BEFORE FIRST START:

During installation consult and work i.a.w. the various

installation manuals

1. Battery/Oil:

Check if the battery is fully charged and oil level is sufficient

2. Calibrate senders/sensors:

Oil temperature, EGT and CHT senders using boiling water

(100°C/ 212 F)

3. Check the Fuel System with a fuel flow test:

Disconnect return line and put into measuring jug

Run pump 1, collecting fuel

Measure fuel flow coming out of the return line +/- 120 l/h or 1

liter(quart) in 30 seconds

Repeat for pump 2

Reconnect lines and check fuel pressure (+/- 3.3bar/49psi)

(without starting the engine)

4. Check ECU warning light:

Power ON to ECU

UL check light should NOT light up

Disconnect Air box temp sensor –if working, the UL check light

comes on. Reconnect sensor –light goes off.

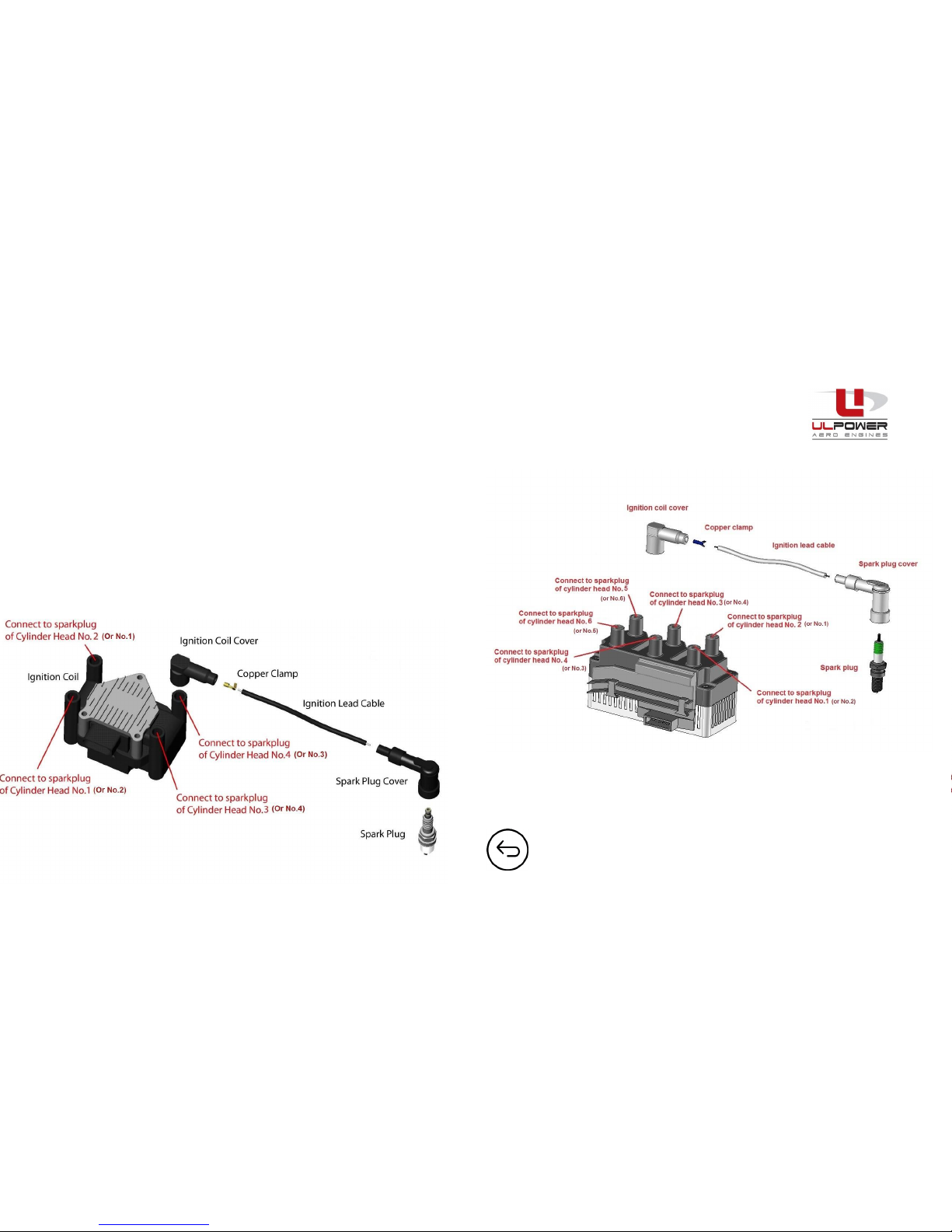

5. Start-up routine with COIL checks

•Ignition coils : set coil 1 ON / coil 2 OFF

•Throttle max 30% open (normally cracked open)

•Safety check –area clear and shout ‘clear prop’

•Master ON

•Main Fuel pump selected ON

•ECU ON

•Activate ‘Start’ - max 5 sec –wait 15 sec - repeat max. 4 times

•Engine should be running. Wait 15+ seconds, stop engine (ECU OFF)

•Repeat with coil 1 OFF / coil 2 ON. Wait 15+ seconds, stop engine

•Repeat with coil 1 ON / coil 2 ON. Leave engine running

6. Other first start checks

•If possible connect with ULread .

•Visual check for oil leaks / fuels leaks / mechanical interference

•Measure oil pressure and to check with instruments/readout

•Run the engine at +/- 1200 rpm until oil temp. is 60°C (140°F)

•Shutdown (switch ECU OFF, Fuel pump OFF, coil 1 OFF , coil 2 OFF

Master OFF

•Adjust idle if necessary

•Allow engine to cool and ‘finger test’ for oil leaks.

7. Running in: Avoid full throttle (max 2800rpm) for the first 10 hours