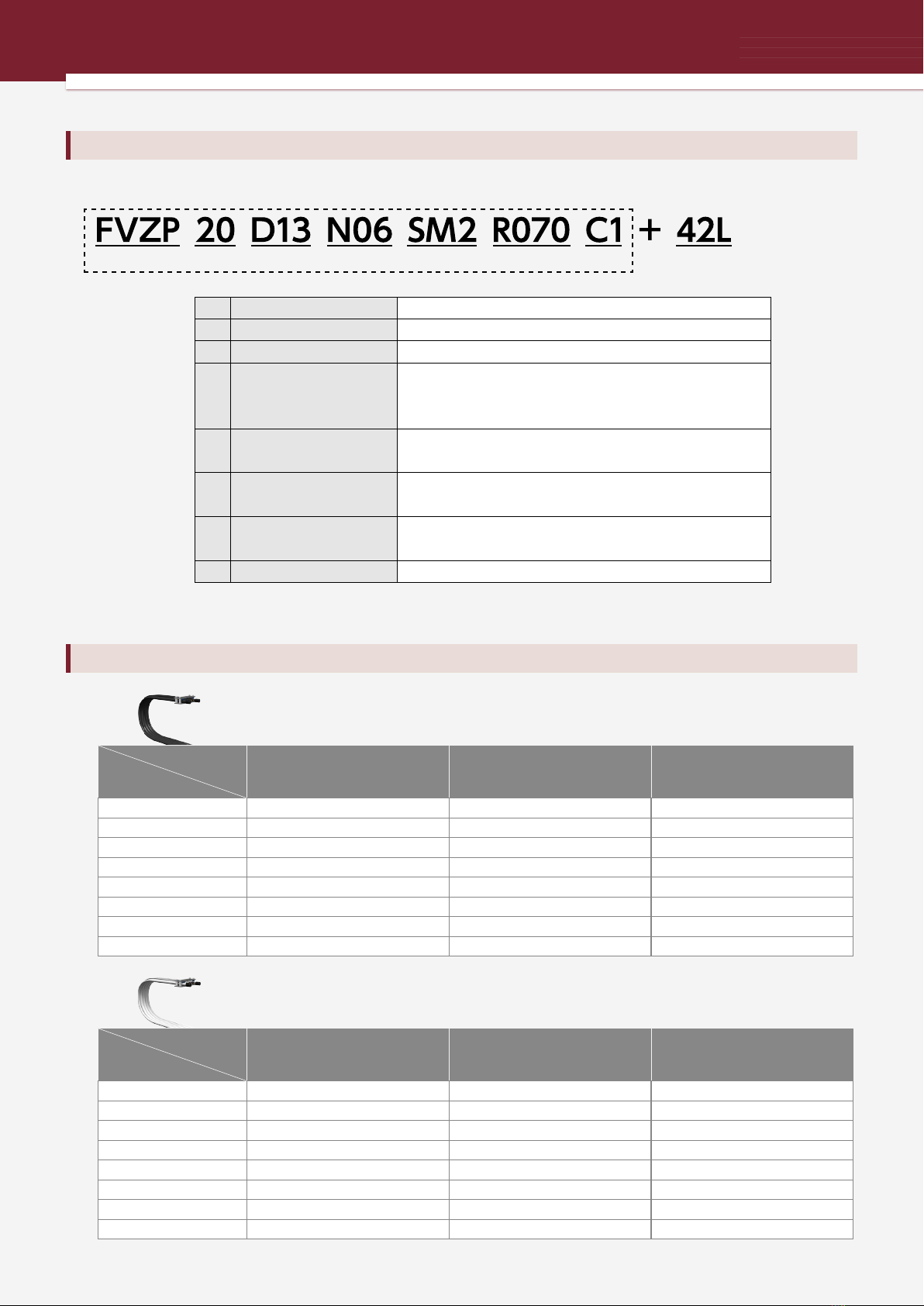

Check of installation dimensions

Step 4

Page

6

Item

Installation dimensions

Reference information

Check the space required for installation.

If the operating conditions exceed the load diagram, contact a Tsubaki representative.

Mounting height

223 to 243 mm

Required space (Width)

186 mm

Required space (Height)

323 to 343 mm

Example:

186 mm

223 to 243 mm

323 to 343 mm

Page

5

Item

Basic specifications

6 Fixing parts and installation dimensions

Reference information

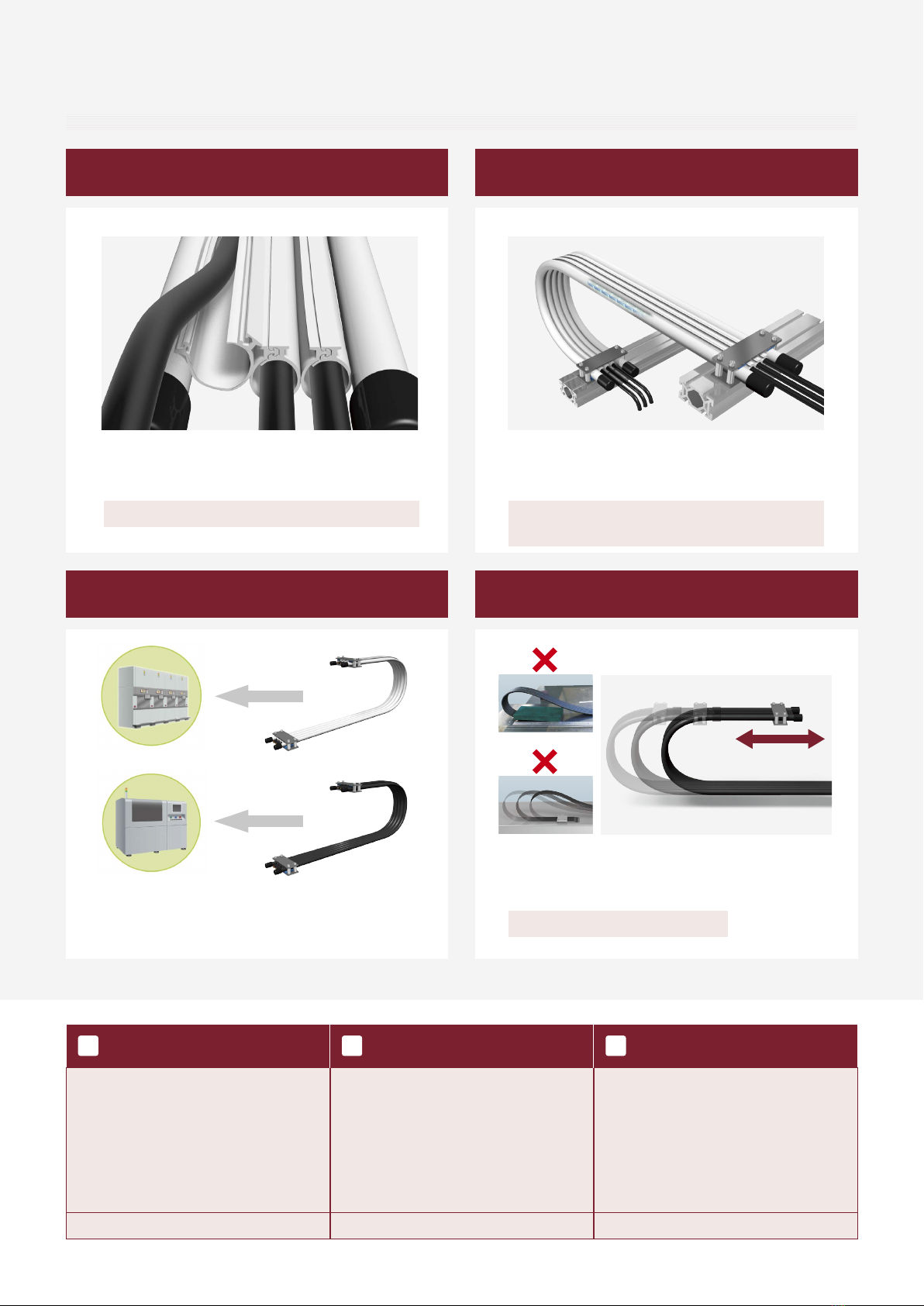

Calculation of the number of support member links

Step 5

2

S

2

(H’ − 23) × π+ 2K+ 2CL +

P

Number of support member links =

Fixed end

Moving end

Travel length S

Clamp length CL

Leeway length K

Mounting height H’

Support member

bending radius R

R = 70/100/130

S

H’

K

P

CL

: Travel length (mm)

: Mounting height (mm)

:

Leeway length = 100 or more (mm)

:

Support member pitch (mm)

: Clamp length = 50 mm

(Recommended)

:

Fixed number for calculation

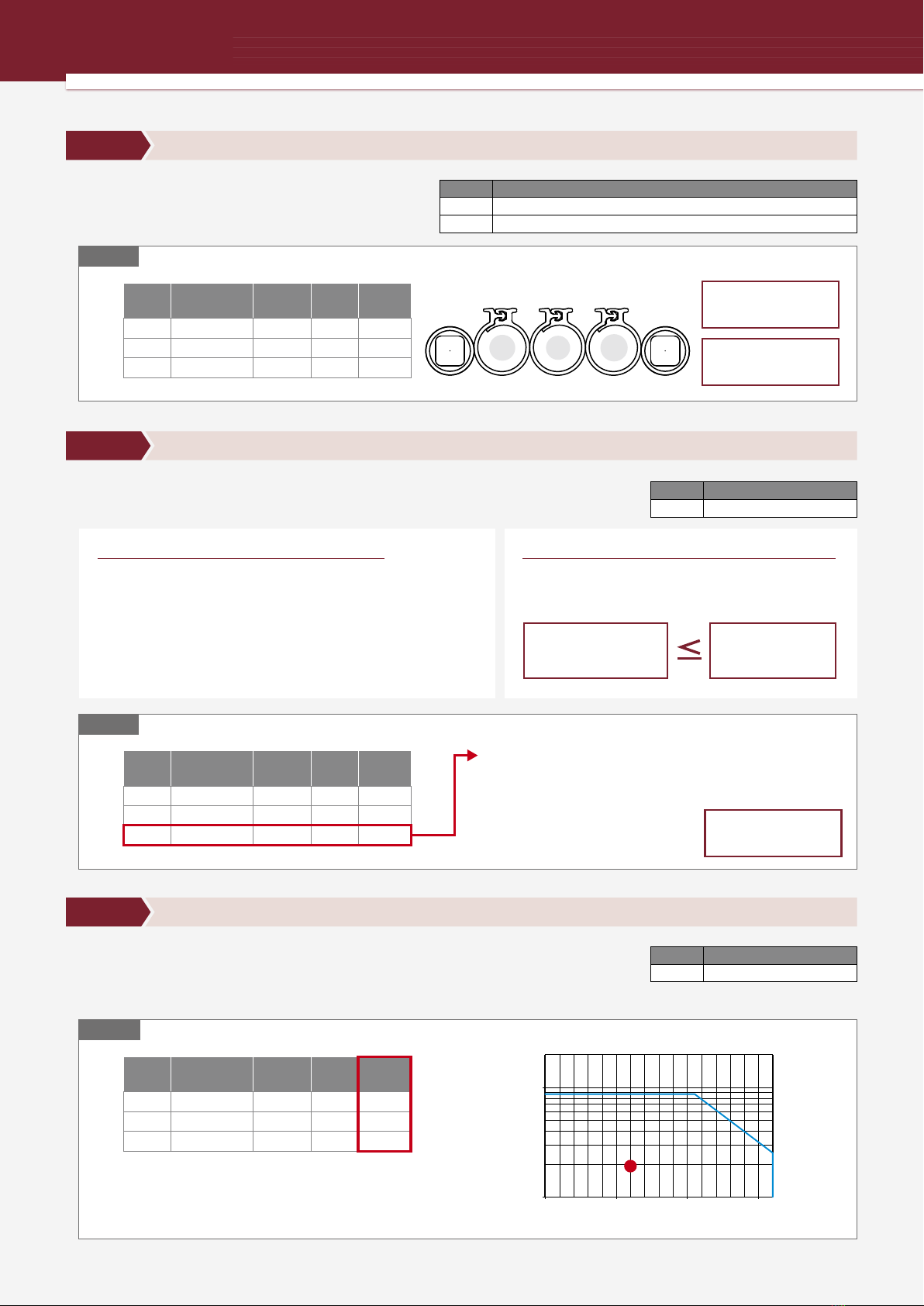

Determination of color

Step 6

Determine the color of the product.

Number of links

49 links

+

2

600

2

(233 − 23) × π

+ + (2 × 100) + (2 × 50) + 46

20

Number of support member links =

In case of S= 600, H’ = 233, support member bending radius R070

= 48.7933...

= 49

Example:

The formula is for the case when the

fixed end is at the center of the travel

length. After calculating, always round

up to a whole number.

Note:

Black White

9

Operating conditions:

Travel length: 0.6 m

Cable mass per meter: 0.195 kg/m

Unsupported length (m)

STravel length (m)

0.1

2

1

0.1

0 0.5 1 1.51.6

0.9

0.87

(kg/m)

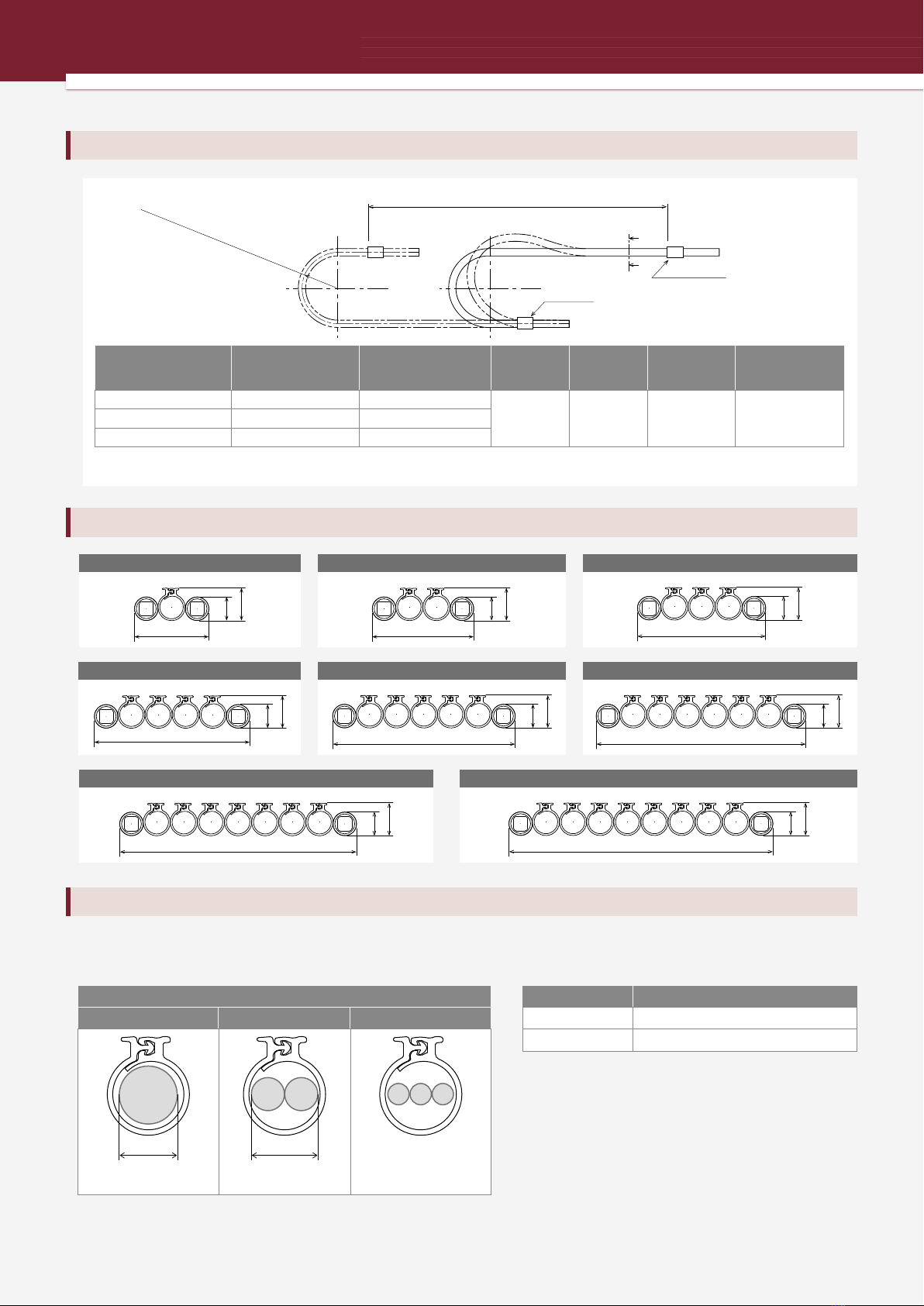

Check of capability with a load diagram

Step 3

Page

11 to 12

Item

Load Diagram

Reference information

Using the load diagram that shows the required number of openable tubes

and the support member bending radius, check that the operating conditions

(travel length, cable/tube mass) are within the capability range.

Example:

No.

(1)

(2)

(3)

Cable outer

diameter

mm

6.6

7.1

7.2

With/without

shield

Shielded

Shielded

Shielded

Quantity

1

1

1

0.052

0.070

0.073

Mass

kg/m

Installation cables

Support member bending radius

R070

Cable allowable bending radius = 7.2 × 8

= 57.6 mm

Select a support member

bending radius greater

than 57.6 mm.

No.

(1)

(2)

(3)

Cable outer

diameter

mm

6.6

7.1

7.2

With/without

shield

Shielded

Shielded

Shielded

Quantity

1

1

1

0.052

0.070

0.073

Mass

kg/m

Example:

Installation cables

Selection

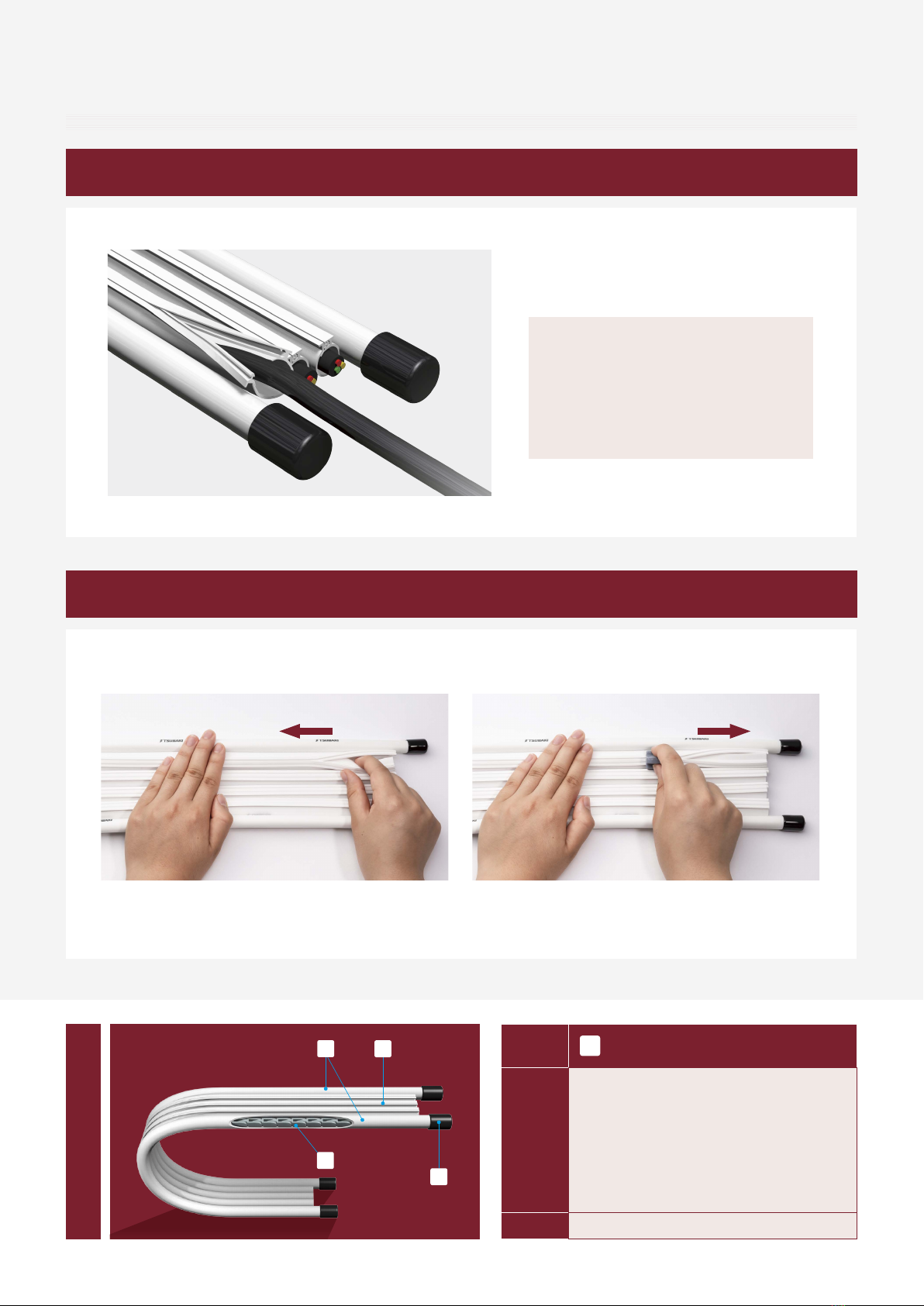

Determination of required number of openable tubes and required space (width) dimensions

Step 1

Page Item

Reference information

Determine the cable/tube arrangement and

required number of openable tubes. After they have

been determined, check the required space (width).

Required number of openable tubes

3

Required space (Width)

186 mm

Example:

5

6

Number of cables (jackets) and tubes to be installed and recommended materials

Installation dimensions

(3)(2) (1)

No.

(1)

(2)

(3)

Cable outer

diameter

mm

6.6

7.1

7.2

With/without

shield

Shielded

Shielded

Shielded

Quantity

1

1

1

0.052

0.070

0.073

Mass

kg/m

Installation cables

Determination of support member bending radius

Step 2

Page

5

Item

Basic specifications

Reference information

Determine the support member bending radius based on the allowable

bending radius of the cable/tube to be installed.

Check the allowable bending radius recommended by

the cable/tube manufacturer (for repeated bending).

Refer to the following guideline.

Cable with shield = Max. cable outer diameter × 8

Cable without shield = Max. cable outer diameter × 6

Tube = Max. tube outer diameter × 9

Select a support member bending radius

greater than the allowable bending radius of

the cable/tube.

Allowable bending radius of cable/tube

Determination of support member bending radius

Allowable bending

radius of cable/tube

Support member

bending radius

Cable/tube mass