Kidde Fire Systems

400 Main Street

Ashland, MA 01721

Ph: 508.881.2000

Fax: 508.881.8920

www.kiddefiresystems.com

KIDDE is a registered trademarks of Kidde-Fenwal, Inc. or its parents, subsidiaries or affiliates.

3M and Novec are trademarks of the 3M Company.

This literature is provided for informational purposes only. KIDDE-FENWAL, INC. believes this data to be accurate, but it is published and presented without any guarantee

or warranty whatsoever. KIDDE-FENWAL, INC. assumes no responsibility for the product's suitability for a particular application. The fire suppression system design,

installation, maintenance, service and troubleshooting must be performed by trained, authorized Kidde Fire Systems distributors for the product to work correctly.

If you need more information on this product, or if you have a particular problem or question, contact:

KIDDE-FENWAL, INC., Ashland, MA 01721 USA, Telephone: (508) 881-2000.

K-45-9144 Rev AB

©2018 Kidde-Fenwal, Inc.

2

EXPORT INFORMATION (USA)

Jurisdiction: EAR

Classification: EAR99

This document contains technical data subject to the EAR.

MAINTENANCE

According to NFPA standards the following inspection

and/or maintenance procedure must be scheduled as

listed below and performed upon the occurrence of any

event which might affect the reliability of the system.

QUARTERLY INSPECTION

1. Check the pressure gauges of each agent storage

container. If the pressure gauge indicates a loss in

pressure of 10% or more, then it shall be recharged

or replaced. Pressure varies with temperature, and

this must be taken into account when checking the

pressure gauge.

2. Check all components, including supporting hard-

ware, and tighten, repair or replace as required.

3. Replace any component if at all in doubt of its ability

to perform properly.

SEMI-ANNUAL INSPECTION

Qualified personnel are to determine the amount of agent

in all containers. The optional liquid level indicator may

be used to measure agent supply and compare it to the

original net weight which is marked on the container

label. If the measured net weight is less than 95% of the

original charged weight the container should be

recharged or replaced.

Inspect all piping, fittings and nozzles for looseness, dirt

or other damage. All outlet piping must be clean and free

of dirt, chips, fillings and other foreign material that may

cause the system to become inoperative or ineffective at

the time of discharge.

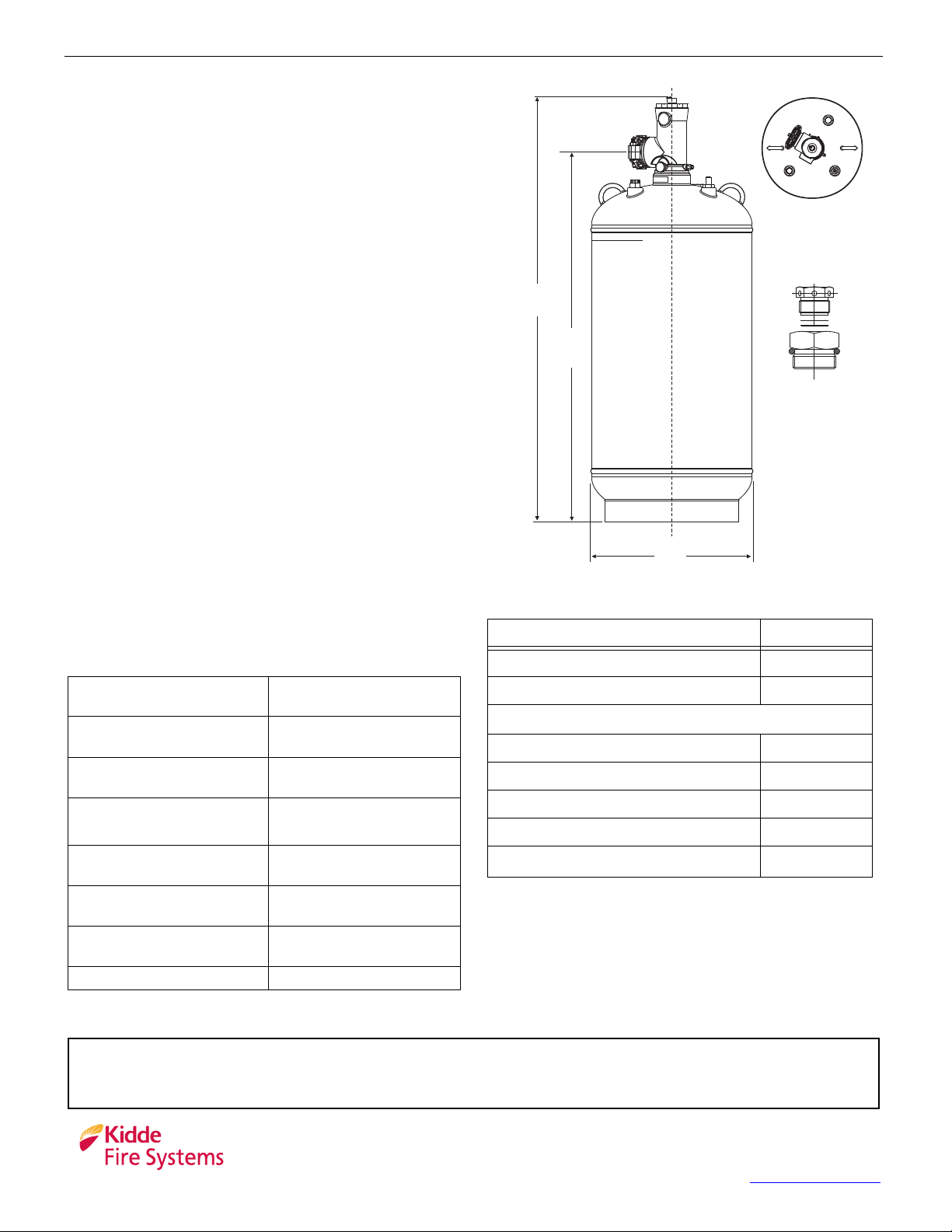

SPECIFICATIONS

DIMENSIONS

ORDERING INFORMATION

Fill Range 455-910 lb.

(206.4-412.8 kg)

Height 70 in.

(1789 mm)

Diameter 24 in.

(610 mm)

Internal Volume 13 ft.3

(0.368 m3)

Empty Weight 505 lb.

(229 kg)

Temperature Range 0°F to 130°F

(-18°C to 54°C)

Safety Relief Burst Range 800 to 975 PSIG

(5.5 to 6.7 Mpa)

Construction Specification DOT 4BW-500

Description Part Number

900 lb. Cylinder with Liquid Level Indicator 45-200901-001

900 lb. Cylinder without Liquid Level Indicator 45-200900-001

Accessories

3-inch stainless steel flexible hose 06-118225-001

3-inch swing check valve 06-118058-001

Cylinder bracket 06-236125-001

Cylinder cradle 06-118300-001

Cylinder supervisory pressure switch 06-118262-001*

*For cylinder valves manufactured prior to May 1, 2013 use super-

visory pressure switch P/N: 06-118263-001.

VALVE ORIENTATION

PLAN VIEW

SAFETY BURST

DISC ASSEMBLY

24 in.

(610 mm)

70 in.

(1789 mm)

62 in.

(1566 mm)