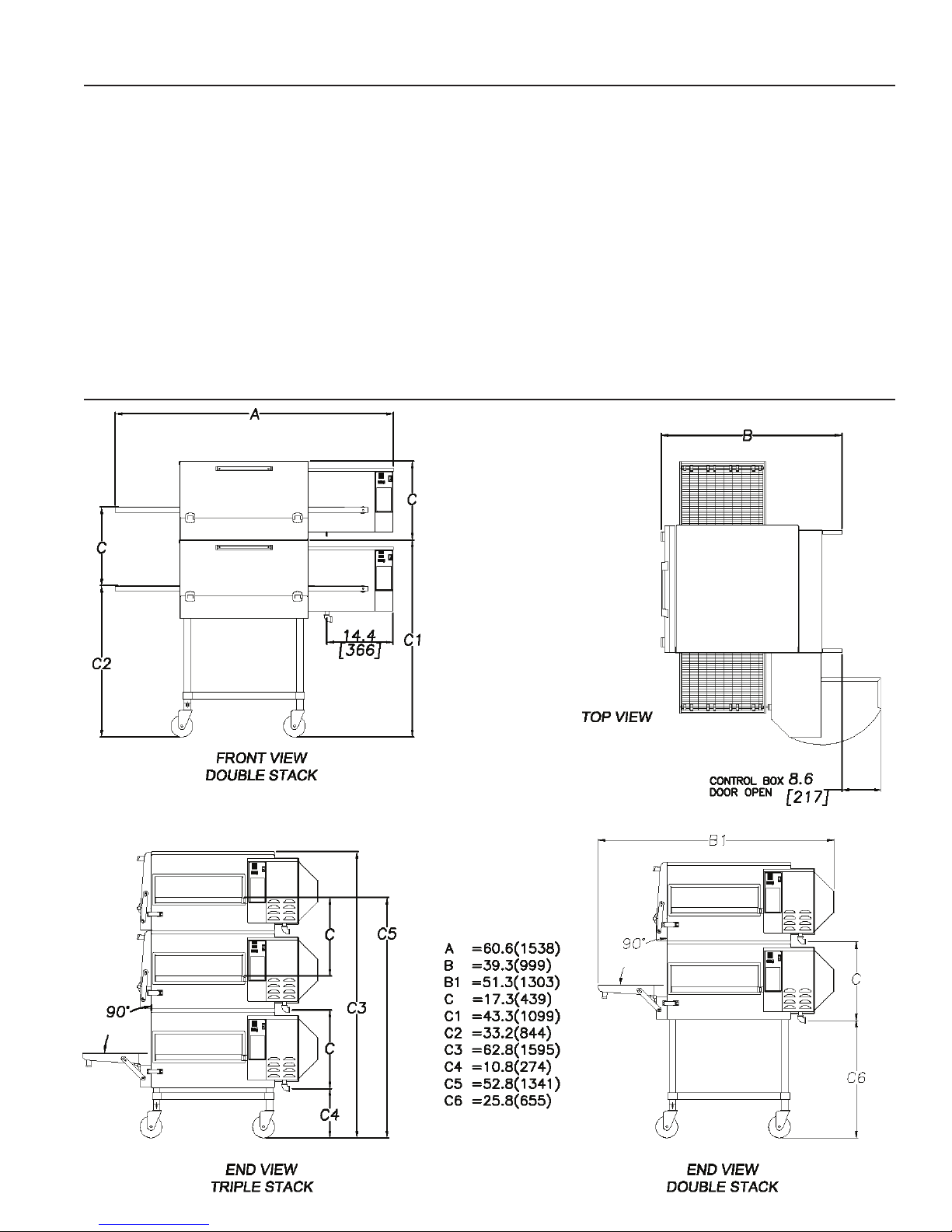

The following drawing shows a typical installation

and is intended to be a guideline. This is not a rigid

specication. Hood dimensions and positioning over

the oven will vary with hood manufacturer.

SMOKE CANDLE TEST

Inordertoverifytheproperfunctionofyourventilation

system,asmokecandletestshouldbedone. Iftesting

a multiple oven system, this test should be done on

the bottom oven. The conveyor coupling should be

disconnected and the oven temperature must be set

and operating at a minimum of 480°F (249°C).

Test Procedure:

1. Wear heat-resistant gloves to prevent burns.

2. Put the smoke candle in an 8"x8"x2" cake pan.

3. Insert candle through conveyor tunnel or oven

door. (Use Star Smoke Candle 2W-Z5668.)

4. Lightthefuseofthesmokecandleandimmediately

center the pan in the oven cavity on the conveyor

belt (keeping the oven door closed).

5. Observethesmokepatterncomingoutofalloven

openings and the collection of this smoke by the

ventilation system.

6. All smoke from the oven must be captured by the

ventilation system.

GAS SUPPLY RATING AND SIZING

Calculations for pipe sizing must take into account

themaximumusagerateofallotherappliancesinthe

kitchenoroneormoreoftheapplianceswillsufferfrom

inadequateordangerousperformance. The1/2"NPT

connection for the oven is generously sized for use

in the control box of the oven. However, unless the

oven installation is within 10 feet of the main building

gassupply,thesupplymustbelarger. Foreachoven,

a 3/4" NPT exible quick connect hose and full port

gas shut-off valve is recommended as a MINIMUM.

Themainpipesupplyingeachovenbranchmayneed

to be larger depending on the number of appliances

serviced, the number of elbows in the piping, and

the pressure. This should be sized and installed by

a professional familiar with any local codes that may

also affect the installation.

ACCESS CONSIDERATIONS

Locating the gas valve(s), quick connect hose(s) and

electrical outlet(s) at the control box end of the oven

will allow easier access for any service visits. This

improvedaccessshouldmakeanynecessaryservice

quickerresulting inless kitchendisruption. Itwillalso

allow easier disconnection of electricity, gas, and

restraints for cleaning around and behind the oven.

ELECTRICAL CONNECTION

Before making any electrical connections to this unit,

checkthatthepowersupplyisadequateforthevoltage,

amperage, and phase requirements stated on the

rating plate. A wiring diagram is included herewith.

When installed, this appliance must be electrically

grounded and its installation must comply withANSI-

NFPA 70, latest version, manufacturer's installation

instructions, and applicable local municipal building

codes. InCanada,allelectricalconnectionsaretobe

in accordance with CSAC22.1 - Canadian Electrical

Code Part 1 and/or local codes.

PRESSURE REGULATION AND TESTING

Eachovenhasbeenadjustedatthefactorytooperate

withnaturalgas. Partscanbeorderedforconversion

for use with propane.

Each oven is supplied with a regulator to maintain

the proper gas pressure. The regulator is essential

to the proper operation of the oven and should not be

removed. Apressure reading can be taken at one of

the 1/8" NPT test ports on the bottom or side of the

combinationvalve. Thereadingshouldbetakenwhile

theovenisheatingup. Theregulatorislocatedonthe

bottom of the gas combination valve, just inside the

control box. There is no need to install an additional

regulator where the oven connects to the gas supply

unless the supply exceeds the maximum.

NOTE: The supplied regulator is evaluated for a

maximum gas supply pressure of 14" water column

(34.5mBar).Therecommendedmaximumgassupply

pressure is 12" water column (29.9 mBar).

Installation must conform with local codes or, in the

absence of local codes, with NFPA54/ANSI Z223.1

- Latest Edition, the Natural Gas Installation Code

CAN/CGA-B149.1 or the Propane Installation Code

CAN/CGA-B149.2 as applicable.

7