Revision 3 –April 2017 Page 6

16. Press foot switch to rotate brush and withdraw flexible drive slowly (hand over hand) from the pipe. Do not

force flexible drive up or down the pipe –allow the brush and machine to do the work

N.B. If resistance is felt then move flexible drive backwards and forwards a few centimetres as you

briefly tap the foot switch on and off. Try again, or wait for your assistant to advise you if the flexible

drive is free from obstruction. If it gets stuck, do not pull hard on the flexible drive, wait for assistant

to help.

It is advisable to have a colleague assist in the cleaning on the floor below to communicate when and where

the brush has come out of the pipe and when to start rotation back up the pipe.

17. The operator MUST keep an eye on the flexible drive behind him when withdrawing it from the pipe –has it

twisted etc? If it has, uncoil in a large arc and start again.

18. If the flexible drive jams up, the motor and/or variable speed unit overload will trip out. Switch machine off,

withdraw flexible drive from spout and allow the thermal overloads to cool down and reset.

If the overload protection trips out regularly, one of the following may be the cause:

a) You are using a brush which is too large.

b) The spout is heavily scaled or blocked.

If none of these is the cause contact Tube Tech International Ltd.

19.Do’s & Don’ts

Do’s

oBlow out vents in outer cover prior to use.

oUse eye protection, face mask & gloves.

oUse an assistant where possible.

oCheck the power light is on.

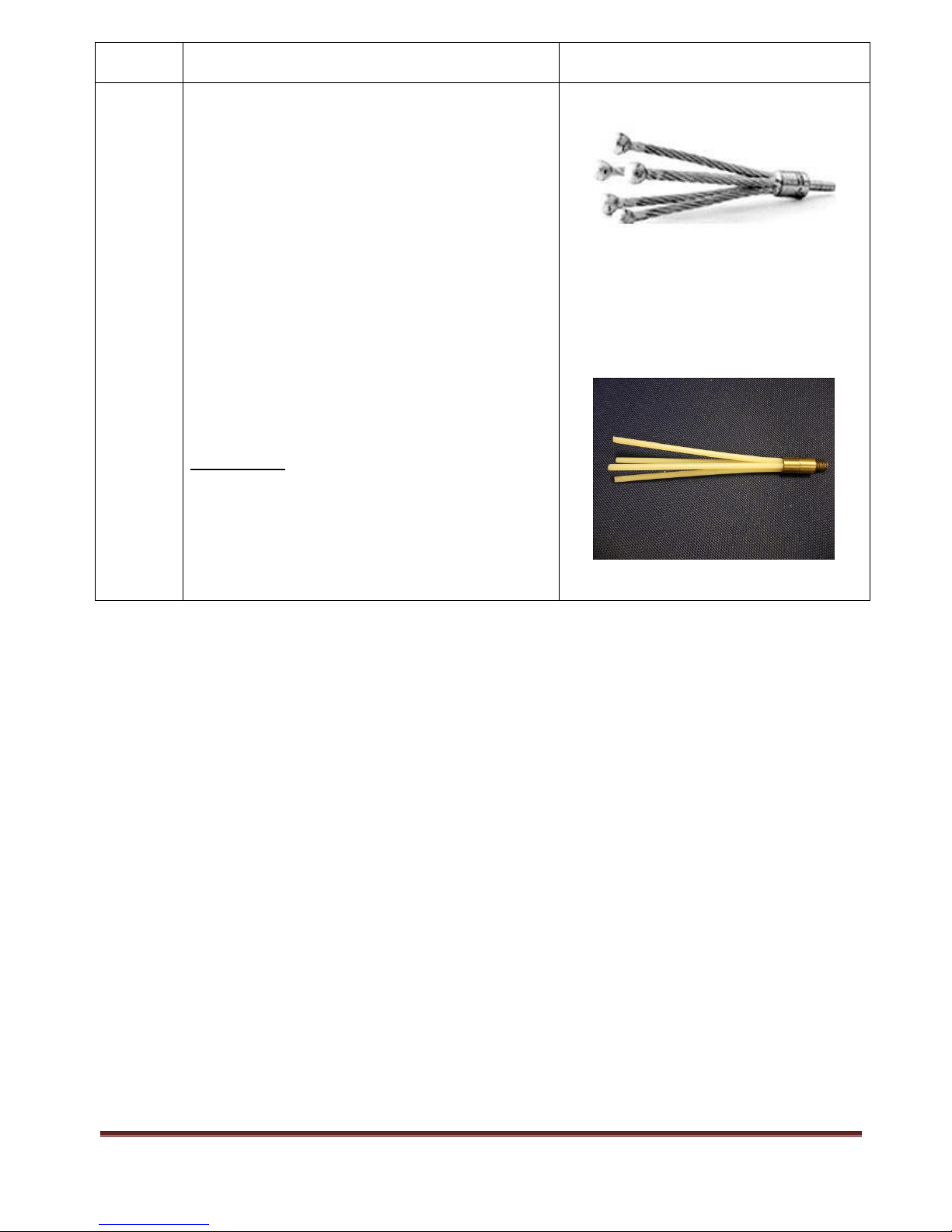

oUncoil flexible drive in large arc and check for damage before starting.

oConnect flexible drive (square drive end) securely into the square recess on the motor spindle and

tighten wing screw.

oConnect outer sheath collar by tightening wing screw into groove in collar.

oUse the correct size brush and speed depending on deposit and diameter of the spout. (Start at

approx 40-50% and work up as required).

oFeed flexible drive down the pipe, NON ROTATING then pull back up slowly ROTATING. Do not

rotate on the way down.

Don’t’s

oDo not wear loose clothing which could get caught.

oDo not start on maximum (100%) speed.

oDo not remove machine cover whilst unit is switched on or power supply connected.

oDo not allow flexible drive to bend sharply at machine end.

oDo not walk or stand on the flexible drive.

oDo not use an incorrect brush size or type.

oDo not allow flexible drive to twist when operating. (If it does, take foot off the foot switch, remove

brush from spout, untwist flex, using reduced speed slowly start again.

oDo not operate the descaler too fast as this may cause damage to the pipe. 25 –50% max.speed

advised.

oDo not force the flexible drive if the brush gets stuck, try to remove gently.

Maintenance of the Rotaflex cleaning system.

- Storage Conditions: - When not is use the machine should be stored in a dry, dust free environment

- Blow out vents in outer cover prior to use.

- The interval for periodic maintenance will depend upon the frequency of use and the environment in which

it operates.