2

"This manual is a translation from the official italian language version. For reasons of environmental respect the Company will not provide the hard copy in the original language which

could be directly requested or downloaded from the Company website at any time. In case of any dispute, the original language manual will be the trusted one"

INDEX

1PURPOSE AND CONTENT OF THE MANUAL.................................................................................................................... 4

1.1 CONSERVATION OF THE MANUAL................................................................................................................................ 4

1.2 GRAPHIC SYMBOLS........................................................................................................................................................... 4

2SAFETY LAWS ........................................................................................................................................................................... 4

3PERMITTED USES..................................................................................................................................................................... 5

4GENERAL SAFETY GUIDELINES ......................................................................................................................................... 5

4.1 WORKERS’ HEALTH AND SAFETY................................................................................................................................. 5

4.2 PERSONAL SAFETY EQUIPMENT.................................................................................................................................... 6

4.3 SAFETY SYMBOLS............................................................................................................................................................. 6

4.4 REFRIGERANT SAFETY DATA SHEET ........................................................................................................................... 7

5INSTALLATION......................................................................................................................................................................... 8

5.1 GENERALITY ...................................................................................................................................................................... 8

5.2 LIFTING AND HANDLING................................................................................................................................................. 8

5.3 LOCATION AND MINIMUM TECHNICAL CLEARANCES............................................................................................ 8

5.4 HYDRAULIC CONNECTIONS ........................................................................................................................................... 9

5.4.1 Characteristics of Water of the plant circuit.................................................................................................................. 9

5.4.2 Drainage connection.................................................................................................................................................... 10

5.4.3 Plant circuit charging .................................................................................................................................................. 10

5.4.4 Plant drainage system.................................................................................................................................................. 10

5.4.5 Hydraulic circuit .......................................................................................................................................................... 11

5.5 REFRIGERANT DIAGRAM OF HP_OWER ONE 70-90.................................................................................................. 11

5.6 REFRIGERANT DIAGRAM OF HP_OWER ONE 120 ..................................................................................................... 12

5.7 REFRIGERANTDIAGRAM OF HP_OWER ONE 140-160.............................................................................................. 12

5.8 ELECTRICAL CONNECTIONS ........................................................................................................................................ 12

5.8.1 Wiring terminal block................................................................................................................................................... 13

5.8.2 Terminal block and the electric box............................................................................................................................. 13

6START UP.................................................................................................................................................................................. 14

7INDICATIONS FOR THE USER ............................................................................................................................................ 14

8SHUTDOWNS FOR LONG PERIODS................................................................................................................................... 15

9MAINTENANCE AND PERIODICAL CONTROLS............................................................................................................ 15

9.1 CLEANING OF THE FINNED BATTERY ........................................................................................................................ 16

9.2 EXTRAORDINARY MAINTENANCE ............................................................................................................................. 16

9.3 ENVIRONMENTAL PROTECTION.................................................................................................................................. 16

10 DISPOSAL.............................................................................................................................................................................. 16

10.1 RESIDUAL RISKS.................................................................................................................................................................... 17

11 TECHNICAL DATA ............................................................................................................................................................. 18

12 PRODUCT FICHE (U.E.811/2013)...................................................................................................................................... 19

12.1 ELECTRIC DATA OF THE UNIT AND AUXILIARIES................................................................................................... 31

13 HYDRAULIC CIRCUIT AVAILABLE HEAD PRESSURE............................................................................................ 31

14 OPERATION LIMITS .......................................................................................................................................................... 34

14.1 EVAPORATOR WATER FLOW RATE............................................................................................................................. 34

14.2 COLD WATER TEMPERATURE (SUMMER OPERATION) .......................................................................................... 34

14.3 HOT WATER TEMPERATURE (WINTER OPERATION)............................................................................................... 34

14.4 AMBIENT AIR TEMPERATURE AND SUMMARIZING TABLES................................................................................ 34

15 CORRECTION FACTORS FOR USE OF GLYCOL........................................................................................................ 36

16 DIMENSIONS........................................................................................................................................................................ 36

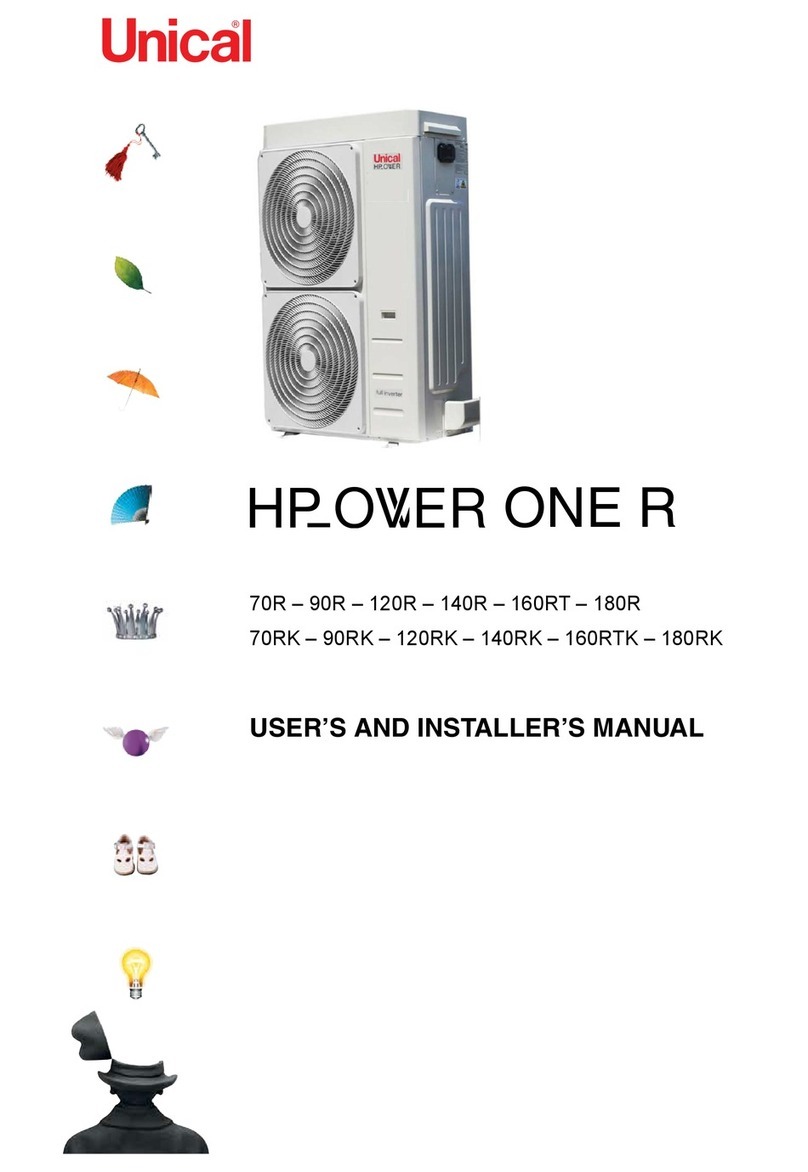

16.1 MODELS HP_OWER ONE 70-90....................................................................................................................................... 36