PAGE 5 OF 6 1111 IS-17880

ENVIRONMENTAL CONSIDERATIONS

INSPECTION CRITERIA

Polyester is seriously degraded at temperatures

above 200° F.

Prolonged exposure to ultraviolet light adversely

affects polyester. Slings become bleached and stiff

when exposed to sunlight or arc welding.

Many chemicals have an adverse effect on polyester.

POLYESTER

Acids *

Alcohols OK

Aldehydes NO

Strong Alkalis **

Bleaching Agents OK

Dry Cleaning Solvents OK

Ethers OK

Halogenated Hydro-Carbons OK

Hydro-Carbons OK

Ketones OK

Oils Crude OK

Oils Lubricating OK

Soap & Detergents OK

Water & Seawater OK

Weak Alkalis OK

* Disintegrated by concentrated sulfuric acid.

** Degraded by strong alkalis at elevated temperatures.

CHEMICAL

OK

NO

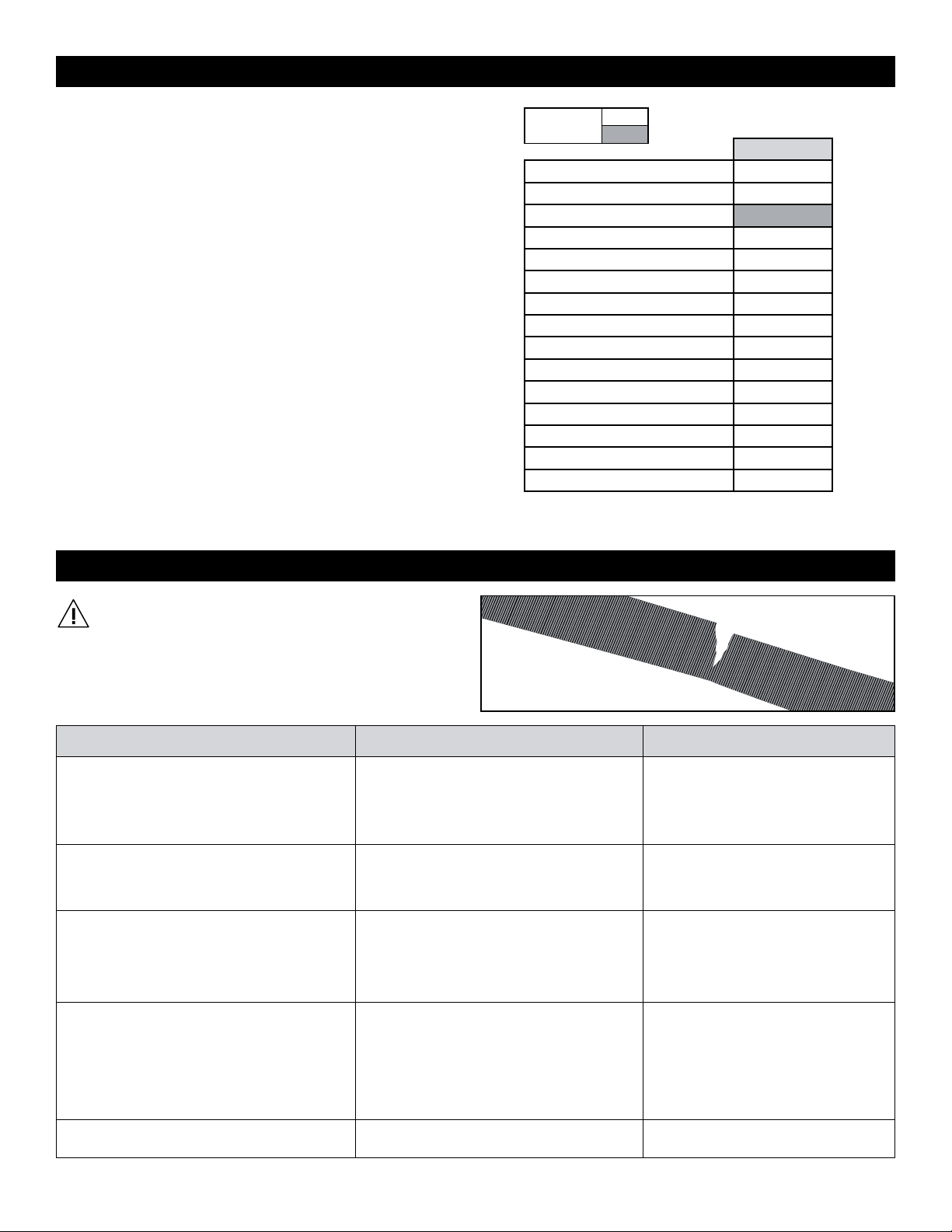

WARNING! All slings should be inspected for

damage prior to each use to assure that their strength

has not been compromised.

THE DAMAGE WHAT TO LOOK FOR TO PREVENT

Surface and Edge Cuts - It is important to realize

that all of the fibers in web slings contribute to

the strength of that sling. When there have been

a significant number of fibers broken in a web

sling, that sling should be taken out of service.

Broken fibers of equal length indicate that

the sling has been cut by an edge. Red core

warning yarns may or may not be visible with

cuts and are not required to show before

removing slings from service.

Use wear pads between the sling and

all edges that come in contact with the

sling.

Holes/Snags/Pulls Punctures or areas where fibers stand out from

the rest of the sling surface.

Avoid sling contact with protrusions,

both during lifts and while transporting

or storing.

Abrasion Areas of the sling that look and feel fuzzy

indicate that the fibers have been broken

by being subject to contact and movement

against a rough surface. Affected areas are

usually stained.

Never drag slings along the ground.

Never pull slings from under loads that

are resting on the sling. Use wear pads

between slings and rough surface

loads.

Heat/Chemical Melted or charred fibers anywhere along

the sling. Heat and chemical damage can

look similar and they both have the effect of

damaging sling fibers and compromising the

slings strength. Look for discoloration and/

or fibers that have been fused together and

often feel hard or crunchy.

Never use polyester slings where they

can been exposed to temperatures

in excess of 200° F. Never use nylon

or polyester slings in or around

chemicals without confirming that the

sling material is compatible with the

chemicals being used.