General information

3

Thesystemmanagermustbeinstructedconcerningtheuseandoperationofhisheatingsystem,inparticular:

• Givethesystemmanagertheseinstructions,aswellastheotherappliancedocumentsinsertedintheenvelope

insidethepackaging.The system manager must keep this documentation for future consultation.

• Informthesystemmanagerabouttheimportanceoftheairventsandtheuegasexhaustsystem,highlighting

theiressentialfeaturesandtheabsoluteprohibitionofmodifyingthem.

• Informthesystemmanagerconcerningcontrolofthesystem’swaterpressureaswellasoperationstorestoreit.

• Informthesystemmanagerconcerningcorrectcontroloftemperatures,controlunits/thermostatsandradiators

tosaveenergy.

• Rememberthatthesystemmustreceiveregularmaintenanceatleastonceayearand a combustion

analysismustbeperformedinthetimetableforeseenbystandardsinforce.

• Shouldtheappliancebesoldortransferredtoanewownerorifyoumoveandleavetheappliance,alwaysmake

surethattheinstructionbookletaccompaniesitinordertobeconsultedbythenewownerand/orinstaller.

The manufacturer will not be held liable in case of damage to persons, animals or objects resulting from

failure to comply with the instructions contained in this manual.

4 - INFORMATION FOR SYSTEM MANAGER

BY INSTALLER/MAINTENANCE TECHNICIAN

5 - SAFETY WARNINGS

ATTENTION!

The appliance must be installed, adjusted and maintained by professionally qualified personnel, in

compliance with standards and provisions in force. Incorrect installation can cause damage to persons,

animals and objects for which the manufacturer cannot be held responsible.

DANGER!

NEVER attempt performing maintenance or repairs on the boiler on your own initiative.

Any work must be done by professionally qualified personnel authorised by Unical.

We recommend stipulating a maintenance contract.

Insufficient or irregular maintenance can jeopardise the operating safety of the appliance and cause damage

to persons, animals and objects for which the manufacturer cannot be held responsible.

Modifying parts connected to appliance

Donotmodifythefollowingparts:

- theboiler

- thegas,air,waterandelectricitylines

- theuegaspipe,safetyvalveandheatingwaterdrainpipe

- constructionpartswhichaffecttheoperatingsafetyoftheappliance

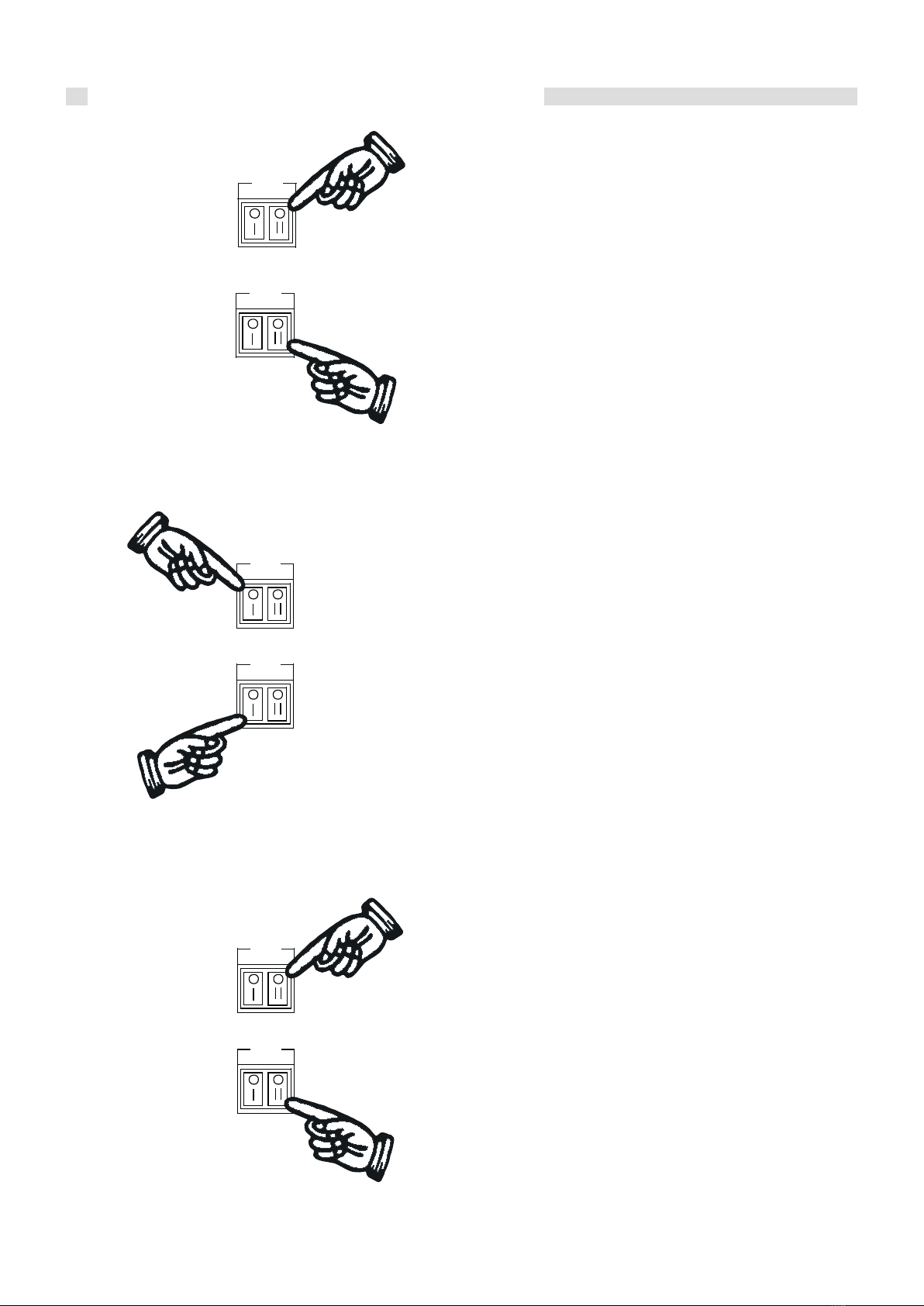

Smell of gas

Shouldasmellofgasbeperceived,followthesesafetyguidelines:

- donotturnelectricswitchesonoroff

- donotsmoke

- donotusethetelephone

- closethegasshut-offvalve

- airouttheareawherethegasleakagehasoccurred

- informthegassupplieroracompanyspecialisedininstallationandmaintenanceofheatingsystems.

Explosive and easily flammable substances

Donotuseorstoreexplosiveoreasilyammablematerials(e.g.petrol,paints,paper)intheroomwheretheap-

plianceisinstalled.