8 Step Installation Process

1.) Prepare Opening & Tools

2.) Install Tips

3.) Mount Build-Out & Guide Rail Assembly

4.) U-Sill, L-Sill or No-Sill

5.) Install Hood Assembly

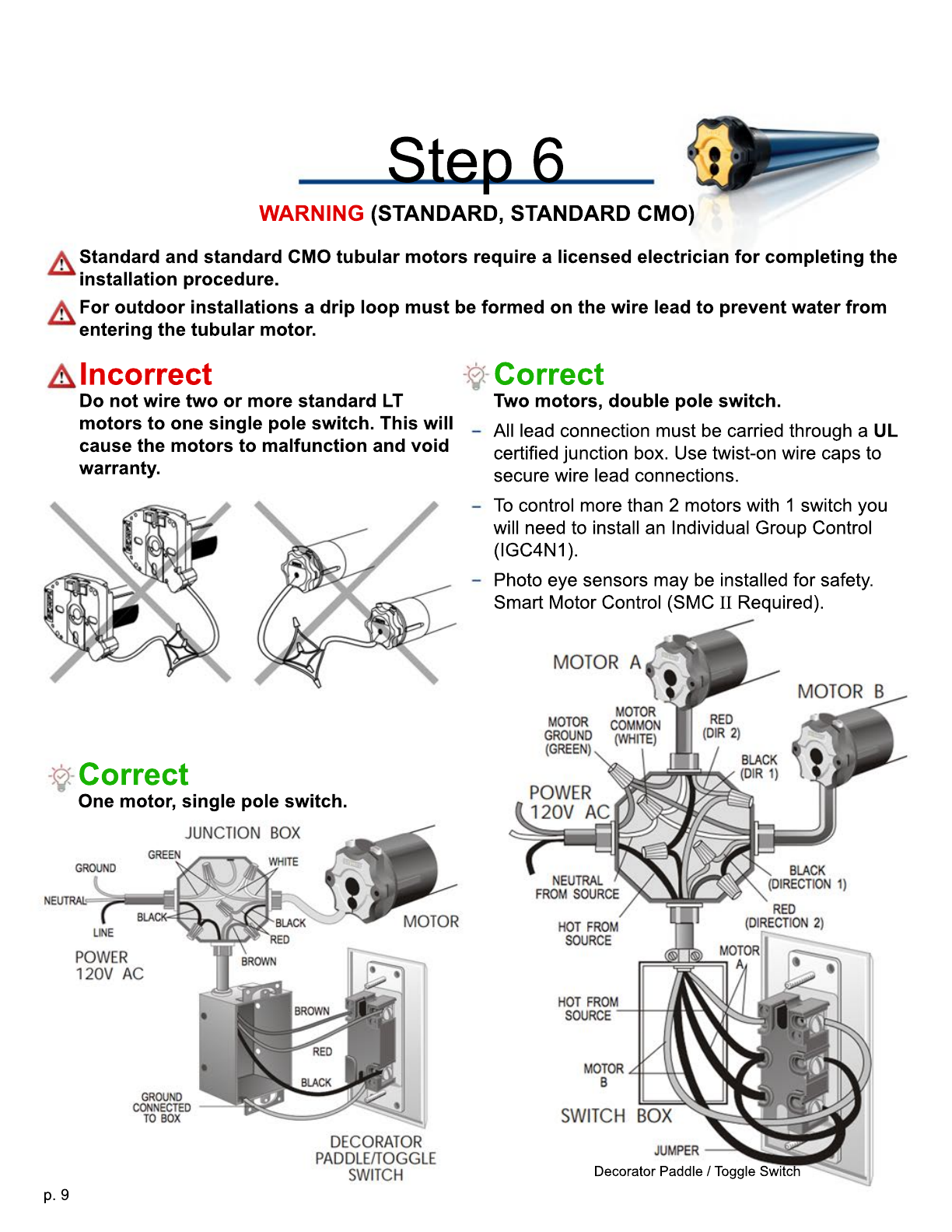

6.) Motor Wiring Diagrams (RTS, Standard, CMO)

7.) Set Limits & Install Shutter Curtain

7.) Set Limits & Install Shutter Curtain

8.) Finalize Installation & Customer Inspection (inform end user of correct operation instructions)

Before beginning please check that shop drawing dimensions match your current project

specification.

(See Opening Measuring Instructions for details)

Installation, servicing and repairs should be performed by a qualified and trained technician.

Please read through the entire guide thoroughl

Please read through the entire guide thoroughly, before proceeding with installation. Security

Shutter Ltd. will not be held responsible for any property damage or charges incurred due to

improperly installed shutter components. The following instructions will not alleviate you from

complying with local building codes and ordinances.

Disclosure

Ensure shutter installation does not interfere with federal, provincial or municipal building codes, safety Ensure shutter installation does not interfere with federal, provincial or municipal building codes, safety

or fire regulations or other restrictions or code that may apply. Security Shutter Ltd. will not be held

responsible for any injury or death from improper installation, application or use of provided shutters.

Think ahead

Important Install Tip

Risk of product damage (handle with care)

Risk of personal injury:

- Motorized operation

- Electrocution / Fire hazard

- Heavy curtain

- Sharp edges

- Pinch points

- Follow safe working practices

- Heavy lifting may cause bodily harm

- Oversized shutters require 2 or more technicians for safe installation and transportation

- Do not climb or stand underneath the shutter system

- The shutter should only be operated when in view

p. 2