2HV-0104January2021

Table of Contents

Section 1: Safety .........................................................................3

Section 2: Product Specifications...............................................4

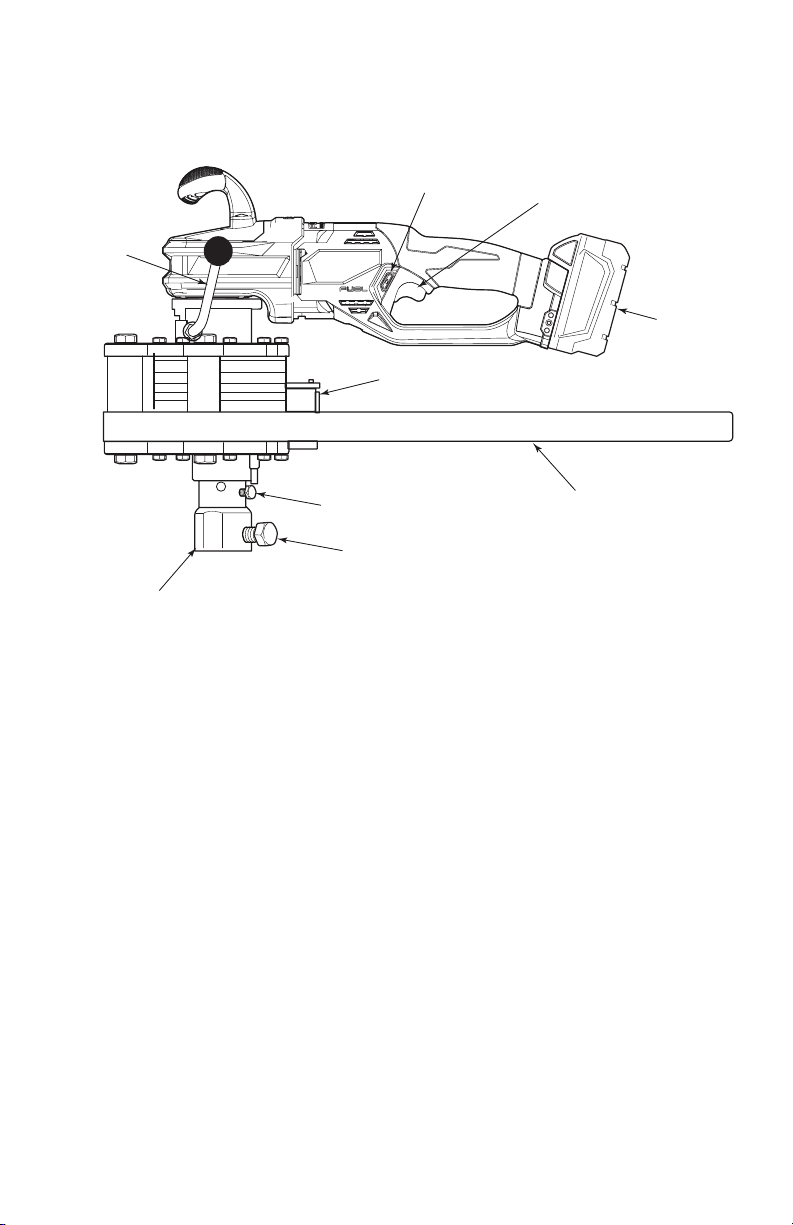

Section 3: Components................................................................5

Section 4: Hydrant Buddy Controls.............................................6

Section 5: Operation ....................................................................7

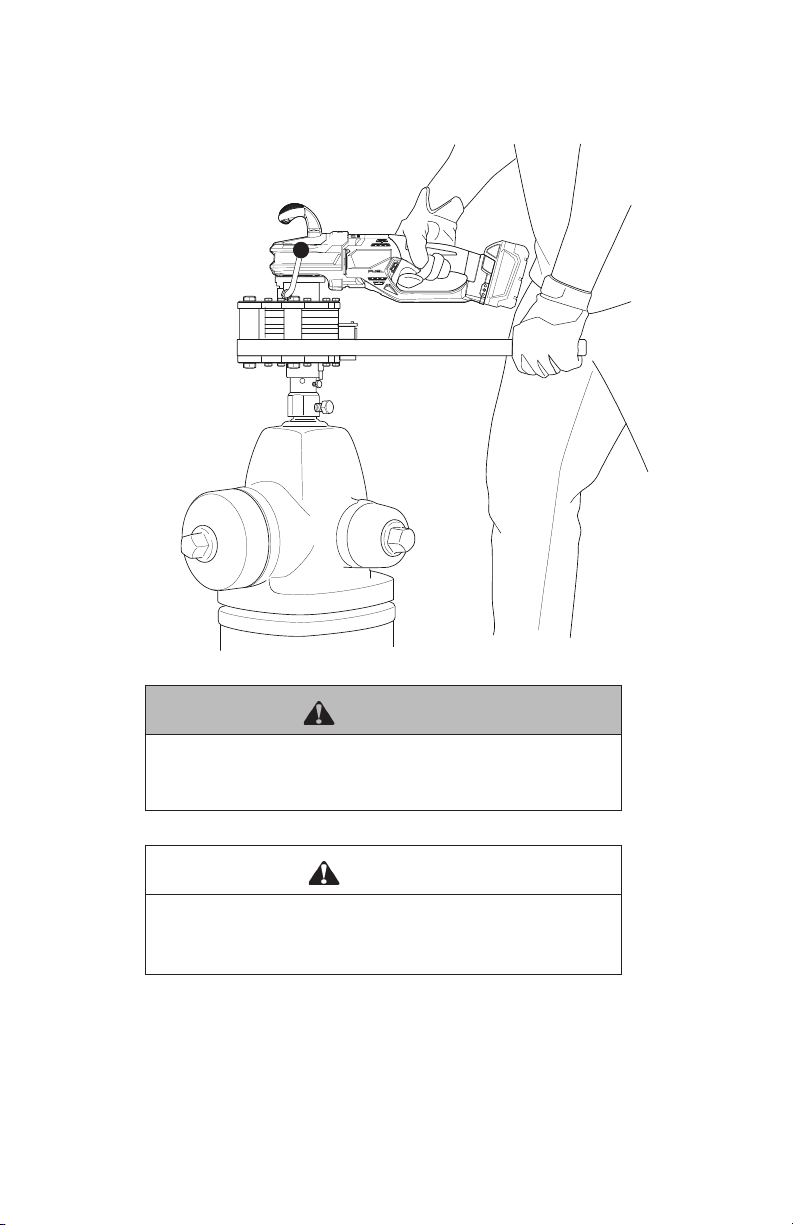

Opening Hydrant Valves.............................................................8

Closing Hydrant Valves...............................................................9

Section 6: Other Attachments ...................................................10

Attachment Options .................................................................10

Gate Valve Key.........................................................................11

Section 7: Maintenance.............................................................14

Greasing the Output Drive........................................................14

Greasing the Output Drive Housing ..........................................15

Section 8: Reference Tables......................................................16

Gate Valve Tables.....................................................................16

Section 9: Troubleshooting........................................................18