Vman C07 Series Technical manual

!

Technical Document

C07 Series

2021

6

Technical Documentation

1

VMAN ENGINE

01

03

03

04

05

07

08

08

08

09

09

11

12

12

13

13

14

17

17

26

27

27

0. To Users and Operators

1. Safety procedures & Diesel engine specification

1.1 Safety Procedures

1.2 Diesel engine specification

1.3 Diesel engine model, order number and series number

1.4 Assembly

2. Engine Operation instruction

2.1 Fuel

2.2 Oil

2.3 Coolant selection

2.4 Engine Start

2.5 Engine Operation

2.6 Engine Shutdown

2.7 Running-in of a new or overhauled engine

3. Engine Maintenance

3.1 Maintenance Schedule

3.2 Tasks and Methods of Engine Maintenance

4. Troubleshooting Guidelines

4.1 Troubleshooting Guidelines

4.2 Injection pump timing check and adjustment

5. Engine storage

6. Processing Requirements For Handling Quality Problems

Table of Contents

Technical Documentation

2

VMAN ENGINE

TO USERS AND OPERATORS

Thank you for purchasing a diesel product of VMAN ENGINE.

The C07 series diesel engine, is a medium-power four-valve diesel engine with six cylinders that is newly

developed by VMAN Company. Featuring strong power and low fuel consumption and with the emissions

conforming to relevant national regulations, C07 series diesel engine is a ideal supporting power for the

middle- and high-end vehicles and industrial equipment.

The diesel engine will improve continuously, so the content described herein may not be the same product

you purchase. Any questions, please inquire our sales department. Please specify the diesel engine model,

order number and produce date so that we can serve you more efficiently. The manual will also be revised

and reprinted according to the diesel engine improvement.

Users should use fuel, lubricant and coolant properly according to this manual.

Users should use and maintain diesel engines according to this manual and keep maintenance records

regularly.

This manual should be delivered to new users along with diesel engine.

If you have any question or suggestion regarding this manual, please contact us.

Thank you.

Technical Documentation

3

VMAN ENGINE

D11 (V6) SERIES DIESEL ENGINE

1. SAFETY PROCEDURES& DIESEL ENGINE SPECIFICATIONS

1.1 Safety Procedures

1.1.1 Abstract

-In order to avoid errors and malfunctions during operation and maintenance, only professional workers

having a full knowledge of safety notes and warnings are allowed to operate.

-This abstract is a compilation of the most important procedures, which can be broken down into main

sections containing the information necessary for preventing injury to persons and damages to property and

pollution. In addition, diesel engine related local regulations are to be observed.

IMPORTANT: If despite all precautions, an accident occurs, especially for corrosive acid, fuel, sharp iron

fillings, hot oil and anti-freeze fluid sputtering into eyes, shall go to doctor immediately.

During start-up and running, any person or tool are not allowed to contact rotating parts!

During running or just stopped, skin and eyes are not allowed to touch extremely hot and corrosive

material like oil, coolant and waste gas!

During running or just stopped, fuel, engine oil, etc. must not be put close to flame, or on the diesel

engine surface.

For safe and stable operation, people authorized to operate and repair must have received special

training and abide by the procedures of this manual!

1.1.2 Operation cautions

-Before start up a new diesel engine, carefully read the instruction and clarify the model, specification as

well as maintenance and tool use requirements.

-Before start up an engine, carefully check the status of fuel, engine oil, coolant, battery charging, electric

parts and fuel injection control system, make sure everything is normal.

-When engine running normally, pay attention to working environment, make sure operating under a safe

circumstance. Frequent transit overspeed and overloaded operation are forbidden. Troubleshooting or

special tools shall be applied as per fault degree after engine stopped. Engine shall stop gradually after

Do not touch oil drain plug or oil filters with bare hands in case of scaldings.

Electrolyte is toxic and corrosive and battery gas is explosive, wherefore battery repair shall be performed

by professional and authorized people only.

Health precautions: Avoid prolonged or repeated skin contact with used engine oil. Protect your skin by

suitable hand creams or wearing protective gloves. Clean skin which has been in contact with engine oil

timely. After washing apply a fatty skin cream to the skin.Change oil-soaked clothing and shoes. Do not

put oily rags into your pockets.

Technical Documentation

4

RATINGS DEFINITION

The power ratings of Emergency Standby and Prime are in accordance with the

standard of IS08528. Fuel Stop power in accordance with the standard of ISO3046.

Electric power (kW) should be estimated by considering generator efficiency,

cooling fan power loss and power derating due to altitude and temperature.

STANDBY POWER RATING is applicable for supplying emergency power for the

duration of the utility power outage. No overload capability is available for this

rating. A standby rated engine should be sized for a maximum of a 70% average

load factor and 200 hours of operation per year, this includes less than 25 hours per

year at the Standby Power rating.

PRIME POWER RATING is available for an unlimited of hours per year in variable

load application. Variable load should not exceed a 70% average the Prime Power

rating during any operating period hours., The Total operating time at 100% Prime

Power shall not exceed 500 hours per year.

10% overload capability is available for a period of 1 hour within a 12 hours period

of operation. Total operating time at the 10% overload power shall not exceed 25

hours per year,

CONTINUOUS POWER RATING is the power that the engine can continue to use

under the prescribed speed and the specific environment condition in the normal

maintenance period stipulated in the manufacturing plant. And continuous power

applicable for supplying utility power at a constant 100% for an unlimited number of

hours per year. No overload capability is available for this rating.

COOLING SYSTEM

Water circulation by centrifugal pump on engine

Coolant capacity

9.6 L

Max.Permissible Temperature

90 ℃

Max.Coolant warning Temperature

95 ℃

Max.Coolant Shutdown Temperature

99 ℃

Thermostat Open Temperature

82 ℃

Max.external coolant system restriction

Not available

Two radiator options are provided, based on allowable maximum Air temperature On radiator inlet ( Air On 40 °C) Air On 50 °C

- ATB (Ambient Temperature before Boiling ) of generator set varies depending on the engine room ventilation design, even if the same radiator applied. Adequate selection of

radiator options by means of the cooling test is highly recommended, and generator set makers are responsible for the selection.

VMAN ENGINE

1.2 Diesel engine specifications

1.2.1 C07 series

GENERAL ENGINE DATA

Engine Model

C07A

C07B

Engine Type

6-Cylinder, Turbo charged & intercooled (air to air)

Prime Power ( kW/Ps )

170/231

180/244

Standby Power ( kW/Ps )

187/254

198/269

Continuous Power ( kW/Ps )

135/183

140/190

Speed

1500 rpm

1800 rpm

Bore x stroke

105*124 mm

Displacement

6.5 L

Compression ratio

16:1

Rotation {Looking at flywheel}

Counter clockwise {CCW}

Firing order

1-5-3-6-2-4

Injection timing

12˚±0.5˚ BTDC @ 1500 rpm

12˚±0.5˚ BTDC@ 1800 rpm

Dry weight {W/O cooling system}

600 kg

Dimension {L x W x H}

1330 * 789 *1079 mm

Flywheel housing

SAE 3 #

Flywheel

SAE (11-1/2) #

Number of teeth on flywheel

127

Piston speed

6.5 m/s

7.8 m/s

ENGINE MOUNTING

Max.Bending Moment at Rear Face to Block

1120 N.m

INTAKE & EXHAUST SYSTEM

Engine Model

C07A

C07B

Max.Intake Restriction (kPa)

6

6

Max.Exhaust Back Pressure (kPa)

<10

<10

Combustion Air Consumption (m³/h)

1126

1848

Max.Exhaust Temp.(After Turbo°C)

550

550

Exhaust Gas Flow (m³/h)

714

882

Technical Documentation

5

VALVE SYSTEM

Type

Overhead valve type

Number of valve

Intake 2, exhaust 2 per cylinder

Valve lashes at cold

Intake 0.25 mm, Exhaust 0.50 mm

Valve timing

Opening

- Intake valve

20.9 deg.BTDC

- Exhaust valve

51.7 deg.BBDC

C07 Series diesel engine drawing

VMAN ENGINE

FUEL SYSTEM

In-line pump with integrated, electromagnetic actuator

Engine Model

C07A

C07B

Governor

Electric type (Original GAC from USA)

Speed drop

G2 Class (ISO 8528)

Feed pump

Mechanical type in pump

Injection nozzle

Multi hole type

Opening pressure

25 MPa

Fuel filter

Full flow, Cartridge type with water drain valve

Maximum fuel inlet restriction

25 kPa

Maximum fuel return restriction

50 kPa

Fuel feed pump Capacity

450 liters / hr

Fuel

Diesel fuel

Fuel Consumption of generator set

Standby power- 100% load (l/h)

44.4

48.4

Prime Power - 100% load (l/h)

39.7

43.4

- 75% load (l/h)

29.5

32.8

- 50% load (l/h)

20.5

22.2

- 25% load (l/h)

11.4

12.6

Continous power - 100% load (l/h)

27.8

30.4

Lowest Fuel Consumption Ratio(g/kW.h)

205.0

215.0

LUBRICATION SYSTEM

Force-feed lubrication by gear pump, lubricating oil cooling water circuit of engine

Force-feed lubrication by gear pump, lubricating oil cooling water circuit of engine

Lub.Method

Fully forced pressure feed type

Oil filter

Full flow, cartridge type

Lube oil specification

CF-4

Lube oil pressure

Idle Speed : Min 80 kPa

Governed Speed: Min 200 kPa

Maximum oil temperature

115 °C

Max.Permissible Oil Temperature

98 °C

Oil Consumption (as % of fuel consumption)

≤0.2

Oil capacity

24 L

ELECTRICAL SYSTEM

Charging Alternator Voltage

28V

Charging Alternator Capacity

35A

Voltage regulator

Built-in type IC regulator

Starting motor

5.5kW

Battery Voltage

24V

Battery Capacity

2 * 120 Ah ( recommended )

Starting aid (Option)

Block heater ( Min. Temperature for Unaided Cold Start -10°C )

Technical Documentation

6

VMAN ENGINE

1.3 Diesel engine model, order number and serial number

The engine model and serial number are printed on the engine label.

These numbers are required when requesting warranty and ordering parts.

1.3.1 Diesel engine model

Power code: Using 1 ~ 9, basic model is not numbered

Development sequence code: represented by A, B, C…

Displacement, 7 represents displacement of 7L

Fuel form code: C represents “C”-inline type,

Example 1: C07A represents VMAN diesel engine, displacement of 7 L

Example 2: C07B represents VMAN diesel engine, displacement of 7 L

1.3.2 Diesel engine model

Diesel engine product order number and feature code are represented by Arabic numerals and letters, the

sequence is shown as below

Model configuration type: 01 ~ 99

Rated speedA says “1500r/min”

B says “1800 r/min”

ExampleA01 says 1500 r/min, first type of configuration.

1.3.3 Diesel engine nameplate

The diesel engine nameplate indicates the

main technical data and information: model,

order no., serial no., date of production,

rated power and rated speed, which are the

major basis for you to purchase service parts

and for VMAN to conduct after-sale technical

service. We hope you to put the information

and data into the daily record of work of your diesel engine or the matched devices for later repair and

reflection of quality problems, which are helpful to the correct settlement of your problems. The nameplate

locates at the top of the cylinder head coverProtect it from being damaged.

Technical Documentation

7

VMAN ENGINE

D11 (V6) SERIES DIESEL ENGINE

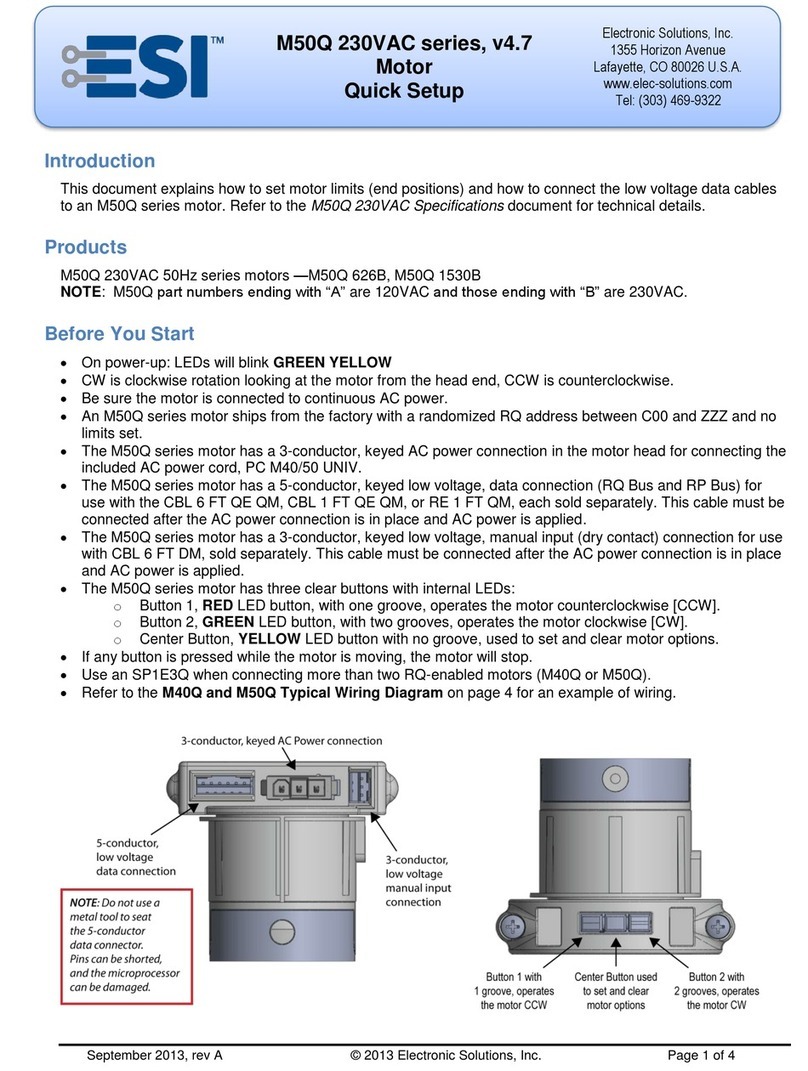

Part Name

1

Turbocharger

2

Valve Cover

3

Engine coolant outlet pipe

4

Left engine lifting plate

5

Fan bearing housing

6

Water pump

7

Alternator

8

Engine coolant inlet pipe

9

Tensioner

10

Oil filter

11

Fan Belt

12

Vibration damper

13

Water drain plug

14

Starting motor

Part Name

15

Intake pipe

16

High pressure fuel pipe

17

Right engine lifting plate

18

Front engine lifting plate (optional )

19

Fuel injection pump ( Electronic

speed governor )

20

Fuel injection pump fuel inlet pipe

21

Fuel filter inlet pipe

22

Fuel filter

23

Oil dipstick

24

Flywheel housing

25

Oil pan

26

Oil drain plug

1.4 Engine Assembly

1.4.1 Peripheral part name - engine intake side

Exhaust Side Front End

Intake Side Rear End

No

Name

Wrench dimension S (mm)

Tightening torque (N•m)

1

High-pressure fuel pipe nuts

19

35 (Injector end )

35 (pump end)

2

Banjo bolts to fuel return pipe of fuel injection pump

18

30-35

3

Banjo bolts to fuel- inlet pipe of fuel injection pump

18

30-35

4

Banjo bolts to fuel return pipe of fuel injector

16

25-30

5

Banjo bolts to inlet/outlet of fuel transfer pump

18

30-35

6

Banjo bolts to fuel filter inlet/outlet

16

25-30

7

Bleed screws on fuel priming pump

19

Until tightened

8

Oil pan drain plug

21

60

9

Valve clearance adjusting nuts

14

24

10

Valve clearance adjusting screws

5 (Inner hexagon)

11

Valve cover nuts

13

24

12

Bolts of cylinder head intermediate cover

10

24

13

Tensioner wrench jaw

1/2 inch

14

Fan clamp nuts

15

40

15

Water drain plug

8

45

1.5 Tightening Torque for Engine Parts

Technical Documentation

8

Hanma Power Supply, APICH-4 Viscosity Rating

Ambient temperature (℃)

Minimum

Highest

SAE0W20

-40

10

SAE0W40

-40

40

SAE5W40

-30

40

SAE10W30

-20

40

SAE15W40

-10

40

SAE20W50

0

50

Grades of fuel

0#

-10#

-20#

-35#

Cetane value

≥49

≥49

≥46

≥45

Solid point/℃

≤0

≤-5

-20

-35

Minimum applicable temperature

(engine working temperature)/℃

Above 4℃

Above -5℃

Above -14℃

Above -29℃

VMAN ENGINE

Caution: Fuel must be kept at the highest level of cleanness and not polluted by dust, impurities or water.

2. ENGINE OPERATION INSTRUCTION

Proper use of your engine can not only keep it in normal working order and good performance, but also can

extent its service life and reduce its use cost. Adopt proper fuel, oil and coolant, as well as the correct

operation steps stipulated in this section.

2.1 Fuel

The grade of diesel fuel should be determined based on the ambient temperature. In cold winter, fuel with

low-freezing-point should be adopted, while in the contrary in summer. The fuel used should be in

accordance with the GB 19147-2009, and the grade of fuel as per recommendations of GB/T 19147. You

may take the recommendations in the table below: e.g. the -35# fuel should be used at the ambient

temperature of -27℃.

Relationship between diesel fuel grades and applicable minimum temperatures

2.2 Oil

In order to ensure the normal operation of the engine, play the best performance, improve reliability,

improve the engine emissions, please use the VMAN engine dedicated to CH-4 grade lubricants and above

is strongly recommended for this engine in order to ensure its normal operation and long service life and

improve its emissions. If the above engine oil is not available, oil of CF-4 grade or above meeting the

requirements of American Petroleum Institute (API) can serve as an alternative.

Operating temperature range for engine oilGB 11122-2006

Caution: Engine oil must be kept clean and free from dust, impurities or water.

Technical Documentation

9

Matter in water

100Water

Chloride

50 ppm max.

Sulfate

50 ppm max.

Mineral saltlime carbonate

100 ppm max

soluble solid

250 ppm max.

PH value

6.5 or above

Freezing temperature

Glycol concentration

15℃

30

23℃

40

37℃

50

51℃

60

VMAN ENGINE

D11 (V6) SERIES DIESEL ENGINE

2.3 Coolant selection

Coolant with antifreeze function is required for the engine at any climate to ensure it normal operation and

service life. Coolant with antifreeze function can not only prevent itself from freezing in ambient condition

and also enhance its boiling point.

The coolant for the engine consists of water and glycol. The mixture of 50% water and 50% glycol is

recommended for most climates, and acceptable content of glycol in water is 40%-60%. The freezing point of

coolant is generally about 10℃below the lowest ambient temperature. The relation between content of

glycol in water and freezing temperature is as below.

Note: Before filling coolant into the engine, mix water and glycol to a certain ratio according to the table

above based on ambient temperature or get a right content mixture from market. The ice point of coolant

can be measured by special testing papers that are available in market.

Caution: Never use 100% glycol as coolant.

Water for coolant should be soft water or processed tap water. Do not use water from river, lake or sea or

unprocessed hard water. For water shortage areas, use boiling method or to base method to process well

water or underground water and take clean water abover the sedimentation. The water used for coolant

should meet requirements as below.

2.4 Engine Start

Before using the engine, choose proper engine oil, fuel and coolant according to actual ambient conditions.

Besides, the following work should be done before starting:

-Make a surround inspection of the engine and its starting system, and solve problems in time if any.

-Check oil pressure and temperature gauges, warning lights and other instruments for normality.

-Check the fault diagnosis indicator for normal working condition.

-Check the service indicator of the air filter for appearance of red piston.

Caution: Do not to start the engine without an air filter to avoid early engine wear.

Technical Documentation

10

VMAN ENGINE

-Check the oil level for being within the specified range.

-Check the coolant level for being within the specified range.

-Check the electrolyte level for being within the specified range.

-If the engine has not been in operation for a long time, or its fuel filter has just been replaced, there may

be air in the fuel system. Prime the fuel system with priming pump if necessary. Refer to section 4.3 for

specific priming operation.

-Check the electric starting lines for normality.

-All the safety devices must be installed in place.

-Check the accelerator pedal for free movement.

2.4.1 Normal starting procedure

-Disengage the engine from all driven equipment, or put transmission into the “neutral” position if equipped.

-Put the mechanical operating devices into the “running” position.

-Insert electric key and turn the switch from the position OFF to the position ON to electrify intake air heating

device and other electrical devices.

-Wait until the pre-heating indicator light goes out (the light flashes on when intake air pre-heating proceeds and

it doesn’t flash when no pre-heating happens). Then turn the switch from the position ON to the position START

to start the engine. For vehicle application, it is required to step on the accelerator pedal when starting.

Caution: Starting time should be no more than 15 seconds and there should be a 2-minute interval before the

next starting so as to prevent the damage to starting motor.

-Each starting usually lasts 2 -3 seconds.

-The switch goes back to the position ON from the position START automatically after starting up.

Caution: The oil pressure gauge should show reading within 15 seconds after the engine has successfully been

started; otherwise, stop the engine immediately to prevent damage to the engine and find the causes according

to Section 5 Troubleshooting Guideline.

-Started up from a hot state, the engine should run at idle for 1-3 minutes before being accelerated and loaded

gradually.

-Started up from a cold state, the engine should run at idle for 3-5 minutes. Increase the engine speed slowly to

have every bearing adequately lubricated and oil pressure stable. Gradually accelerate and load the engine after

oil pressure is stable.

-Check the instruments for operational conditions in engine idle running.

Caution: Do not accelerate and load the engine immediately after it is started up.

Caution: Do not idle the engine for long period or it can cause problems to the engine. When an engine idles,

the temperature in combustion chamber is low and combustion is not complete. It can cause carbon deposition

in cylinder that results in blocking of orifice of fuel injector, as well as the seizures of piston rings and valve, thus

leading to engine performance deterioration.

NoticeIf the engine is start by a jumper cable, parallel connection of the cable should be adopted by

connecting the positive pole to the positive terminal and the negative pole to the negative terminal. If the

engine is start by external power supply, the circuit breaker should be set to the position OFF. Take out the key to

prevent accidental activation before connection of jumper cable.

Technical Documentation

11

VMAN ENGINE

D11 (V6) SERIES DIESEL ENGINE

2.4.2 Cold starting

The engine has the ability to start successfully without any pre-warming aid if the temperature is above -15℃.

The engine is equipped with an intake air heating device for fast and smooth start, as well as for keeping

speed stable and improving the smoke.

There are two types of intake air heating device: electric heating and flame heating.

1) Electric heating device consists of electric heater, electronic controller, temperature sensor and indicator

light. Its work is governed by the electronic controller.

2) Flame heating device consists of flame heating plug, solenoid valve, fuel inlet pipe, electronic controller,

temperature sensor and indicator light. Its work is governed by the electronic controller.

The electronic controller governs intake air heating action according to ambient temperature. The heating is

divided into two stages: heating intake air before and after engine start. Generally, it is not allowed to start

engine during the first stage of heating (pre-heating). Once the engine is started, the pre-heating will

automatically stop. Start the engine after the pre-heating is over.

-Insert the electric key and turn the switch from the position OFF to the position ON to electrify the

electronic controller. Pre-heating intake air starts and the indicator light flashes on. Heating intake air ends

and the indicator light flicker. The engine is ready for starting.

-Turn the switch from the position ON to the position START to start the engine after the indicator light goes

out. Heating after starting begins and duration of it is governed by the electronic controller. The indicator

light does not flash in the process. The switch turns back to the position ON from the position START

automatically. Refer to Normal Starting procedure for other engine starting instructions.

Note: If startup does not happen or the engine has not been started up within 30 seconds after the indicator

light starts flickering, the electronic controller will automatically disconnect the circuits of glow plug, solenoid

and indicator light, entering delay protection. If another startup is initiated, turn the electric key back to the

position OFF, and wait for 5 seconds before repeating the above process.

2.4.3 Starting after a long-time stop or engine oil replacement

If the engine hasn’t been used for more than 30 days or its engine oil has just been replaced, it is necessary

to check its oil level before starting for being within the dipstick marks range, and prime the fuel system, see

Section 4.3-Priming Fuel System for specific operation. Then start the engine with the normal or cold starting

procedure.

2.5 Engine Operation

-Cautions for operation of the engine:

-Pay frequent attention to oil pressure, coolant temperature and fault indicator light. In case of any abnormality,

stop the engine immediately for inspection.

-When engine overheating starts to happen that is indicated by the coolant temperature alarming, reduce

engine speed or place the transmission to lower gear or take the both actions until the temperature falls down

into the normal range; otherwise, the engine should be inspected as per Section 5 “Troubleshooting

Guideline”.

-When driving down a steep slope, the transmission gear and brake should be used simultaneously to control

the vehicle speed and engine speed; when driving up a steep slope, a proper gear must be chosen to prevent

the vehicle from rushing on the slope.

Caution: Over-speed running will cause serious damage to the engine.

Technical Documentation

12

VMAN ENGINE

-Proper lubricating oil, fuel and coolant must be used for the engine when it runs in an extremely cold area.

There are significant signs before the faults of an engine occur. Listening and observing will help to detect in

advance or predict some problems of the engine that will occur later, with which the proper measures can be

taken in time to eliminate such problems that would lead to a serious engine failure..

Typical engine fault signs:

Fault indicator light flickers

Engine misfires abnormally

Engine vibrates abnormally

Engine sounds abnormal

Engine coolant temperature and oil pressure change abruptly

Engine produces black smoke

Engine power output is insufficient

Engine oil consumption is too much

Fuel consumption is too much

There is leakage of oil, fuel or/and coolant

2.6 Engine Shutdown

2.6.1 Normal shutdown

If the engine has just worked at a high speed and heavy load for a long time, reduce its load and speed

gradually and run it at idle for 3-5 minutes before stopping it to let turbocharger speed fall considerably so

as to protect the engine and turbocharger. Turn the switch from the position ON to the position OFF and take

out the electric key after the engine has been stopped.

If the engine will not be used for a period of time, keep it properly. Refer to Section 6 for engine storage.

2.6.2 Emergency shutdown

Under an emergency or special condition, make an emergency stop to avoid serious engine failure. Manually

pulling of the emergency stop handle can achieve an emergency shutdown.

2.7 Running-in of a new or overhauled engine

Before beginning to use a new or overhauled engine, run it for 60 hours or about 2,000 km in running-in

condition and change its oil thereafter to improve its moving parts working condition and its reliability and

service life. The way of running-in varies from one engine application and loading manner from another. In

principle, engine speed and load in running-in process will be increased gradually with the running-in going

on. Load should be 50%-80% of its full load, and speed should not exceed 80% of its rated speed.

Do not run an engine at idle or with low load for a long-time either in running-in period or normal working

period thereafter. Continuous idle running for the engine is usually not longer than 5 minutes to avoid early

wear due to carbon deposit or engine performance being affected.

Technical Documentation

13

Maintenance tasks

Daily

Every 3

months or

250h or

10,000 km

Every 6

months or

500h or

20,000 km

Every 12

months or

1,000h or

40,000 km

Every 2

years or

2,000h or

80,000 km

Checking engine periphery

●

●

●

●

●

Checking fuel tank

●

●

●

●

●

Checking air filter service indicator

●

●

●

●

●

Checking first stage fuel filter service

indicator

●

●

●

●

●

Checking oil level

●

●

●

●

●

Checking coolant level

●

●

●

●

●

Checking electrolyte level

●

●

●

●

●

Checking fan belt *

●

●

●

●

●

Checking cooling fan

●

●

●

●

●

Checking intake system

●

●

●

●

Replacing engine oil and oil filter

●

●

●

●

Replacing fuel filter (first/second stages)

●

●

●

●

Priming the fuel system

●

●

●

●

Adjusting the valve clearance

●

●

●

●

Checking air filter element

●

●

●

Checking intercooler

●

●

●

Checking the rubber-belt tensioner **

●

●

Checking the fan bearing

●

Checking the turbocharger

●

Checking the vibration damper

●

Checking the air compressor

●

Replacing coolant

●

* The belt must be replaced when it has

crack or defects that affect its use.

** The tensioner must be replaced when its

pulley doesn’t spin freely.

VMAN ENGINE

D11 (V6) SERIES DIESEL ENGINE

3. ENGINE MAINTENANCE

3.1 Maintenance Schedule

The following table gives maintenance period and tasks for the engines. Take regular maintenance for the

based on this table. If the engine frequently operates at the ambient temperature of below -18°C or above

38°C, or in dusty environment or under a stop-and-go condition, the maintenance period should be

shortened properly.

Note: The maintenance interval in this table is in months, hours or kilometers, whichever comes first.

Technical Documentation

14

VMAN ENGINE

3.2 Tasks and Methods of Engine Maintenance

Checking engine periphery

Check the periphery of the engine each time before starting:

(1) Check the connectors and sealed faces of the fuel system, cooling system and lubricating system for

leakage.

(2) Check if the fan and its safety guard are fastened in place.

(3) Check the fastenings of the accessories.

(4) Check the electrical circuits for looseness and the lead for intact.

(5) Check the drive belt for intact.

Checking fuel tank

Check the fuel level in the fuel tank everyday.

Checking air filter service indicator

Check the maintenance indicator of the air filter everyday.If the viewing window

Shows red piston, it represents that the intake resistance of the air filter exceeds

The specified value, and the filter element requires to be replaced. Press the

button on the top of service indicator for reposition after the replacement.

Caution: Be sure that both end faces of the air filter are reliably sealed without leakage after the air filter

element is changed.

Caution: Do not start the engine without an air filter, and failure to do so would easily cause early engine

wear.

Checking first stage fuel filter service indicator

Check the service indicator daily. When the first stage fuel filter contains a certain

amount of foreign particulates and causes difficulty for the fuel transfer pump to pump

fuel, the indicator on the filter appears in red, reminding you that the fuel filter must be

replaced. The filter must be replaced too even the indicator does not appear red after

being used for 250 hours. The filter is a spin-on type one and the procedure of its

replacement is the same as the second stage fuel filter. Refer to Replacing fuel filter

(second stage) for the procedure

Checking oil level

Check the oil level daily before starting the engine or the engine is in stop (at least 15 minutes after being

stopped) to provide enough time for oil to flow back to the oil pan. The oil

level should be between the marks ADD and FULL. If oil is not enough,

supplement it. The oil volume difference between the low level ADD and

the high level FULL is about 2 L for 4L engine and 2.5 L for 7L engine.

Caution: Do not run the engine when the oil level is below the mark ADD, otherwise it can result in poor

engine performance, or even damage to the engine.

Technical Documentation

15

VMAN ENGINE

D11 (V6) SERIES DIESEL ENGINE

Checking drive belt

Perform visual check of the drive belt everyday for any intersecting cracks. The

transverse crack along the width direction of the belt is acceptable, while

longitudinal cracks (along the length direction) that intersect with transverse

cracks are not allowed. If any wear or abrasion occurs on the belt, replace it

Checking cooling fan

Perform visual check of the cooling fan for flaw or any other defect. The fan should be installed reliably.

Tighten the fastening bolts (15 mm) or replace the damaged fan if necessary.

Warning: Damaged fan blades can cause serious personal injury. Do not pull or pry the fan, and never

rotate the engine with the fan.

Checking intake system

Check the intake hoses for any crack, as well as perforation, and clamps for looseness. Replace the hose(s) if

any fault is found, and tighten clamp screw(s) with tools if looseness is found to ensure leak-proof of the

intake system.

Replace engine oil and oil filter

Warning: Be careful when replacing engine oil and oil filter because skin contact with the hot engine oil or

hot engine surface can cause scald.

(1) Don’t stop the engine until the temperature of coolant reaches 60°C, then

remove the oil drain plug (21 mm), scrap the gasket and drain the engine

oil.

Caution: Do not drain engine oil when an engine is in cold-state at which

foreign particles has deposited and attached to the bottom of an oil pan,

and will not drain with oil. When engine oil is warm, foreign particles

suspend in it and can easily drain with engine oil.

(2) Clean the installation surface of the oil drain plug on the oil pan. Fit the drain plug with a new gasket and

tighten it to 60 N•m.

(3) Replace second the stage fuel filter.

(4) Clean the periphery of the oil filter head. Remove the oil filter and scrap it.

(5) Before installing a new oil filter, fill it with clean oil from the peripheral

holes. The oil level should be 3-15mm below the threaded hole. Apply a

light film of clean engine oil on the O-ring on the new filter to form a

lubricating film.

Caution: Do not add oil from the central hole of a filter.

(6) Turn the filter by hand until the O-ring touches the sealed surface of the filter head, and further tighten it

by 3/4 to 1 turn with tool.

(7) Open the filler cap, and fill the engine with clean engine oil until the oil level is near the mark FULL.

Lubricating system capacity - 20L

Technical Documentation

16

VMAN ENGINE

(8) Start the engine and keep it running at idle, and then check the oil filter and drain plug for oil leaks.

(9) Shut off the engine, wait for about 5 minutes to provide enough time for the oil to flow into the oil pan,

and check the oil level. Add engine oil until it is near the mark FULL (high level) if required.

(10) Install the filler cap and tighten it until you feel suitable.

Replace fuel filter (second stage)

(1) Remove the fuel filter with tool and scrap it.

(2) Clean the filter head and its sealed face. There should be no old O-ring left.

(3) Before installing a new fuel filter, fill it with clean fuel from the peripheral

holes. The fuel level should be 3-15 mm below the threaded hole. Apply a

light film of clean engine on the O-ring of the new fuel filter to form a

lubricant film.

Caution: Do not add oil from the central hole of a filter.

(4) Screw the filter by hand until the O-ring touches the sealed surface of the

filter head, and further tighten it by 3/4 to 1 turn with tool.

Priming fuel system

If the engine has not been used for a long time or fuel filter (first- or/and second- stage) is changed, air will

enter the fuel system. It is required to prime the fuel system as per following steps:

(1) Loosen the joint of the fuel return pipe.

(2) Loosen fully the priming pump knob on the fuel transfer pump and prime until there is no bubble visible

in the fuel that outflows from the bolt.

(3) Tighten the bolt 20 N•m.

(4) Tighten the priming pump until you feel suitable.

Caution: Priming the fuel system is required if air enters the fuel pipeline due to untimely fuel supplement

or there is air in the fuel system due to other reasons.

Drain water

The first stage fuel filter has the function of water and fuel separation. When

water level in the water container of the first stage fuel filter reaches a certain

height, the water-level sensor will send a signal to the water-level indicator light

in cab, reminding the driver to drain the water timely. Loosen the water drain

valve about three and half turn to drain the water and sediment until clean fuel

outflows. Then tighten the valve until you feel suitable. Don’t over-tighten it.

Checking turbocharger

Perform visual check of turbine and compressor blades of the turbocharger for damage, crack, or contact

between the turbine or compressor housings when a light finger pressure applied on them. And check the

turbocharger shaft for free spinning. In case that any of the above problems occur, the turbocharger should

be replaced.

Technical Documentation

17

Possible cause

Correction

The terminals and connectors of the starting circuit

and/or the battery are loose, open or eroded

Clean and tighten all the terminals and the

connectors

Insufficient battery output

Adopt a battery with sufficient output or add some

more battery in parallel

Starting motor fault

Check the starting motor.

Possible cause

Correction

The instrument or indicator light failure

Check/replace the instrument or indicator light

The battery connector(s) is loose or eroded

Clean/tighten the battery connector(s)

The drive belt slip or failure of the tensioner

Check/replace the belt and check the spring

performance of the tensioner

Poor terminal contact of the alternator

Tighten all terminal connects of the alternator

No

Fault mode

No

Fault mode

1

Alternator refuses to charge or fails to charge

enough

17

Diesel knock

2

Starting motor fault

18

Excessive noise

3

Engine is difficult to start or will not start

19

Black smoke

4

Engine starts, but will not keep running

20

White smoke

5

Liable misfire or unsteady speed

21

Blue smoke

6

Liable misfire at low speed

22

Fuel consumption too much

7

Engine output power low

23

Coolant temperature above normal --

gradual overheat

8

Engine cannot reach rated speed under load

24

Coolant temperature above normal—

sudden overheat

9

Rough running and misfiring

25

Coolant temperature below normal

10

Unexpected engine halt or misfire in deceleration

26

Coolant contamination

11

Poor acceleration performance

27

Oil pressure too high

12

Engine deceleration too slow

28

Oil pressure too low

13

Engine will not stop

29

Oil consumption too much

14

Engine rough running at idle speed

30

Engine oil contamination

15

Unsteady idle speed and engine hunting

31

Excessive belt abrasion

16

Excessive vibration

VMAN ENGINE

D11 (V6) SERIES DIESEL ENGINE

4. TROUBLESHOOTING GUIDELINES

4.1 Troubleshooting guidelines

Some typical and simple diesel engine fault symptoms, possible causes and troubleshooting steps are listed

in the table below. If any one of symptoms occurs in service, it is required to eliminate it by taking

appropriate measures. Otherwise, it would lead to severe accidents of the engine. For simple and external

engine faults, you can locate and eliminate them on your own according to the sequence of possible causes

(namely the steps of detection). For complex faults, contact VMAN’s after-sale service center for technical

guidance.

Fault mode 1Alternator refuses to charge or fails to charge enough

Fault mode 2Starting system fault

Technical Documentation

18

Possible cause

Correction

The engine is engaged with the driven device

Disengage the engine with the driven device

Fuel arises solidification because of cold weather

Choose proper fuel specified in this manual based on

the ambient condition

Air in the fuel system

Check for air in the system. Tighten or replace the fuel

joints, fuel pipes and relevant parts if necessary and

then prime the system

The fuel filter or fuel suction pipe is blocked

Replace the fuel filter or fuel suction pipe

The resistance of intake system exceeds the

specified value

Check the intake system and replace the air filter

element if necessary

The resistance of exhaust system fails to meet the

requirements

Check the exhaust system.

Fuel fails to meet required specification or its

quality is poor

Use the fuel specified in this manual and fill a

temporary tank with right high-quality one, with which

to run the engine and verify the fuel issue

VMAN ENGINE

Possible cause

Correction

Improper starting method

Refer to the operating instruction manual of the

vehicle or the equipment for proper starting method

The time for engine start up is 2-3 seconds

It is normal and needs no adjustment

The driven device is engaged

Disengage the driven device

Too low starting speed (Minimum starting speed

is 100 rpm)

Check battery for voltage and check starting motor

for loose or eroded connection

Insufficient fuel in the tank

Add fuel

Air in the fuel system

Check for air in the system. Tighten or replace the fuel

joints, fuel pipes and relevant parts if necessary and

then prime the system

The connectors of low-pressure fuel pipeline is

loose

Check the low-pressure fuel pipeline and tighten all

the connectors

The fuel filter or fuel suction pipe is blocked

Replace the fuel filter or fuel suction pipe

Fuel arises solidification because of cold weather

Choose proper fuel specified in this manual based on

the ambient condition

There is no fuel in the fuel injection pump

Check the fuel transfer pump.

The resistance of the intake system exceeds the

specified value

Check the intake system and replace the air filter

element if necessary

The resistance of the exhaust system fails to meet

the requirements

Check the exhaust system

The crankshaft rotation is restricted

Barring the crankshaft and check for restriction.

Injection pump timing is not correct

Check and adjust injection pump timing. Refer to 5.2

for the procedure

Intake/exhaust valve clearance error (s)

Check and adjust valve clearance

Fault mode 3Engine is difficult to start or will not start

Fault mode 4Engine starts, but will not keep running

Technical Documentation

19

Possible cause

Correction

Inquire the driver

Obtain all the information related to the problem

Overloaded operation

Reduce the load to allowed range

Vehicle drives on the plateau beyond the

specification

Drive on the specified plateau. Engine power decreases

with increase of altitude

The driven system has been changed and cannot

match the engine

Check the transmission gears for mismatch of the

engine

Oil level is too high

Check and lower oil level to the specified range

The accelerator pedal doesn’t arrive at the bottom

Check accelerator pedal for restriction

The load of driven accessories is too heavy

Check the cycle period of the cooling fan and vehicle

braking for friction

Possible cause

Correction

Fuel level is low in the tank

Add fuel

Air in the low-pressure fuel pipeline

Check the low-pressure fuel pipeline for air source.

Tighten or replace joints or pipes if necessary and then

prime the system

Possible cause

Correction

Fuel level in the fuel tank too low

Add fuel

Air in fuel system

Check for air in the system. Tighten or replace the fuel

joints, fuel pipes and relevant parts if necessary and

then prime the system

Fuel pressure too low

Check the fuel tank for fuel level, check the pipe

between the tank and the fuel transfer pump for

leakage, serious deformation, bent or plug and for air

Leakage at high-pressure fuel pipe connectors

Tighten the connectors and make replacement if

required

Injection pump timing is not correct

Check and adjust injection timing. Refer to 5.2 for the

procedure

Intake/exhaust valve clearance error (s)

Check and adjust valve clearance

VMAN ENGINE

Air in the fuel system

Check for air in the system. Tighten or replace the fuel

joints, fuel pipes and relevant parts if necessary and

then prime the system

Fuel inlet temperature is high

Add fuel into the fuel tank.

The fuel supply is blocked

Check the fuel inlet resistance and replace the fuel filter

(first stage) and fuel filter (second state) if necessary

Leakage of the exhaust manifold or turbocharger

Check the exhaust manifold and boost pressure to find

and eliminate the source of leakage

Fault mode 5Liable misfire or unsteady speed

Fault mode 6Liable misfire at low speed

Fault mode 7Engine power output low

This manual suits for next models

2

Table of contents