2

MANUAL - AUTOMATIC DUST VACS - UR700QVAC Revised 2013-12

Follow the procedures in this manual to operate this machine safely and effectively. Ensure that this

manual is readily available to the operator at all times. If you have any questions about the operation of

this machine, contact:

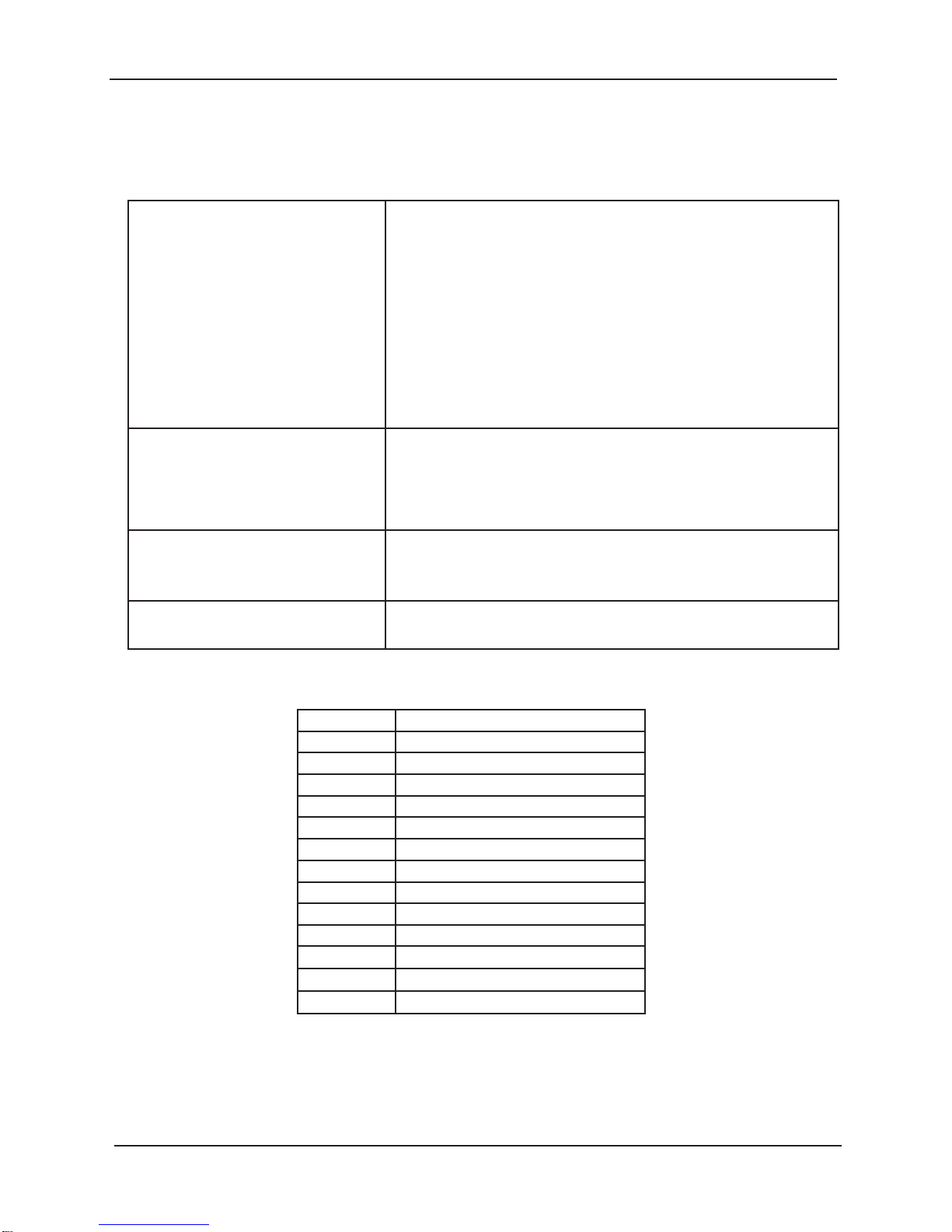

FEATURES AND SPECIFICATIONS

The UR700QVAC is 120 V, 2000 W, 50/60 Hz and the UR700QVAC-H is 240 V, 2000 W, 50/60 Hz.

These mobile vacuums are ideally suited for automotive, marine and industrial applications wherever air

operated, vacuum-assist tools are used. Two technicians can work on different projects at the same time.

• Portable. • A Single Cartridge Filters is standard. High Density

Filters are available.

• One or two operators can work simul-

taneously, 20 foot power cord, 16 foot

vacuum hose.

• Electrical outlet for use with one electrical sander.

• Automatic activation of vacuum by air

tool, manual override. •

•

•

Sealed Vacuum: 99” water (2500mm)

Supply air pressure: 100 -150 PSI (6.510.0 bar)

Weight: (700) 72 lb / 33 kg

• 2 motors 1,000 W each; Select single or

dual vacuum motors, single - 1,000 W

and dual 2,000 W. Maximum decibel rat-

ing at 2,000 W is 70 db. Wattage (power

consumption) can be reduced using the

Variable Power Adustment dial.

•

•

Motor is a bypass, 2 stage motor for long life and va-

cum power. Diecast housing. Internal fan for cooling.

Shipping Dimensions (WDH): 41 X 23 X 24”

North America: Uni-ram Technical Service 1-800-417- 9133

Other Continents: Contact Your Supplier

SETUP

• Check for transportation or handling damage.

• Make sure the Vacuum Head is securely clamped.

• The Pressure Switch is in a separate carton. Install the Pressure Switch. Connect the Short Power

Cord from the Presure Switch to the Control Panel connector on the Vacuum Head. Make sure the

connection is secure.

• Install 1/4” npt male air plug to the the female air inlet on the pressure switch.

• Connect the two Air Supply Lines and two Vacuum Hoses to the Pressure Switch.

• Provide at least 100 PSI (7 bar) supply to the air plug on the pressure switch. To ensure dry air use a

moisture filter (not provided).

• Connect the Air Tools.

• Make sure the correct voltage is supplied. Plug in the unit. Set On / Off control toAuto. Test the

operation of the vacuum and sander. Ensure all air fitting connections are secure without air leakage.

CAUTIONS AND WARNINGS

Do not use this vacuum with hazardous dust such as alumina and magnesia dust

and do not use with flammable liquids like gasoline. Repair must be carried out

by a qualified technician.

PREVENTATIVE MAINTENANCE

Replace brushes every 450 hours. See the list of Replacement Parts.