NOVUS AUTOMATION 1/4

TXMINI-DIN43650

– V1.0x F

1. CONFIGURATION

TxMini-DIN43650 Transmitter is a 4-20 mA 2-wires temperature

transmitter for head mount, powered by the current loop. It can be

configured using SigNow or TxConfig II software or SigNow app.

The output current is linearized according to the selected input

sensor and adjusted to the configured range.

2. SPECIFICATIONS

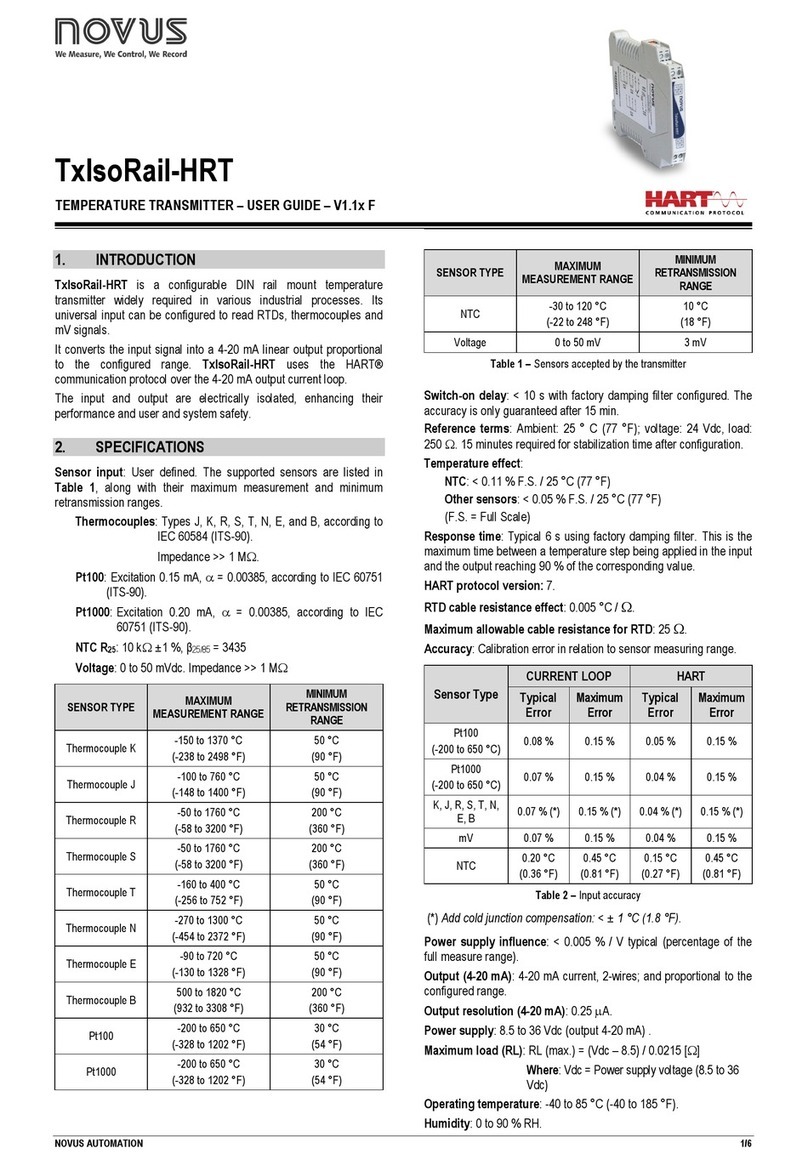

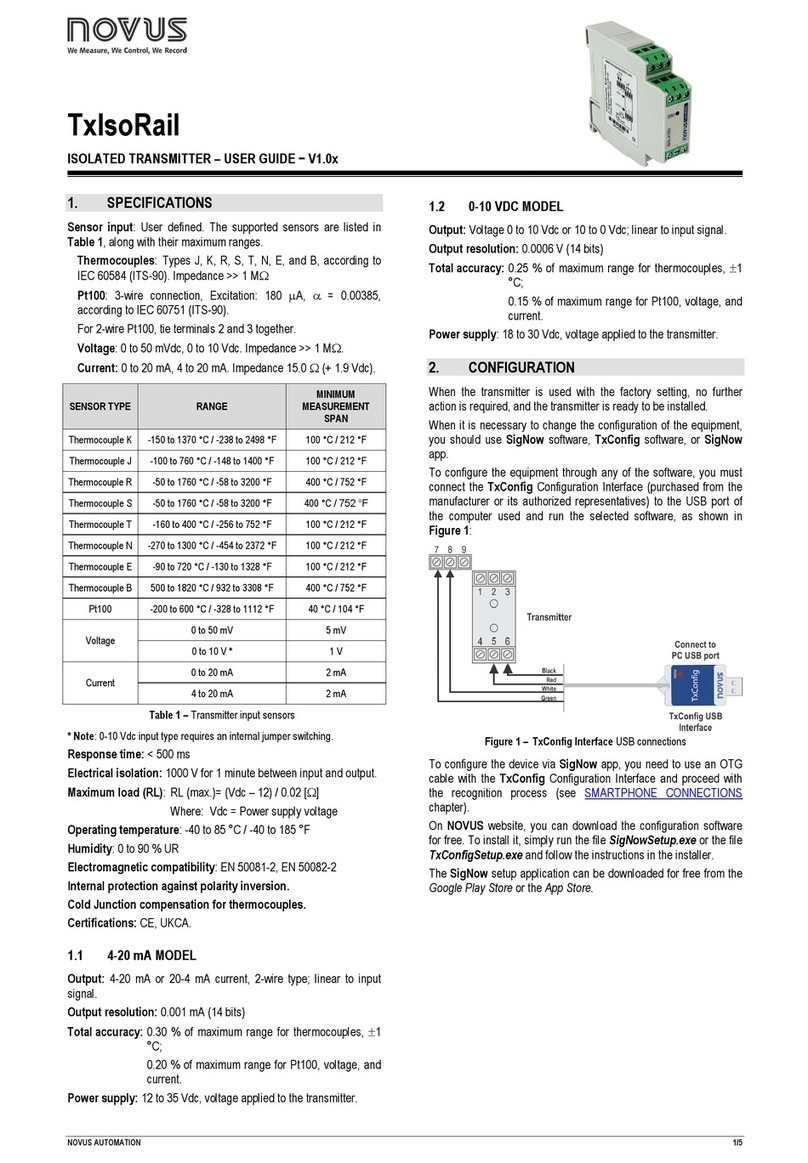

Sensor Input: User defined. The supported sensors are listed in

Table 1, along with their maximum ranges.

Pt100: 3-wire type, Excitation: 0.8 mA, α= 0.00385, according

to IEC 60751 (ITS-90).

Pt1000: 3-wire type, Excitation: 0.8 mA, α= 0.00385, according

to NBR 13773. IEC 60751 (ITS-90).

For 2-wire sensors, tie terminals 3 and 4 together.

Switch-on delay: < 2.5 s. The accuracy is only guaranteed after 15

minutes.

Calibration error:< 0.12 % (RTD).

Reference terms: Ambient: 25 °C; voltage: 24 Vdc, load: 250 Ω;

settling time: 15 minutes.

Temperature Effect: <± 0.2 % / 25 °C.

Response time: Typical 1.6 s

Maximum voltage allowed at input terminals no sensor: 3 V.

RTD current: 800 µA.

RTD cable resistance effect: 0.005 °C / Ω.

Maximum allowable cable resistance for RTD: 25 Ω.

SENSOR TYPE TYPICAL

ACCURACY

MINIMUM

ACCURACY

Pt100 / Pt1000 0.1 % 0.2 %

Table 1 –Calibration error, percentage of the full measurement range

Power supply influence: 0.006 % / V typical (percentage of the full

measure range).

Output:4-20 mA or 20-4 mA current, 2-wired; linear in relation to the

temperature measurement by the selected sensor.

Output resolution: 2 µA.

Power supply: 8 to 35 Vdc, across the transmitter.

Maximum load (RL):RL (max.) = (Vdc – 8) / 0.02 [Ω]

Where: Vdc = Power supply voltage (8-35 Vdc)

Operating temperature: -40 to 85 °C.

Humidity: 0 to 90 % RH.

Electromagnetic compatibility: EN 61326-1:2006.

No electrical isolation between input and output.

Internal protection against polarity inversion.

Cold junction compensation for thermocouples.

Thread type: M24x2.

Connection wire cross section: 0.14 a 1.5 mm² (*).

* When soldering the Pt100 wires, each wire should be inserted

no more than 1 mm into the hole.

SENSOR

TYPE

MAXIMUM

MEASUREMENT

RANGE

MEASUREMENT

RANGE

Pt100 -200 to 650 °C

(-328 to 1202 °F)

40 °C

(104 °F)

(-328 to 1202 °F)

(104 °F)

Table 2 –Sensors accepted by the transmitter

Order Codes:

-P/N: 8806050406: TxMini-DIN43650 transmitter.

-P/N: 8816021069: TxConfig-DIN43650 Interface.

3. CONFIGURATION

The factory setting of the transmitter is for Pt100 input with a range of

0 to 100 °C and output for maximum current in case of error. When

using the transmitter with this setting, no further commissioning is

required. In this case, its installation can be carried out immediately.

When it is necessary to change the configuration of the equipment,

you should use SigNow software, TxConfig II software, or SigNow

app.

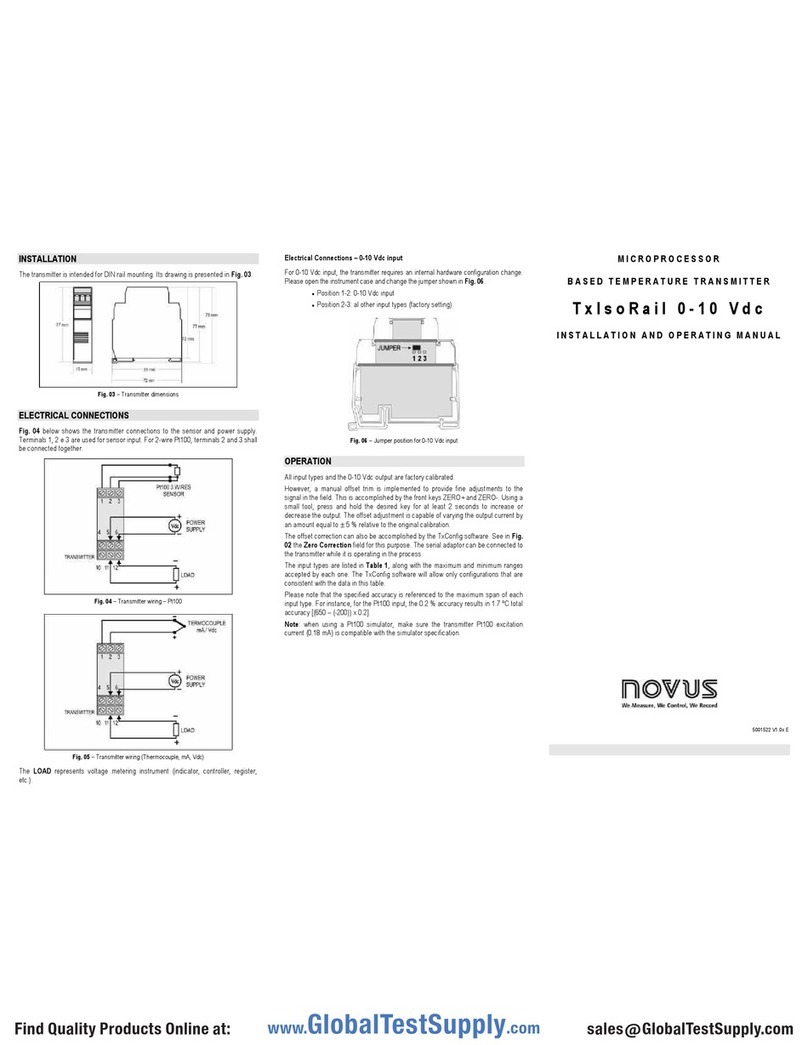

To configure the equipment through any of the software, you must

connect the TxConfig-DIN43650 Configuration Interface (purchased

from the manufacturer or its authorized representatives) to the USB

port of the computer used and run the selected software.

To configure the device via the SigNow app, you need to use an

OTG cable with the TxConfig-DIN43650 Configuration Interface and

proceed with the recognition process (see SMARTPHONE

CONNECTIONS chapter).

On NOVUS website, you can download the configuration software for

free. To install it, simply run the file SigNowSetup.exe or the file

TxConfigIISetup.exe and follow the instructions in the installer.

The SigNow setup application can be downloaded for free from the

Google Play Store or the App Store.

The communication interface TxConfig-DIN43650

is not electrically isolated from the transmitter

input.