Assembly and Repair Instructions Page 6 of 7

Revision 0

INTEC K210-FS File: Montage-und

Rep.-Anl. K210-FS

Author: Roth Release:

Printed pages are not su ject to Change Management

Date: 09.12.2009

5Deinstallation

5.1 Precautionary measures

In order to ensure that any product residues which may have remained in the interior of the valve cannot endan-

ger the deinstallation personnel, they must wear appropriate fully- ody protective clothing made of chemical and

solvent-resistant material and equally resistant facial protection.

As a precautionary measure, the deinstallation should take place via a collecting vessel. Appropriate drainage

must e ensured so that hazardous gases or vapours cannot reach the deinstallation personnel. This also applies

for the final cleaning after deinstallation has taken place.

The all valves must e put in depressurised condition for repair purposes. To do this, they should e rought in-

to “semi-open” position. Cleaning inside and out is also necessary prior to deinstallation. During interior cleaning,

it is expedient to switch the all several times.

5.2 Deinstallation preparation

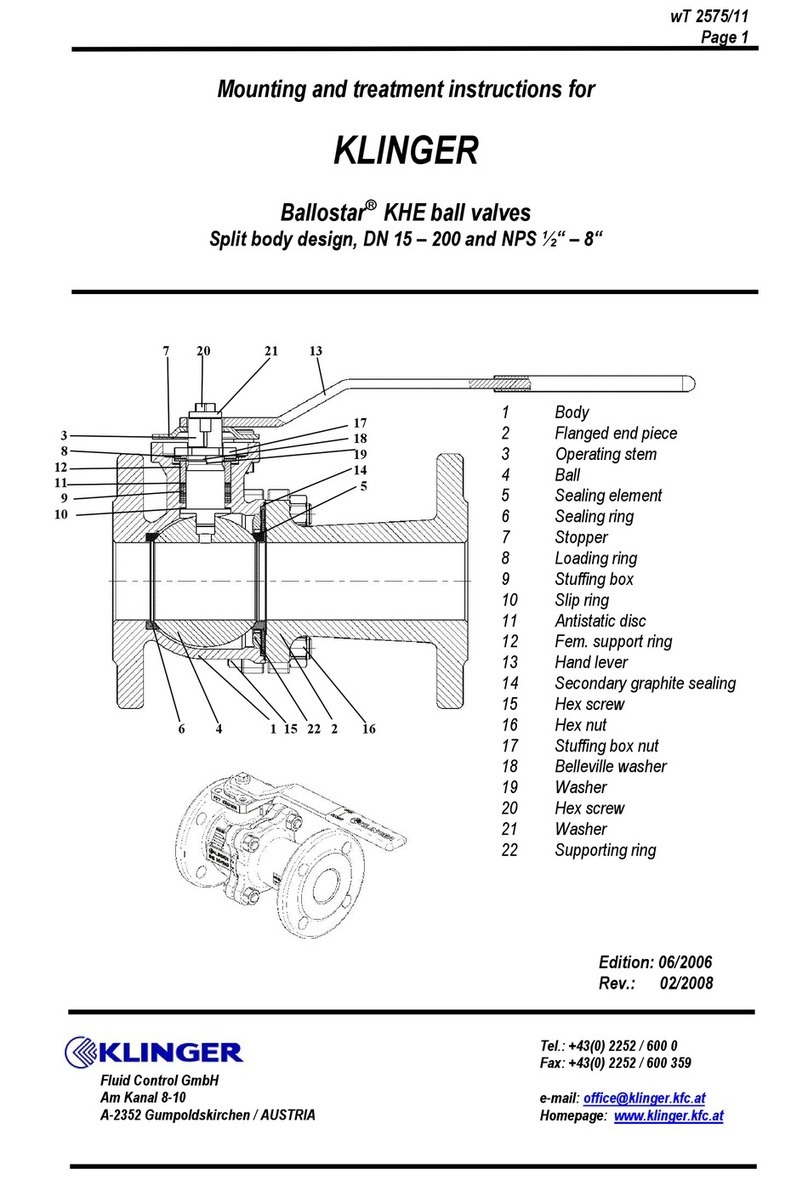

Prior to deinstallation, the ody (1), the cap (2) and the all valve parts must e la elled so that their assem ly

positions can e comprehended over the course of the process.

5.3 Deinstallation

Prior to deinstallation, the valve should e clamped tightly and securely in a suita le device. An expedient solu-

tion would e onto the flange of the ody (1) in order to guarantee free access to the intermediate flange, the inte-

rior and the stem. By loosening the middle flange screws (21), the cap (2) can now e removed. Bring the all (3)

into open position (dihedron longitudinal to valve passage). Press the all (3) ack into the ody (1) using a suita-

le device in order to release the prestress on the all seat (4). In this way, the trunnion can e removed. Re-

move the device and the all.

Next, if availa le, the hand lever is removed. To do this, the screw with a hexagon socket must e loosened and

removed completely, as the screw interlocks into the stem recess and thus makes it impossi le to remove the

hand lever. In case it proves hard to move, the hand lever can e spread at the slot using a screwdriver or cone

and thus more easily removed.

Using a fork wrench, the nut(16) can e unscrewed from the stem (7) y turning it to the left. Prior to this, loosen

the threaded pin. In order to ease this process, it is possi le to counter it using the hand lever which has just een

dismantled or a suita le fork wrench on the dihedron. Now the stem can e carefully pressed into the all space.

Secure the stem against falling and eing damaged. The friction washer (15) and the fire-safe support ring (14)

can e removed and the secondary sealing parts (11)(12)(13) removed from the dome.

The primary sealing parts (9)(10) may remain in the ody, making the removal of the stem (7) more difficult at

small nominal widths. These seals can e carefully pressed out using a small screwdriver in the ody in the direc-

tion of the ody or stem collar, and then the stem can e removed more easily. All damage in the sealing area of

the ody (1) must e avoided.

Then the all seat parts (4)(5)(6) can e removed.

Last of all, the ody seal (20) is to e removed. No auxiliary equipment is generally required for this step.