2

Table of Contents

1 Scope of the manual .......................................................................................................................3

2 Warranty and liability .....................................................................................................................3

2.1 Repair or adjustment..............................................................................................................3

3 Support, ordering, and contact information...................................................................................3

4 Overview.........................................................................................................................................3

5 Operating and setup conditions .....................................................................................................4

6 Installation and setup of UniAmp and software.............................................................................4

6.1 Installation of the SensorTrace Suite software.......................................................................5

6.2 Connect the UniAmp to the PC...............................................................................................5

7 Getting started................................................................................................................................6

7.1 Connecting sensors with automatic settings..........................................................................6

7.2 Manually setting the Pre-amplification ..................................................................................6

7.3 Manually setting the sensor polarization ...............................................................................6

7.4 Adjusting the offset.................................................................................................................7

7.5 Setting STOX sensor parameters ............................................................................................7

7.6 Polarizing amperometric sensors without a PC connected....................................................8

8 Sensor connections and compatibility............................................................................................8

8.1 Sensors, connectors, and adaptors.........................................................................................8

8.2 Grounding ...............................................................................................................................8

8.3 Software..................................................................................................................................9

9 Analog in and out............................................................................................................................9

10 Digital in and out.........................................................................................................................9

11 Auxiliary equipment..................................................................................................................10

12 Temperature compensation .....................................................................................................10

12.1 Electrochemical sensors........................................................................................................10

12.2 Oxygen optodes ....................................................................................................................11

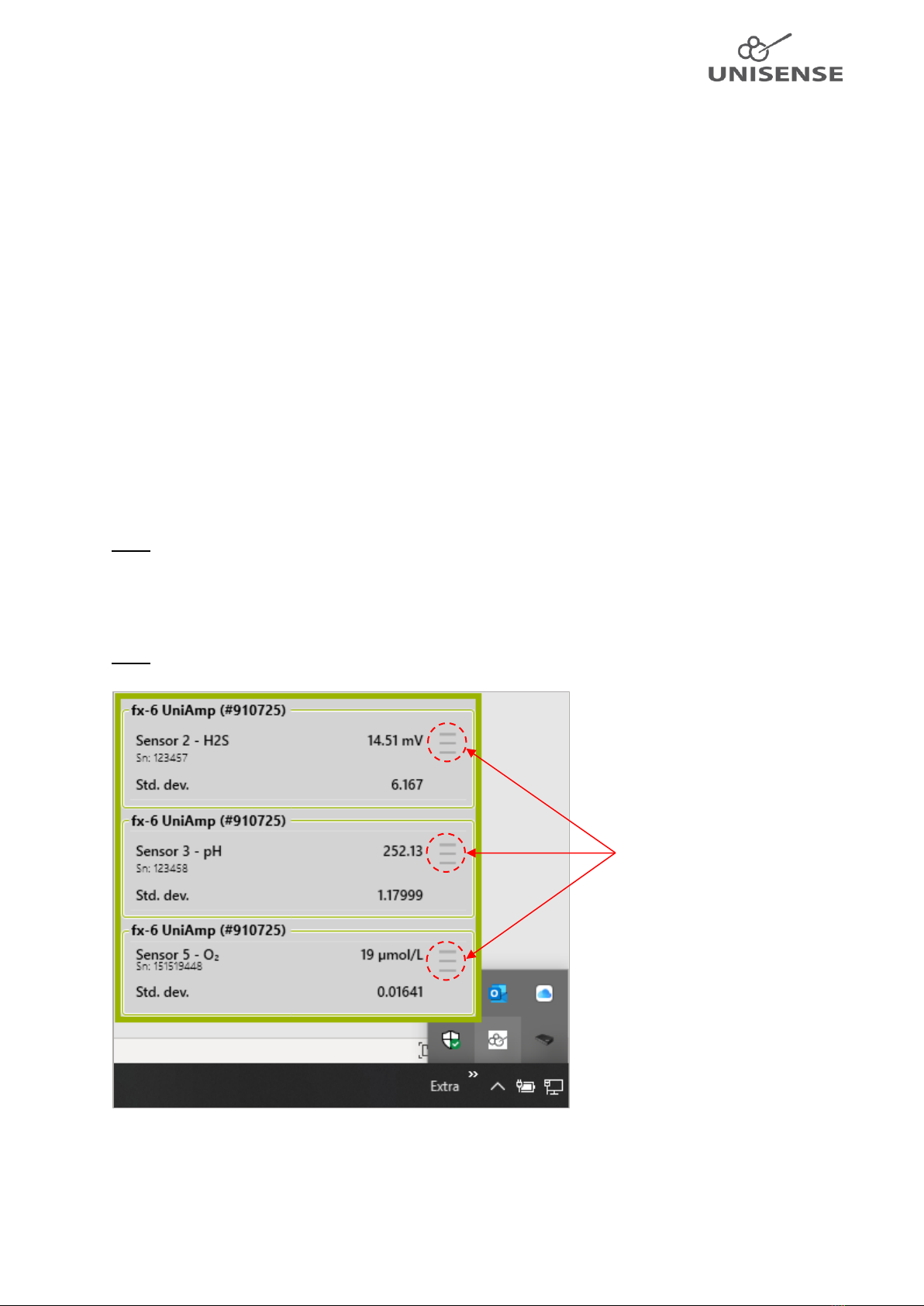

13 Troubleshooting........................................................................................................................11

13.1 Problems logging over long periods of time.........................................................................11

13.1.1 Windows Update ..........................................................................................................11

13.1.2 Loss of connection to the UniAmp because of USB power saving ...............................12

13.1.3 Disable power saving on the PC....................................................................................12

13.2 Electrical noise ......................................................................................................................12