6.5.4. FORK ASSEMBLY ....................................................................................................................................................................................................................48

6.5.5. FRONT BRAKE ........................................................................................................................................................................................................................ 49

6.5.6. FRONT WHEEL........................................................................................................................................................................................................................ 50

6.5.7. HANDLEBAR...............................................................................................................................................................................................................................51

6.5.8. HANDLEBAR MOUNTING .......................................................................................................................................................................................................52

6.5.9. DROPPER POST ......................................................................................................................................................................................................................53

6.5.10. FINAL ADJUSTMENTS ..........................................................................................................................................................................................................54

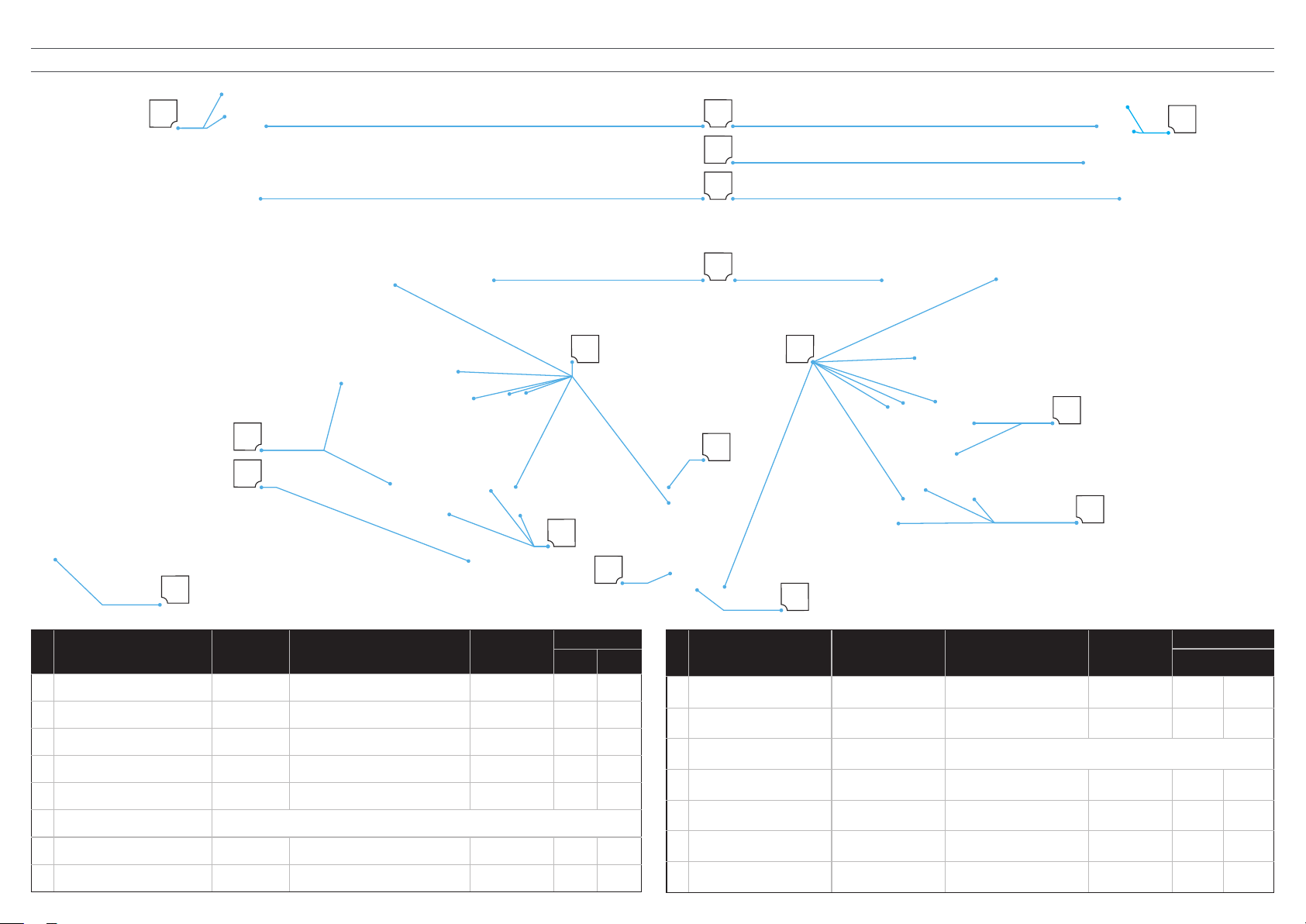

7. CABLING DIAGRAMS ...................................................... 55

7.1. CABLE ROUTING .....................................................................................................................55

7.1.1. CARBON FRAME — NON AXS ..................................................................................................................................................................................................55

7.1.2. CARBON FRAME — AXS EQUIPPED ........................................................................................................................................................................................56

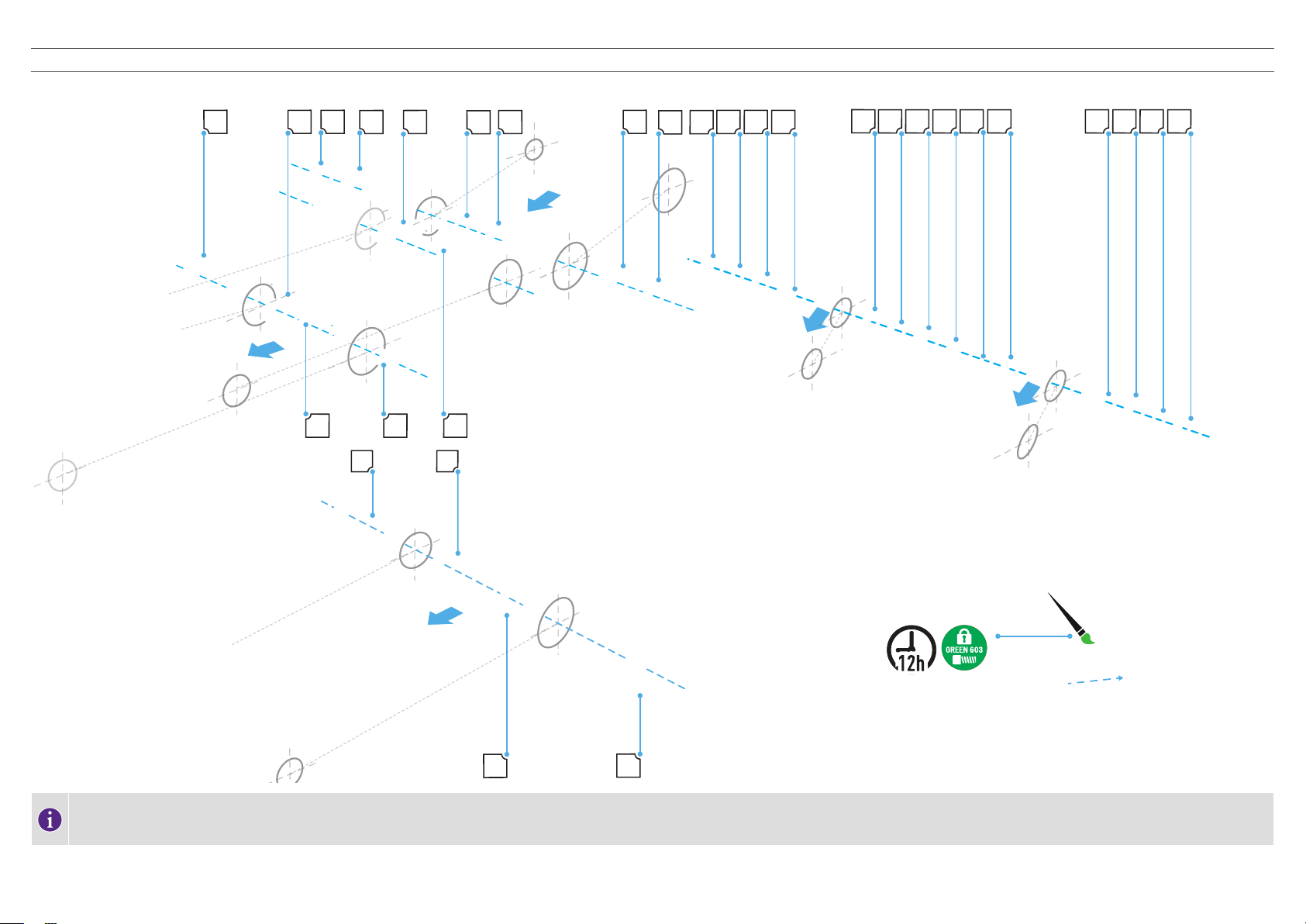

7.2. ELECTRICAL SCHEMATICS .................................................................................................... 57

7.2.1. SYSTEM SCHEMATICS — TCU ...............................................................................................................................................................................................57

7.2.2. SYSTEM SCHEMATICS — MASTERMIND TCU .....................................................................................................................................................................58

8. SERVICE PARTS ............................................................ 59

8.1. SERVICE PARTS: SHARED PARTS ..........................................................................................59

8.2. SERVICE PARTS: CARBON FRAME.........................................................................................60

INDEX

1. INTRODUCTION................................................................3

1.1. IMPORTANT............................................................................................................................... 3

1.2. WARNING SYMBOLS ................................................................................................................3

1.3. ASSEMBLY SETUP AND PREPARATION ....................................................................................4

2. FRAME GEOMETRY ..........................................................5

2.1. FRAME AS SOLD ......................................................................................................................5

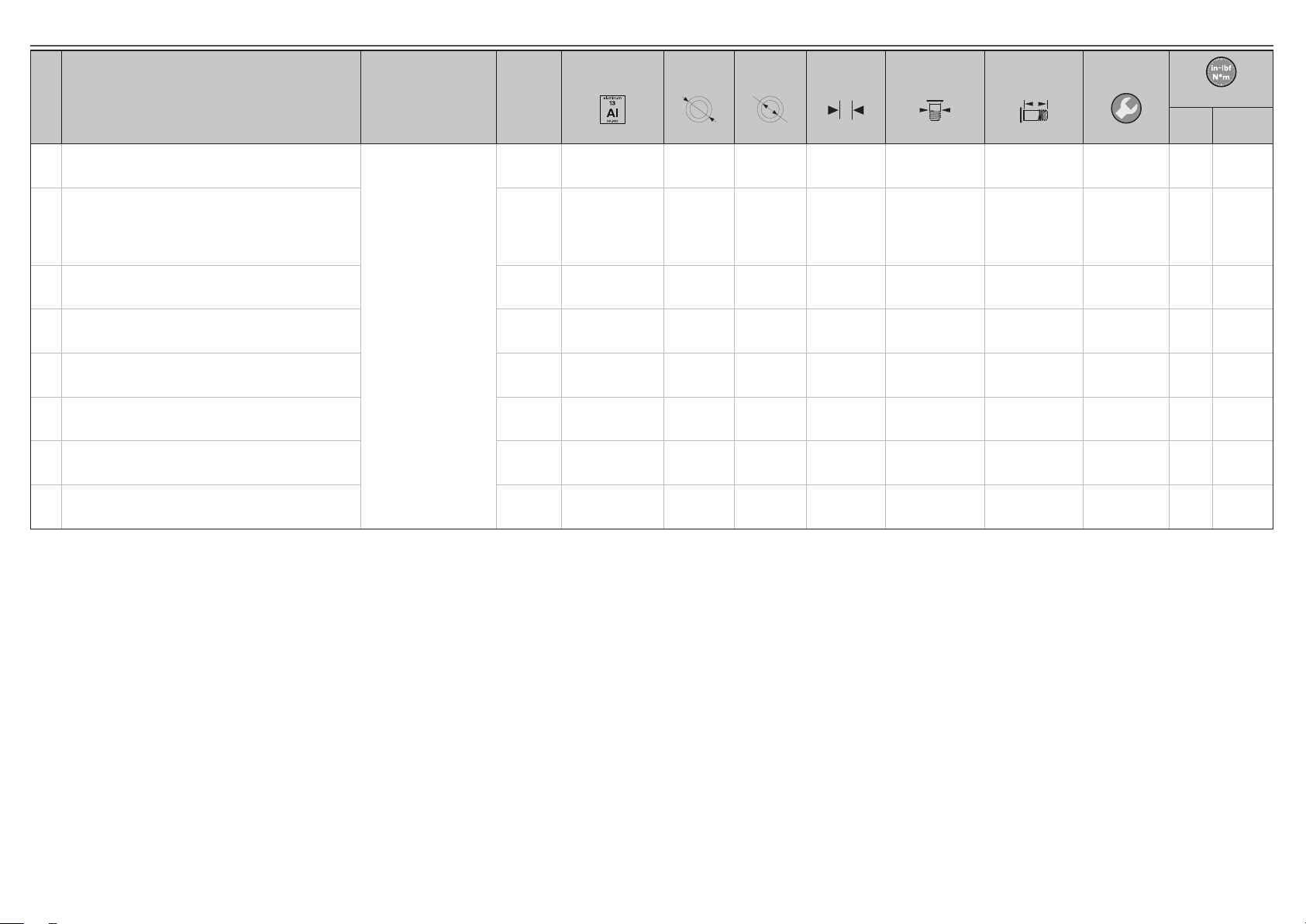

3. TORQUE SPECIFICATIONS .................................................6

3.1. QUICK REFERENCE .................................................................................................................. 6

4. PIVOT BEARINGS AND SPACERS ......................................... 7

4.1. PIVOT BEARINGS AND SPACERS — EXPLODED VIEW ................................................................ 7

4.2. PIVOT BEARINGS AND SPACERS — SPECIFICATIONS ..............................................................8

5. PIVOT BOLTS ..................................................................9

5.1. PIVOT BOLTS — EXPLODED VIEW..............................................................................................9

5.2. PIVOT BOLTS — SPECIFICATIONS............................................................................................10

6. ASSEMBLY PROCESS ....................................................... 11

6.1. REAR TRIANGLE ASSEMBLY ................................................................................................... 11

6.1.1. SUSPENSION LINK BEARINGS ............................................................................................................................................................................................... 11

6.1.2. LINK AT SEAT TUBE ...................................................................................................................................................................................................................12

6.1.3. LINK AT SHOCK EXTENSION ....................................................................................................................................................................................................13

6.1.4. CHAINSTAY BEARINGS .............................................................................................................................................................................................................14

6.1.5. MAIN PIVOT ................................................................................................................................................................................................................................15

6.1.6. DOWN TUBE CHANNEL PLUG ................................................................................................................................................................................................ 16

6.1.7. HORST PIVOT — BEARINGS AND SPEED SENSOR ...............................................................................................................................................................17

6.1.8. LINK AT SEATSTAY PIVOT .........................................................................................................................................................................................................18

6.1.9. HORST PIVOT ............................................................................................................................................................................................................................ 19

6.1.10. MUD FLAP ............................................................................................................................................................................................................................... 20

6.1.11. DERAILLEUR HANGER .............................................................................................................................................................................................................21

6.1.12. DERAILLEUR ASSEMBLY .......................................................................................................................................................................................................22

6.1.13. REAR BRAKE CALIPER ...........................................................................................................................................................................................................23

6.2. REAR CABLES ......................................................................................................................24

6.2.1. REAR BRAKE HOSE .................................................................................................................................................................................................................24

6.2.2. DERAILLEUR CABLE ...............................................................................................................................................................................................................25

6.2.3. NON-DRIVE SIDE ICR PORT ...................................................................................................................................................................................................26

6.2.4. DROPPER CABLE ....................................................................................................................................................................................................................27

6.3. MOTOR AND BATTERY ASSEMBLY ........................................................................................28

6.3.1. MAIN HARNESS ........................................................................................................................................................................................................................28

6.3.2. DRIVE SIDE ICR PORT .............................................................................................................................................................................................................29

6.3.3. BATTERY .................................................................................................................................................................................................................................. 30

6.3.4. MOTOR PREPARATION ............................................................................................................................................................................................................31

6.3.5. MOTOR: STEP 1 ........................................................................................................................................................................................................................32

6.3.6. MOTOR: STEP 2 .......................................................................................................................................................................................................................33

6.3.7. MOTOR: STEP 3.........................................................................................................................................................................................................................34

6.3.8. ROCK GUARD ...........................................................................................................................................................................................................................35

6.3.9. TCU ASSEMBLY AND SYSTEM POWER UP..........................................................................................................................................................................36

6.3.10. MASTERMIND TCU ASSEMBLY AND SYSTEM POWER UP...............................................................................................................................................37

6.3.11. REAR SHOCK: CARBON SHOCK EXTENSION .....................................................................................................................................................................38

6.3.12. REAR SHOCK : ALLOY SHOCK EXTENSION ......................................................................................................................................................................39

6.3.13. SUSPENSION BOLTS............................................................................................................................................................................................................. 40

6.4. DRIVETRAIN ASSEMBLY ........................................................................................................41

6.4.1. REAR WHEEL ............................................................................................................................................................................................................................ 41

6.4.2. CHAIN GUIDE ............................................................................................................................................................................................................................42

6.4.3. SPIDER AND CHAINRING........................................................................................................................................................................................................43

6.4.4. CHAIN GUIDE ADJUSTMENT ................................................................................................................................................................................................. 44

6.5. FRONT END ..........................................................................................................................45

6.5.1. HEADSET....................................................................................................................................................................................................................................45

6.5.2. HEADSET CUPS ADJUSTMENT .............................................................................................................................................................................................46

6.5.3. FORK STEERER TUBE ............................................................................................................................................................................................................47