SKU 91831 For technical questions please call 1-800-444-3353 PAGE 5

3. Use clean, dry, regulated, compressed air at 90 PSI. Do not exceed the

recommended 90 PSI. Never use oxygen, carbon dioxide, combustible gases, or

any other bottled gas as a power source for this tool.

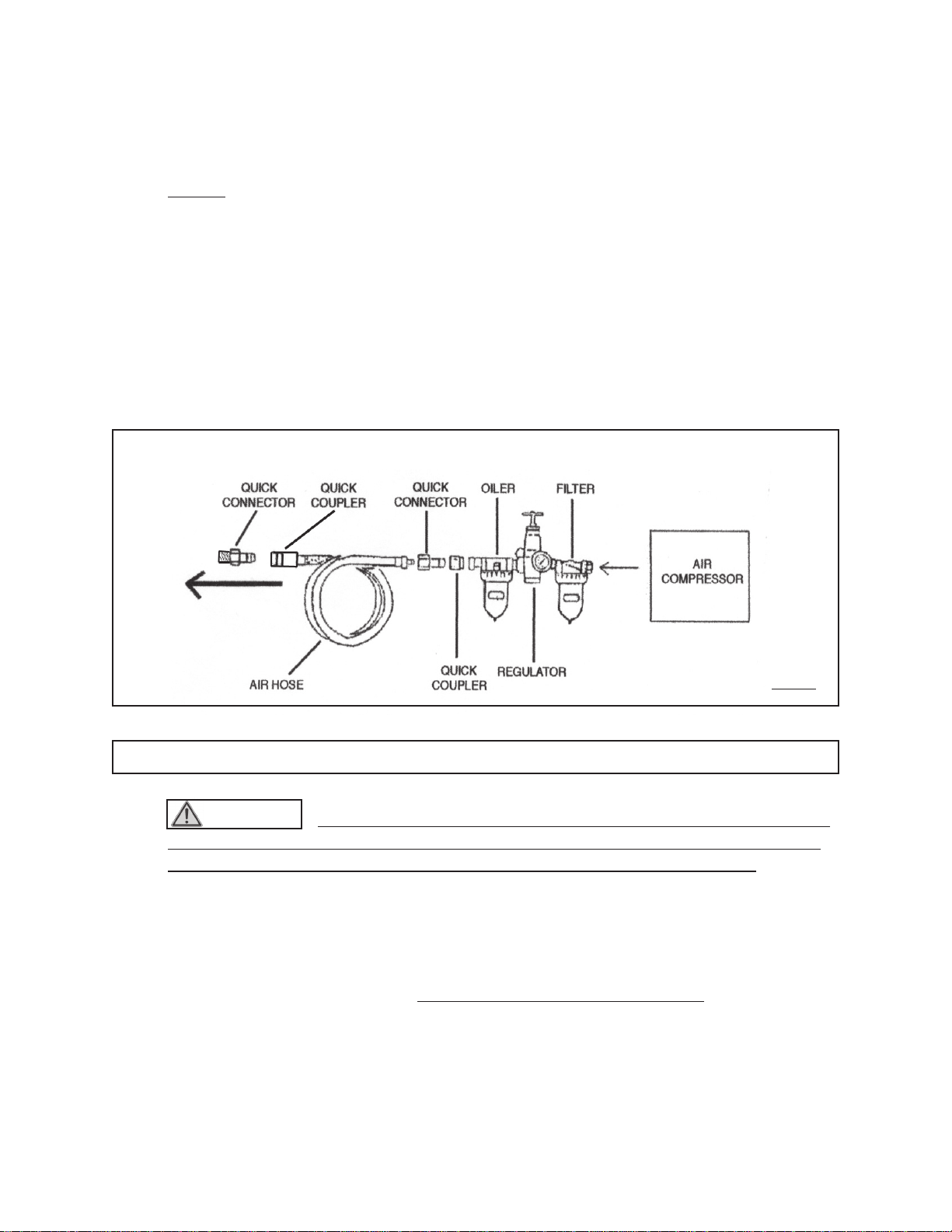

4. When connecting to the air supply: Prior to each use, if an automatic oiler is

not

used, add two drops of air tool oil (not included) into the Air Inlet (47) fitting of

the Impact Wrench.

5. Always disconnect the Impact Wrench from its compressed air supply

source, and squeeze theTrigger (43) to release all compressed air in the

tool after use and before performing any maintenance or services.

6. Industrial applications must follow OSHA requirements.

7. WARNING! The warnings, precautions, and instructions discussed in this

manual cannot cover all possible conditions and situations that may occur. The

operator must understand that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

ASSEMBLY AND OPERATING INSTRUCTIONS

NOTE: For additional references to the parts listed in the following pages, refer to the

Assembly Diagram on page 9.

To Attach A Quick Connector:

1. WARNING! Prior to performing any assembly and/or adjustment

procedures, make sure the air supply hose (not included) is disconnected

from the Impact Wrench.

2. Prior to use, the Impact Wrench requires the attachment of a

Quick Connector

(not included) into its Air Inlet (47). To do so, wrap approximately 3” of pipe

thread sealer tape (not included) around the male threads of a Quick Connector.

Then, firmly tighten the Quick Connector into the Air Inlet.

(See Figure A, next page.)

To Operate The Impact Wrench:

1. WARNING! always wear ANSI approved safety glasses, a full face

shield, and hearing protection when operating the Impact Wrench.