4

4

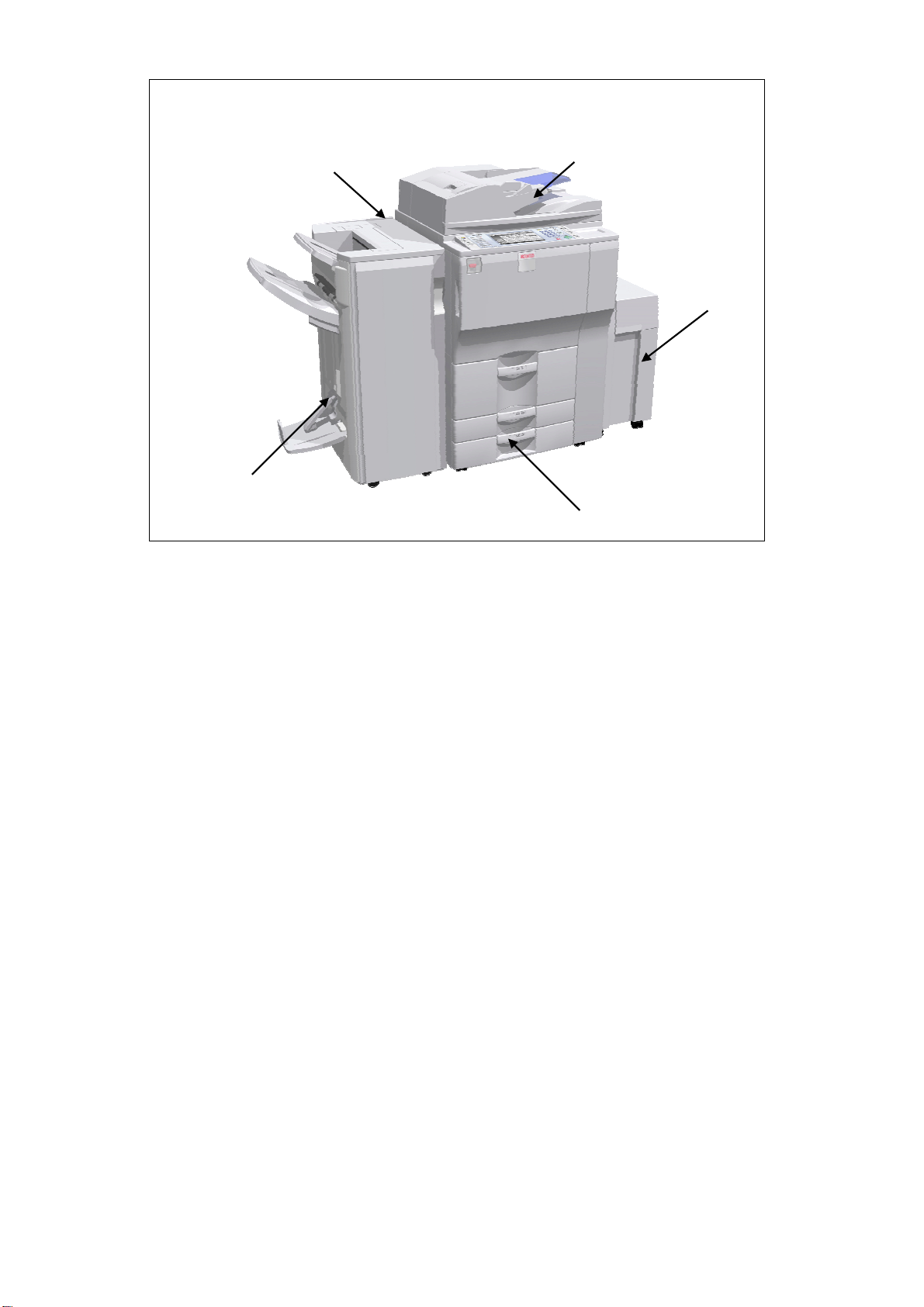

Product Appearance

Optional Booklet Finisher

Optional Cover Interposer

Optional

LCT

ARDF

(standard equipment)

Three paper trays

(standard equipment)

PRODUCT APPEARANCE

The first few slides illustrate what the machine looks like, with some of the options

connected.

Here we see a finisher and an LCT attached.

The ARDF (capacity: 100 sheets) is standard equipment for this model, not an

option. It has a CIS built in, which allows both sides of a double-sided original to be

scanned at the same time.

The three built-in paper trays are as follows:

¾Tray 1: 1550 sheet x 2, tandem LCT

¾Trays 2 and 3: 550 sheets each

¾In addition, the built-in bypass tray has a capacity of 100 sheets.

¾Optional LCT: 4,000 sheets (2,500 if the LG/B4 kit is installed)

¾Adding it all up, the machine has a maximum paper capacity of 8,300 sheets

(A4/LT).

The tandem tray (main frame, tray 1) can only handle sizes up to A4/LT. The

DLT/A3 tray allows tray 1 to hold sizes up to DLT/A3 (1000 sheets). However, this

will not be a tandem tray.

Trays 2 and 3 are adjustable to hold a wide range of paper sizes.

The LCT can only handle sizes up to A4/LT. The LCT can be fitted with an LG/B4

option to allow it to hold paper sizes up to LG and B4.

¾However, if the tray is modified in this way, some short paper sizes, such as

A4SEF, cannot be added, because the end fence will not reach them. A4LEF

can still be used.

The cover interposer is used with the finishers. It inserts cover sheets in the

locations specified by the user.