Table of Contents

3-1-10 Page 3

Form No. Pages

IV. DESIGN 4-1 – 4-14

Step No. 1 – Determine the Floor Area and Gross Volume of the Room 4-1

Step No. 2 – Determine the Minimum Number of Atomizers Required 4-1

Step No. 3 – Verify Atomizer Array Placement 4-2

Step No. 4 – Determine Location of System Supply 4-2

Step No. 5 – Sketch Pipe Routing 4-2

Water Calculation Procedure 4-3 – 4-4

Piping and Fitting Notes 4-3

Step No. 6 – Determine Total Atomizer Pressure (TAP) 4-5 – 4-7

Step No. 7 – Select Appropriate Atomizer Assembly 4-8

Step No. 8 – Determine Volume of Water Supply Required 4-8

Step No.9 – Determine Number of Water Tanks Required 4-9

Step No. 10 – Determine Atomizer Pressure Loss 4-11 – 4-13

Step No. 11 – Determine Regulator Flowing Set Pressure 4-13

Step No.12 – Select the Appropriate Regulator 4-13

Step No. 13 – Determine the Number of Nitrogen Cylinders 4-13

Step No. 14 – Complete Layout of the System 4-13

Step No.15 – Create a Bill of Materials 4-13

Step No.16 – Create Installation Drawings 4-14

V.INSTALLATION 5-1 – 5-14

General Information 5-1

Nitrogen Cylinder Installation 5-1 – 5-4

Bracketing Without Uprights – Double Row 5-2

Bracketing With Uprights – Back-To-Back 5-2

Bracket With Uprights – Double Row Back-To-Back 5-3

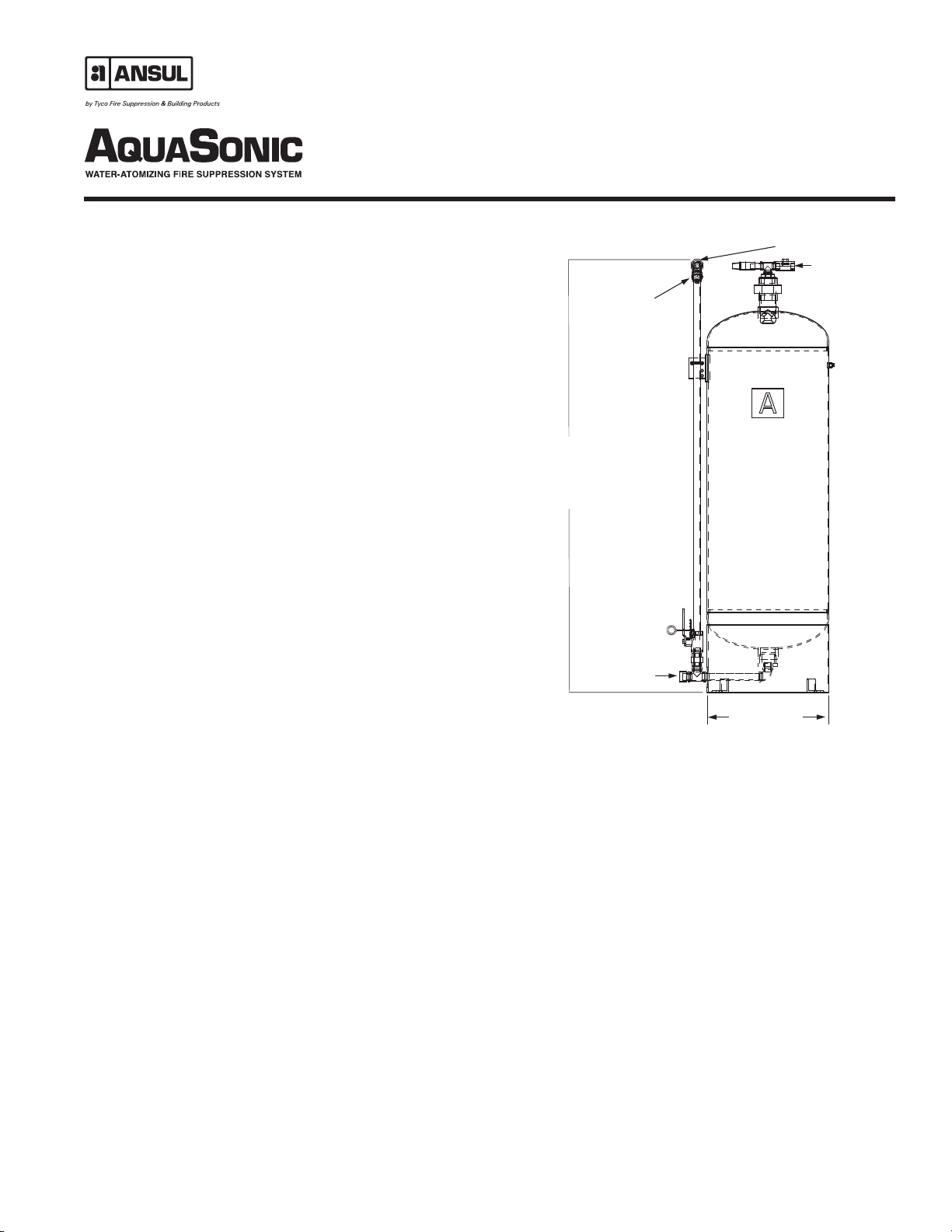

Water Tank Installation 5-4

Atomizer Installation 5-4

Releasing Devices 5-5

General Piping Requirements 5-5

Pipe Assembly 5-5

Hanger Requirements 5-5

Actuation Piping 5-5 – 5-6

Actuation Pipe,Tubing, and Fitting Requirements 5-5

Installation of Actuation Piping 5-6

High Pressure Manifold and Regulator 5-6 – 5-7

High Pressure Pipe and Fitting Requirements 5-6

Installation of High Pressure Manifold and Regulators 5-6 – 5-7

Discharge Piping (After Regulators) 5-7 – 5-10

System Piping, Tubing, and Fitting Requirements 5-7

Installation of Water Tank Pressurization Piping 5-8

Installation of Water Discharge Piping 5-8

Installation of Nitrogen Discharge Piping 5-9

Setting the Regulator 5-9 – 5-10