TTI Pool Heat Pump User manual

POOL HEAT PUMP

OWNER’S MANUAL

INSTALLATION MANUAL

No : 2004.1

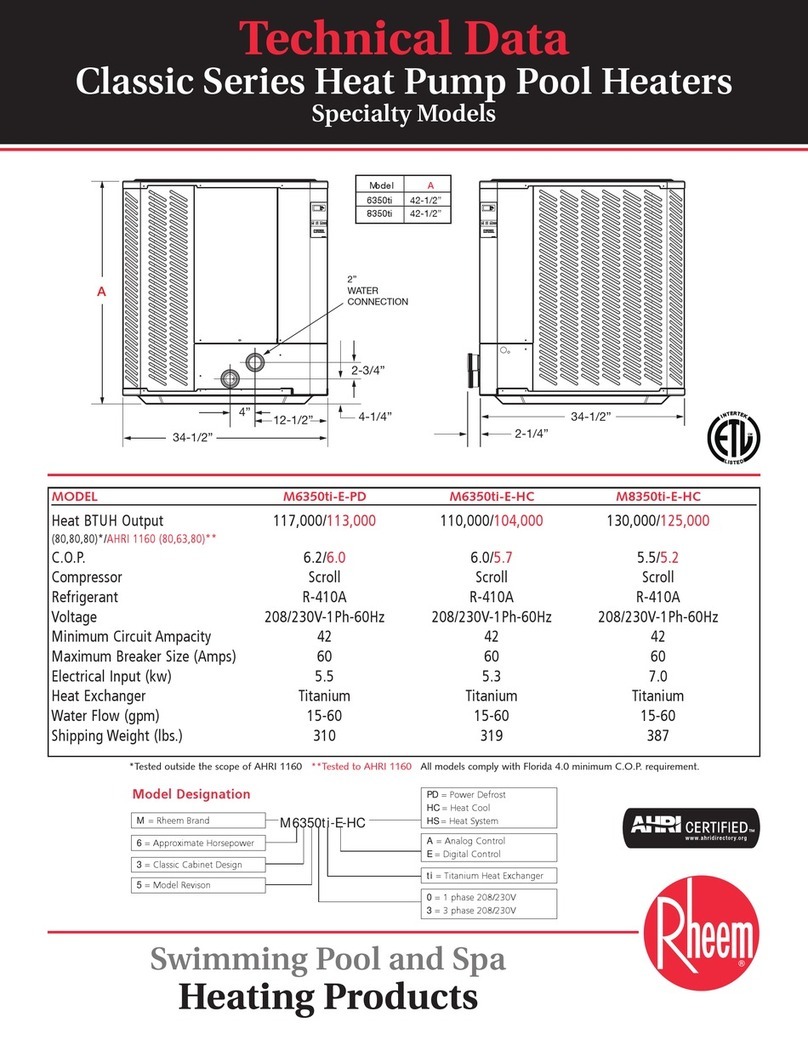

GENERATION MODEL ECLIPSE MODEL

READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR

USING YOUR NEW POOL HEAT PUMP.

TABLE OF CONTENTS

Introduction...............................................................................................p.3

ACost-EfficientHeater

How Does It Work?

LowMaintenance

Selecting the location.................................................................................................p.4

Supply andAccessibility

Other Recommendations for Spas

WaterInletandOutletConnections..............................................................p.5

Basic Connection

Chlorinators, Brominators and Other Automatic Systems

Pressure-Type Chlorinator or brominator

In-line Chlorinator or Brominator

Salt Chlorinator

Dual Units Connection

PoolandSpa Connection............................................................................p.8

Using One Pump and One Filter for the Pool and the Spa

Using Independent Pumps and Filters for the Pool and the Spa

ElectricalConnection..................................................................................p.9

Maintenance...........................................................................................p.10

Cleaning

Winterizing

Seasonal Start-up

Water Deviation

WaterMaintenance.....................................................................................p.13

Why Perform Water Maintenance?

Water Chemistry

Sanitizers

What to Do?

Swimming Pool Heat Pump Control.....................................................p.18

SolvingProblems........................................................................................p.24

QuestionsandAnswers.............................................................................p.25

Warranty..................................................................................................p.26

A Cost-efficient Heater

Your newpoolheatpumpwill helpyousavemoney comparedtoothertypesofpoolheat-

ers. In fact, even if your pool heat pump has a lower heat capacity which makes it run for 24

hoursaday,thepoolheatpump remainsthemosteconomicsystem, becauseoftheuseofstate

oftheart technicsinthermodynamics.

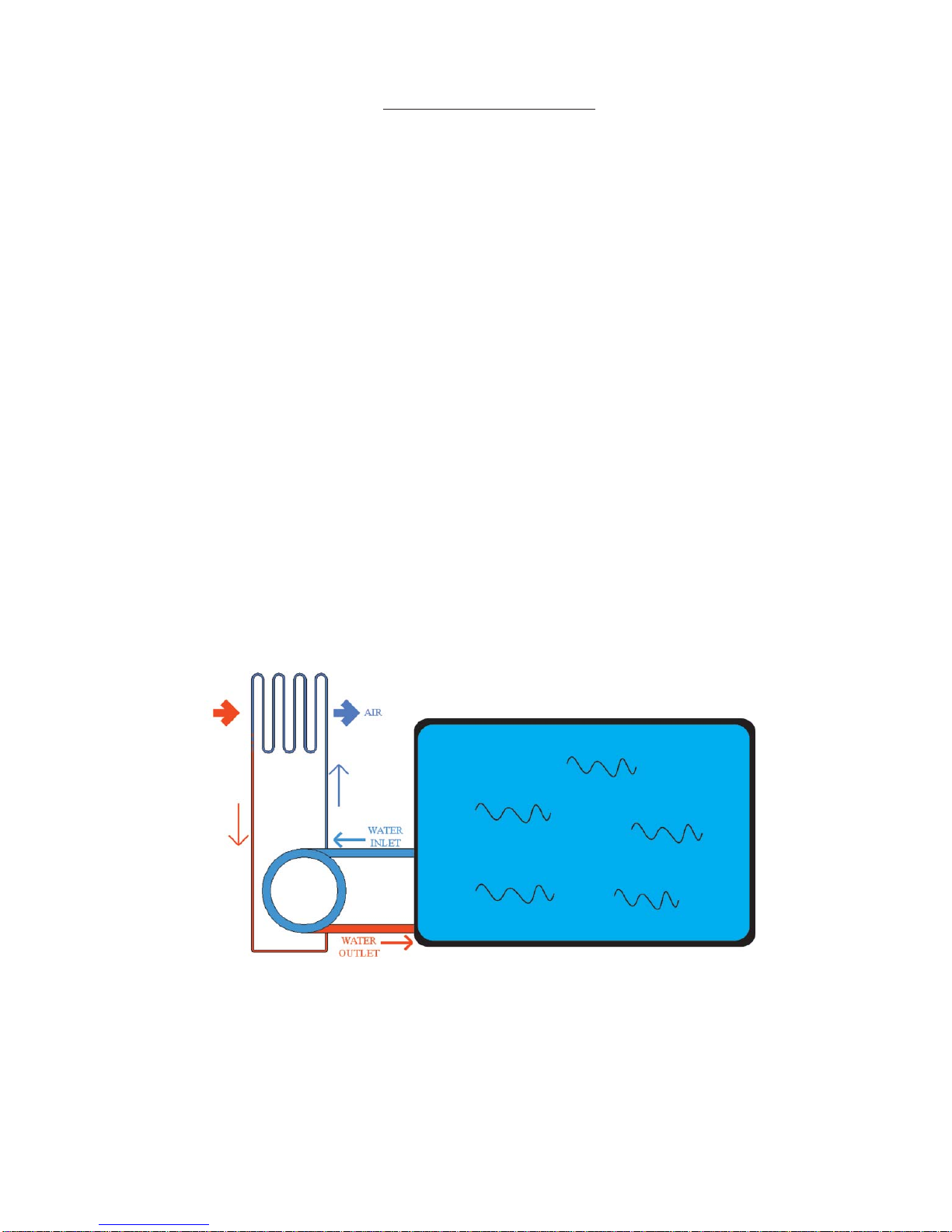

How Does It Work?

Yourpoolheatpumpworksjustasawaterpumpdoes. Whereasawaterpumpistranferring

waterfromoneplace toanother,your poolheatpumpis transferringheatbetweenthe surround-

ingairandyourpoolwater. Moreover,yourpoolheatpumpisnotproducingheatwith theenergy

it is consuming just as a water pump is not producing water. It is because of this principle that

yourpool heat pumpmay attain efficiencyratios going upto 600% or700% in thebest climatic

conditions. Thismeans thatfor each kilowattyour poolheater consumes,it istransfering 6or 7

kilowattsfromthesurrounding airtothe poolwater. Thedifferenceisastronomicalcomparedto

oil,gas or electricresistance heatersyielding only80 to95%output. But itis trueto saythatthe

outputof traditionalpool heatersstays constantat anyoutdoor climatic conditions whereas the

outputof apool heatpump varies. However, even whentemperatures arecooler thepool heat

pumpcontinuesto transferheat betweenair and waterand itstays thebestchoice fortempera-

turesdownto 5Celcius (41Fahrenheit) overnight.

Low Maintenance

Your pool heatpump is designedfor lower maintenanceat a lower cost. But ifyou want

yourpool tobeheated efficiently,youmustfollow theadvice supplied inthis manual.

INTRODUCTION

3

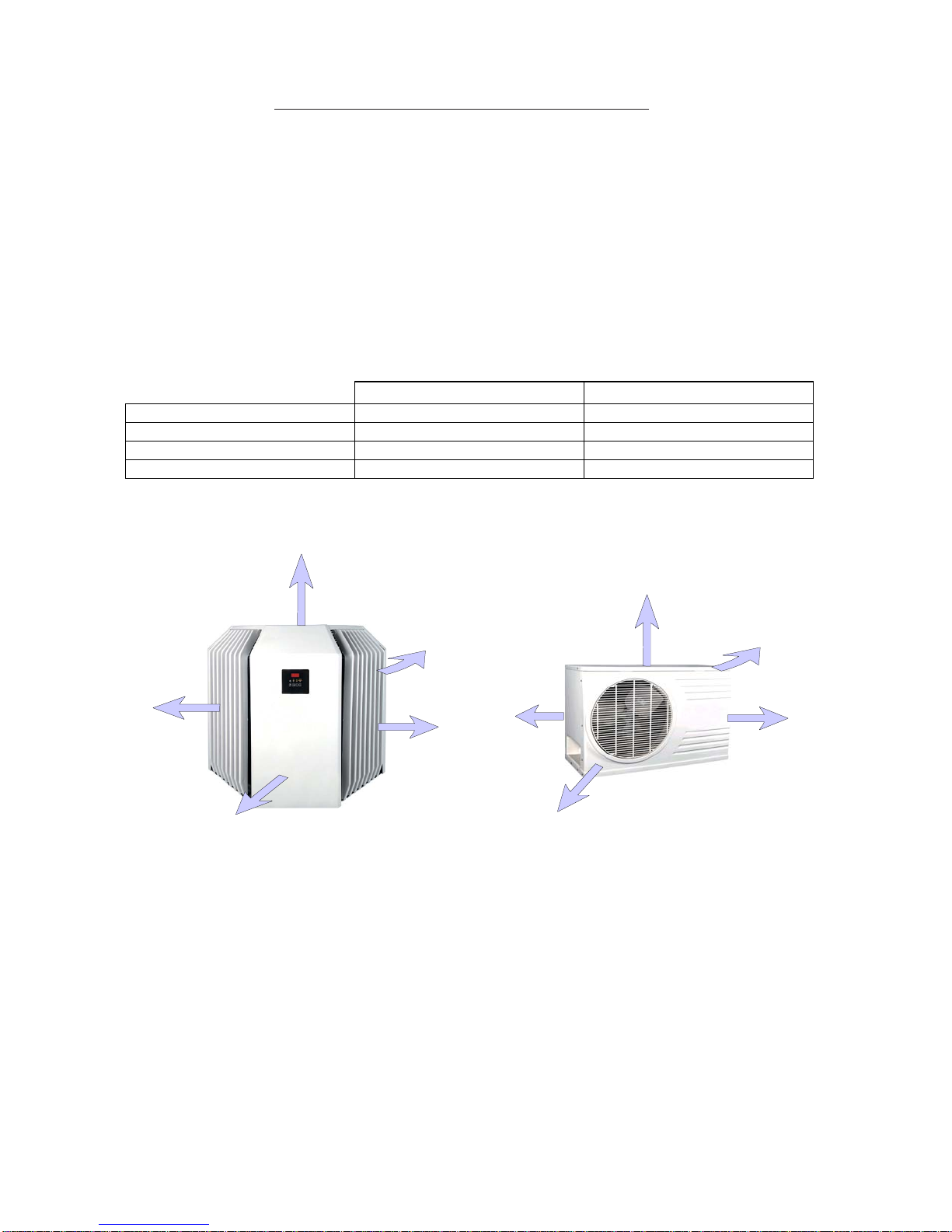

SELECTING THE LOCATION

The area you choose for your pool heat pump is very important. You must consider the

following.

Air Supply and Accessibility

Yourheat pumpuses thesurroundingair towork. It isveryimportantthatyou makesure

there is enough air circulation around the heat pump. Do not install the heat pump in a closed

space like a garden shed, a garage, or a basement.

Thetablebelowindicatestheminimumdistancefromtheheatpumpthatanyobjectshould

belocated.

Other Recommendations

Donotinstalltheheatpumpunderaroof. Doingthiswill protect theheatpumpfrombeing

buriedbysnow orreceiving heavyrainfall from theroof thatdoes nothavegutters.

Also,make sure thatthe digital controldoes not facethe sun. The controlwill not break

butits digital display will be more difficult to read.

Ifyouhaveanautomated sprinklersystemforyourlawn, makesurethattheheat pumpis

notshoweredby asprinkler.

The pool heat pump should be installed on a firm and leveled surface, preferably on a

concreteslabor somethingequivalent.

Keep in mind that the heat pump will cause condensation. Therefore water will be drip-

pingfromthe heatpump.

11

2

3

2

21

4

4

3

Generation (CP) Eclipse (MP)

(1) facing the coil surfaces 2 feet = 61 cm 2 feet = 61 cm

(2) facing other surfaces 10 inch = 25.4 cm 14 inch = 35.5 cm

(3) facing fan * 4 feet = 122 cm 4 feet = 122 cm

(4) facing service panel 2 feet = 61 cm or accessible 2 feet = 61 cm or accessible

* Objects should be placed as far as possible from where the air is discharged.

CP Model MP Model

4

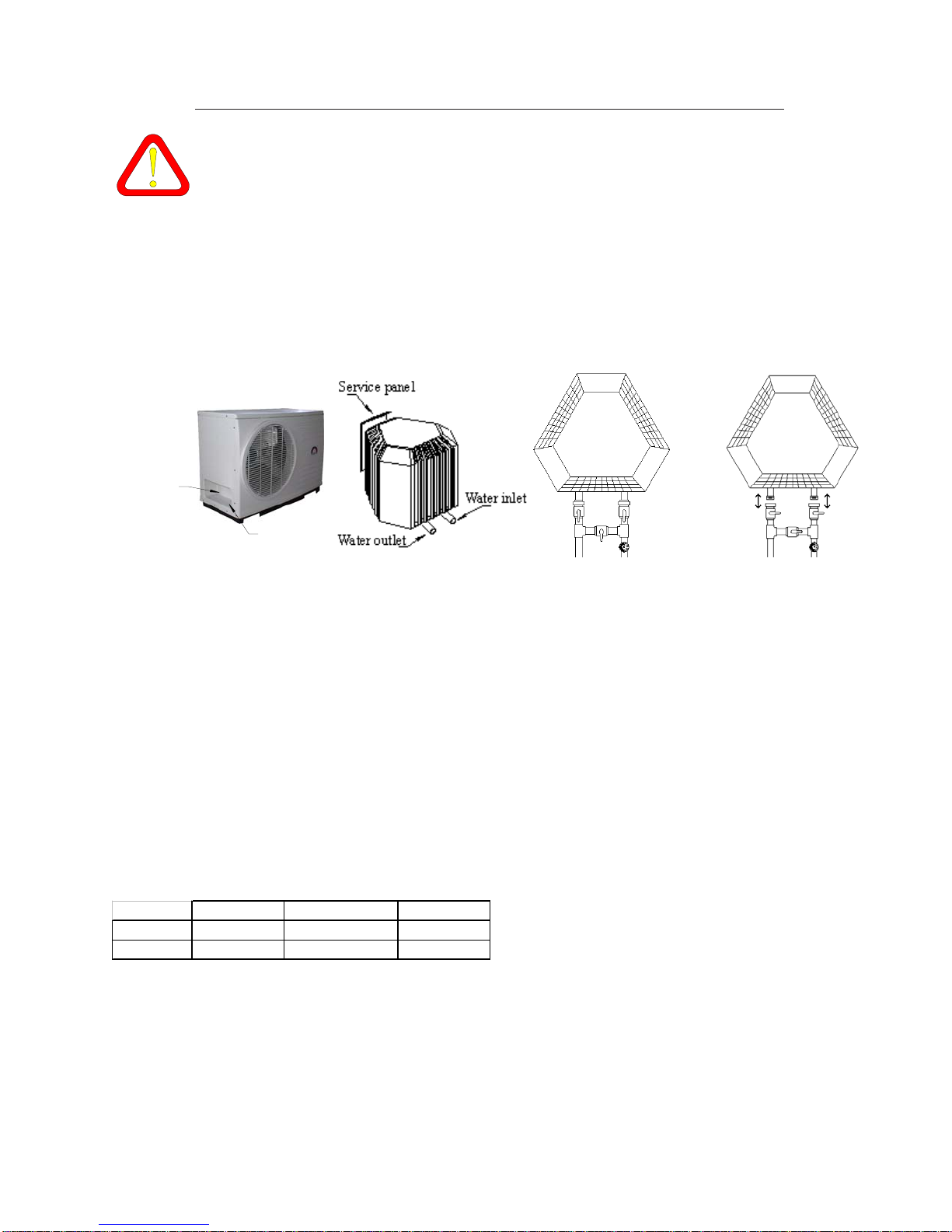

WATER INLET AND OUTLET CONNECTIONS

For all Eclipse (MP) models, connection pipes are 1 1/2 inches in diameter. For all

Generation(CP) models, theconnection pipes are2 inches indiameter. For all the pool

heaters,we recommend(obligatory forthe Eclipse series)the installationof aset ofvalves

allowingto isolatethe poolheater from thefiltration systemwhen necessary. (Seethe drawing

below.) Moreover, youhaveto makesure thatyour poolheat pumpmay bedisconnected from

thepool pipeswithout havingto stopthe waterpump orwithout losinggreat quantitiesof water.

Toadjustthewaterflow goingthroughthepoolheater,pleaseadjusttheby-passvalve(a)

inthefollowingway:

MP30 - MP50 : 3/4 opened

MP70 : 1/2 opened

AllCP’s:Closed-the internalcalibratedvalve regulatesthewater flow, exception

for those who have a water pump of 2hp or greater, adjust the valve to obtain the flows listed

below.

If the previous settings are not respected, the pump or the pool heater may be over-

chargedandresult infailure ofyourequipement.

Your water pumpmust provide thequantity of waterindicated inthe table below. These

numbersmustbe usedfor eachpoolheat pumpinstalled. A flowmetermust beinstalled onthe

waterinletofthe poolheatertoknow theexactwaterflow. Caution:manyflowmeters requirea

longdistance ofstraight tubingon theinlet sideto offeran adequatemeasurement.

Foryourown security,andtoensureproper operationofthe unit,thewaterconnec-

tionmust beperformed by aqualified personas per allapplicable national,provin-

cial, state or local codes.

Minimum Ideal Maximum

Eclipse 15 GPM(US) 20-30 GPM(US) 50 GPM(US

)

Generation 25 GPM(US) 40-50 GPM(US) 65 GPM(US

)

Front View

W

ater Outlet

Water Inlet Setof valves a

a

GMP(US): Americangallons (3,78l)per minute

5

Table of contents

Popular Swimming Pool Heater manuals by other brands

Bestway

Bestway 58259 owner's manual

Maytronics

Maytronics HeatMiser II installation manual

Certikin

Certikin MB50S Operating, installation and servicing instructions

Jandy

Jandy PRO Series JXI200 Quick reference guide

Sungrabber

Sungrabber IN-GROUND Installation and operation manual

Koriks

Koriks 60 kW pool heater Installation and user manual

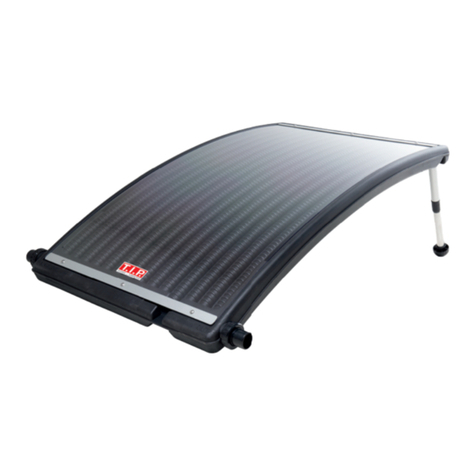

T.I.P.

T.I.P. SPH 10000 Translation of original operating instructions

SIRAIR

SIRAIR ZSXP07i User and service manual

EcoOnline

EcoOnline PoolMasterpro Installation and user manual

Roberts Gorden

Roberts Gorden Vantage TF-120 Service manual

HydroTherm

HydroTherm 42 installation instructions

Hayward Pool Products

Hayward Pool Products HP40A Installation instructions manual