IMTX200H-03

www.ueonline.com

CP04112000

UNITED ELECTRIC

CONTROLS

180 Dexter Avenue, P.O. Box 9143

Watertown, MA 02471-9143 USA

Telephone: 617 926-1000 Fax: 617 926-2568

http://www.ueonline.com

RECOMMENDED PRACTICES AND WARNINGS

United Electric Controls Company recommends careful consideration of the fol-

lowing factors when specifying and installing UE pressure and temperature units.

Before installing a unit, the Installation and Maintenance instructions provided

with unit must be read and understood.

• To avoid damaging unit, proof pressure and maximum temperature limits stated

in literature and on nameplates must never be exceeded, even by surges in the

system. Operation of the unit up to maximum pressure or temperature is accept-

able on a limited basis (e.g., start-up, testing) but continuous operation must be

restricted to the designated adjustable range. Excessive cycling at maximum

pressure or temperature limits could reduce sensor life.

• A back-up unit is necessary for applications where damage to a primary unit

could endanger life, limb or property. A high or low limit switch is necessary

for applications where a dangerous runaway condition could result.

• The adjustable range must be selected so that incorrect, inadvertent or mali-

cious setting at any range point cannot result in an unsafe system condition.

• Install unit where shock, vibration and ambient temperature fluctuations will

not damage unit or affect operation. When applicable, orient unit so that

moisture does not enter the enclosure via the electrical connection. When

appropriate, this entry point should be sealed to prevent moisture entry.

• Unit must not be altered or modified after shipment. Consult UE if modifica-

tion is necessary.

• Monitor operation to observe warning signs of possible damage to unit, such

as drift in set point or faulty display. Check unit immediately.

• Preventative maintenance and periodic testing is necessary for critical appli-

cations where damage could endanger property or personnel.

• Electrical ratings stated in literature and on nameplate must not be exceed-

ed. Overload on a switch can cause damage, even on the first cycle. Wire

unit according to local and national electrical codes, using wire size recom-

mended in installation sheet.

• Do not mount unit in ambient temp. exceeding published limits.

LIMITED WARRANTY

Seller warrants that the product hereby purchased is, upon delivery, free from

defects in material and workmanship and that any such product which is found to

be defective in such workmanship or material will be repaired or replaced by Seller

(Ex-works, Factory, Watertown, Massachusetts. INCOTERMS); provided, however,

that this warranty applies only to equipment found to be so defective within a

period of 36 months from the date of manufacture by the Seller. Seller shall not

be obligated under this warranty for alleged defects which examination discloses

are due to tampering, misuse, neglect, improper storage, and in any case where

products are disassembled by anyone other than authorized Seller’s representatives.

EXCEPT FOR THE LIMITED WARRANTY OF REPAIR AND REPLACEMENT STATED

ABOVE, SELLER DISCLAIMS ALL WARRANTIES WHATSOEVER WITH RESPECT TO

THE PRODUCT, INCLUDING ALL IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR ANY PARTICULAR PURPOSE.

LIMITATION OF SELLER’S LIABILITY

SELLER’S LIABILITY TO BUYER FOR ANY LOSS OR CLAIM, INCLUDING LIABILITY

INCURRED IN CONNECTION WITH (I) BREACH OF ANY WARRANTY WHATSO-

EVER, EXPRESSED OR IMPLIED, (II) A BREACH OF CONTRACT, (III) A NEGLIGENT

ACT OR ACTS (OR NEGLIGENT FAILURE TO ACT) COMMITTED BY SELLER, OR (IV)

AN ACT FOR WHICH STRICT LIABILITY WILL BE INPUTTED TO SELLER, IS LIM-

ITED TO THE “LIMITED WARRANTY” OF REPAIR AND/OR REPLACEMENT AS SO

STATED IN OUR WARRANTY OF PRODUCT. IN NO EVENT SHALL THE SELLER BE

LIABLE FOR ANY SPECIAL, INDIRECT, CONSEQUENTIAL OR OTHER DAMAGES OF

A LIKE GENERAL NATURE, INCLUDING, WITHOUT LIMITATION, LOSS OF PROFITS

OR PRODUCTION, OR LOSS OR EXPENSES OF ANY NATURE INCURRED BY THE

BUYER OR ANY THIRD PARTY.

UE specifications subject to change without notice.

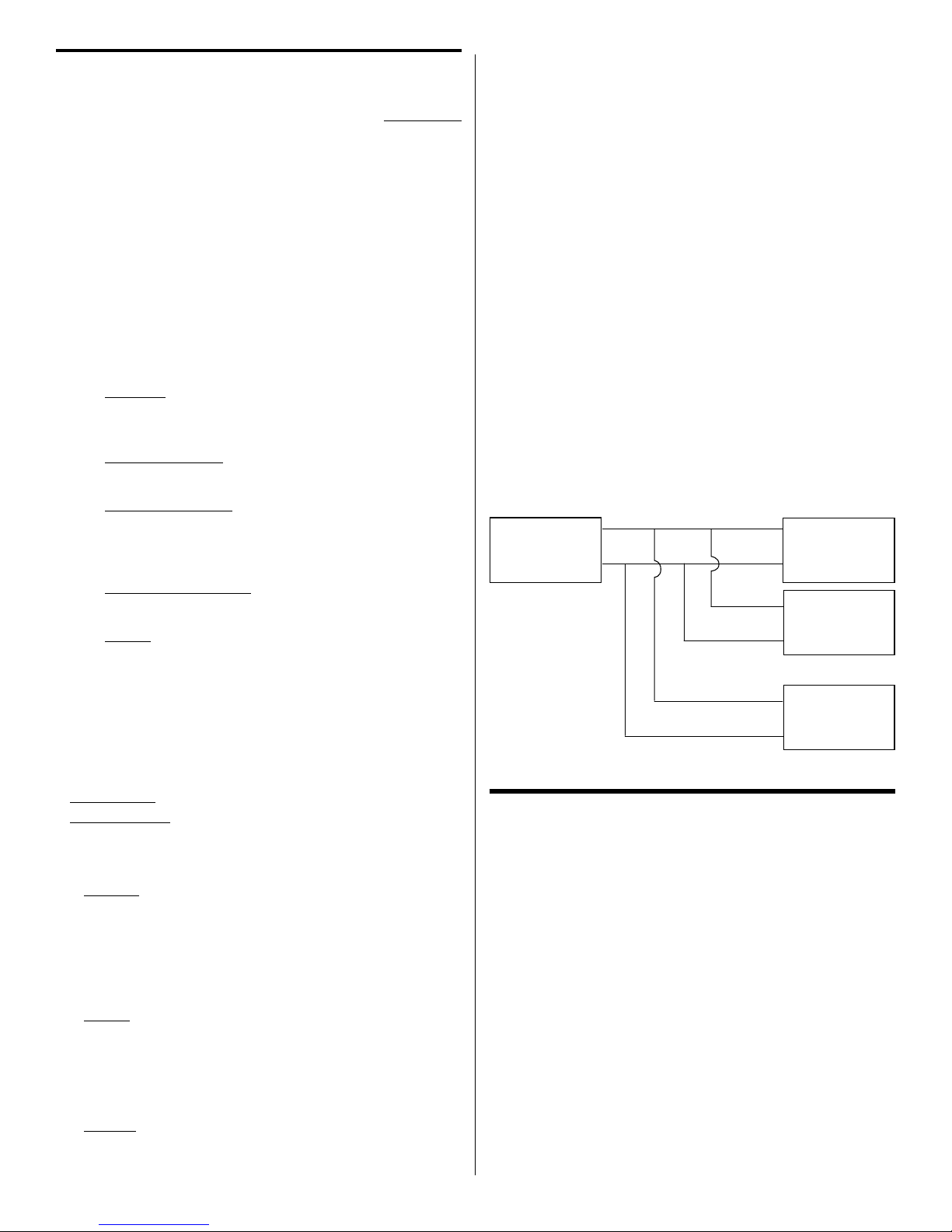

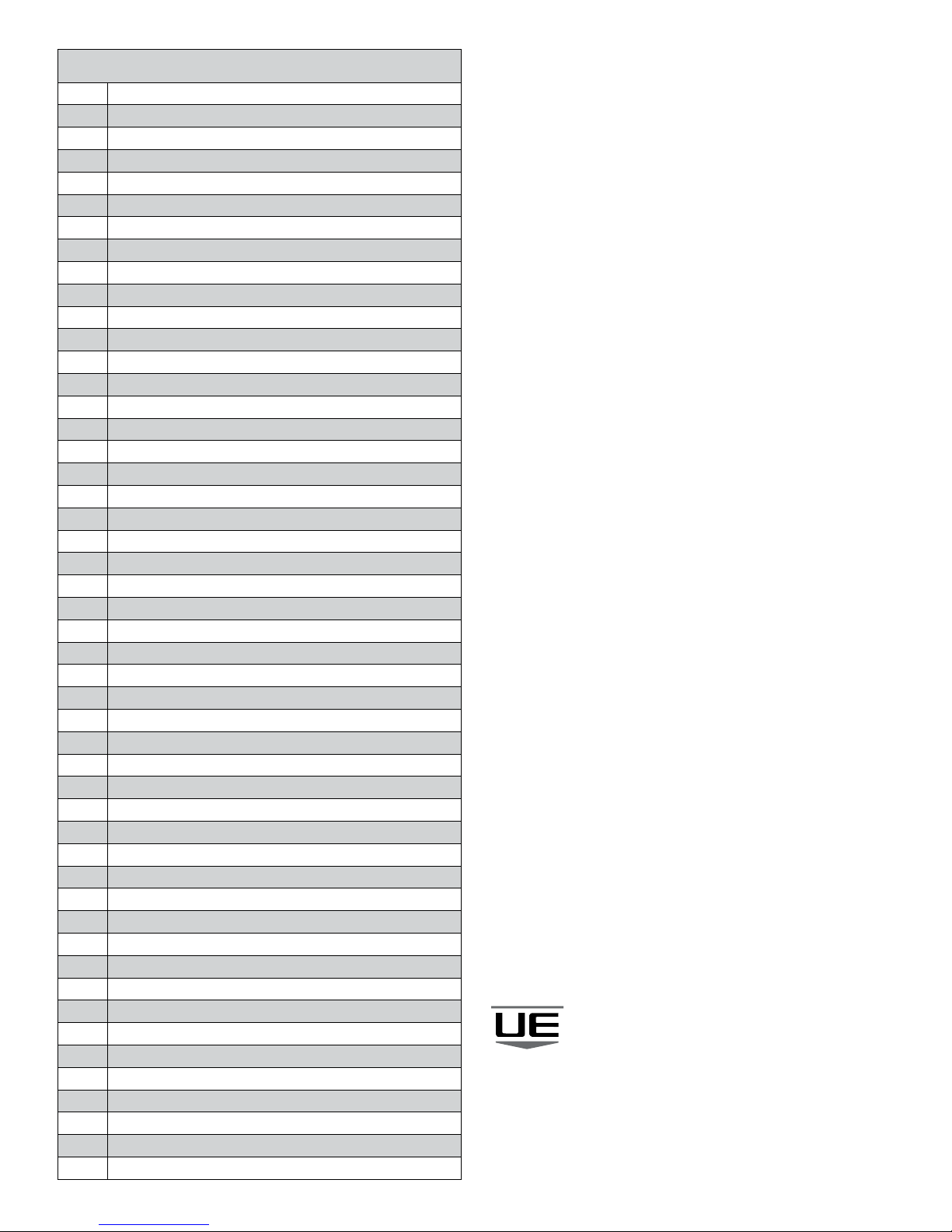

Response Codes

Code Descripon

0Success

2Invalid Selecon

3Passed Parameter Too Large

4 Passed Parameter Too Small

5 Too Few Data Bytes Received

6Error (Device Specic Command Error)

7In Write Protect Mode

8 Mul-Denion Warning

Update Failure

Set to Nearest Possible Value

All but running delayed responses ushed

9Mul-Denion Error

Lower Range Value too High

Applied Process too High

Not in Proper Current Mode

10 Mul-Denion Error

Lower Range Value too Low

Applied Process too Low

Invalid Local Panel Code

11 Mul-Denion Error

Upper Range Value too High

In Mul-Drop Mode

Invalid Device Variable Code

Trim Error Excess Correcon Aempted

Cannot Lock Panel

12 Mul-Denion Error

Upper Range Value too Low

Invalid Units Code

13 Mul-Denion Error

Both Upper and Lower Range Values Out of Limits

14 Mul-Denion Error

Span too Small

New Lower Range Value Pushed Upper Range Value Over Limit

16 Mul-Denion Error

Invalid Analog Channel Number

Access Restricted

17 Invalid Device Variable Index

18 Invalid Units Code

19 Device Variable Index Not Allowed

20 Invalid Extended Command Number

28 Invalid Range Units Code

30 Command Response Truncated

32 Busy

33 Delayed Response Iniated

34 Delayed Response Running

35 Delayed Response Dead

36 Delayed Response Conict

64 Command Not Implemented