Prior to Operation

〞

〞

〝〞

Adjusting Vise Square to the Blade

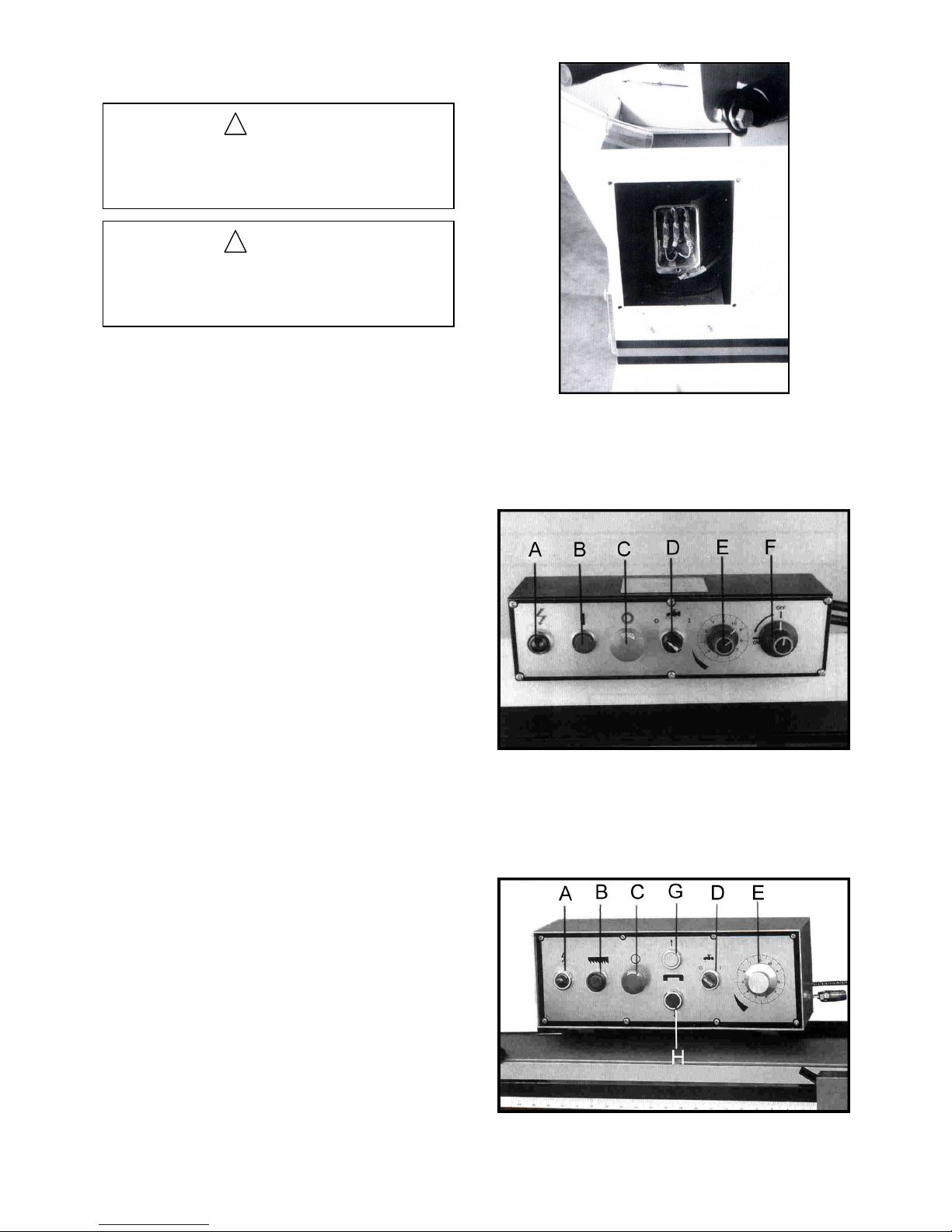

Adjust the Variable Speed

Fig. 4

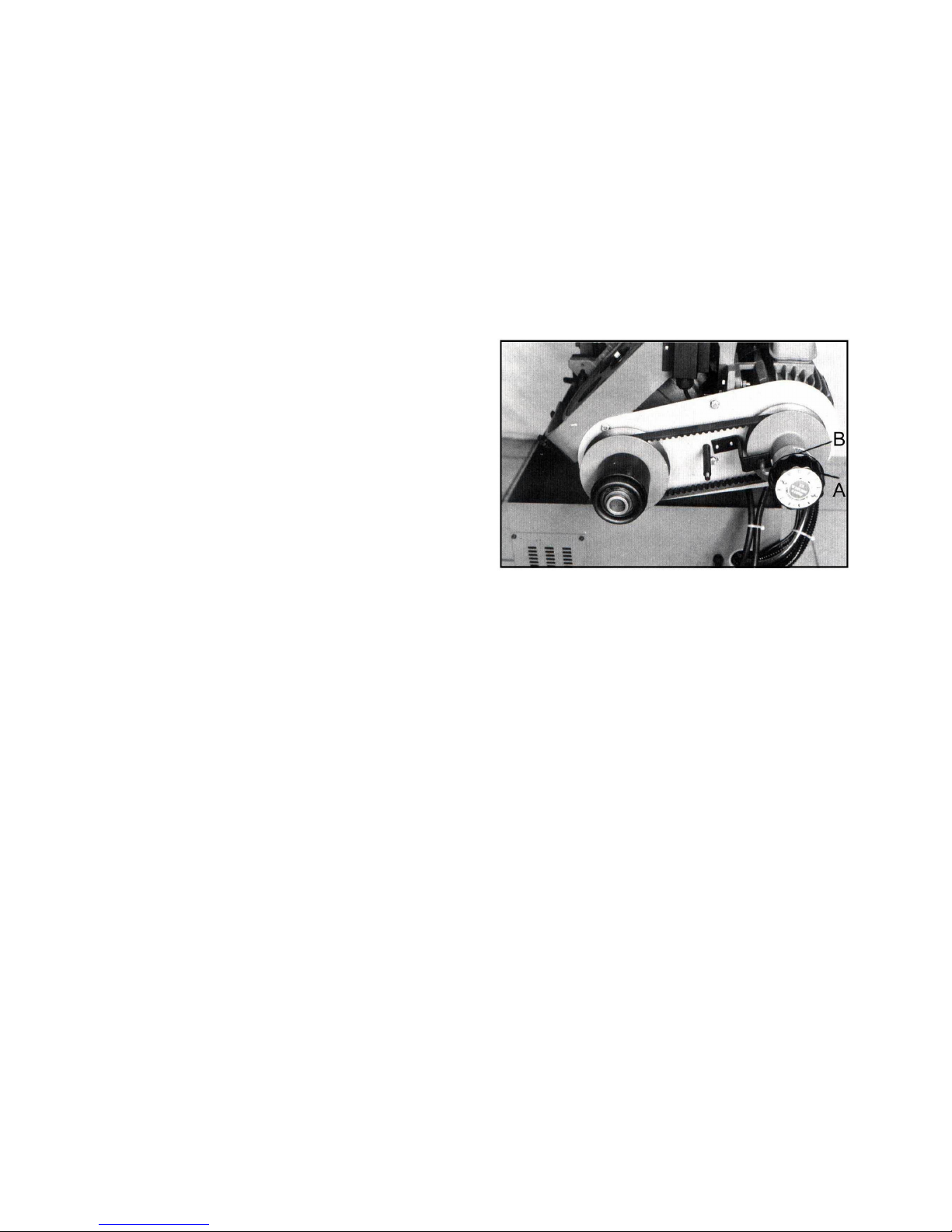

Automatic Shut-Off Adjustment

The motor should shut off immediately after the blade has

cut through the material and just before the head comes to

rest on the horizontal stop bolt. If the machine continues to

run after the workpiece has been fully cut, locate and adjust

the micro switch mounting plate down. If the machine shuts

off before the workpiece has been completely cut, move the

micro switch mounting plate up.

Adjusting Feed Rate